Patents

Literature

53results about How to "Promote resource recycling" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

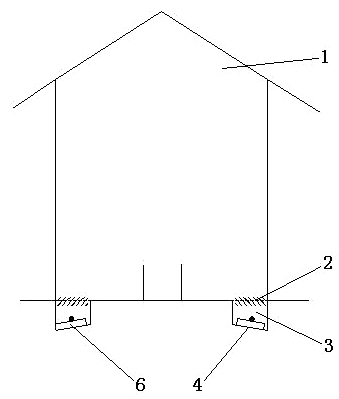

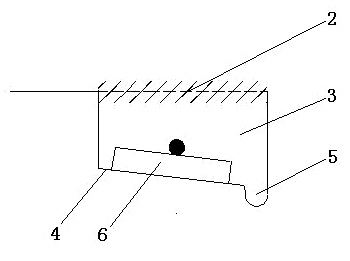

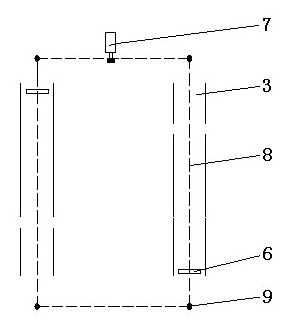

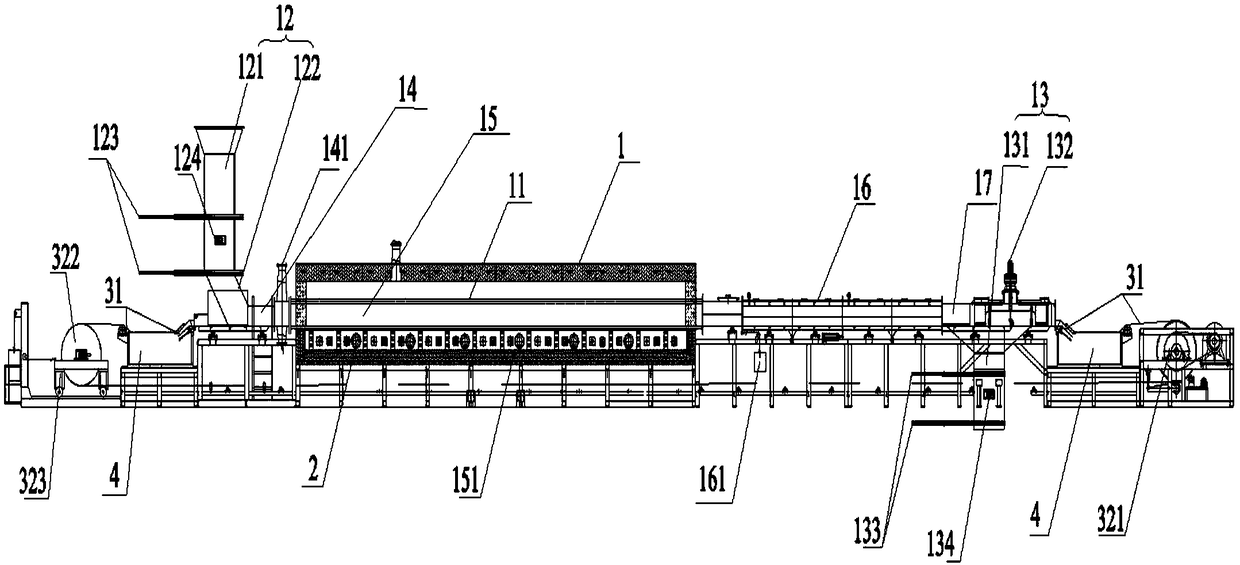

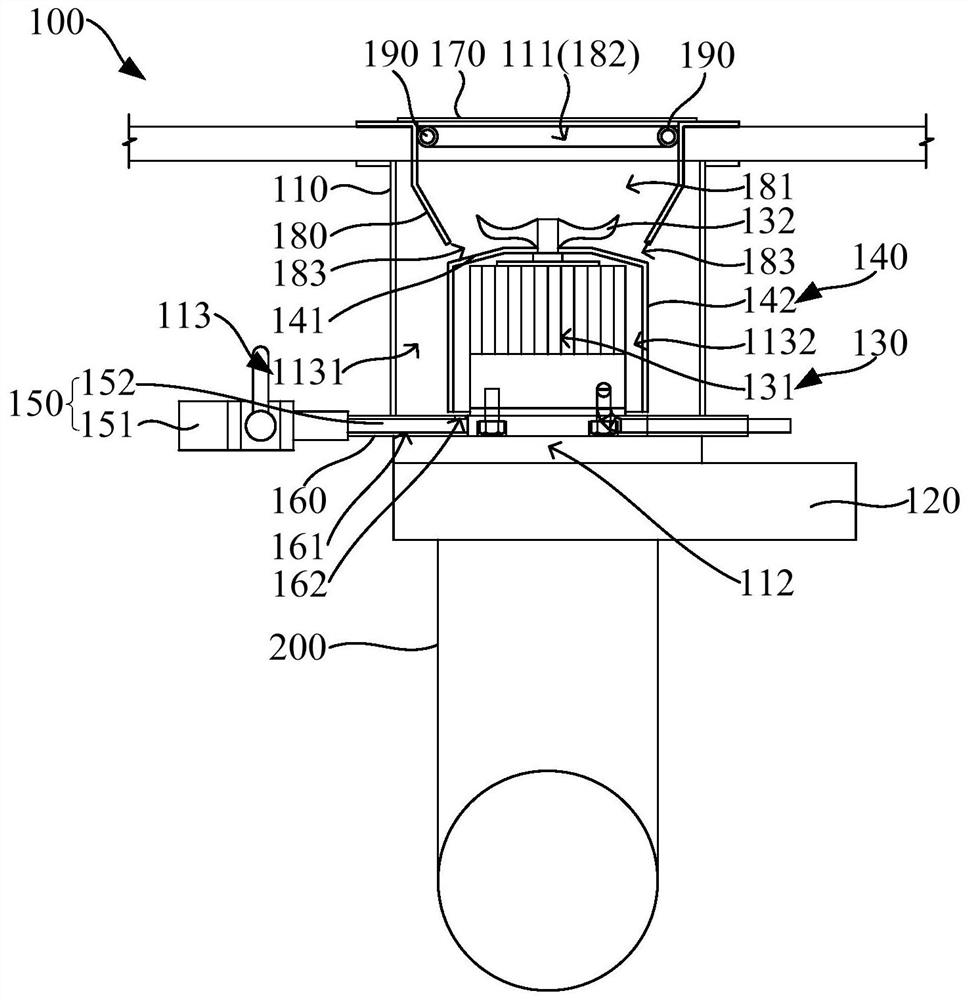

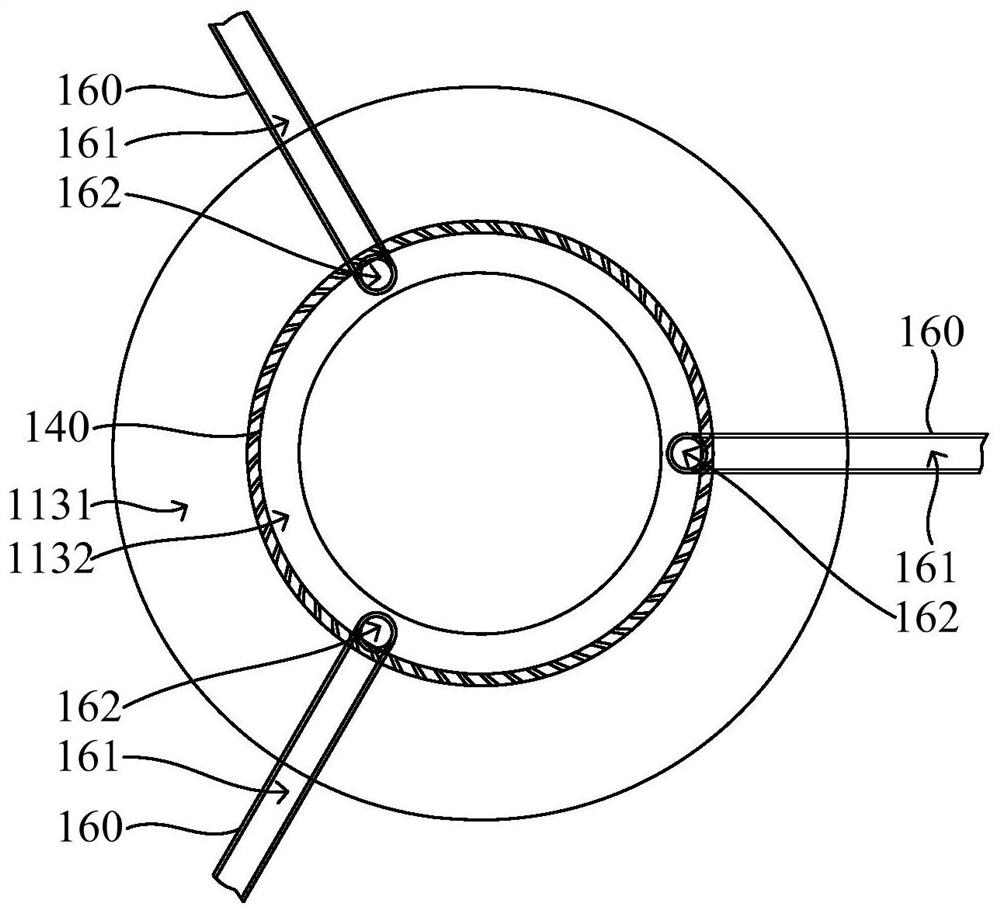

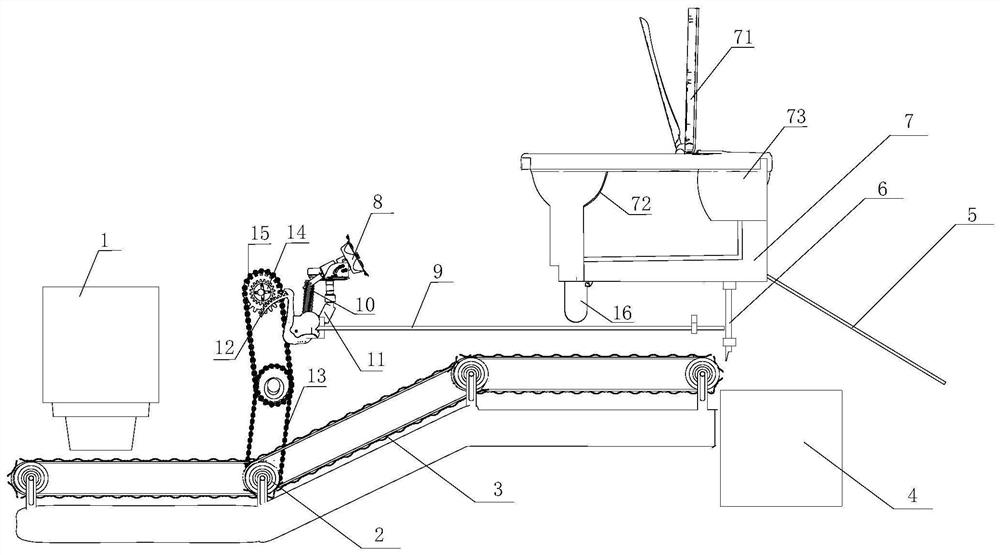

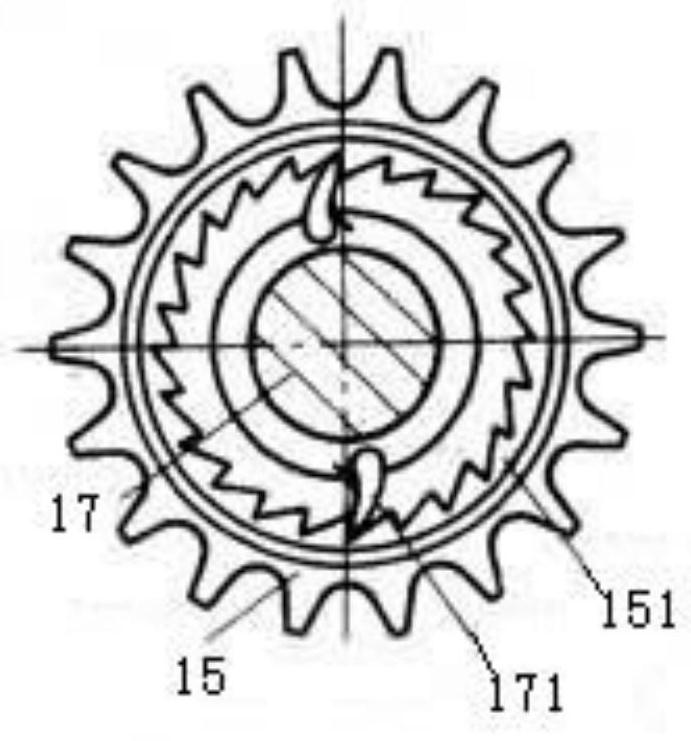

Device and method for mechanically cleaning manure of leaky pigsty

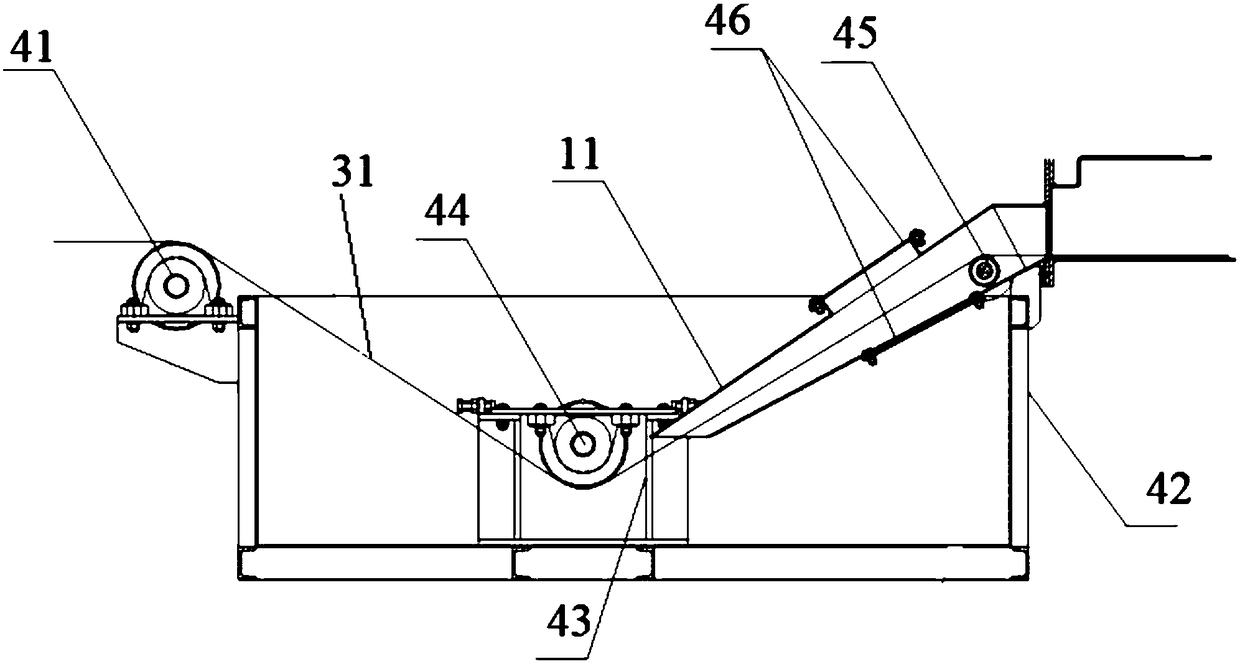

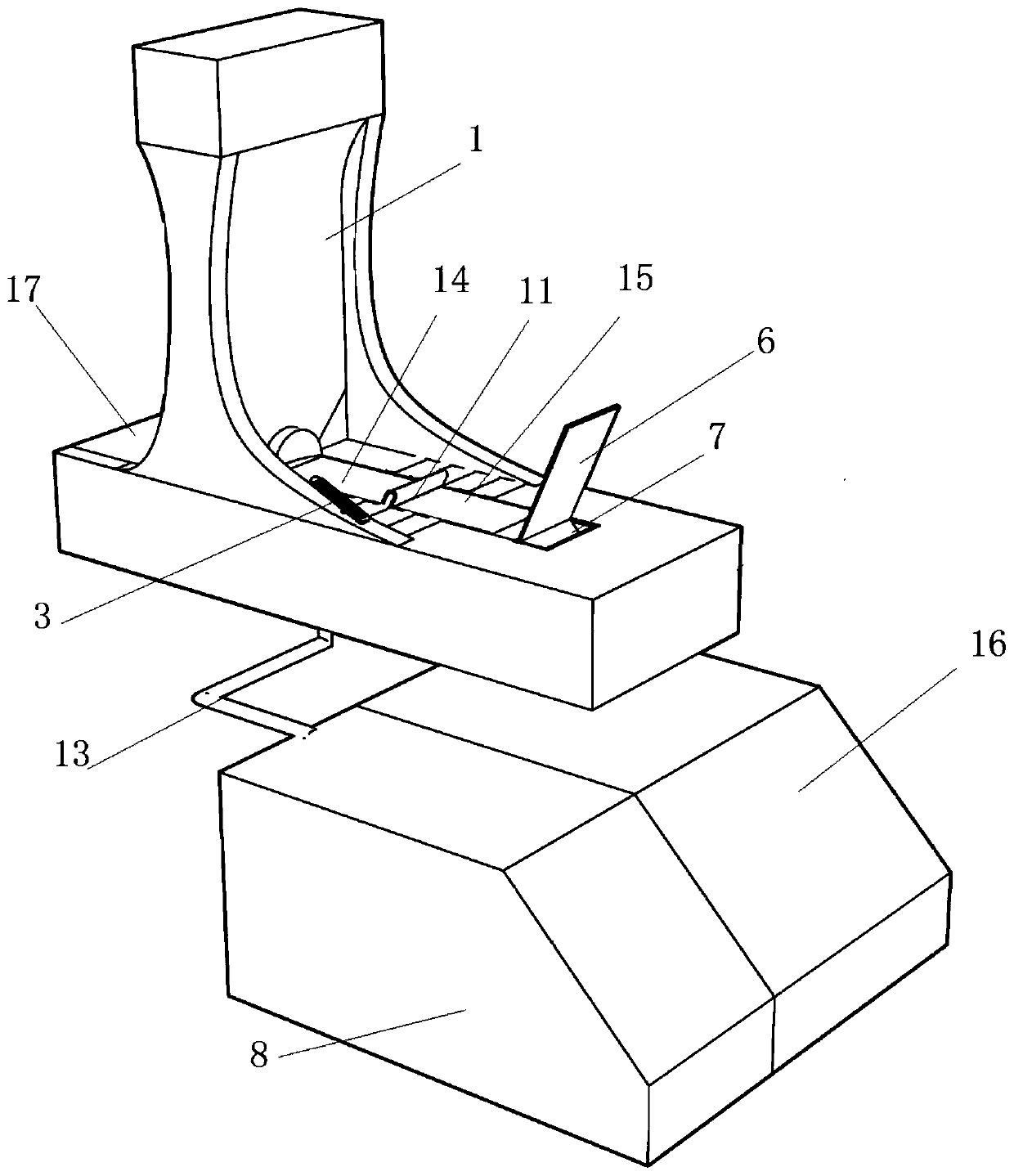

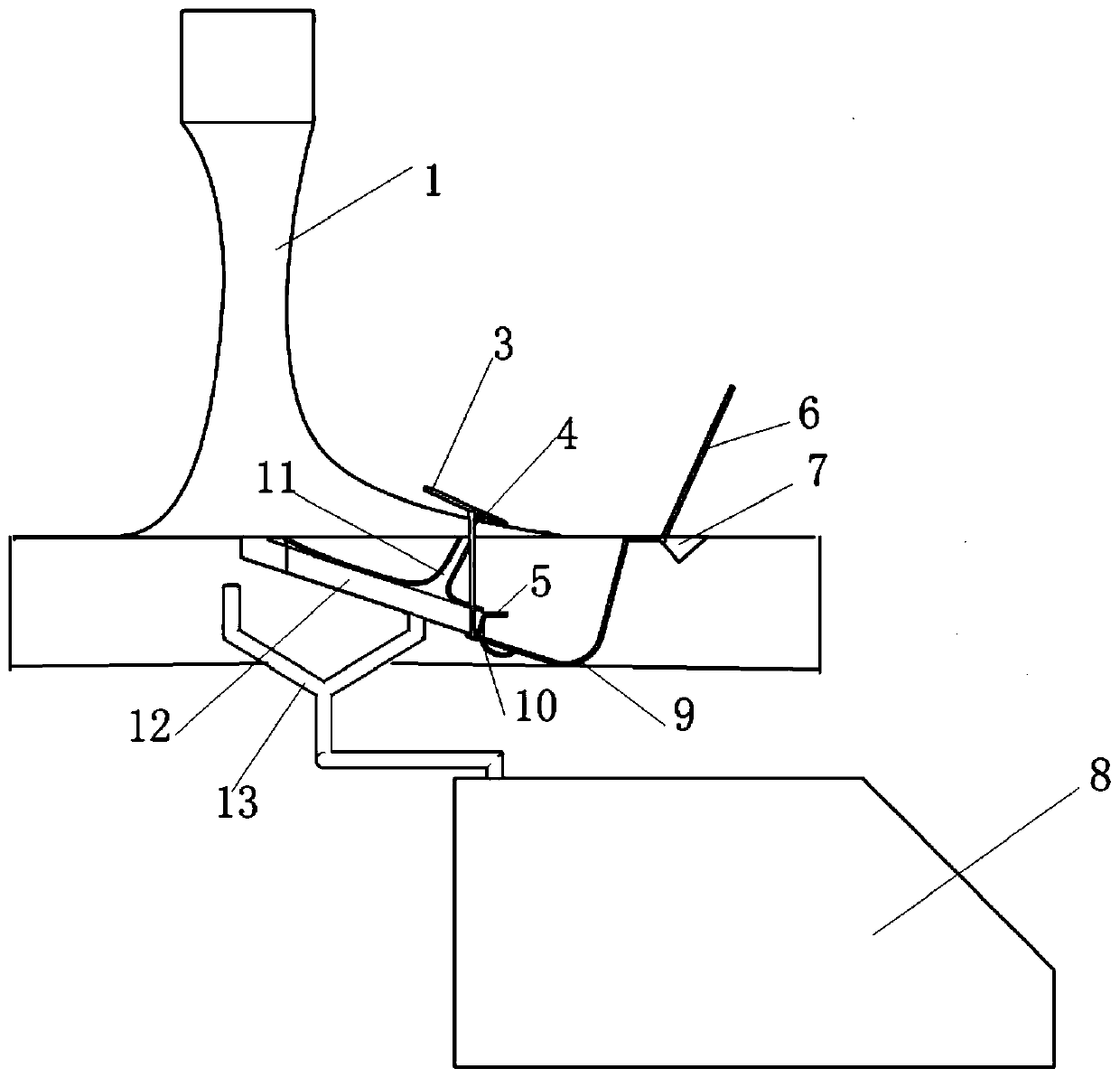

InactiveCN102487833AEmission reductionReduce the amount requiredAnimal housingMotor driveReciprocating motion

The invention relates to a device for mechanically cleaning manure of a leaky pigsty. The device comprises the pigsty and is characterized in that: the bottom of the pigsty is provided with at least one manure leaking plate; at least one manure trough is arranged below the manure leaking plate; the bottom of the manure trough is provided with at least one inclined plane; the lower side of the manure trough is provided with a drainage ditch; scrapers used for cleaning the manure and driven to reciprocate by a motor driving mechanism are arranged in the manure trough; and the motor driving mechanism comprises a motor, steel ropes connected with the scrapers and driven by the motor, and guide wheels for guiding the ropes. Meanwhile, the invention also relates to a pigsty structure and a corresponding method for mechanically cleaning manure of a leaky pigsty. By the invention, the manure sewage discharging amount can be reduced, the total amount of organic pollutants can be decreased, and the invention has the advantages that: the cost is low, the operation is simple and convenient, the manure cleaning efficiency is high, the discharge reduction effect is good, the pig manure which is mechanically cleaned and collected has low water content and is easily subjected to subsequent concentrated composting reutilization and the like.

Owner:INST OF AGRI ENG TECH FUJIAN ACAD OF AGRI SCI

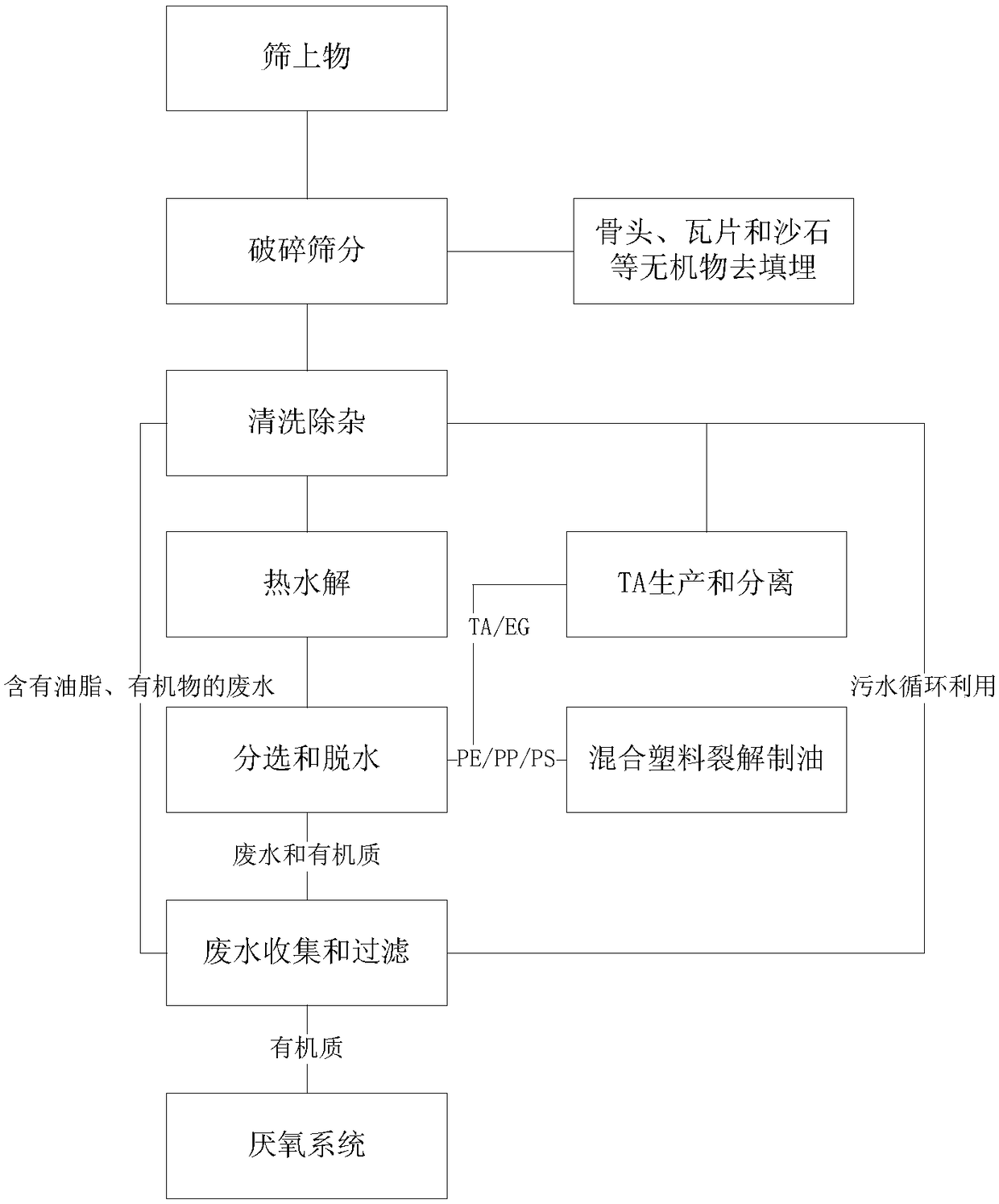

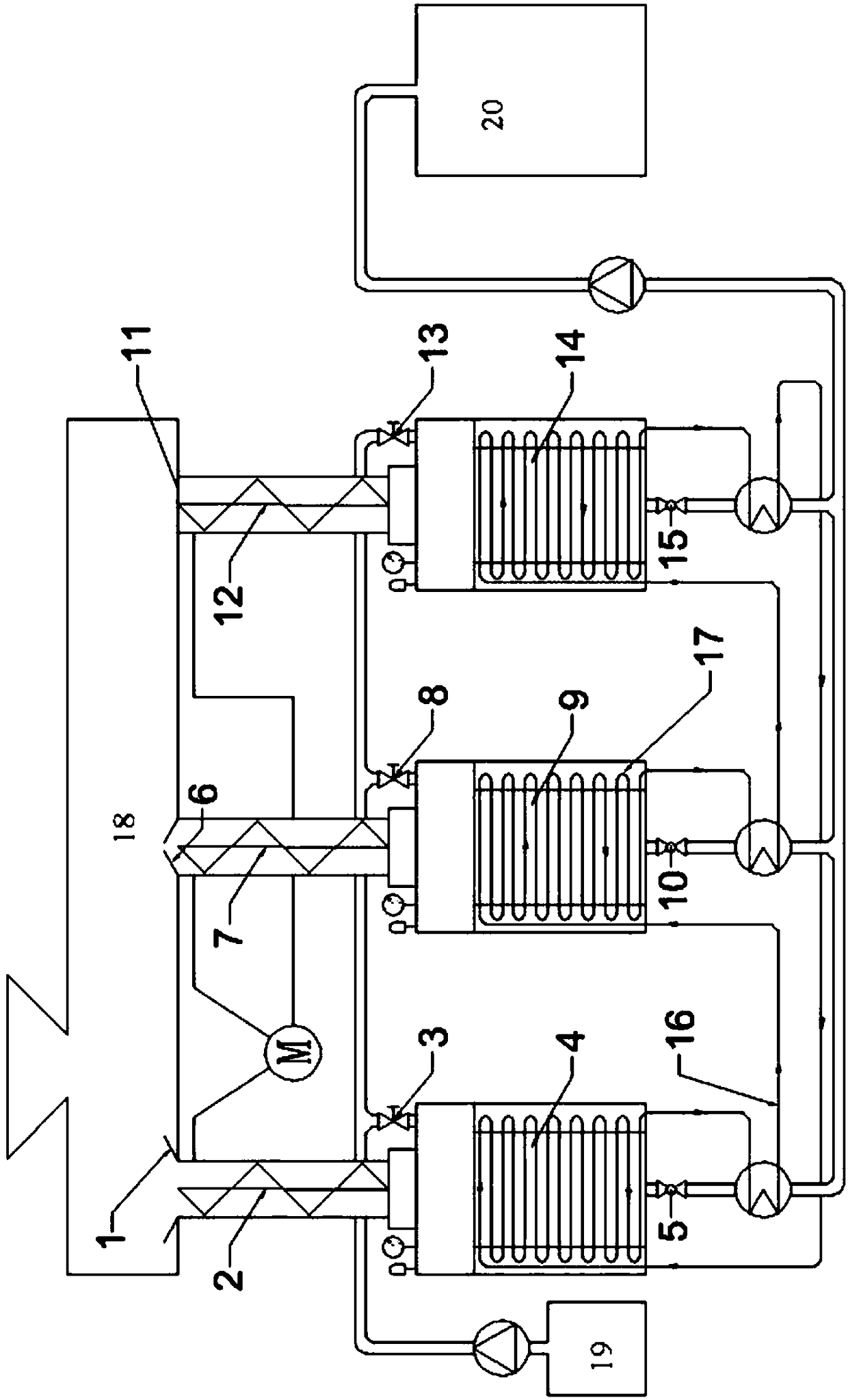

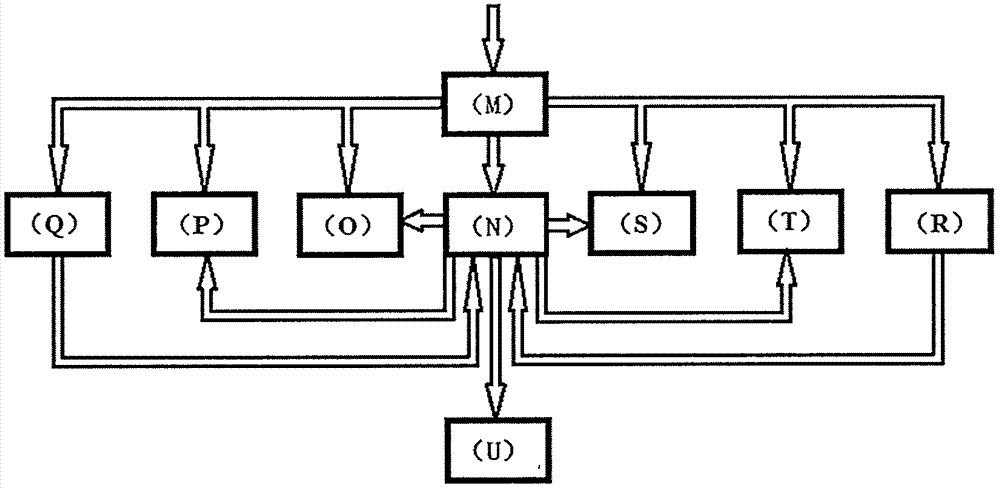

Method and hydrothermal reaction system for efficient and clean oil production by using mixed plastic waste

ActiveCN106635115BEfficient and clean oil productionReduce adverse effectsLiquid hydrocarbon mixture productionHydrocarbon oils treatment productsCompanion animalFermentation

The invention provides a method for efficiently and cleanly preparing oil through mixed waste plastic garbage and a hydrothermal reaction system. The method comprises the steps that under the conditions that the temperature ranges from 160 DEG C to 300 DEG C and the pressure ranges from 20 bar to 220 bar, an alkaline water solution is used for carrying out pyrohydrolysis treatment on the mixed waste plastic garbage; the mixed waste plastic garbage contains one or more of PE, PP and PS, and PET, and the mixed waste plastic garbage can selectively comprise PVC; a water phase and a solid phase in a material obtained after hydro-thermal treatment are separated, and the solid phase obtained after separation is subjected to oil preparation. The negative influence of the PET and PVC in mixed waste plastic on the quality of the oil is avoided, the oil can be prepared efficiently and cleanly, a product, such as TA powder or particles and PS reprocessed plastic, with high additional value can be produced, organic matter in screened materials can also be utilized for anaerobic fermentation, the economical efficiency of this type of projects is improved, and meanwhile better circular using of resources is achieved.

Owner:扬州首创投资有限公司

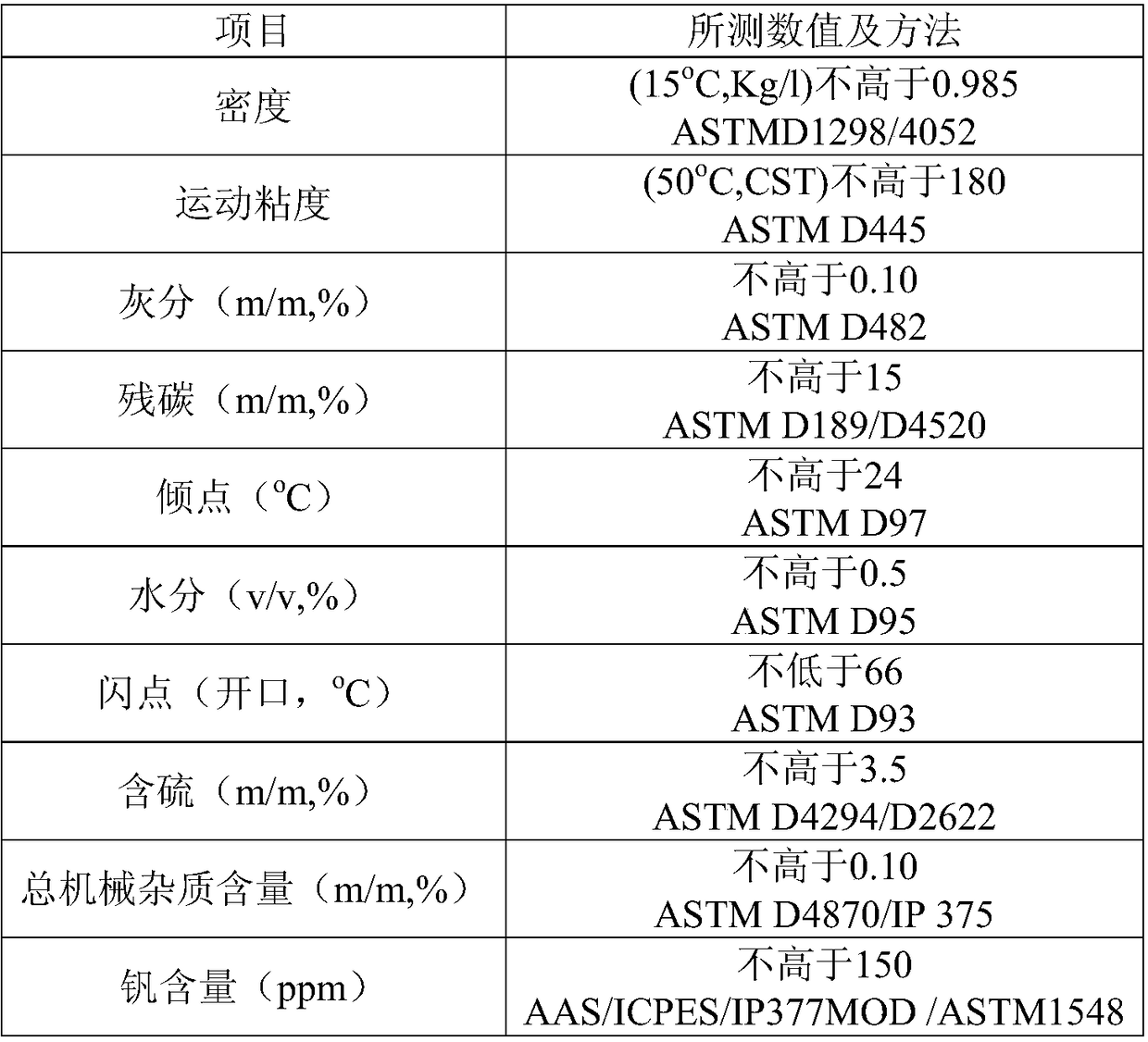

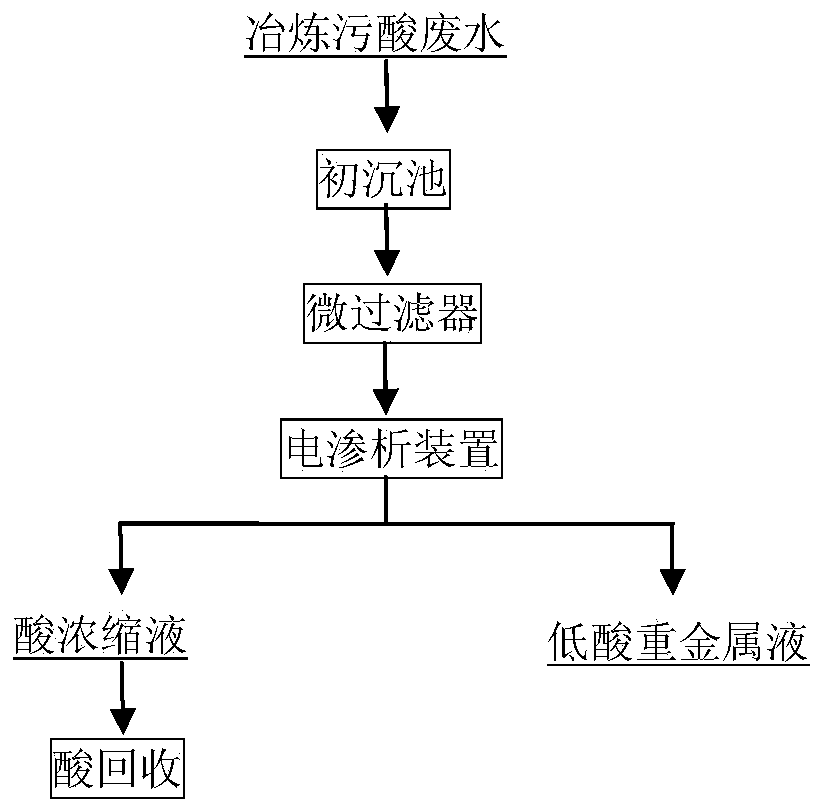

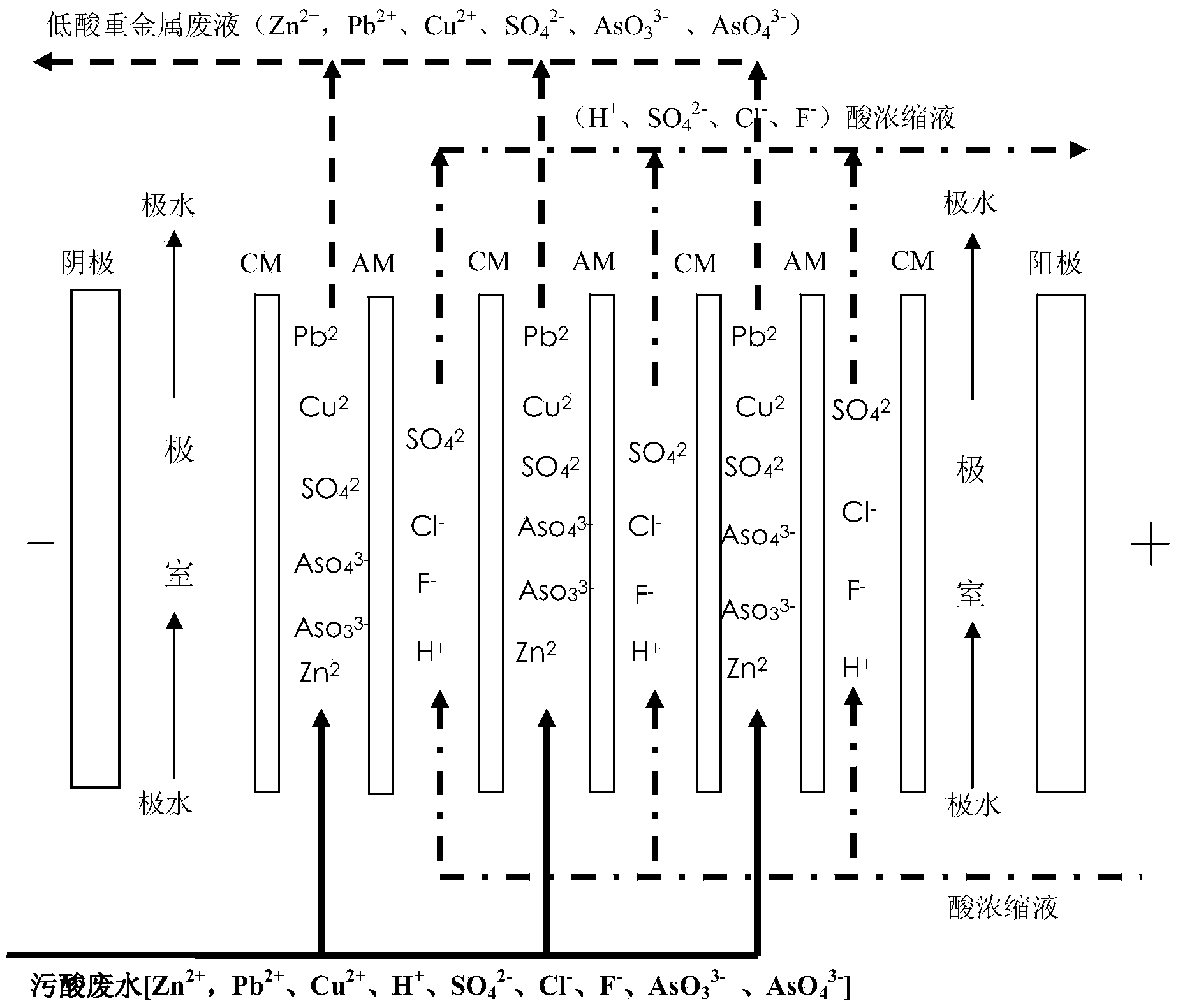

Method for separating and concentrating acid in contaminated acid

The invention discloses a method for separating and concentrating acid in contaminated acid. According to the invention, acid in contaminated acid can be separated and further concentrated by selecting proper anionic and cationic ionic membranes and utilizing the electrodialysis integration technology; the separated and concentrated acid is above 8% in concentration and can be recycled; the acidity of the contaminated acid solution in which acid is separated is reduced till the pH is above 3.0; heavy metal ion cannot pass through a selective membrane and is reserved in the contaminated acid solution in which acid is separated; further subsequent treatment is conveniently carried out.

Owner:CHANGSHA SCI ENVIRONMENTAL TECH +1

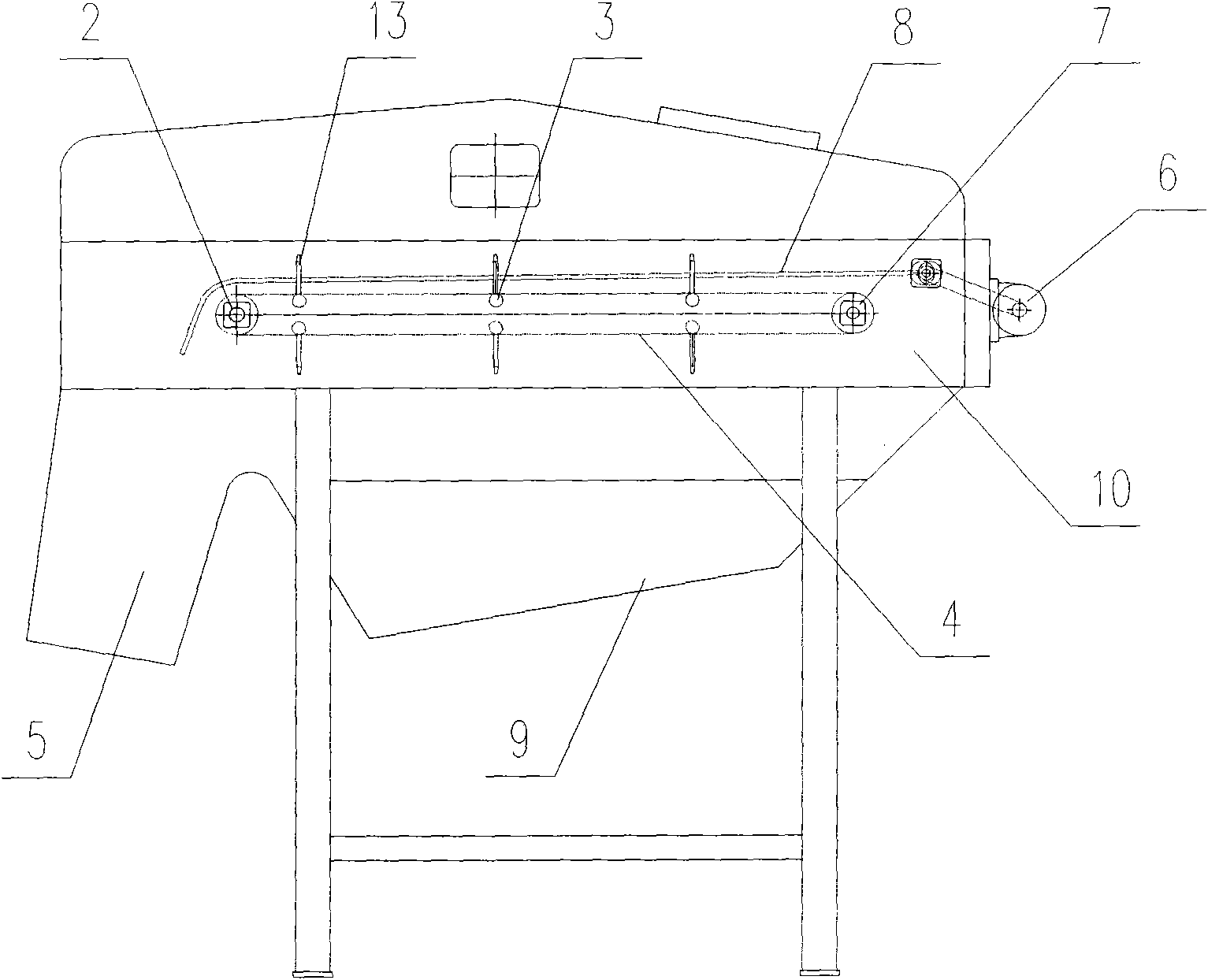

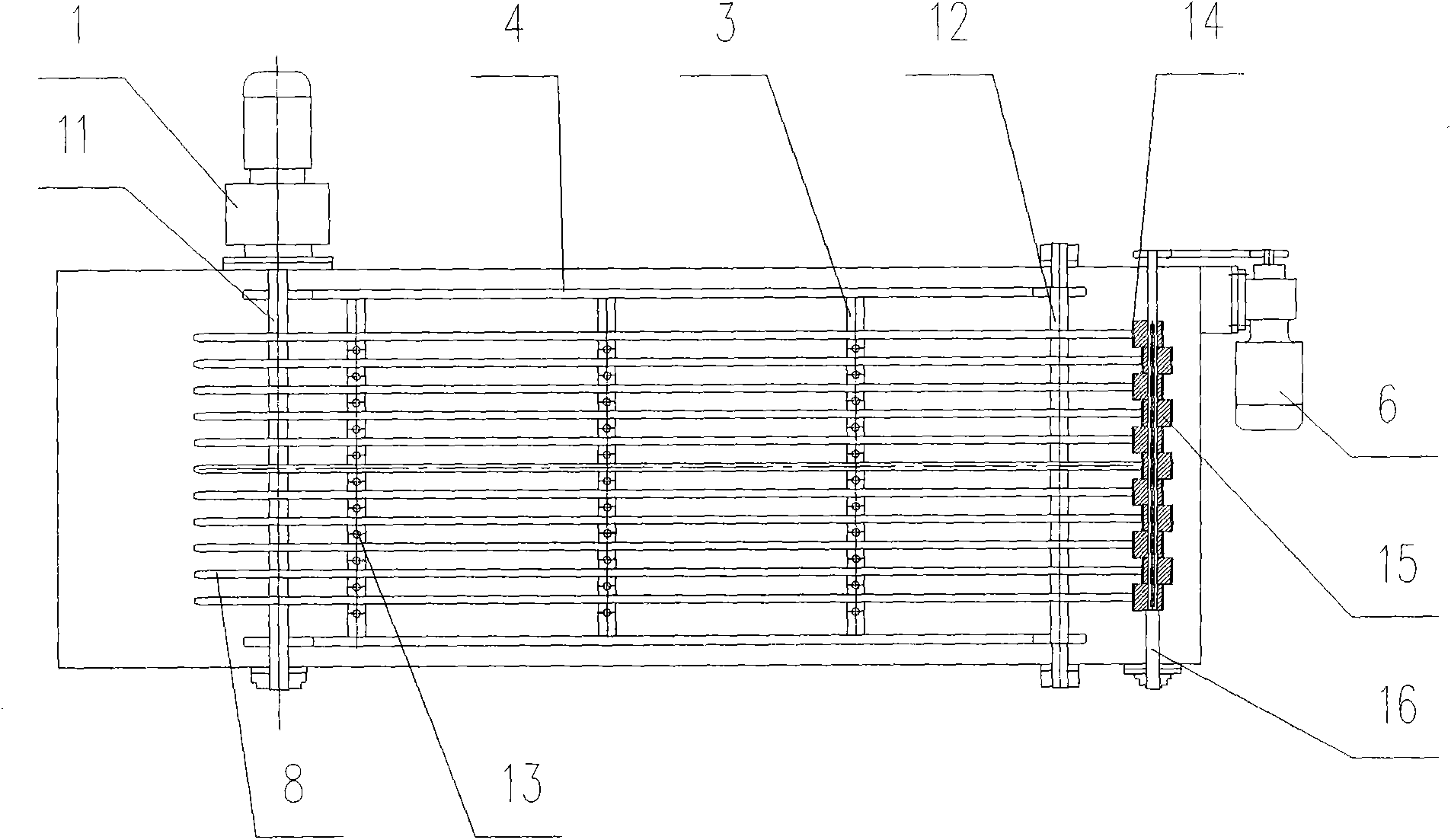

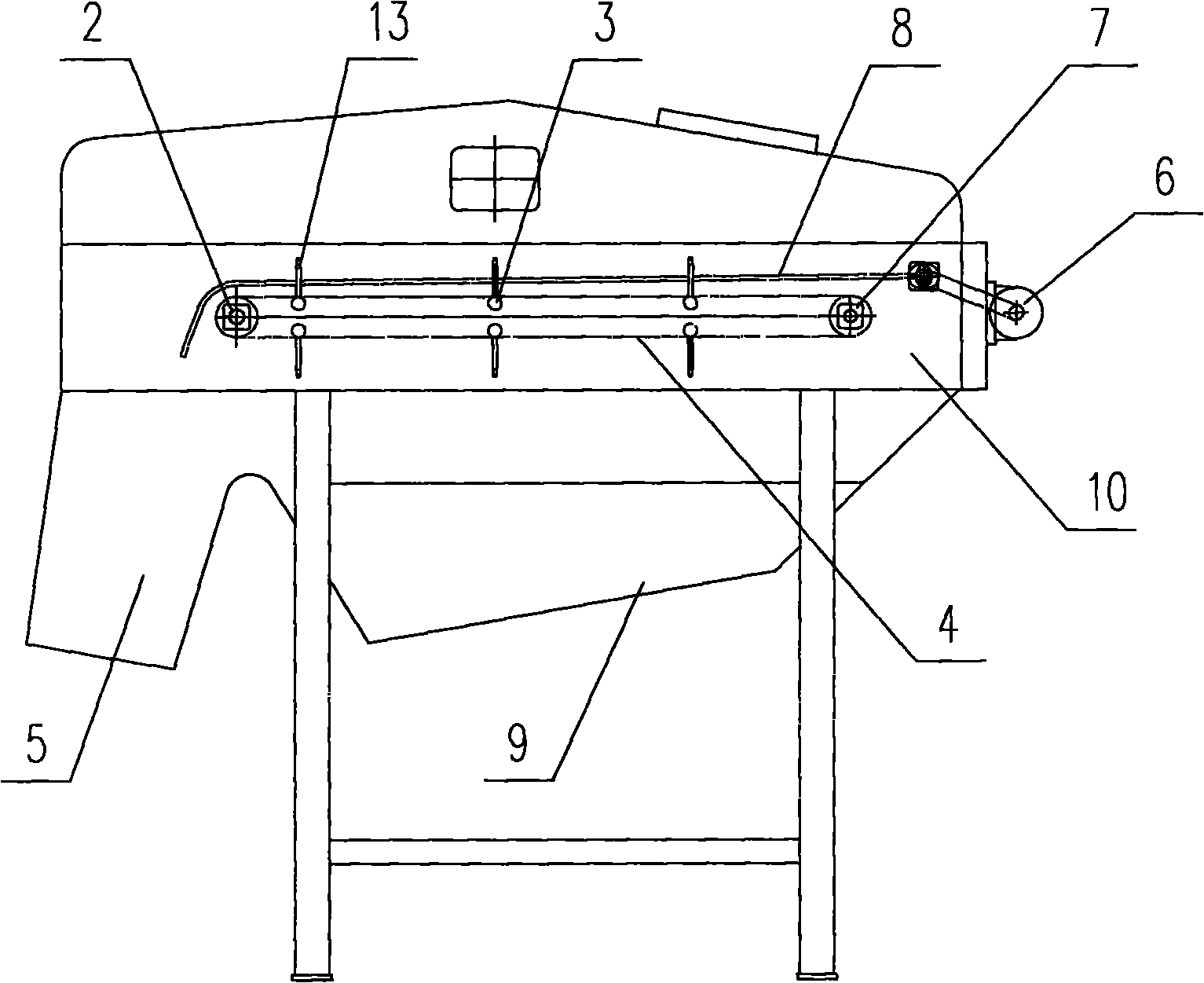

Vibrating screen classifier for kitchen waste

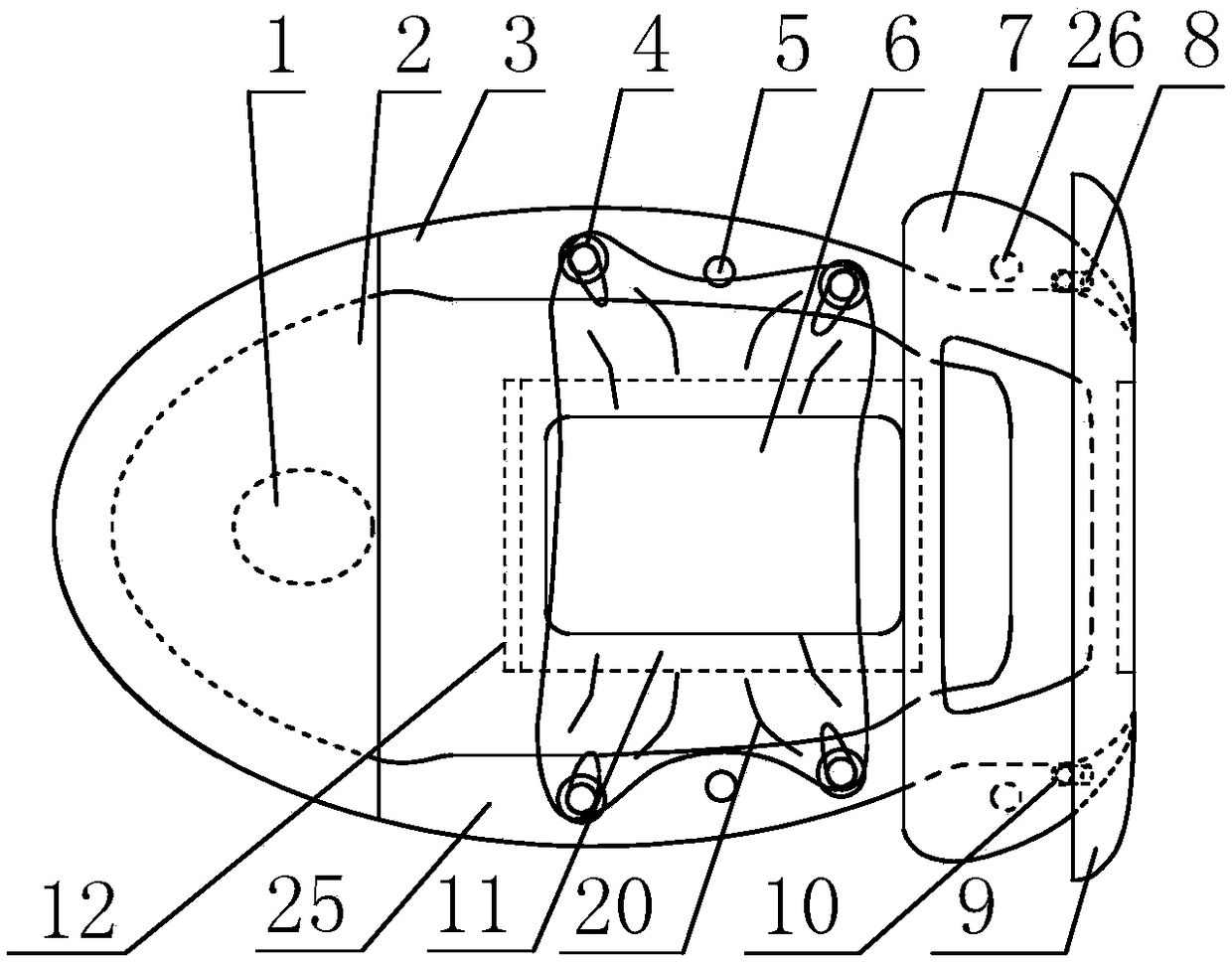

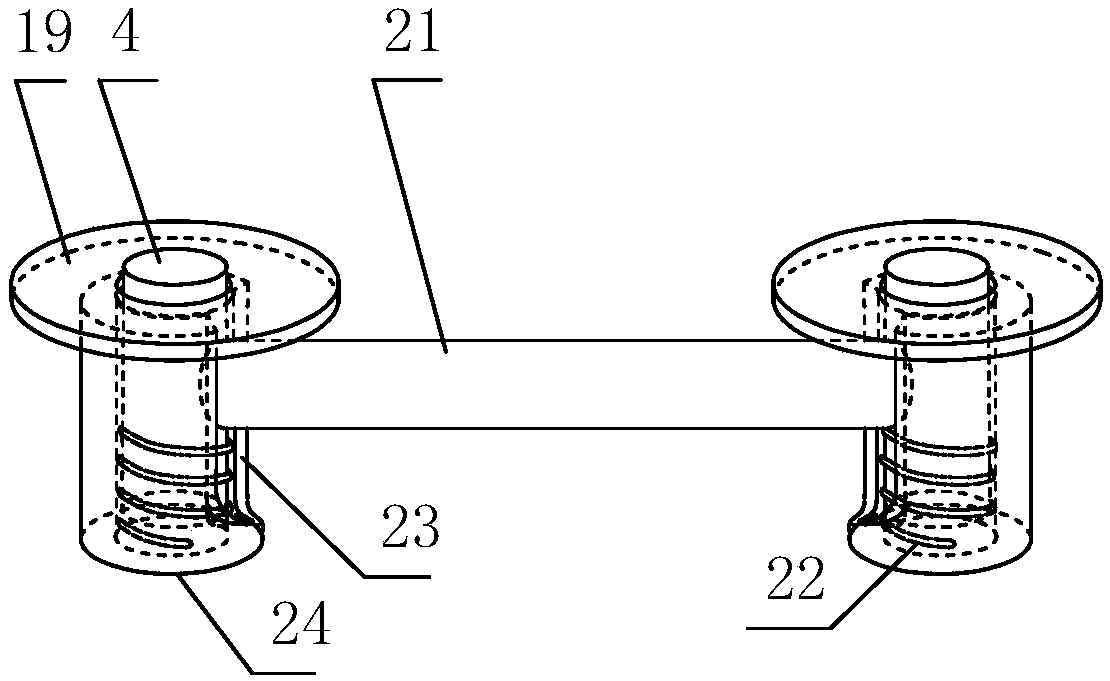

ActiveCN102078859APromote resource recyclingCompact and reasonable structureSievingScreeningDrive shaftReducer

The invention discloses a vibrating screen classifier for kitchen waste. The vibrating screen classifier comprises a frame which is provided with a tooth rake device and a grid device, wherein the tooth rake device comprises multiple parallel tooth rake shafts which are fixedly connected between two transmission chains, and each tooth rake shaft is provided with rake teeth; the grid device comprises multiple grids which are arranged on the tooth rake shafts and staggered with the rake teeth and are parallel to the transmission chains; one end of each grid is a free end, and the other end of each grid is fixedly connected with a connecting sleeve; the connecting sleeve is sleeved on an eccentric sleeve; the eccentric sleeve is mounted on a second driven shaft; the second driven shaft is connected with the output end of a motor reducer through chain transmission; an screen overflow outlet is arranged below the free end of each grid; and an organism outlet is arranged below each grid. According to the invention, the organism in the kitchen waste is completely screened and classified by a mechanical processing method and is used as a raw material for a post-processing device.

Owner:天津百利阳光环保设备有限公司

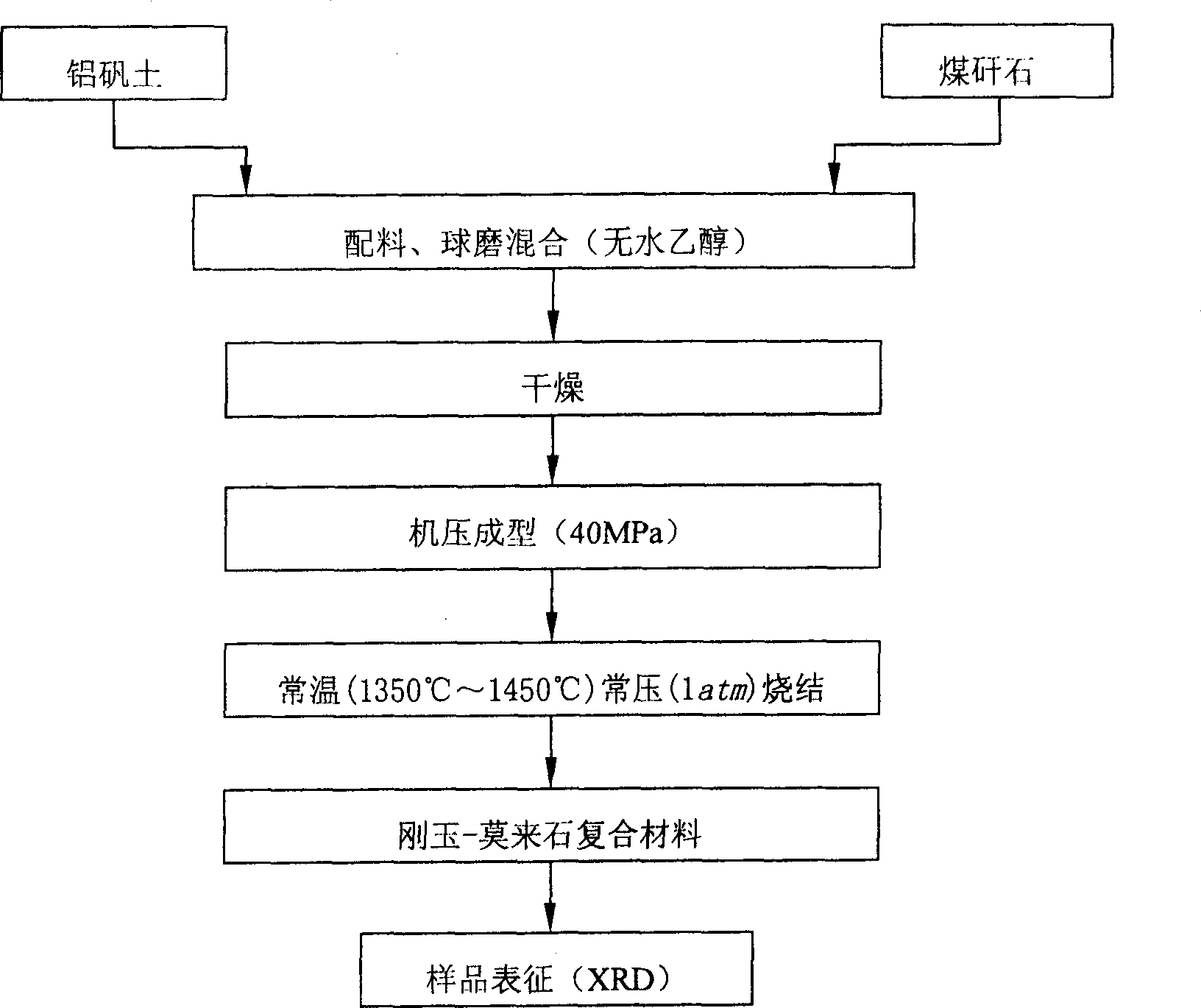

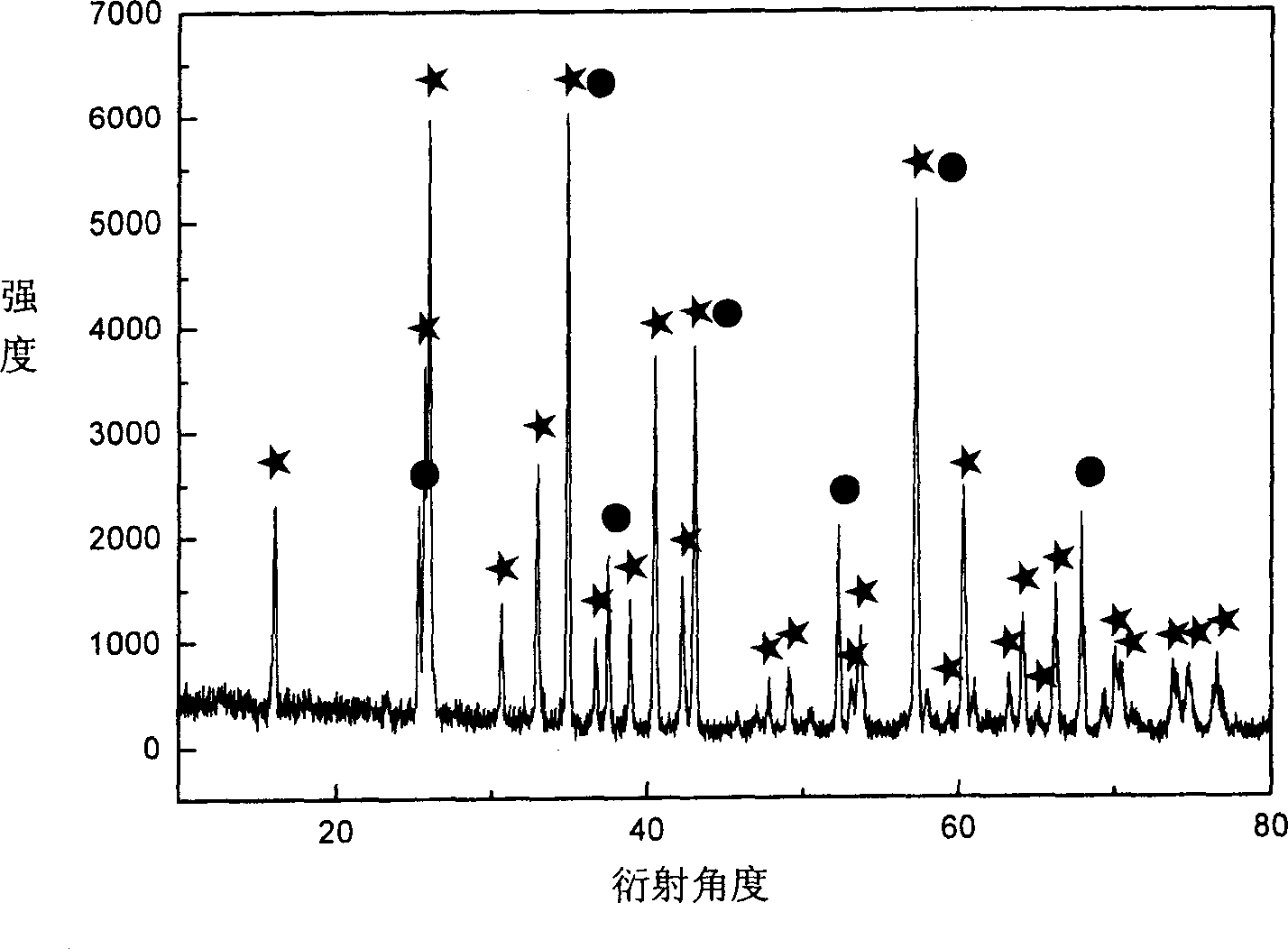

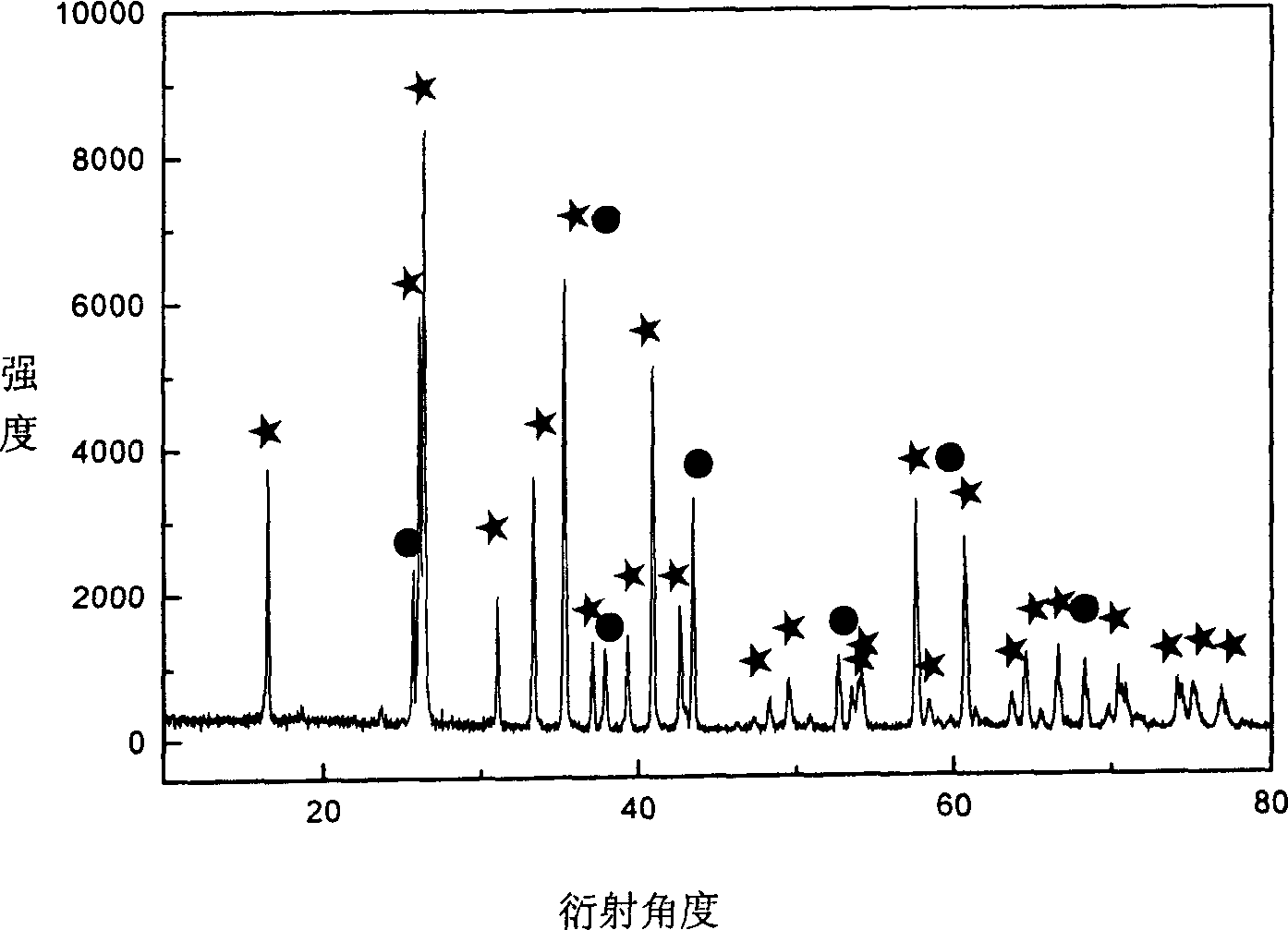

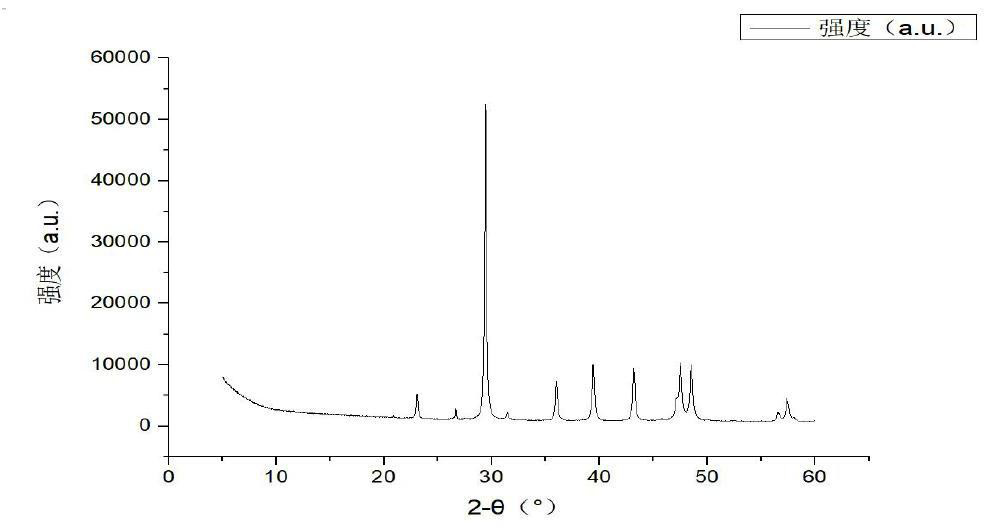

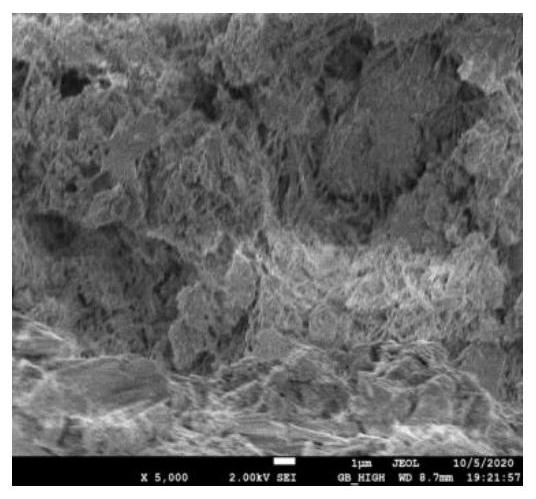

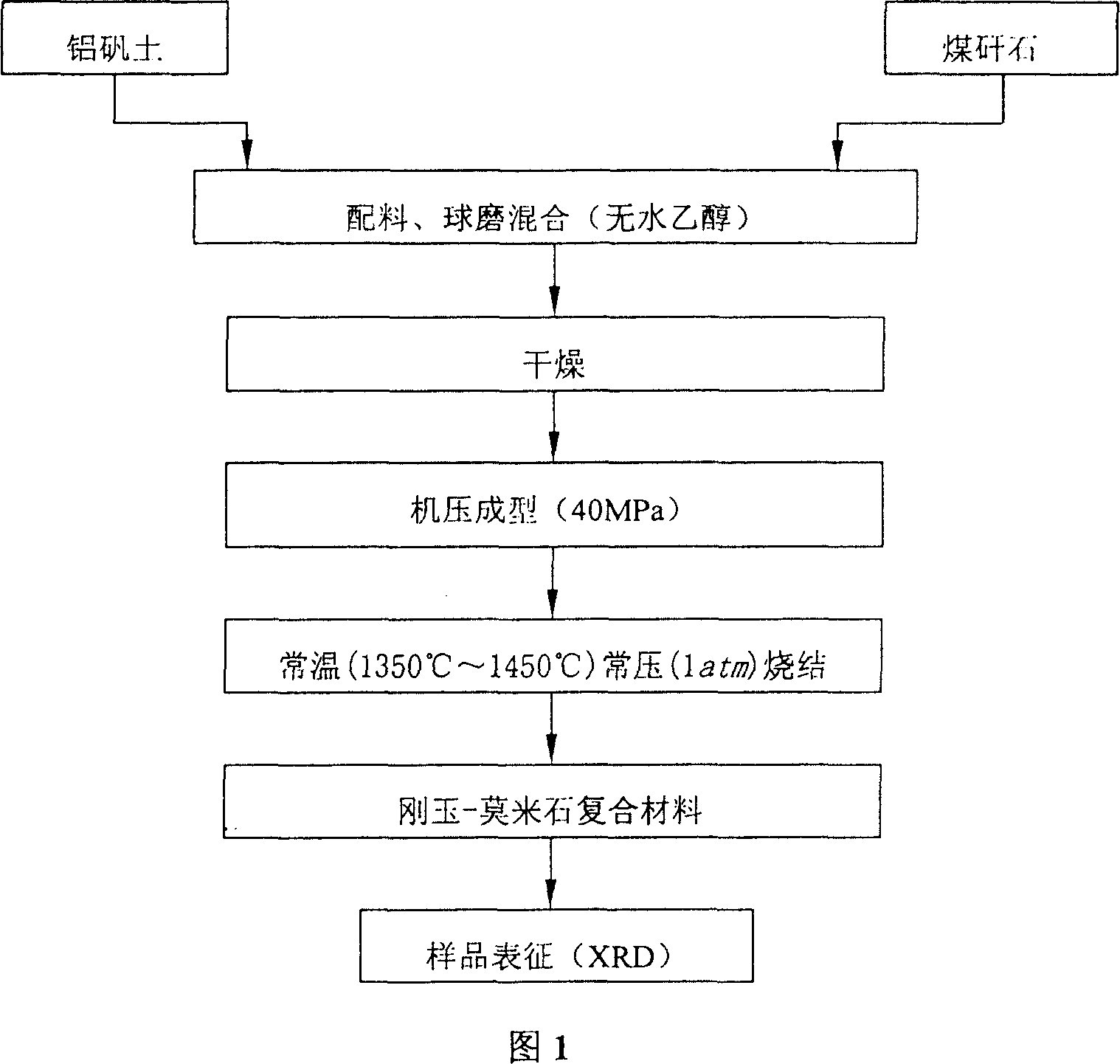

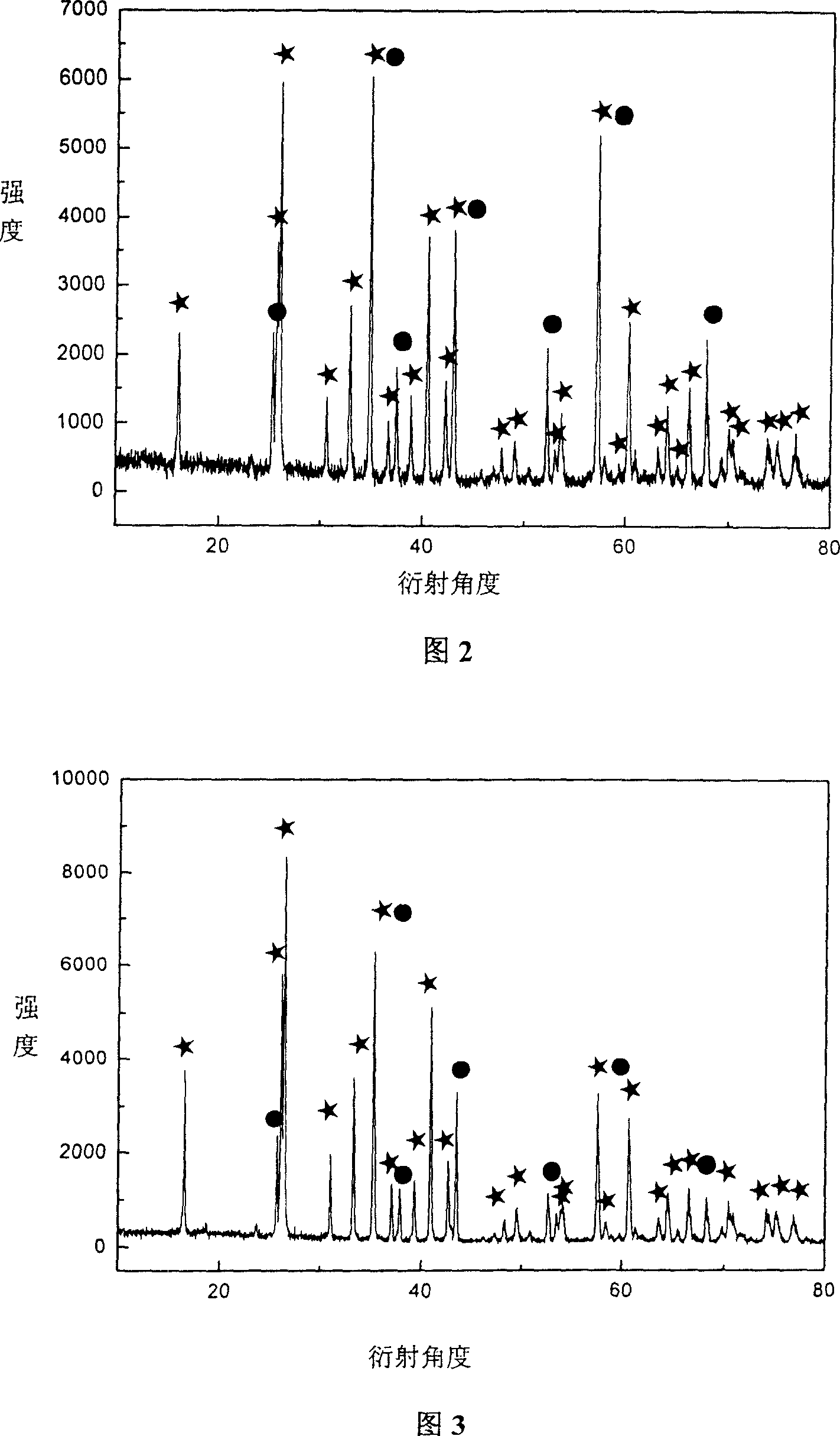

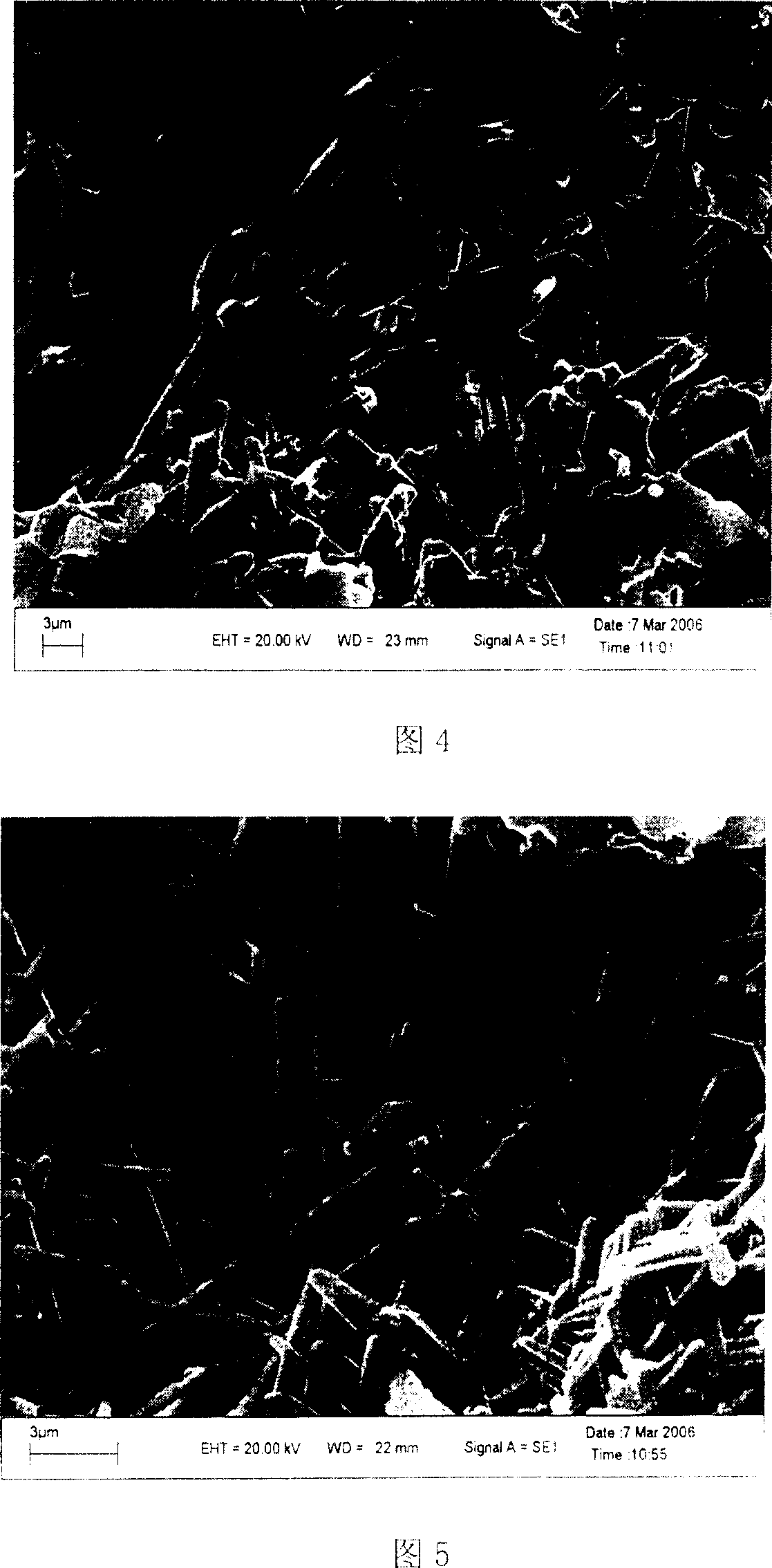

Corundum-mullite composite material and preparing method

The present invention belongs to the field of refractory material field, and is especially one kind of composite corundum-mullite material. The composite corundum-mullite material is prepared with coal gangue in 5-25 wt% and bauxite in 75-95 wt%, with the bauxite containing Al2O3 over 75 wt%. The preparation process of the composite corundum-mullite material includes the following steps: ball milling the material in absolute ethyl alcohol as medium for 6 hr, maintaining in stoving for 12hr, pressing to form, and maintaining at 1350-1450deg.c for 3-6 hr in air atmosphere to synthesize. Test shows that the composite corundum-mullite material has high purity. Preparing composite corundum-mullite material with coal gangue and bauxite as main material has rich and cheap material source, so that the present invention provides one new way of preparing high temperature refractory material.

Owner:ZHONGYUAN WEIYE NEW MATERIAL

Low-solubility salt paper pulp and preparation method thereof

ActiveCN107119479APromote resource recyclingAchieving foam releaseFibrous raw materialsSolubilityMagnesium salt

The invention provides low-solubility salt paper pulp and a preparation method thereof. The low-solubility salt paper pulp is characterized in that the paper pulp is harmless to vegetation; harmlessness is as follows: cultivated wheat seedling test is carried out on the basis of wet paper pulp free of pulp washing treatment and the harm of impurities in the paper pulp to wheat seedlings cannot be seen at least within a growth period from germination of wheat grains to over 5cm of seedlings; or the gram molar concentration of at least Na<+> or / and K<+> or / and Mg<2+> contained in the wet pulp is smaller than or equal to 0.034mol / L, namely the total concentration of at least soluble sodium salt, potassium salt and magnesium salt contained in a solution in the wet pulp is smaller than or equal to an upper limit value of intolerance 0.20% (wt%) of rice and wheat growth; or the wet paper pulp is only dried to absolute dryness of which the moisture content is not greater than 15%, and the weight of the Na<+> or / and K<+> or / and Mg<2+> contained in 1,000g of absolute dry paper pulp is smaller than or equal to 1.6g; the paper pulp is an offline chemical foaming production line; or the paper pulp is screened and classified paper pulp or unscreened or unclassified paper pulp of which the pulp degree value is within a range from 10 degrees SR and 90 degrees SR and the superimposed screening indicator is within a range from a 10mesh screen to a 200mesh screen hole.

Owner:沙良宝 +2

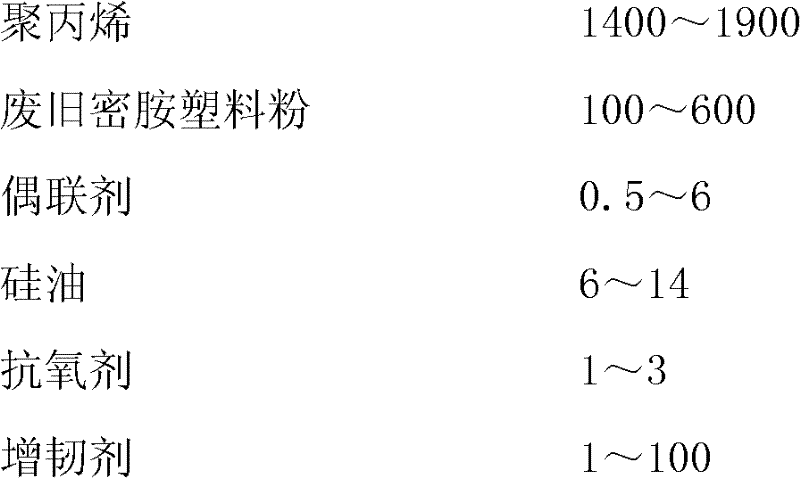

Flame-retardant polypropylene plastic composition and preparation method thereof

InactiveCN102234398APromote resource recyclingImprove bending strengthHeat deflection temperaturePolymer science

The invention discloses a flame-retardant polypropylene plastic composition and a preparation method thereof, and belongs to the field of polypropylene plastic preparation. The composition comprises the following components in part by mass: 1,400 to 1,900 parts of polypropylene, 100 to 600 parts of waste melamine plastic powder, 0.5 to 6 parts of coupling agent, 6 to 14 parts of silicon oil, 1 to 3 parts of antioxidant and 1 to 100 parts of toughening agent. The waste melamine plastic powder, the coupling agent, the silicon oil, and the antioxidant are added into the polypropylene, and the flame-retardant polypropylene plastic composition is formed; the waste melamine plastic powder modifies the polypropylene, so that the bending strength, bending modulus and distortion temperature of the composition are greatly improved, the forming shrinkage is obviously reduced and the flame retardancy is obviously improved; and the flame-retardant polypropylene plastic composition is prepared at low cost, and waste plastics are recycled, so that the environment is protected.

Owner:GUANGDONG RONGTAI IND +1

Method for recycling waste tires

The invention relates to a method for recycling waste tires, which specifically comprises the following steps: cutting and crushing waste tire rubber, separating and screening impurities such as steel wire and fiber components in waste tire rubber particles, and then separating and screening the obtained waste tire particles Washing, soaking and drying are carried out, and the dried waste tire particles are sent to a fine crusher for further grinding to obtain finished rubber powder. Finally, the rubber powder obtained above is used according to the waste tire rubber powder: butyl rubber: sulfur: vulcanizing agent DTDM: accelerator DM: zinc oxide: stearic acid: carbon black: paraffin oil: processing aid H501: tackifier TKO‑ 90: The quality of anti-aging agent is 50:20:0.7:0.45:0.4:3.0:0.6:30:13.5:1.6:2.2:0.35 for film production. The film prepared by using the above formula has good mechanical properties, durability Abrasion resistance, corrosion resistance and oil resistance, etc., can be applied to the production of various wheel inner tubes.

Owner:青岛华诺金属制品有限公司

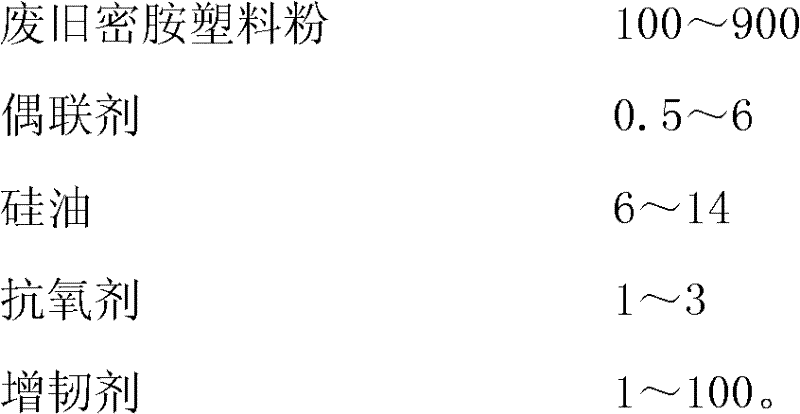

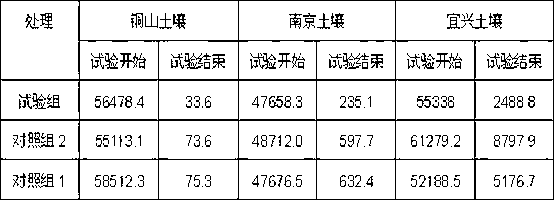

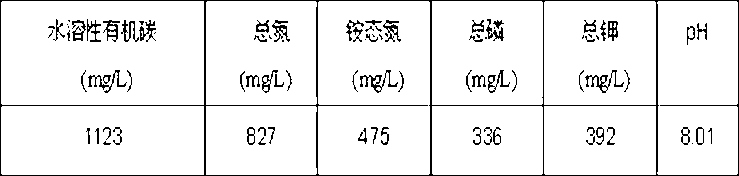

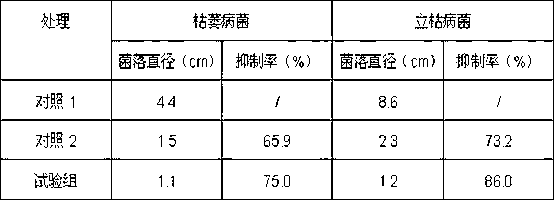

Method for preventing soil-borne diseases of crops by using ammonium-reinforced biogas slurry

The invention relates to a method for preventing soil-borne diseases of crops by using ammonium-reinforced biogas slurry. The method comprises the specific steps as follows: a leisure period of a greenhouse after planting, harvest and cleaning is selected for turn over the soil; ridging is performed in the greenhouse along the periphery, the height of the ridge ranges from 15 cm to 20 cm, and the width ranges from 15 cm to 20 cm; anaerobic fermentation raw materials for biogas engineering are introduced into an anaerobic fermentation tank for fermentation, discharged fresh biogas slurry which is fermented for more than 25 days is taken to be injected into a biogas slurry storage pool and stirred to a suspension state, during stirring, ammonium sulfate is added to dissolve the slurry completely, and the concentration of ammonium nitrogen in the biogas slurry is regulated to 1000 mg / L; the biogas slurry in the biogas slurry storage pool is pumped out and introduced into the greenhouse for flood irrigation, at least 10 cm biogas slurry is kept on the surface of the soil layer within the flooding period, when the liquid level drops due to evaporation or infiltration, the biogas slurry is introduced repeatedly until the flooding period is over, and then natural ventilation or air-cure is performed; and when the moisture content of the soil reaches 15%-25%, the ridge is tilled, and the soil is turned over for ridging combined with a base fertilizer.

Owner:JIANGSU ACAD OF AGRI SCI

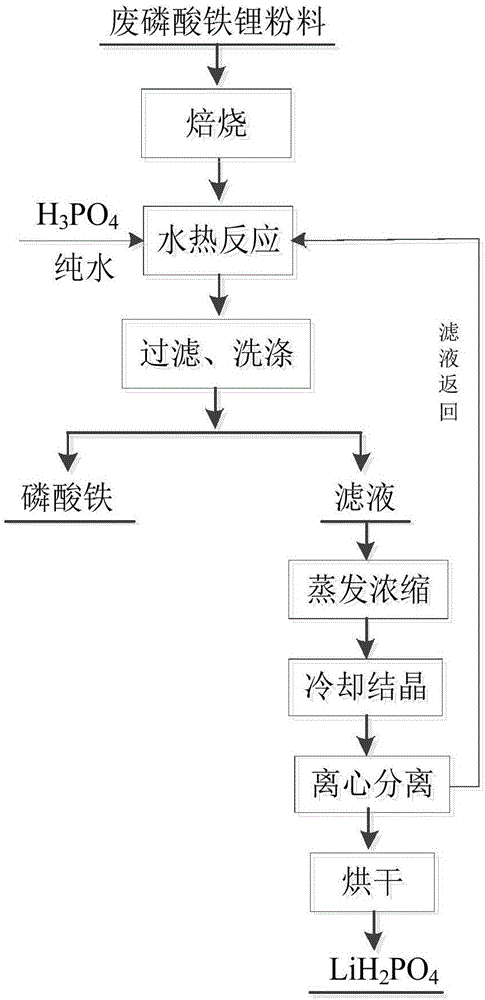

Resource recovery method of lithium iron phosphate waste materials

The invention discloses a resource recovery method of lithium iron phosphate waste materials. The method concretely comprises the following steps of 1, roasting; 2, phosphoric acid solution preparation; 3, hydrothermal reaction; 4, filtering; 5, evaporation and concentration; 6, cooling and crystallization; 7, drying, and a LiH2PO4 product is obtained. The method provided by the invention has the advantages that the introduction problems of other acid, alkali and salts (H2SO4, HCl, NaOH, Na2CO3 and the like) in a conventional wet process recovery process are avoided, so that the purification of a reaction system is ensured; the P, Fe and Li resources in the waste materials can be sufficiently utilized; through conversion and synthesis between substances, the high-added-value iron phosphate and lithium dihydrogen phosphate products are prepared; no Fe waste slag is generated; all elements are efficiently utilized; the technical flow process is short; the reaction system is simple; the reagent consumption is low; the process is simple; the cost is low; the resource recovery utilization is high; the method is very suitable for industrial scaled production.

Owner:JINGMEN GEM NEW MATERIAL

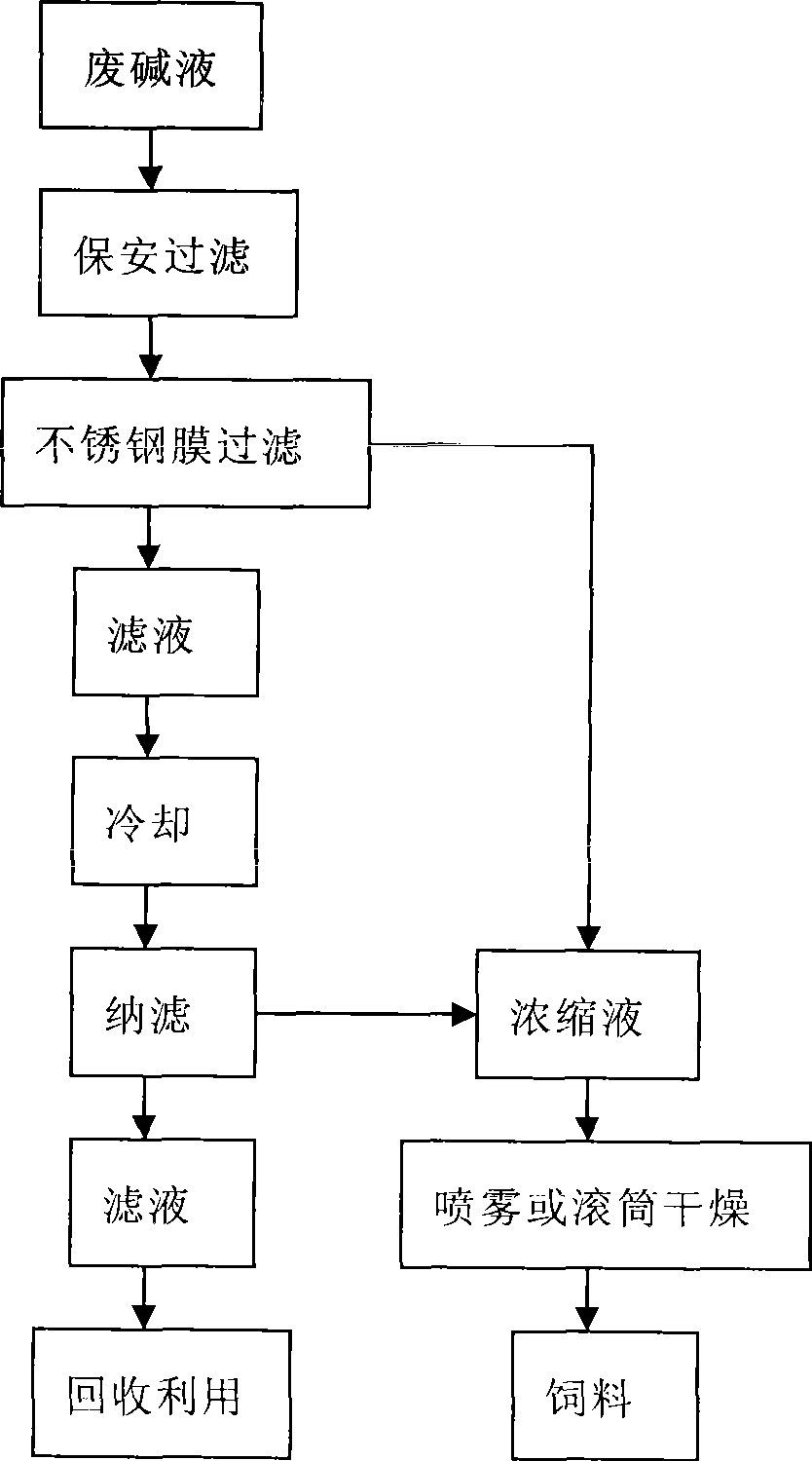

Method for recycling spent caustic liquid during chitin production process

ActiveCN101423307ASolve pollutionHigh purityAnimal feeding stuffAccessory food factorsHigh concentrationFiltration

The invention discloses a method for recycling alkali waste liquid generated during the production of chitin and relates to the technical field of treatment and comprehensive use of wastewater generated during food processing. The method comprises the following steps: alkali waste liquid generated in a deproteinization process during the production of chitin is used as a raw material and subjected to stainless steel membrane filtration and nanofiltration to obtain clean alkali liquid to be reused; and concentrated solutions obtained after the stainless steel membrane filtration and nanofiltration are mixed, neutralized and subjected to spray drying and roller drying to obtain high-protein feed additives. Compared with the prior method for treating waste liquid, the method realizes recycling of alkali liquid, comprehensive use of active ingredients, and prevention of discharge of alkali liquid into environment, adopts a separation and purification process which is simple, reasonable, short in process, convenient in operation, high in yield and quality of alkali, and combines a stainless steel membrane filtration separation system and a nanofiltration separation system which have advantages of low operation cost, high filtration precision, high concentration factor, high concentration of the concentrated solutions and so on, contributes to production of high-protein feed additives through solidification of concentrated solutions and avoids secondary pollution.

Owner:HAINAN ZHENGYE ZHONGNONG HIGH TECH

Low temperature cracking furnace

PendingCN108998066ASet evenlyFully lysedLiquid hydrocarbon mixture productionHydrocarbon oils treatmentElectricityEngineering

The invention relates to a low temperature cracking furnace. The low temperature cracking furnace comprises a horizontal furnace body, a furnace tube is installed in the horizontal furnace body, the furnace tube has a cracking chamber, the first end of the horizontal furnace body is provided with a charging mechanism, the second end of the horizontal furnace body is provided with a discharging mechanism, the horizontal furnace body is provided with a feeding section, a low temperature cracking section communicated with the feeding section, a cooling section communicated with the low temperature cracking section and a discharging section communicated with the cooling section, the charging mechanism is communicated with the feeding section, the discharging mechanism is communicated with thedischarging section, a heating mechanism is arranged below the low temperature cracking section and is used for heating the furnace tube so that a waste circuit board in the cracking chamber undergoesa cracking reaction, and the low temperature cracking furnace also comprises a transmission mechanism passing through the horizontal furnace body and used for conveying the waste circuit board, a sealing mechanism used for sealing an input end and an output end of the transmission mechanism, and an electric control mechanism respectively electrically connected to the heating mechanism and the transmission mechanism. The low temperature cracking furnace has the advantages of high degree of automation, good sealing performance, continuity, high efficiency and low carbon.

Owner:ADVANCED FOR MATERIALS & EQUIP

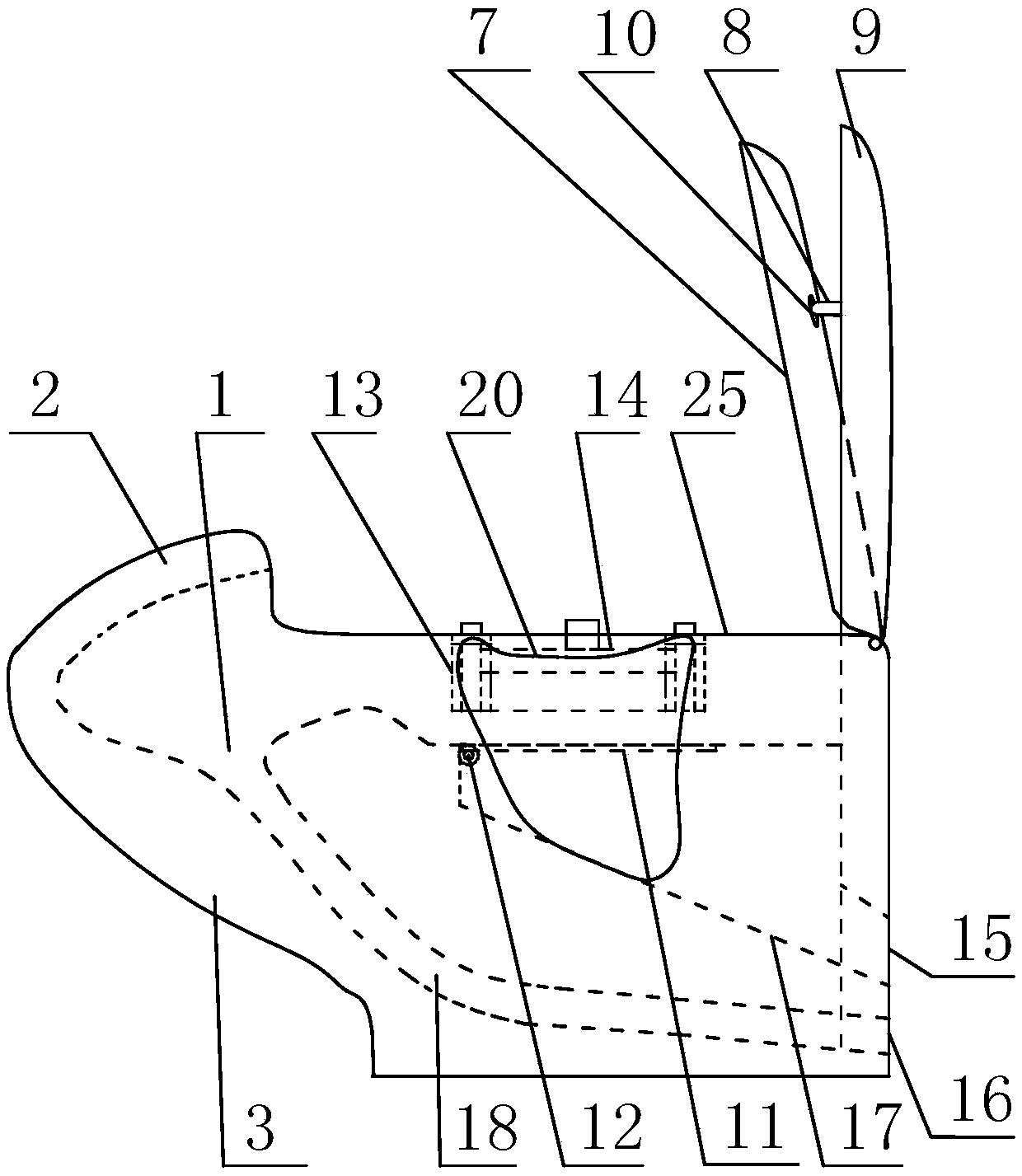

Novel source separation squatting pan

InactiveCN110731719AEasy to useImprove securityBathroom coversAgainst vector-borne diseasesWood ashEngineering

The invention discloses a novel source separation squatting pan. The novel source separation squatting pan comprises a rear urinal; a clapboard is arranged in the rear urinal, so that the rear urinalis separated into a rear urine urinal and an excrement urinal; an urine discharging hole is arranged at the bottom in the rear urine urinal, and connected to an urine storage barrel through a pipeline; an excrement cabin is arranged below the excrement urinal; an excrement urinal cover plate and a defecation plate are also included; the cover plate is positioned over the excrement urinal; the defecation plate is positioned below the excrement urinal; both the two can rotate around a rotating shaft; when the cover plate is opened, the defecation plate is positioned below the excrement urinal, and used for isolating the excrement urinal from the excrement cabin; and, when the defecation plate is opened, the cover plate is positioned over the excrement urinal, and used for covering the opening of the excrement urinal. Excrement and urine source separation is realized through a rear urine hole and an excrement hole; a lot of water sources can be saved; simultaneously, independent collection of excrement and urine is realized; in the use state, contact between an excrement box and a user is blocked by the defecation plate; upward overflowing of bad smell is inhibited; and simultaneously, the bad smell of excrement is further adsorbed by auxiliary materials, such as wood dust and plant ash.

Owner:TONGJI UNIV

Separation and recycling method for partition plates in waste lead-acid storage batteries

ActiveCN109796041APromote resource recyclingEfficient separationWaste accumulators reclaimingLead oxidesGlass fiberSlag

The invention discloses a separation and recycling method for partition plates in waste lead-acid storage batteries. The method comprises the following steps of separating the partition plates, loosening and disassembling the partition plates, conducting carbonization treatment, acidifying and dissolving, performing recycling, and recovering waste lead, so that glass fibers and waste lead impurities bonded with the surfaces of the glass fibers are effectively separated from each other, and resource recycling of the waste partition plates is promoted. According to the method, high additional energy consumption caused by the fact that the partition plates participate in smelting of regenerated lead is avoided, slag discharge is greatly reduced, the pollution control cost is reduced, the economic benefits of the regeneration industry are increased, and improvement of an energy conservation and emission reduction process is greatly promoted.

Owner:贵州麒臻实业集团有限公司

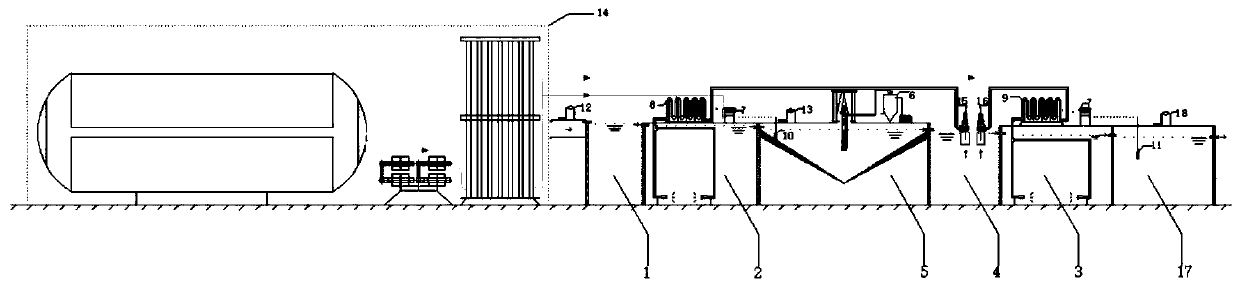

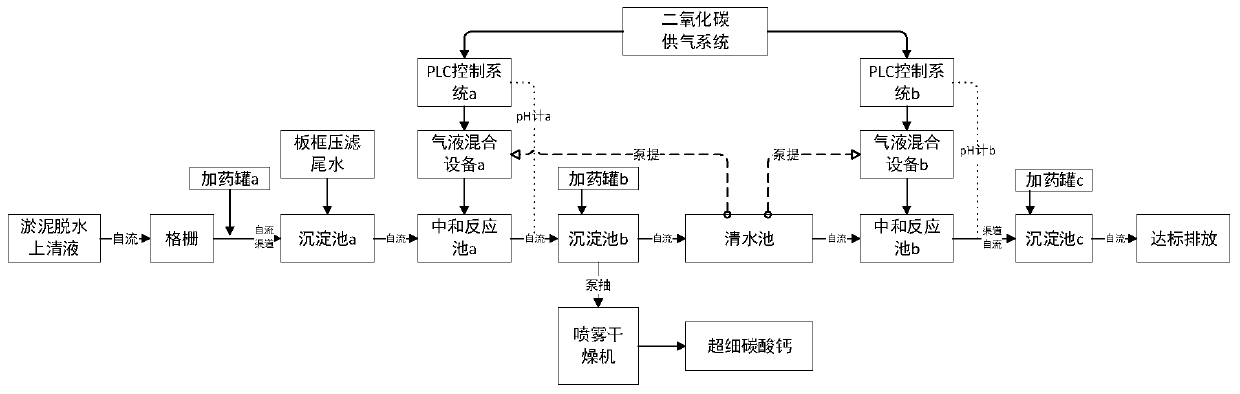

Sludge dewatering high-alkalinity tail water treatment device and method

InactiveCN110950477AReduce alkalinityAvoid secondary pollutionCalcium/strontium/barium carbonatesMultistage water/sewage treatmentIron sulfateScrew pump

The invention relates to a sludge dewatering high-alkalinity tail water treatment device. The device comprises a sedimentation tank a, a neutralization reaction tank a, a neutralization reaction tankb, a clean water tank, a sedimentation tank b, a spray dryer, a PLC control system, gas-liquid mixing equipment a, gas-liquid mixing equipment b, a pH meter a, a pH meter b, a dosing tank a, a dosingtank b, a dosing tank c, a screw pump, a CO2 supply system, a submerged pump a and a submerged pump b, wherein the sedimentation tank a, the neutralization reaction tank a, the sedimentation tank b, the clean water tank and the neutralization reaction tank b are sequentially connected; the dosing tank a is connected with a channel in front of the sedimentation tank a, and a polymeric ferric sulfate flocculant is contained in the dosing tank a; cationic polyacrylamide flocculants are contained in the dosing tanks b and c and are respectively connected with the sedimentation tanks b and c. Compared with an inorganic acid alkali reduction process, a CO2 alkali reduction device is more economical and environment-friendly, the operation cost can be reduced by more than 30%, the CO2 utilizationrate reaches 70% or above, meanwhile, calcium carbonate recovery is achieved, and clean production and resource recycling in the sludge dewatering industry are promoted.

Owner:GEZHOUBA ZHONGGU TECH CO LTD

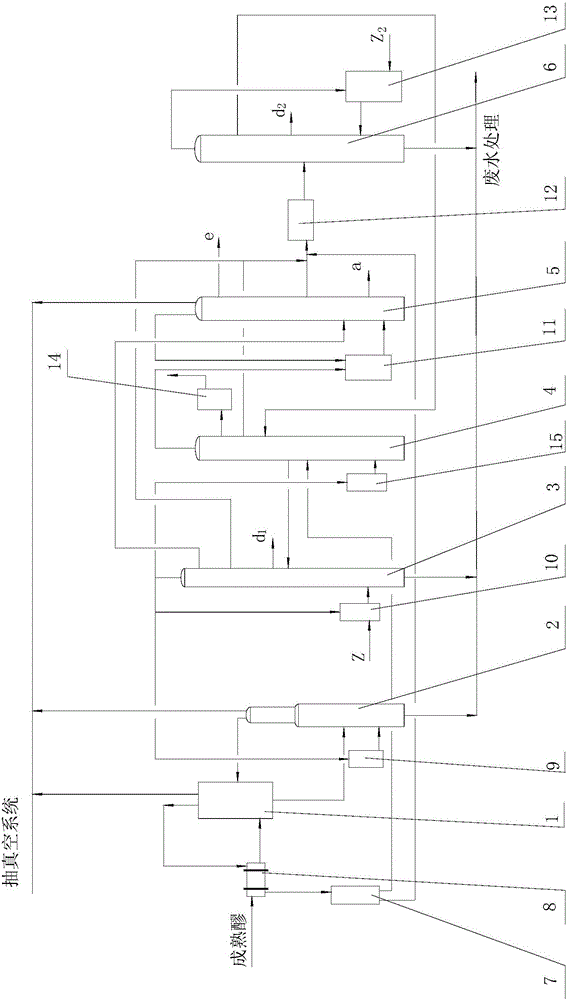

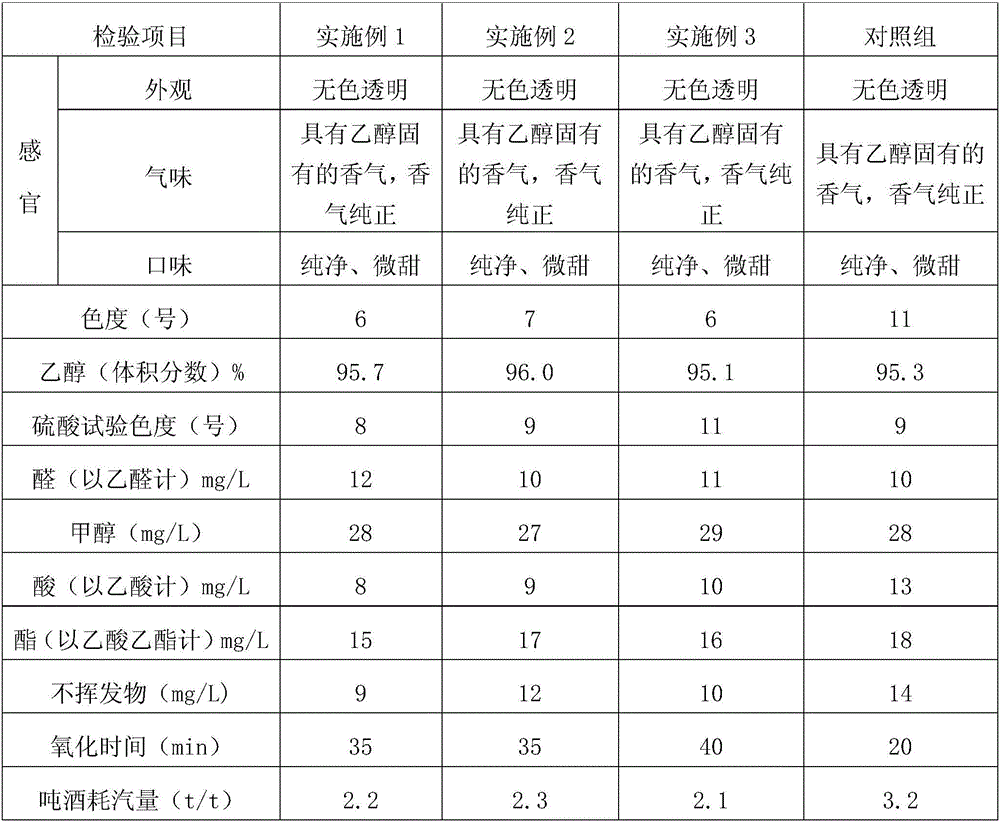

Processing method for alcohol production by cassava residues and molasses

ActiveCN106434769AIncreased ability to convert to sugarAct as a sterilizerOrganic compound preparationHydroxy compound preparationDistillationAlcohol production

The invention relates to an alcohol production process, in particular to a processing method for alcohol production by cassava residues and molasses. The method includes steps of (1) pretreatment, (2) cooking, (3) saccharifying, (4) fermenting and (5) distilling. The molasses and the cassava residues subjected to starch extraction are recycled and mixed to serve as raw materials, acid-free fermentation is adopted while various process improvements including avoiding of addition of antibacterial agents or bactericidal agents in a fermentation process, improving of a five-tower distillation process and the like are performed, and consequently product quality improvement, raw material saving, energy saving, consumption reduction, cost reduction and economic benefit increasing are further realized.

Owner:GUANGXI LUOCHENG KECHAO FOUND SCI & TECH DEV

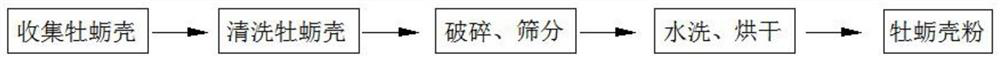

Ecological artificial fish reef concrete utilizing various solid wastes and preparation method of ecological artificial fish reef concrete

InactiveCN112876170AReduce alkalinityImprove resource utilizationCement productionOyster shellsEnvironmental engineering

The invention belongs to the technical field of artificial fish reefs, and particularly relates to ecological artificial fish reef concrete using various solid wastes and a preparation method thereof. The invention provides ecological artificial fish reef concrete utilizing various solid wastes. The ecological artificial fish reef concrete is prepared from the following raw materials in parts by mass: 1420-1598 parts of aggregate, 555-657 parts of fine materials, 1-5 parts of a water reducing agent and 164-197 parts of water, the aggregate comprises natural aggregate and / or recycled aggregate, and the recycled aggregate accounts for 0-100% of the aggregate in percentage by mass; the recycled aggregate is prepared from construction waste; the fine material comprises cement or a mixture of cement and oyster shell powder, and the oyster shell powder accounts for 0-40% of the mass of the mixture of cement and oyster shell powder; the recycled aggregate and the oyster shell powder cannot be 0 at the same time. Cement is partially replaced by the oyster shell powder, so that the alkalinity of the concrete is reduced, and the influence of the artificial fish reef on the living environment of marine organisms is avoided.

Owner:QINGDAO AGRI UNIV

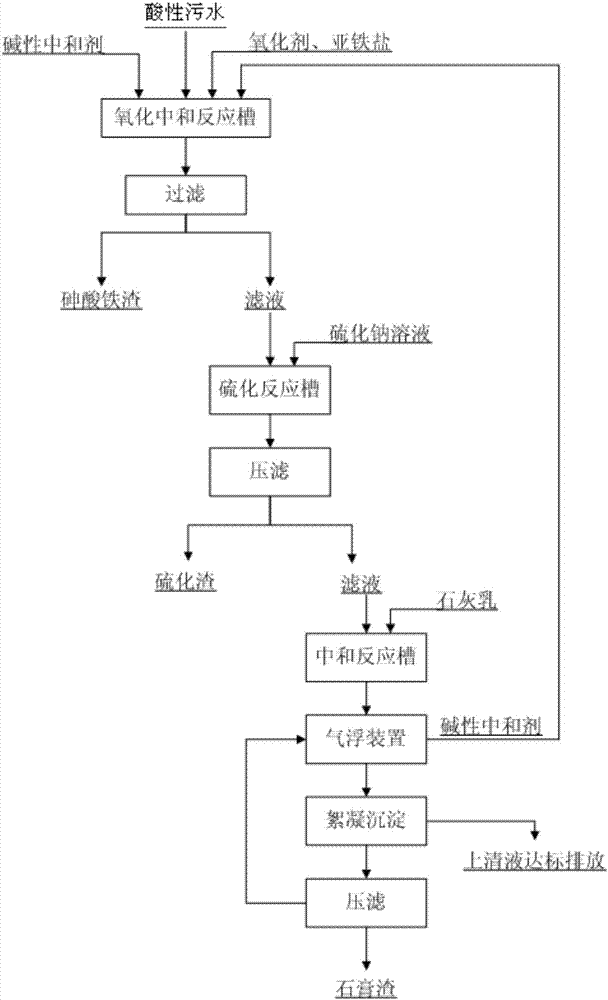

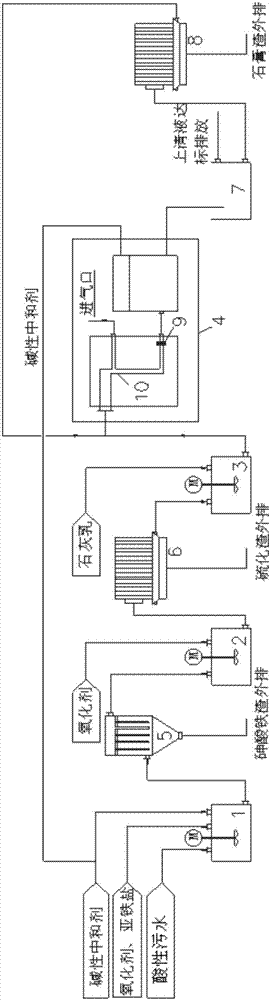

Sewage treatment method and sewage treatment system

PendingCN106865827AHigh recycling valueNot easy to secondary pollutionWater contaminantsTreatment involving filtrationChemistryHeavy metals

The invention discloses a sewage treatment method and a sewage treatment system. The treatment method comprises the following steps: adding an oxidant, a ferrous salt and an alkaline neutralizer to acidic sewage, carrying out a reaction, filtering the obtained sewage, adding sodium sulfide to the obtained filtrate, carrying out a reaction, carrying out press filtration, adding lime milk to the obtained filtrate, carrying out a reaction, and carrying out air floatation separation and post-treatment. The treatment system comprises an oxidation and neutralization reaction tank, a filter, a sulfuration reaction tank, a first filter press, a neutralization reaction tank and an air flotation device which are sequentially connected, and the first outlet of the air floatation device communicates with the oxidation and neutralization reaction tank. The treatment method and the treatment system have the advantages of high-efficiency treatment of acidic sewage with high content of heavy metals, respective enrichment of arsenic and other heavy metals, recycling and harmless utilization of hazardous waste residues, high recovery value and no secondary pollution.

Owner:湖南求是检测科技有限公司

Kitchen garbage treatment device and garbage treatment system

ActiveCN113235704AEnhanced pulverizationImprove filtration efficiencyClimate change adaptationDomestic plumbingProcess engineeringRefuse Disposals

The invention relates to a kitchen garbage treatment device and a garbage treatment system. The kitchen garbage treatment device comprises a treatment body, a discharge part, a smashing assembly and a rotary inner barrel, wherein the treatment body is provided with a first inlet, a first outlet and a treatment cavity, the first inlet and the first outlet both communicate with the treatment cavity, the first inlet and the first outlet are oppositely arranged, the discharge part is arranged on the treatment body in an openable and closable manner, when the discharge part is closed, the first outlet is covered, the smashing assembly comprises a driving part and blades, and the blades are in driving connection with the driving part. According to the kitchen garbage treatment device, through rotation of the smashing assembly and the rotary inner barrel, the smashing effect on kitchen garbage is effectively improved, and kitchen waste particles and liquid are separated and discharged separately; and meanwhile, due to the action of an air extractor, the air flow achieves the back flushing effect on the rotary inner barrel, the rotary inner barrel is effectively cleaned, the filtering efficiency of the rotary inner barrel is improved, the cleaning frequency is reduced, and then the treatment efficiency of the kitchen garbage is improved.

Owner:广州恩华特环境技术有限公司

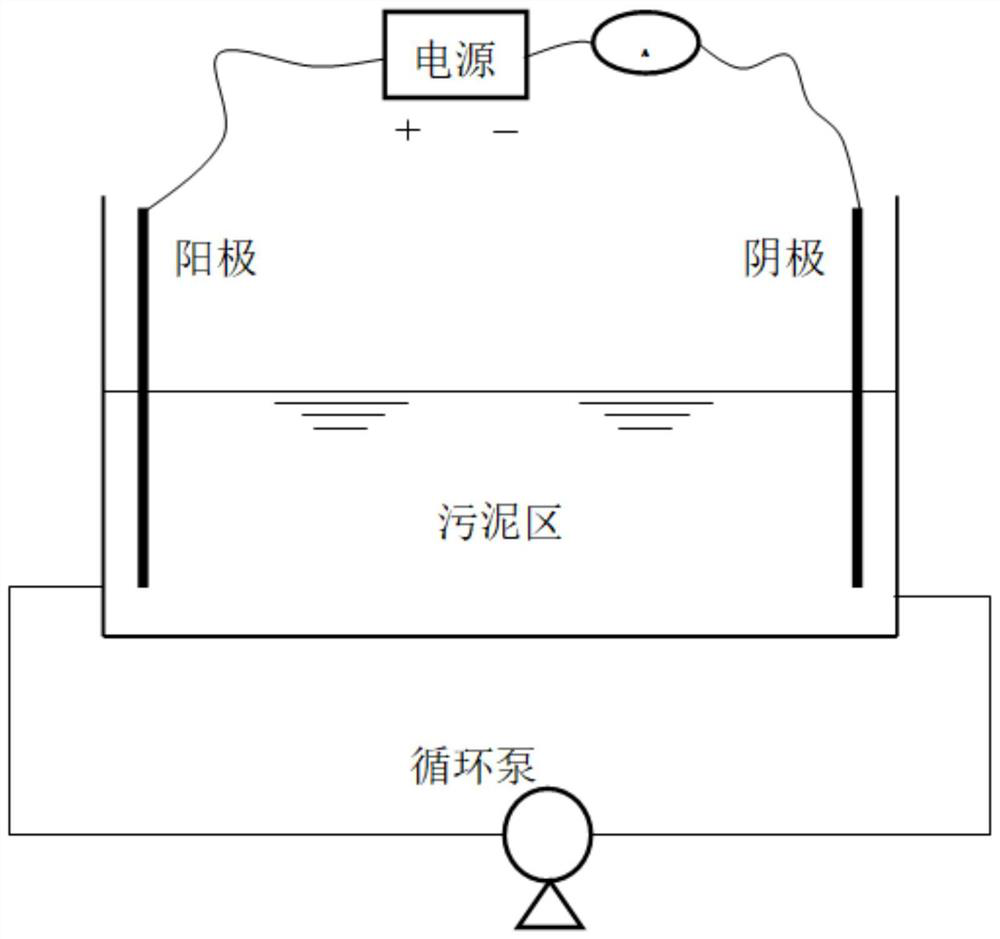

Method for degrading heavy metals in sludge through alkaline hydrolysis-electrolysis combination

InactiveCN112939384AShort degradation cycleReduce energy consumptionWater contaminantsElectrochemical sludge treatmentElectrolytic agentMicroorganism

The invention provides a method for degrading heavy metals in sludge through alkaline hydrolysis-electrolysis combination, and belongs to the technical field of sludge resource utilization. Sludge in a secondary sedimentation tank of a sewage treatment plant is sieved and settled, supernate is removed, microorganisms in the sludge are subjected to cell breaking by adopting a hot-alkali combined method, internal dissolved substances in the microorganisms are released, and a sludge lysate is prepared. An electrolyte is added into the sludge lysate solution in which the heavy metals in the microbial cells are released, and an electric field and a circulating device are externally added. According to the method, microbial cells are broken through the heat-alkali combined method, intracellular heavy metals are released, and then the concentration of the heavy metals in the sludge hydrolysate is effectively degraded through electrolysis. The electrochemical method is short in degradation period, simple in equipment, low in energy consumption and free of secondary pollution, subsequent sludge resource reutilization is facilitated, the cost can be controlled by controlling electrolysis operation parameters, and the disclosed method is economical, stable and reliable.

Owner:DALIAN UNIV OF TECH

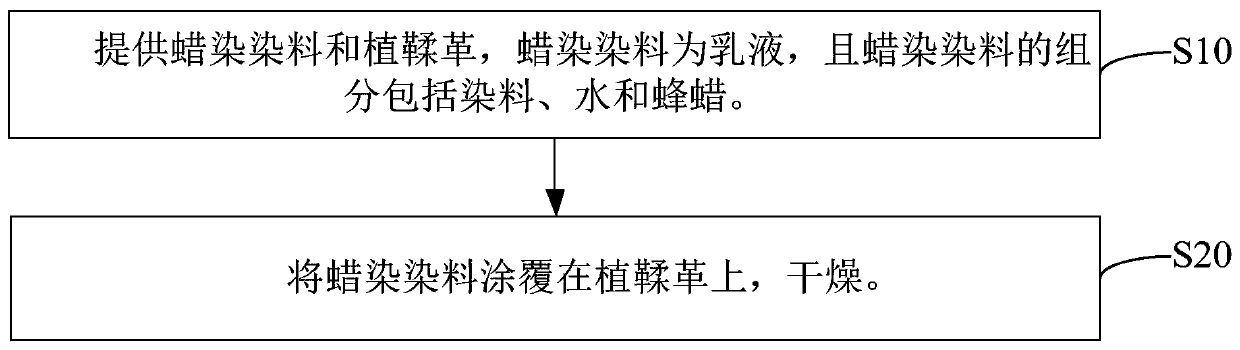

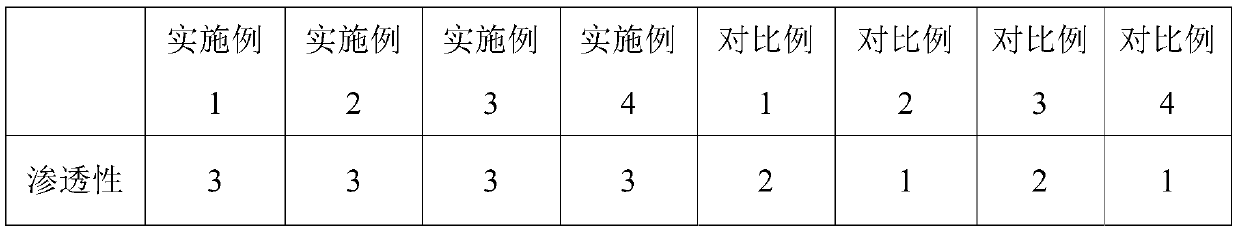

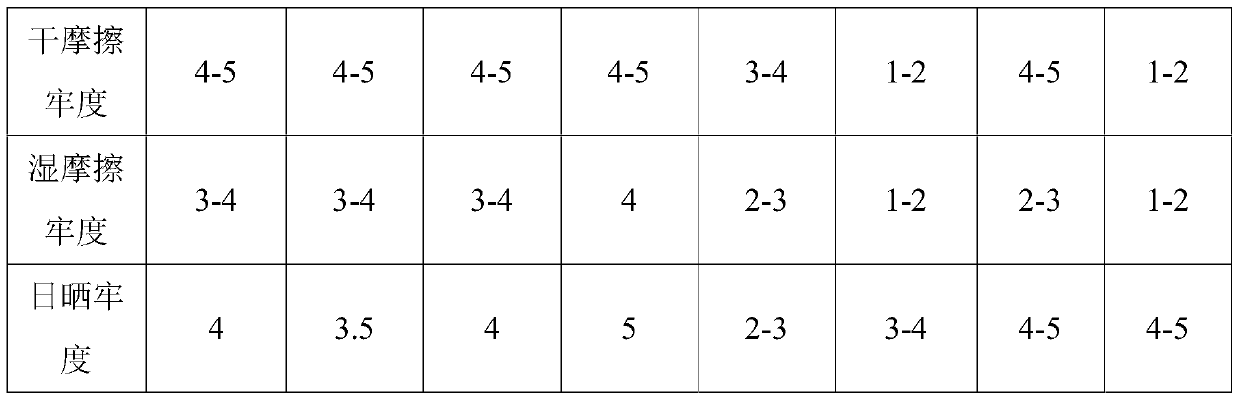

Wax dyeing dye, vegetable tanned leather wax dyeing product and vegetable tanned leather wax dyeing method

The invention relates to a wax dyeing dye, a vegetable tanned leather wax dyeing product and a vegetable tanned leather wax dyeing method. The wax dyeing dye is an emulsion, and the wax dyeing dye comprises the following components: a dye, water and beeswax. The wax dyeing dye is produced into the emulsion by coating the dye with the beeswax, and dye particles coated with the wax have a good dyeing effect, so that the dyeing fastness of vegetable tanned leather wax dyeing is improved; in addition, the wax dyeing dye contains the dye and the beeswax, so that dyeing and waxing processes can be finished in one step, the need of dyeing and waxing separately is avoided, and thus a wax dyeing technology is simplified.

Owner:GUANGDONG VOCATIONAL & TECHNICAL COLLEGE

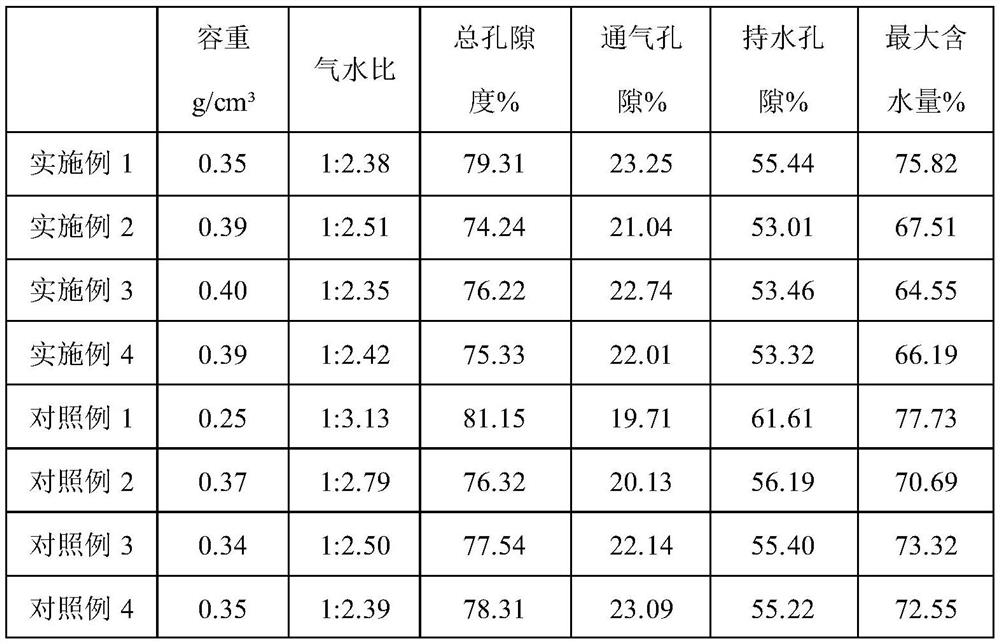

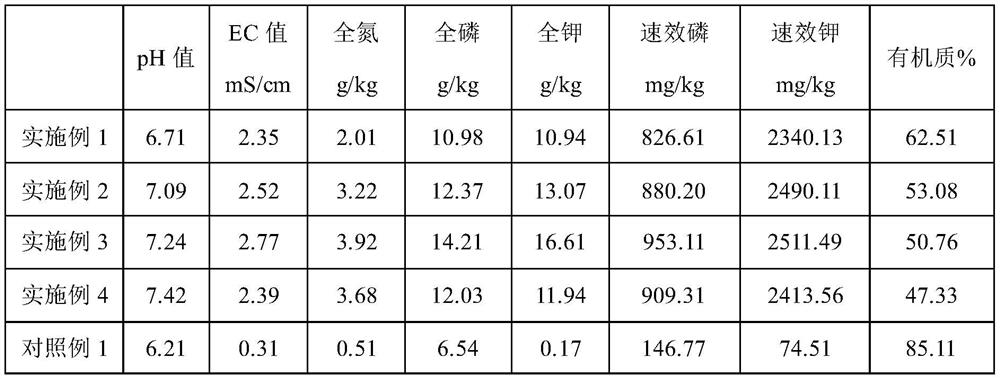

Vegetable seedling substrate and preparation method thereof

PendingCN112400655APromote recycling of resourcesReduce pollution problemsGrowth substratesCulture mediaCompostSeedling

The invention discloses a vegetable seedling substrate and a preparation method thereof. The preparation method of the vegetable seedling substrate comprises the following steps of firstly, conductingmixed substrate fermentation treatment on a mixed substrate; then adding fermentation treatment rice washing water into a fermented mixed material; and conducting drying treatment to obtain the vegetable seedling substrate, wherein the mixed substrate is prepared from vermiculite, peat and cow dung compost. The prepared vegetable seedling substrate is high in nutrient substance content and good in air permeability and water permeability, and the purposes of increasing the emergence rate of vegetables and promoting seedling growth are achieved under the condition that the peat is reduced.

Owner:BEIJING FORESTRY UNIVERSITY

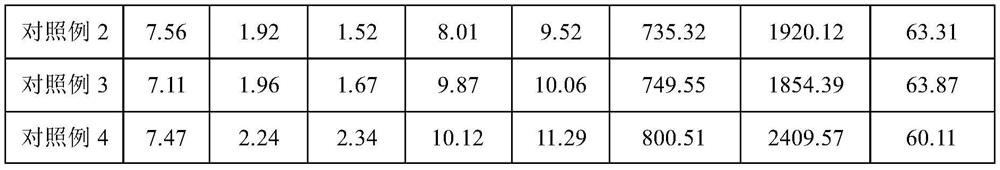

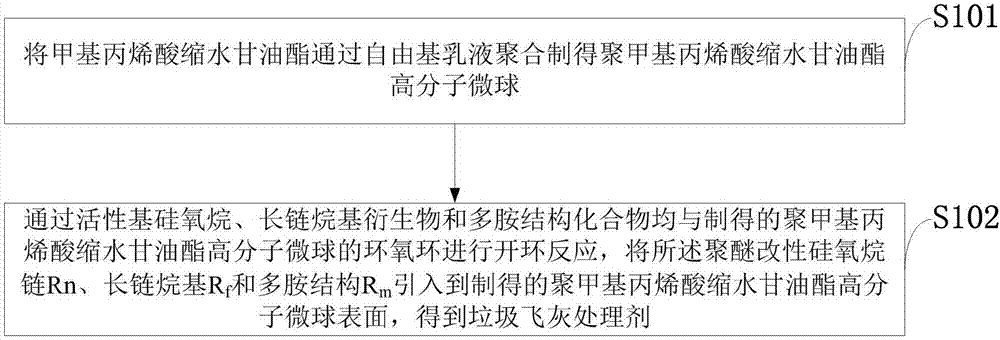

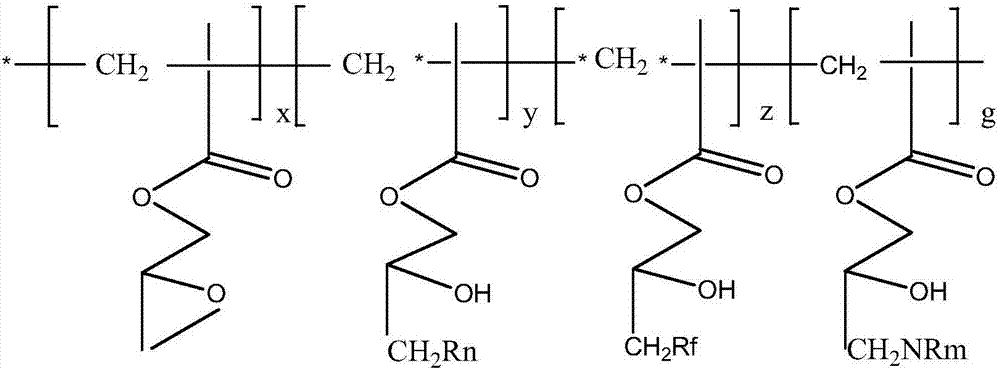

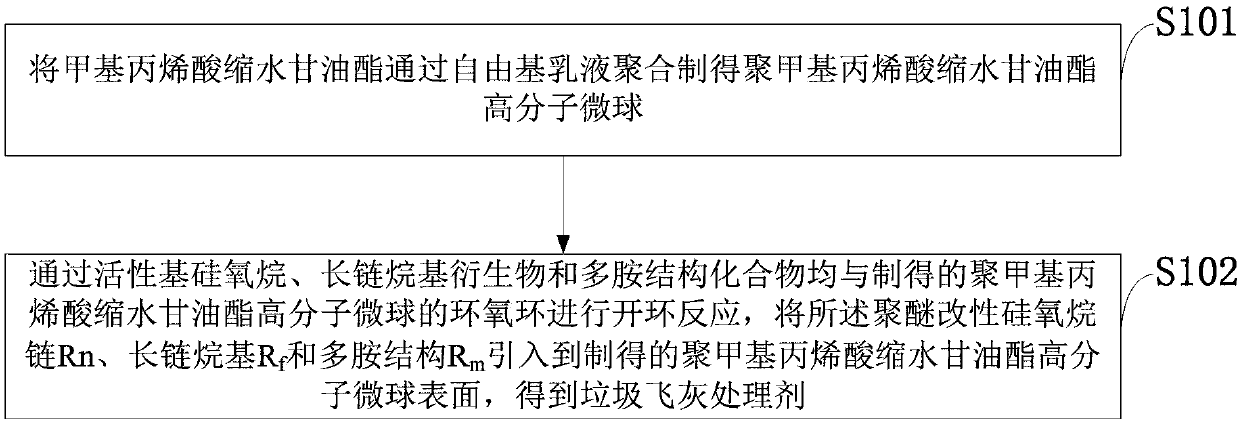

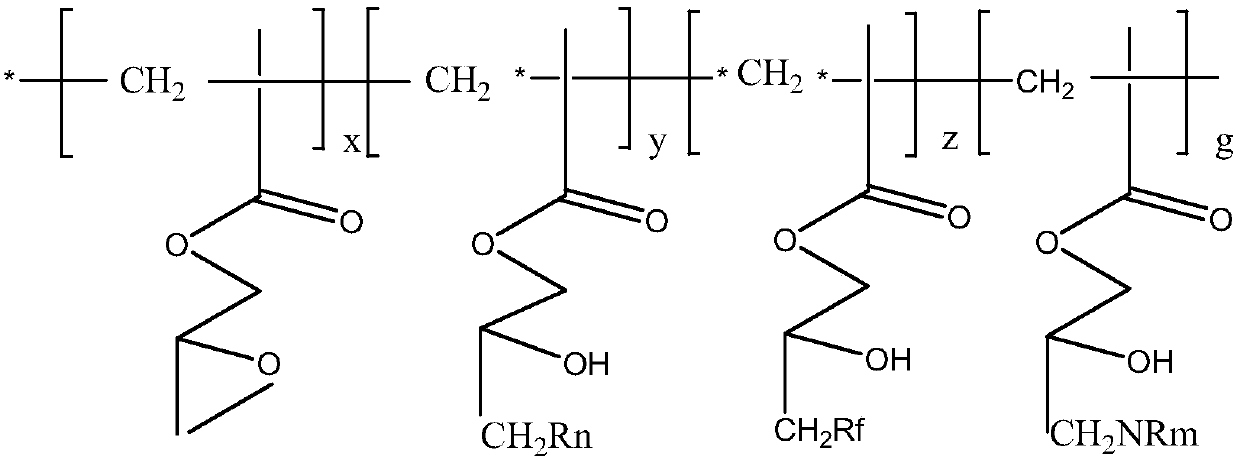

Waste fly ash treatment agent, and preparation method and application thereof

ActiveCN106947017APromote resource recyclingThe stabilization effect is efficient and long-lastingTransportation and packagingSolid waste disposalAsphaltFly ash

The invention belongs to the technical field of environment treatment, and discloses a waste fly ash treatment agent, and a preparation method and an application thereof. The waste fly ash treatment agent has a plurality of heavy metal binding sties and a long hydrophobic chain, can realize long-acting and high-efficiency stability of heavy metals, and forms a hydrophobic coating on the surface of ash to prevent the re-dissolving of the stable metals and reduce the surface energy of treated waste fly ash, so the compatibility with asphalt and cement is increased, and harmless treatment and recycling of the waste fly ash are convenient.

Owner:沐联环境科技(重庆)股份有限公司

A kind of garbage fly ash treatment agent and its preparation method and application

ActiveCN106947017BPromote resource recyclingThe stabilization effect is efficient and long-lastingTransportation and packagingSolid waste disposalGrazingBinding site

Owner:沐联环境科技(重庆)股份有限公司

Water-free flushing feces and urine separation packing toilet

ActiveCN106175549BRealize water-free flushingSave waterBathroom accessoriesAgainst vector-borne diseasesEngineeringFlush toilet

The invention discloses a flushing-free feces-urine-separation packaging toilet bowl. The toilet bowl is provided with a urinating inlet and a feces inlet which are independently separated; bag hanging mechanisms are embedded into the toilet bowl faces of the upper ends of the two sides of a toilet bowl body respectively, and provided with four bag hanging columns jointly, and hanging-column connecting rods are transversely and fixedly connected to the middles of the bag hanging columns; the bag hanging columns are sleeved with hanging-column sleeves, sleeve side openings are formed in the hanging-column connecting rods of the hanging-column sleeves, openings are formed in the tops of the hanging-column sleeves, the lower portions of the hanging-column connecting rods of the bag hanging columns are sleeved with reset springs, and under the condition that external force is free, the tops of the bag hanging columns are ejected out of the top openings in the hanging-column sleeves and the toilet bowl faces through the reset springs, and feces packaging bags can be hung to the bag hanging columns; after toileting is completed, and a cover plate of the toilet bowl is put down, a triggering rod on the cover plate presses the hanging-column connecting rods to allow the packaging bags to fall off. According to the flushing-free feces-urine-separation packaging toilet bowl, a traditional flushing toilet bowl and the existing feces-packaging using mode in the world at present are overturned, the enormous social value, the enormous ecological value and the enormous economic value are contained, and the flushing-free feces-urine-separation packaging toilet bowl has broad application prospects.

Owner:云南八卫科技有限公司

High-softening-point asphalt preparation method suitable for asphalt-based spherical activated carbon raw materials

ActiveCN109251759ARealize continuous productionSimple processWorking-up pitch/asphalt/bitumen by chemical meansHeptaneCoal

The invention relates to a high-softening-point asphalt preparation method suitable for asphalt-based spherical activated carbon raw materials, special asphalt with the softening point of 130-220 DEGC is used as a raw material, a synergistic effect of negative pressure extraction and thermal polymerization reaction is utilized, a double-screw extruder with a certain number of vacuumizing ports isadopted, and the molecular weight distribution, softening point, group composition and other physical and chemical properties of high-softening point coal asphalt can be adjusted by adjusting the temperature and the extrusion speed of each temperature zone of the double-screw extruder, the number, the setting positions and the vacuum degrees of the vacuumizing ports. The softening point of the prepared high softening point asphalt is 240-280 DEG C, the content of n-heptane soluble substances is lower than 10%, the content of toluene soluble substances is lower than 30%, the content of quinoline insoluble substances is higher than 35%, the content of pyridine insoluble substances is higher than 20%, and the ash content is 0.02-8%. The high-softening-point asphalt preparation method has important significance for promotion of resource reutilization of the special asphalt and the asphalt-based spherical activated carbon and related materials (such as asphalt-based foam carbon).

Owner:湖南曦威新材料有限公司

Method for extracting cellulose compound enzyme from agricultural by-products

InactiveCN107083377AEasy to operateMethod stableMicroorganism based processesOxidoreductasesNutrientChemistry

The invention provides a method for extracting cellulose composite enzyme from agricultural by-products, which specifically includes pre-processing edible fungus chaff, and using Bacillus subtilis solid-state fermentation to produce cellulose composite enzyme powder. The invention has extensive raw materials, low cost, simple method and operation, effectively utilizes low-molecular-weight nutrients in agricultural by-products to produce industrial enzymes, turns waste into treasure, and has strong vitality of Bacillus subtilis, avoiding the problem of miscellaneous bacteria infection in the traditional industrial enzyme preparation process. , has a strong promotion value.

Owner:信阳学院

Conveying belt type source separation pedestal pan

PendingCN112450783AAchieve separate collectionPromote resource recyclingSludge treatment by de-watering/drying/thickeningSpecific water treatment objectivesUrineStructural engineering

The invention discloses a conveying belt type source separation pedestal pan which comprises a supporting frame, a pedestal pan body, a conveying belt assembly, an ash storage box, a manure box, a urine storage barrel and a pedal mechanism. A partition plate is arranged in the pedestal pan to divide the pedestal pan into a urinal and an excrement pool, the conveying belt assembly comprises a conveying belt and rollers, the rollers are used for driving the conveying belt to rotate, the ash storage box and the excrement box are located at the two ends of the conveying belt respectively, the ashstorage box is located above the conveying belt, an ash discharging opening is formed in the bottom of the ash storage box, and the distance between the ash discharging opening and the conveying beltis 1-3 cm. The blocking door is located below the pedestal pan, can rotate so as to be opened and closed, and is used for blocking gas flow between the closestool and the excrement box when being closed. When the toilet stool is in a use state, the blocking door blocks the contact between the excrement box and a user, the upward escape of odor is inhibited, meanwhile, ash materials such as wood chips and plant ash further adsorb the odor of excrement, no mosquitoes and flies breed, and the toilet stool is clean and sanitary.

Owner:TONGJI UNIV

Corundum-mullite composite material and preparing method

The present invention belongs to the field of refractory material field, and is especially one kind of composite corundum-mullite material. The composite corundum-mullite material is prepared with coal gangue in 5-25 wt% and bauxite in 75-95 wt%, with the bauxite containing Al2O3 over 75 wt%. The preparation process of the composite corundum-mullite material includes the following steps: ball milling the material in absolute ethyl alcohol as medium for 6 hr, maintaining in stoving for 12hr, pressing to form, and maintaining at 1350-1450deg.c for 3-6 hr in air atmosphere to synthesize. Test shows that the composite corundum-mullite material has high purity. Preparing composite corundum-mullite material with coal gangue and bauxite as main material has rich and cheap material source, so that the present invention provides one new way of preparing high temperature refractory material.

Owner:ZHONGYUAN WEIYE NEW MATERIAL

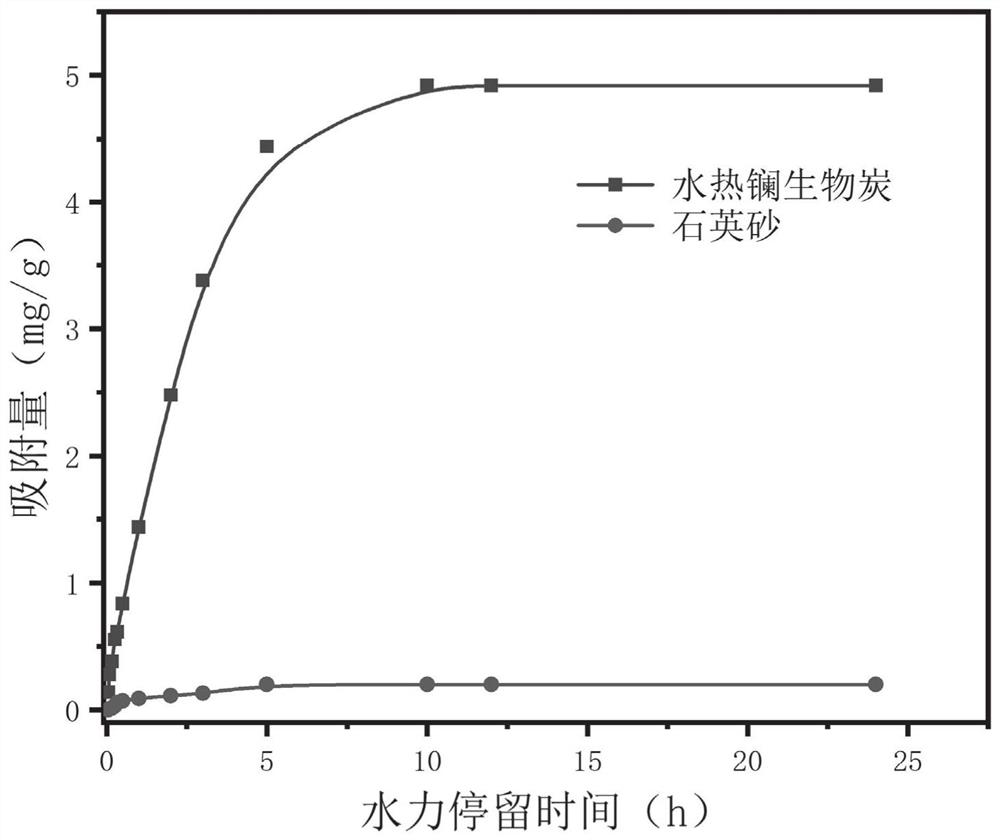

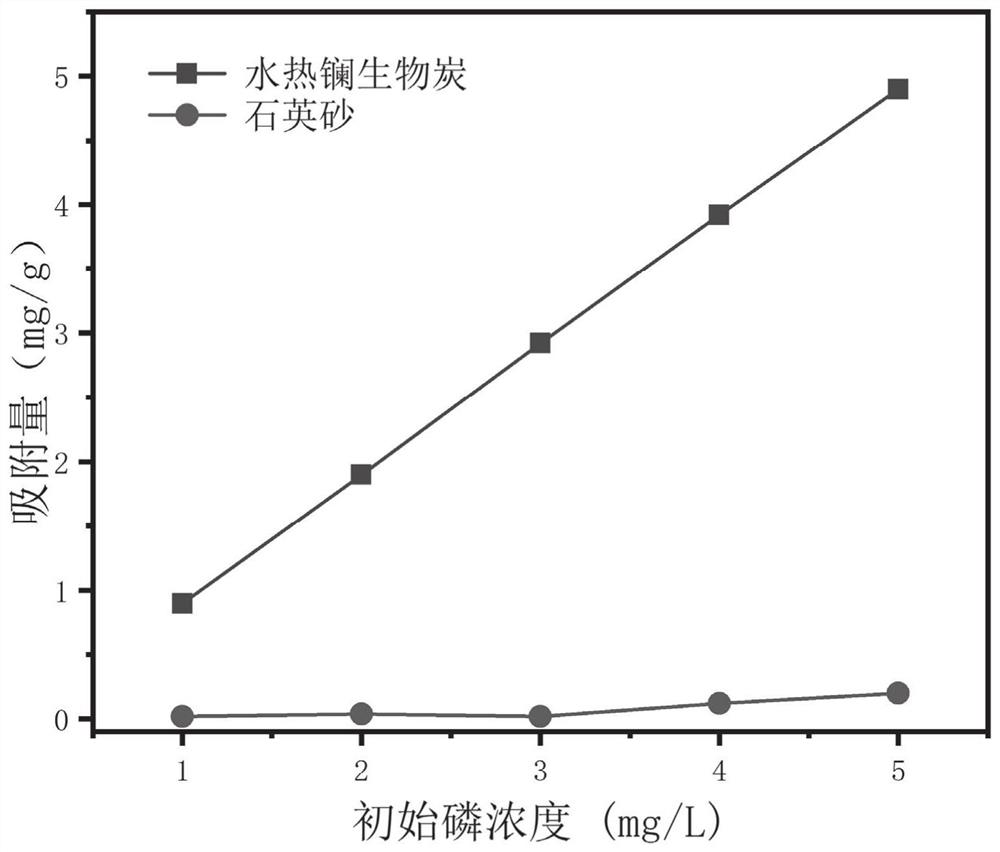

Hydrothermal method lanthanum modified constructed wetland biochar matrix and preparation method thereof

ActiveCN112194244AEfficient phosphorus removalIncrease incomeOther chemical processesWater treatment compoundsConstructed wetlandWater chlorination

The invention discloses a hydrothermal method lanthanum modified constructed wetland biochar matrix and a preparation method thereof. The preparation method comprises the following steps: airing, cleaning, drying and chopping straws of wetland plants, putting the chopped straws into a hydrothermal reaction kettle, and adding a mixed aqueous solution of ammonia water and lanthanum chloride; carrying out hydrothermal carbonization treatment on the hydrothermal reaction kettle in an oxygen-limited environment; and after the hydrothermal carbonization treatment reaction is finished, filtering andseparating precipitates, washing with deionized water, and drying to constant weight to obtain the hydrothermal method lanthanum modified constructed wetland biochar which is used as a constructed wetland matrix.

Owner:SHANDONG UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com