Ecological artificial fish reef concrete utilizing various solid wastes and preparation method of ecological artificial fish reef concrete

An artificial fish reef and concrete technology, applied in solid waste management, sustainable waste treatment, cement production, etc., can solve the problem of low utilization rate of construction waste recycling, less than 10% recycling rate of construction waste, and acid-base balance in seawater environment. adverse effects, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

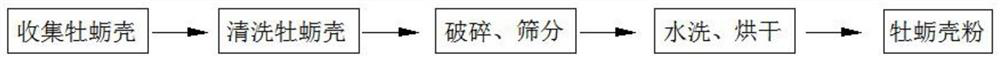

[0062] In the present invention, the preparation method of the oyster shell powder preferably includes the following steps: crushing the oyster shell and then sieving to obtain the oyster shell powder.

[0063] In the present invention, the crushing process preferably further includes: cleaning the oyster shells and removing impurities after drying. In an embodiment of the present invention, the oyster shells come from a breeding and processing plant in Panlong Village, Qingdao City. The present invention is not particularly limited to the cleaning, as long as dirt such as sludge on the surface of the oyster shell can be removed. The present invention has no special limitation to the drying, as long as the moisture on the surface of the oyster shell after cleaning can be removed. In the present invention, the removal of impurities is preferably to remove the remaining oyster meat in the oyster shell.

[0064] In the present invention, there is no special limitation on the cr...

Embodiment 1

[0100] Collect discarded oyster shells from the breeding and processing factory in Panlong Village, Qingdao City, and dry the collected oyster shells in a cleaning pot to remove the remaining oyster meat in the oyster shells after drying; crush the removed oyster shells and pass through a 16-mesh standard net Sieve, take the undersieve, and obtain oyster shell powder with a particle size below 1000 μm (specific surface area is 0.230~0.300m 2 / g, the apparent density is 3050~3065kg / m 3 );

[0101] After the construction waste is crushed, the recycled aggregate with a particle size of 5-20 mm (apparent density of 2623 kg / m 3 ; water absorption rate is 3.2%; porosity is 50.9%; crushing value is 25.4%; needle flake particle mass content is 15.8%);

[0102] Stir 445kg of ordinary Portland cement P.O 42.5, 167kg of water and 1.67kg of non-air-entraining aliphatic superplasticizer at a speed of 45r / min for 60s to obtain cement slurry;

[0103] The cement slurry and 111kg of oyster...

Embodiment 15

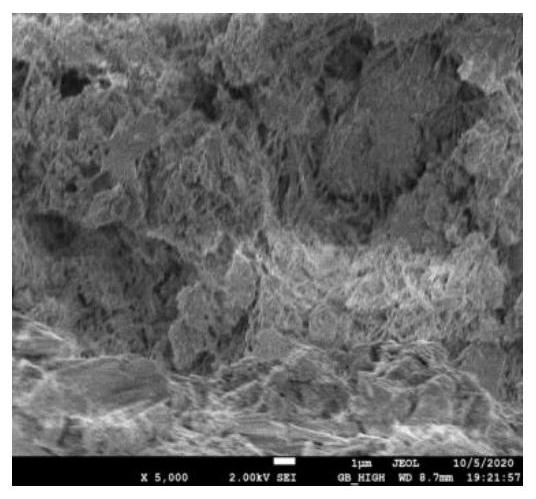

[0114] Put the artificial fish reef concrete prepared in Examples 1 to 14 and the comparative example in three layers into a cube mold with a size of 100mm×100mm×100mm. The concrete mold was removed after being set at 23° C. for 24 hours; the removed product was maintained at 20° C. in an environment with a relative humidity of 95% for 28 days to obtain an artificial fish reef.

[0115] The physical figure of the finalized artificial fish reef concrete prepared by the artificial fish reef concrete prepared in Example 1 is as follows Figure 4 As shown, the section diagram of the finalized artificial fish reef concrete is as follows Figure 5 shown. Depend on Figure 4 and Figure 5 The finalized artificial fish reef concrete shown has a certain porosity and is suitable for the survival of marine organisms.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com