Corundum-mullite composite material and preparing method

A composite material, mullite technology, applied in the field of refractory materials, can solve problems such as increasing the production cost of materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] 1. Raw material selection

[0019] ①Chemical analysis results of bauxite

[0020] ②Chemical analysis results of coal gangue

[0021] 2. Raw material synthesis

[0022] Raw material ratios are: 5, 10, 20wt.% coal gangue and 95, 90, 80wt.% bauxite

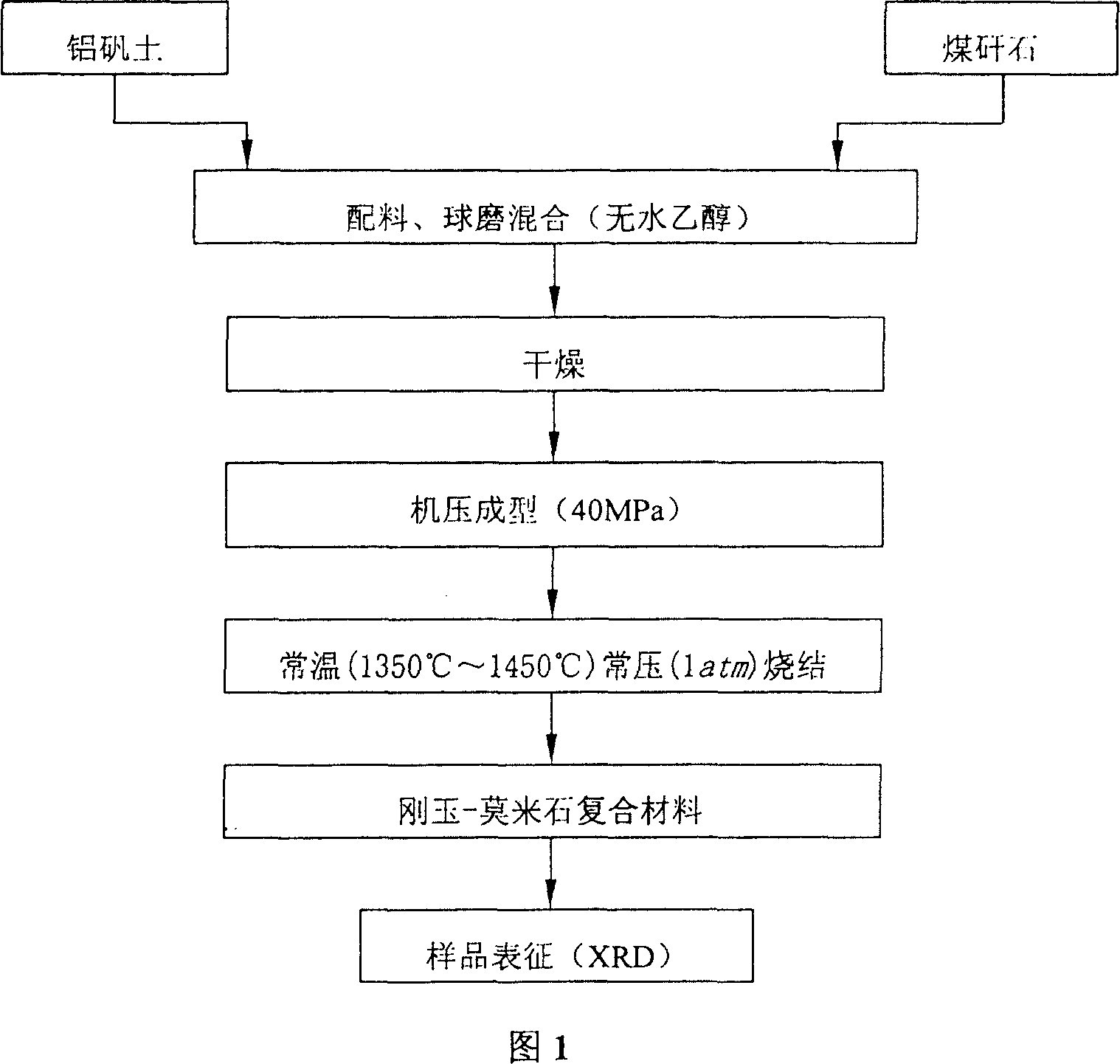

[0023] 3. Synthesis steps: see Figure 1

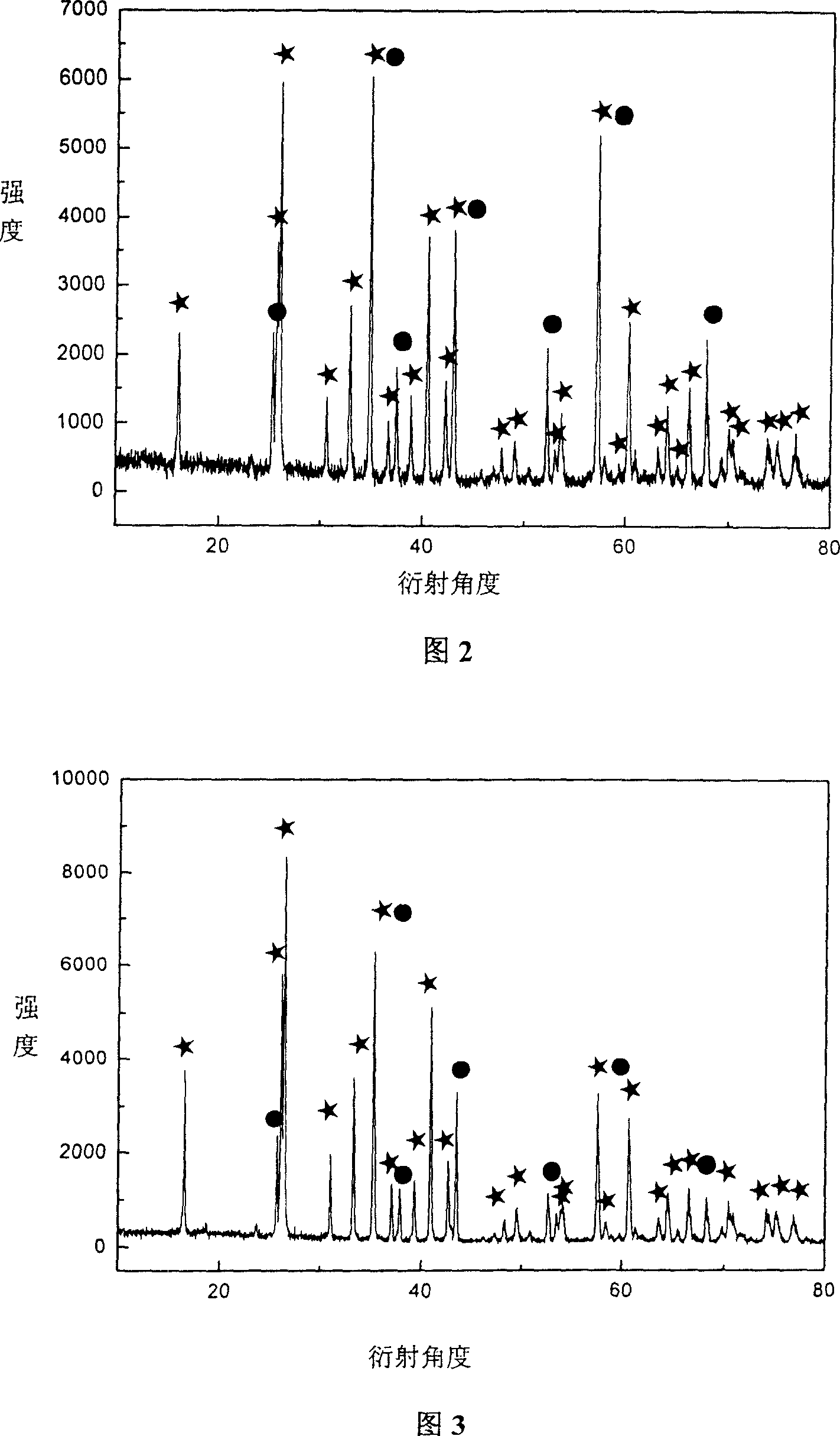

[0024] It is clear from the XRD diagram that a very pure corundum-mullite composite material was synthesized under this test condition.

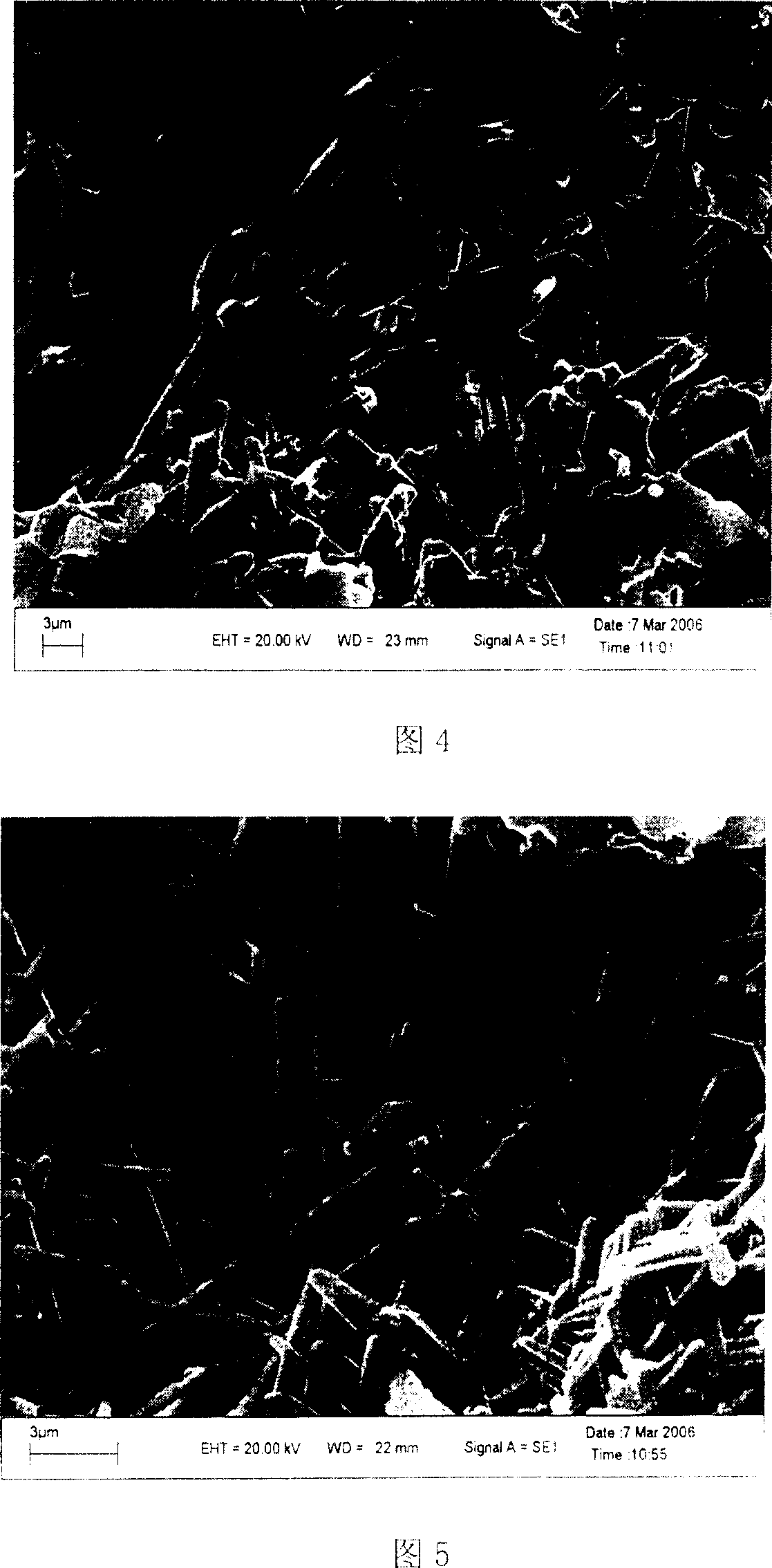

[0025] From the analysis of SEM fracture morphology, it can be seen that the crystal morphology is a typical long columnar crystal, densely grown in an interlaced shape, and its length-to-diameter ratio is about 8:1 or even greater. The method is transgranular fracture, which can significantly improve the performance of the material in all aspects.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com