Method for degrading heavy metals in sludge through alkaline hydrolysis-electrolysis combination

A heavy metal and sludge technology, which is applied in the direction of electrochemical sludge treatment, sludge treatment, chemical instruments and methods, etc., can solve the problems of inability to be recycled in agriculture, long storage time, and increased heavy metal content, and achieve economic stability and reliability. The effect of short degradation cycle and cost control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] (1) Hot-alkali hydrolysis: Take the remaining sludge from the secondary sedimentation tank of the sewage treatment plant and sieve it to remove the leaves and other clogged pipe substances. After standing overnight, pour off the supernatant and measure the sludge parameters. The TCOD content of the sludge is 13392.02mg / L. Configure 1mol / L NaOH solution, slowly adjust the pH of the sludge solution to 13, and place it in a shaker at 30°C and 150rpm to fully react to fully crack the sludge cells. After 12 hours, the sludge TCOD increased by 55.1%.

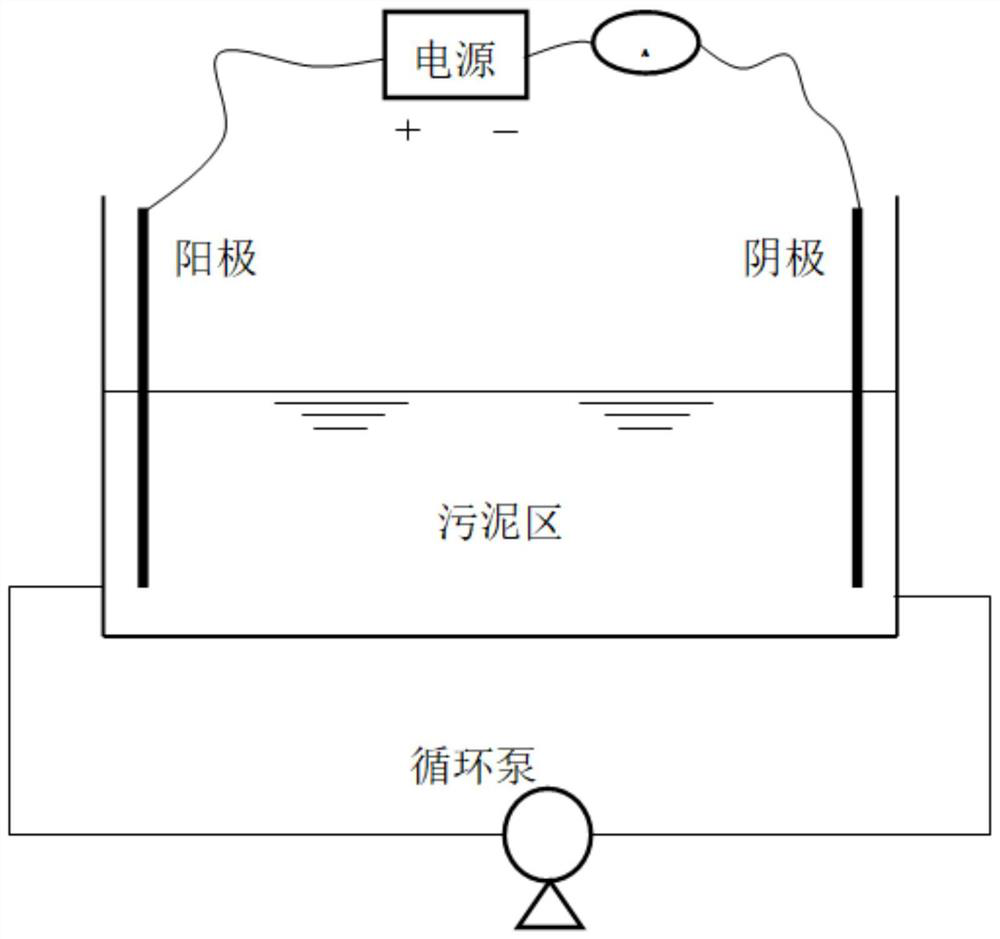

[0022] (2) Electrolysis: Potassium dihydrogen phosphate is used as the electrolyte, and the concentration of the electrolyte potassium dihydrogen phosphate contained in the sludge solution is controlled to be 0.1mol / L. The sludge hydrolyzate after adding alkali and shaking for 12 hours is added to the electrolytic cell, and The circulation pump ensures that the solution can fully flow during the entire electrolysis process, an...

Embodiment 2

[0025] (1) Thermal alkaline hydrolysis: Take the remaining sludge from the secondary sedimentation tank of the sewage treatment plant, sieve it, settle it, and discard the supernatant, and measure the TCOD content of the sludge to be 13392.02mg / L. Configure 1mol / L NaOH solution, slowly adjust the pH of the sludge solution to 14, and place it in a shaker at 30°C and 150rpm to fully react to fully break down the sludge cells. After 12 hours, the sludge TCOD increased by 57.2%.

[0026] (2) Electrolysis: Potassium dihydrogen phosphate is used as the electrolyte, and the concentration of the electrolyte potassium dihydrogen phosphate contained in the sludge solution is controlled to be 0.1mol / L. The sludge hydrolyzate after adding alkali and shaking for 12 hours is added to the electrolytic cell, and The circulation pump ensures that the solution can fully flow during the entire electrolysis process, and the rotation speed of the circulation pump is adjusted to 40rpm. The rutheniu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com