Conveying belt type source separation pedestal pan

A conveyor belt and toilet technology, which is applied in the field of public health appliances, can solve the problems of odor pollution, poor use effect, burst or overflow, etc., and achieves the effect of saving water resources and preventing the breeding of mosquitoes and flies.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] Specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

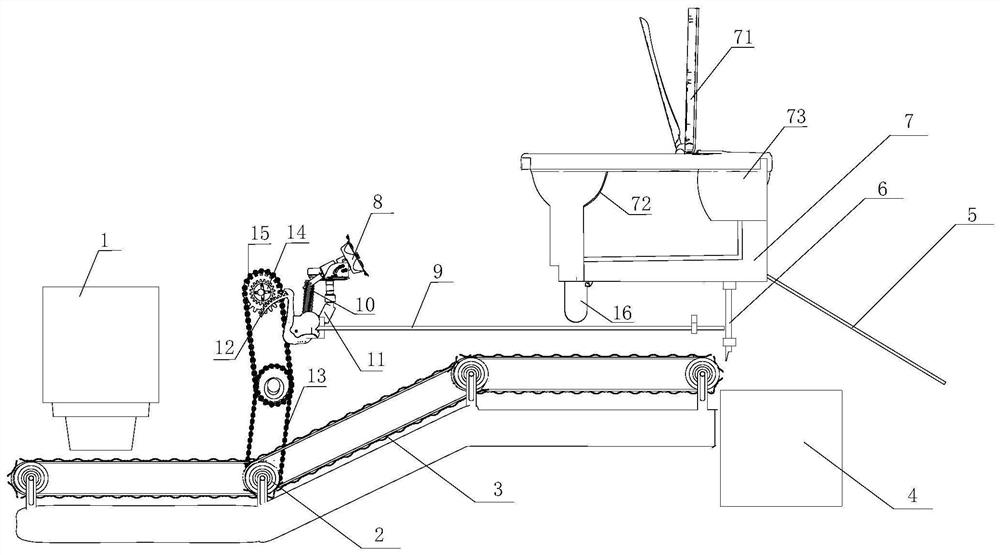

[0022] like figure 1 As shown, the conveyor-type source separation toilet of the present invention includes a support frame (not shown in the figure), a toilet 7, a conveyor belt assembly, an ash storage box 1, a feces box 4, a urine storage barrel, and a pedal mechanism; wherein the toilet 7 A partition 72 is set in the middle to divide it into a urine urinal and a cesspool to collect urine and feces respectively. In addition, a baffle 71 can also be set on the top of the toilet to divide the cesspool again, and embed the urine collection in the cesspool. Cavity 73 is used for man standing to urinate. The urine collection cavity is communicated with the pipeline 16, and the bottom of the urinal is provided with a urination outlet and connected to the urine storage bucket (not shown in the urine storage bucket figure) through the pipeline 16. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com