Sewage treatment method and sewage treatment system

A sewage treatment method and sewage technology, which are used in flotation water/sewage treatment, neutralized water/sewage treatment, oxidized water/sewage treatment, etc., can solve the waste of valuable metal resources, cannot be recycled, harm the ecological environment, etc. problems, to achieve the effect of reducing treatment costs, saving pharmaceutical dosage, and high recovery value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

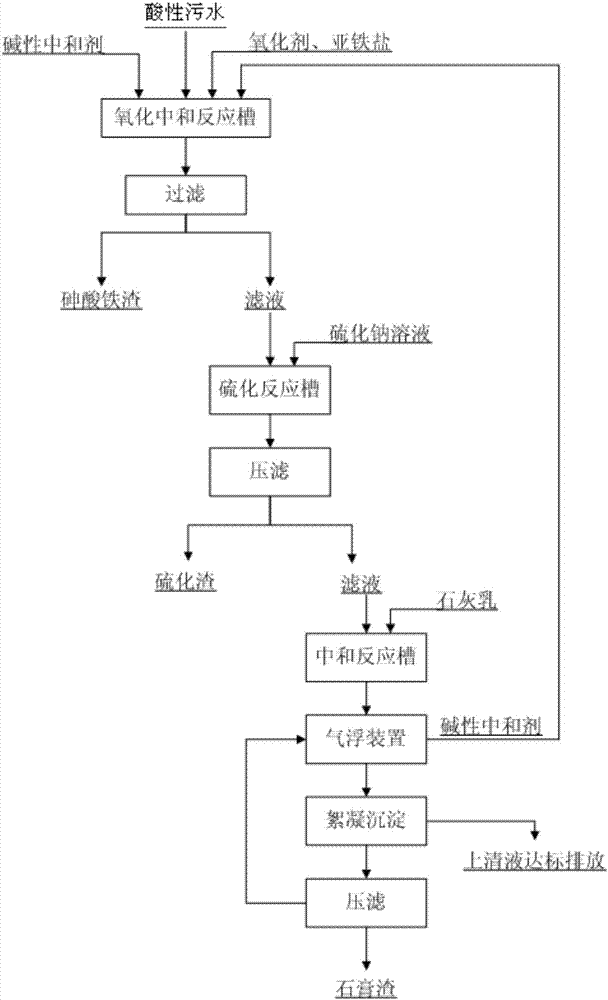

[0050] A sewage treatment method of the present invention, treating 1L of acidic sewage from a certain colored smelter, wherein the acid mass fraction (calculated as sulfuric acid) is 1.5%, the concentration of arsenic ions is 125.163mg / L, the concentration of lead ions is 4.518mg / L, and the concentration of copper ions is 36.35mg / L, cadmium ion concentration 21.896mg / L, nickel ion concentration 80.089mg / L, zinc ion concentration 50.949mg / L, sulfate radical concentration 35000mg / L. The processing method includes the following steps, the process is as follows: figure 1 Shown:

[0051] (1) Oxidation-neutralization reaction: add hydrogen peroxide (industrial grade 30wt% content) 280mg, ferrous sulfate heptahydrate (industrial grade 56wt% content) 1700mg in the acid sewage after homogenization treatment, add Mg(OH ) 2 600mg, adjust the pH of the sewage to 3.5, react for 2 hours, filter and separate, and obtain 350mg of filter residue, the main component is iron arsenate; the co...

Embodiment 2

[0058] A sewage treatment method of the present invention, treating 1L of acid sewage from a certain colored smelting industry, wherein the acid mass fraction (calculated as sulfuric acid) is 2.8%, the arsenic ion concentration is 820.51mg / L, the lead ion concentration is 7.68mg / L, and the copper ion concentration is 56.75mg / L, cadmium ion concentration 45.968mg / L, nickel ion concentration 127.89mg / L, zinc ion concentration 73.493mg / L. The processing method includes the following steps, the process is as follows: figure 1 Shown:

[0059] (1) Oxidation-neutralization reaction: add hydrogen peroxide (industrial grade 30wt% content) 1.8g, ferrous sulfate (specifically ferrous sulfate heptahydrate, industrial grade 56wt% content) 12.5 g in the acid sewage after homogenization treatment After g, add Mg(OH) 2 1.1g, adjust the pH of the sewage to 3.6, react for 2 hours, filter and separate, and obtain 2.1g of filter residue, the main component is iron arsenate; the concentration o...

Embodiment 3

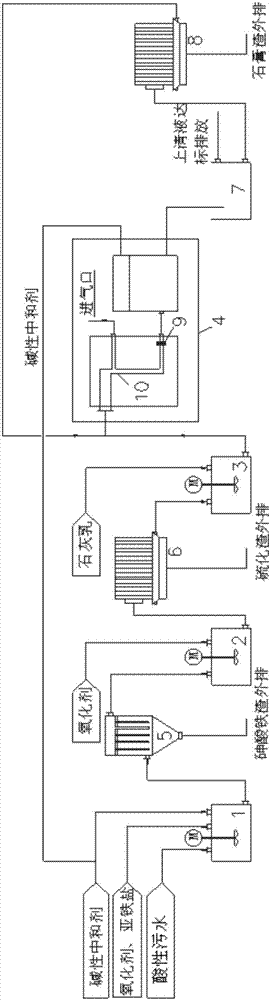

[0066] A sewage treatment system of the present invention, the treatment methods of Embodiment 1 and Embodiment 2 can be implemented using this treatment system, but not limited to this system.

[0067] Such as figure 2 As shown, the sewage treatment system includes an oxidation neutralization reaction tank 1, a filter 5, a vulcanization reaction tank 2, a first filter press 6, a neutralization reaction tank 3 and an air flotation device 4 connected in sequence, and the air flotation device 4 is provided with a The first outlet of the air flotation device 4 communicates with the oxidation neutralization reaction tank 1 after discharging the first outlet of the alkaline neutralizing agent obtained by air flotation separation.

[0068] In this embodiment, the air flotation device 4 is provided with a gas-liquid mixing tube 10, and the gas-liquid mixing tube 10 is provided with a nano-distribution head 9 near the outlet end. The gas-liquid mixing tube 10 is used to mix the reac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com