Method and hydrothermal reaction system for efficient and clean oil production by using mixed plastic waste

A waste plastic and clean technology, which is used in the preparation of liquid hydrocarbon mixtures, the treatment of hydrocarbon oil, and the petroleum industry. It can solve the problems of low recycling rate, unstable properties, and easy oxidation of plastics.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

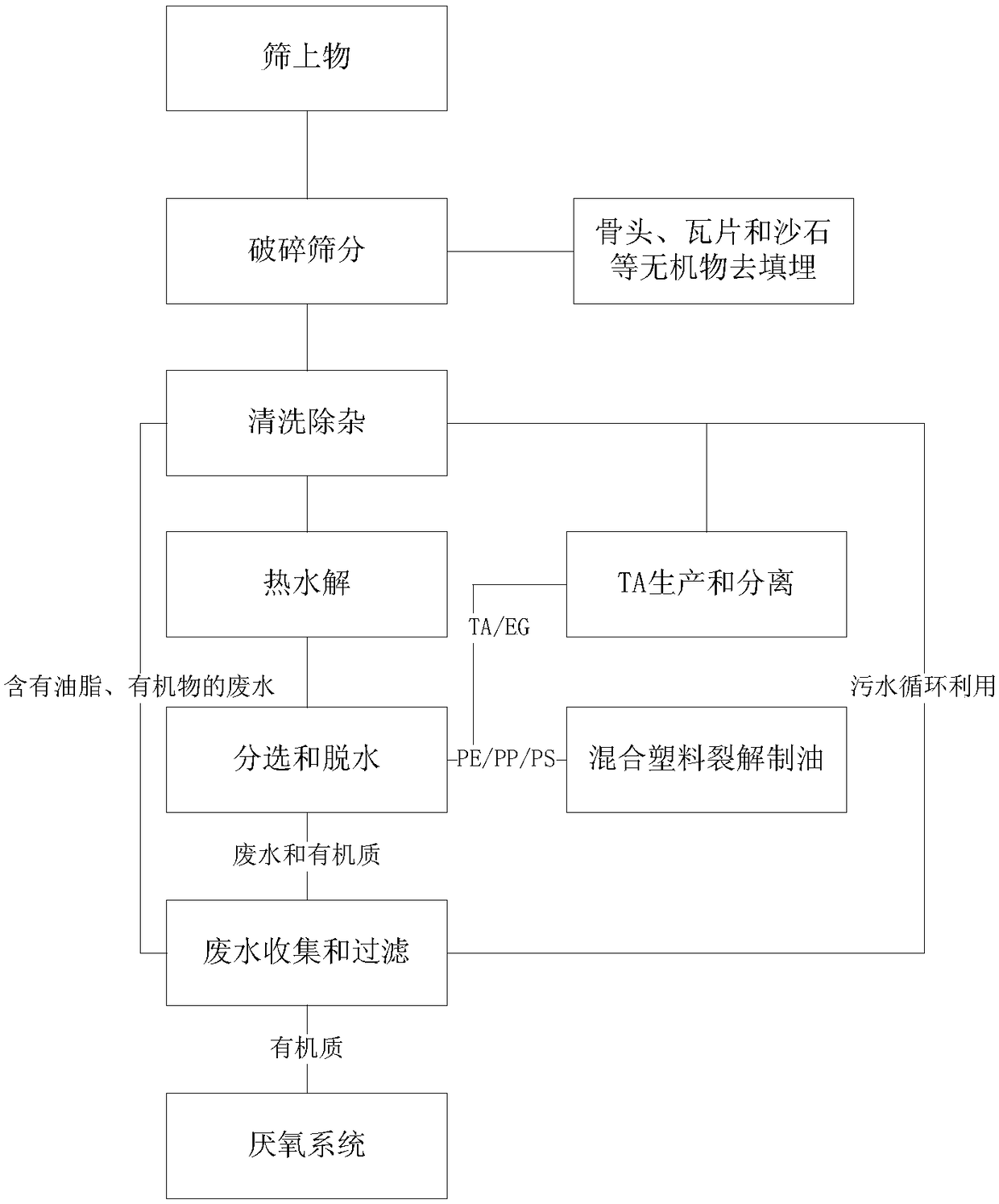

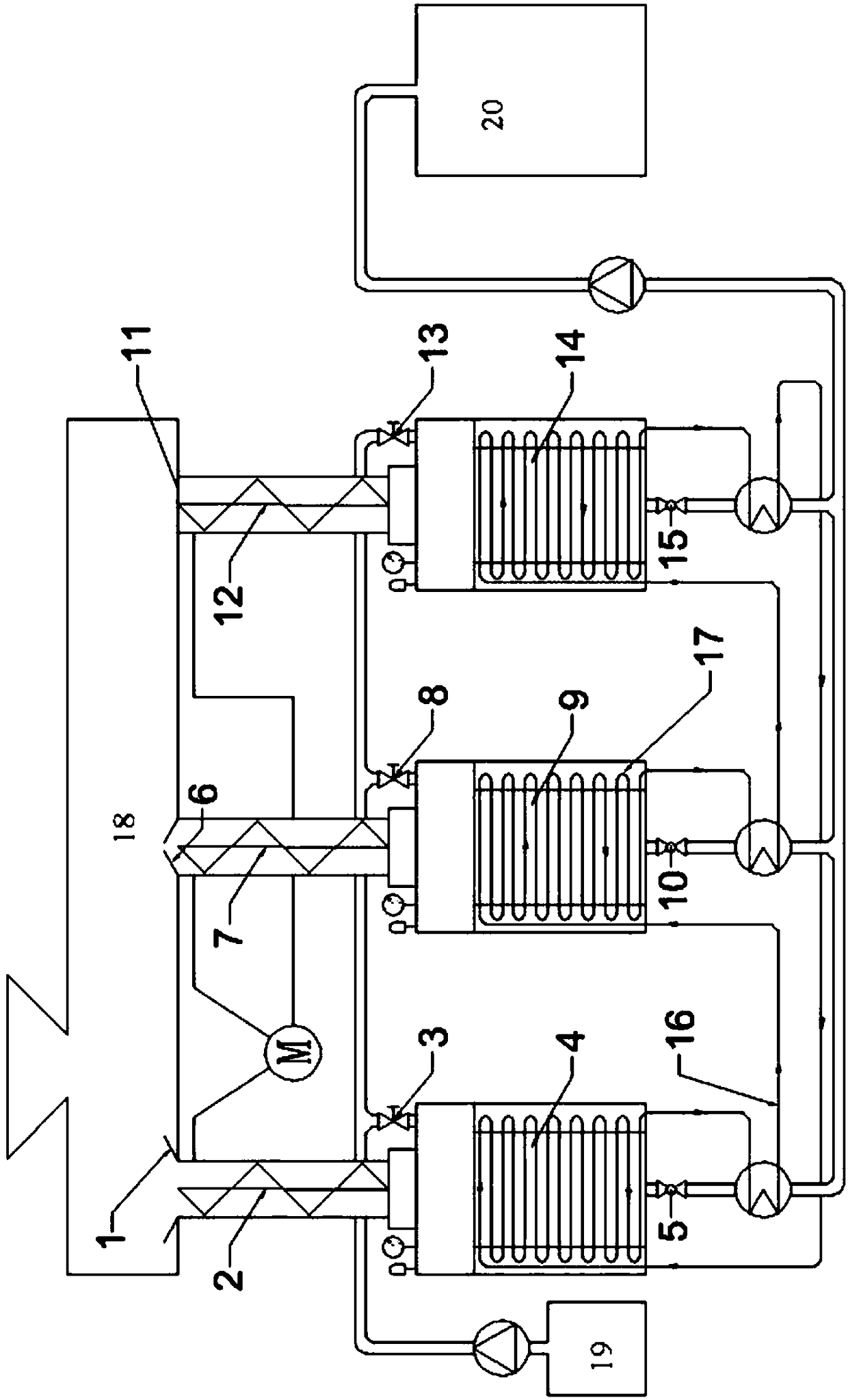

[0037] This embodiment provides an overall process and a hydrothermal reaction system for efficiently cleaning oil by using mixed plastic waste. The overall process is as follows figure 1 As shown, the sieve material (in this embodiment, the sieve material is the kitchen waste obtained through the drum sieve after breaking the bag, and the main components are plastics (containing PP, PE, PS, PET and PVC), paper, bamboo and wood, and also Including bones, tiles, and sand attached to the material, of which the volume fraction of mixed plastics exceeds 70%.) By crushing and screening, inorganic substances such as bones, tiles and sand are removed to obtain waste plastics and waste paper. , bamboo and other raw materials; carry out the next step of cleaning and impurity removal to remove the grease and other organic matter adhered to the surface; the next step is to convert PET into products such as terephthalic acid (TA) and ethylene glycol (EG) by thermal hydrolysis ( water phas...

PUM

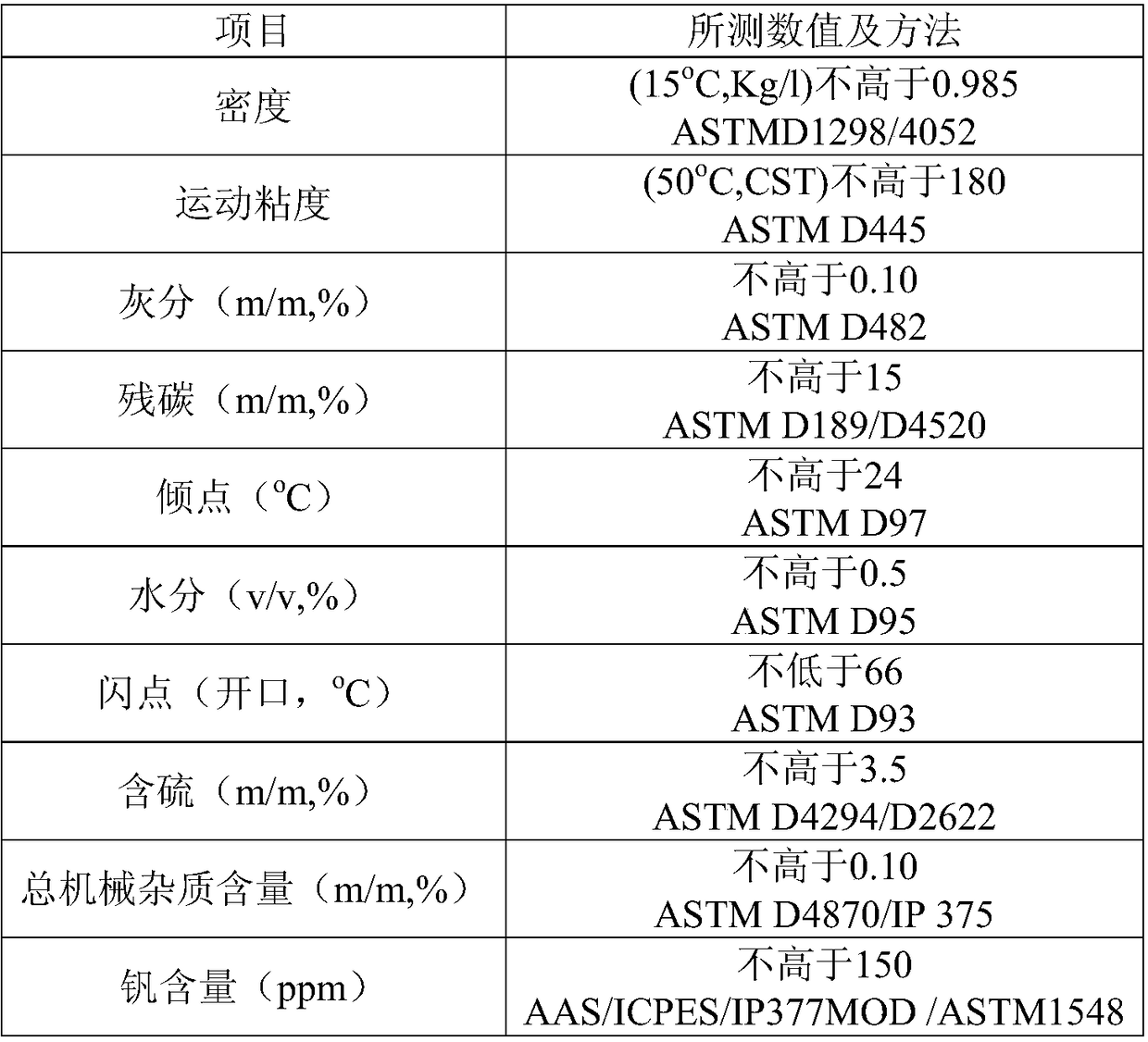

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com