Vibrating screen classifier for kitchen waste

A technology of kitchen waste and vibrating screen, applied in the direction of filter screen, solid separation, grille, etc., can solve the problems of large collection and processing technology, high perishability and deterioration of kitchen waste grease, etc., to achieve good screening effect and convenient The effect of resource recycling and convenient installation and maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

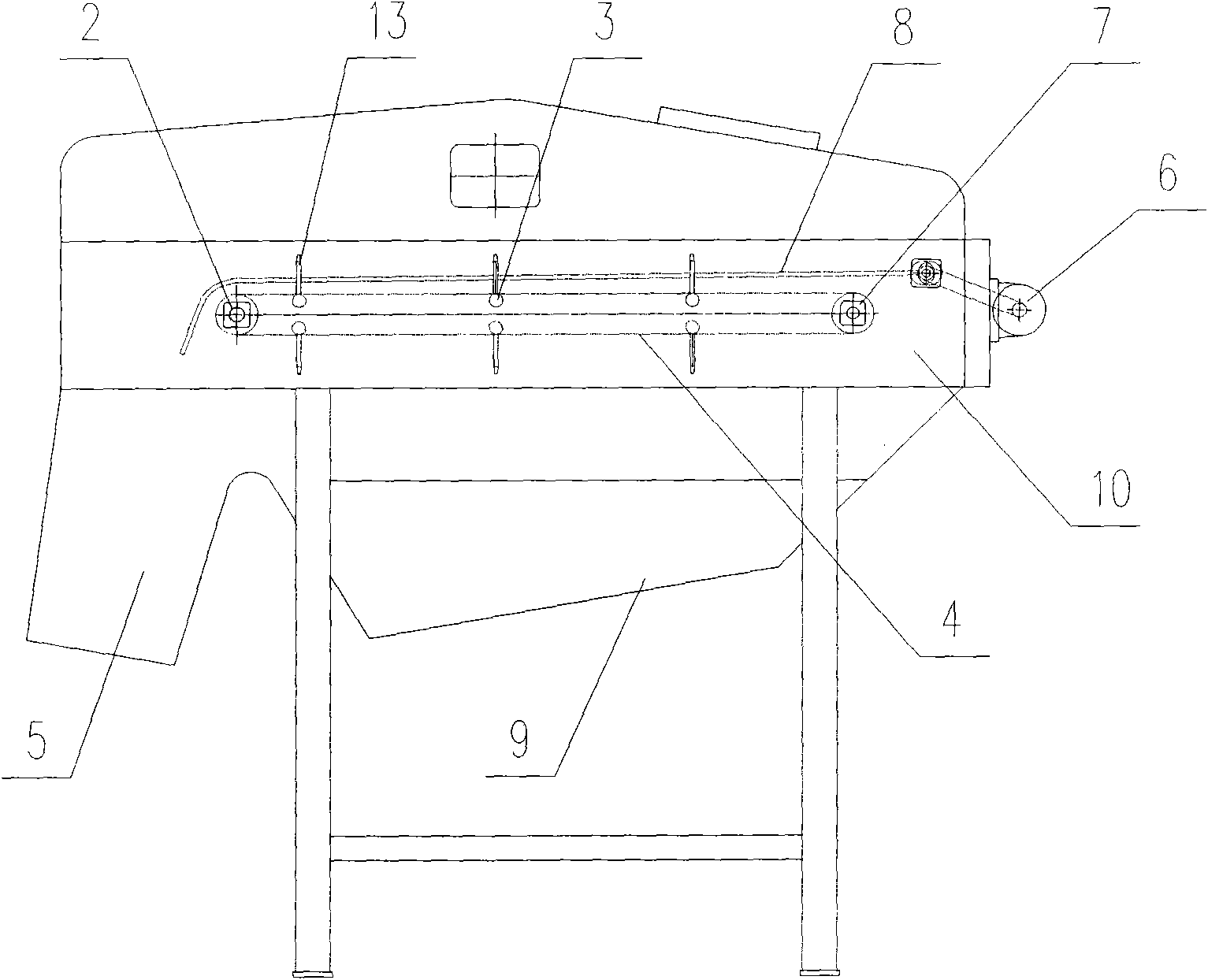

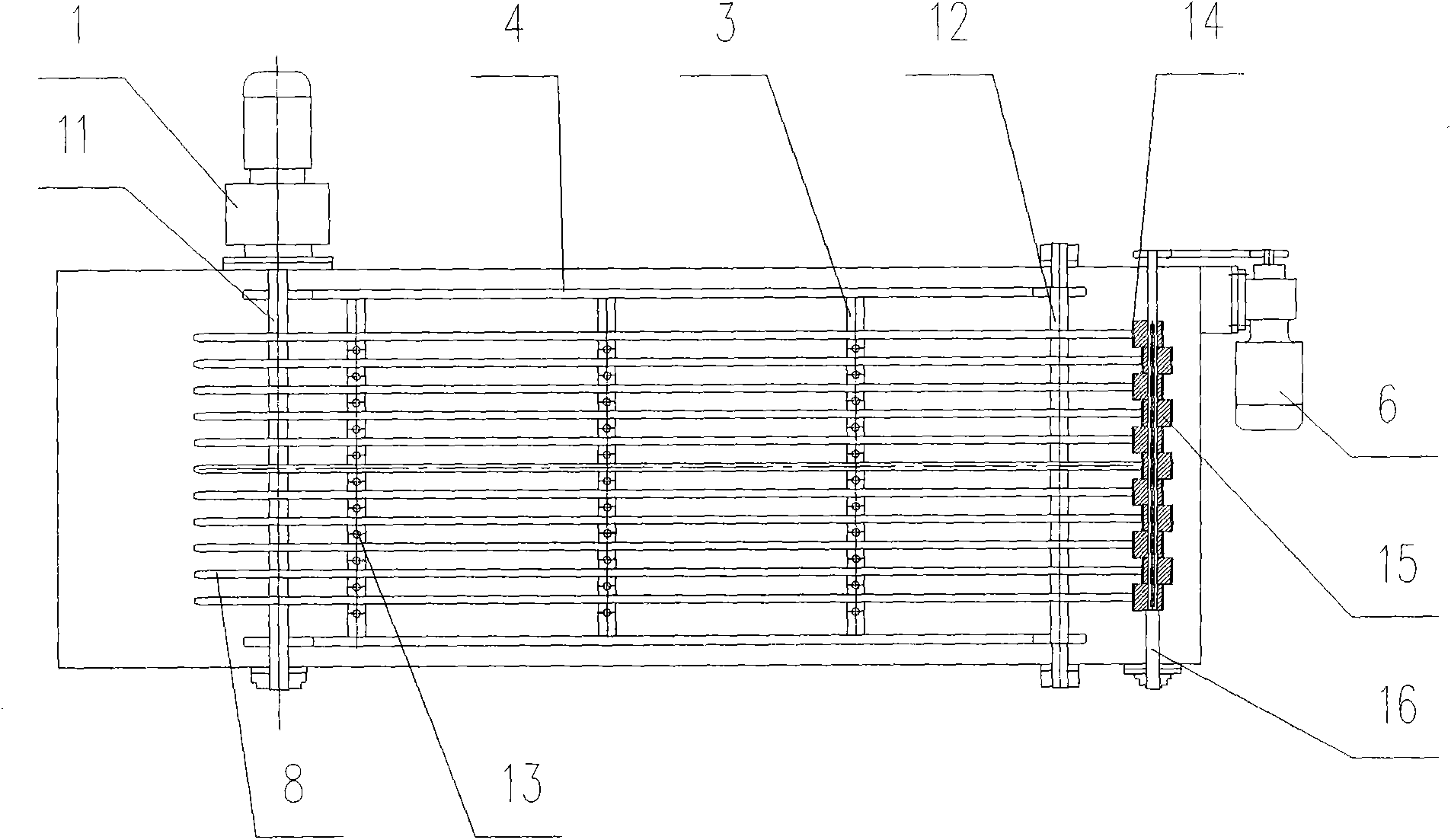

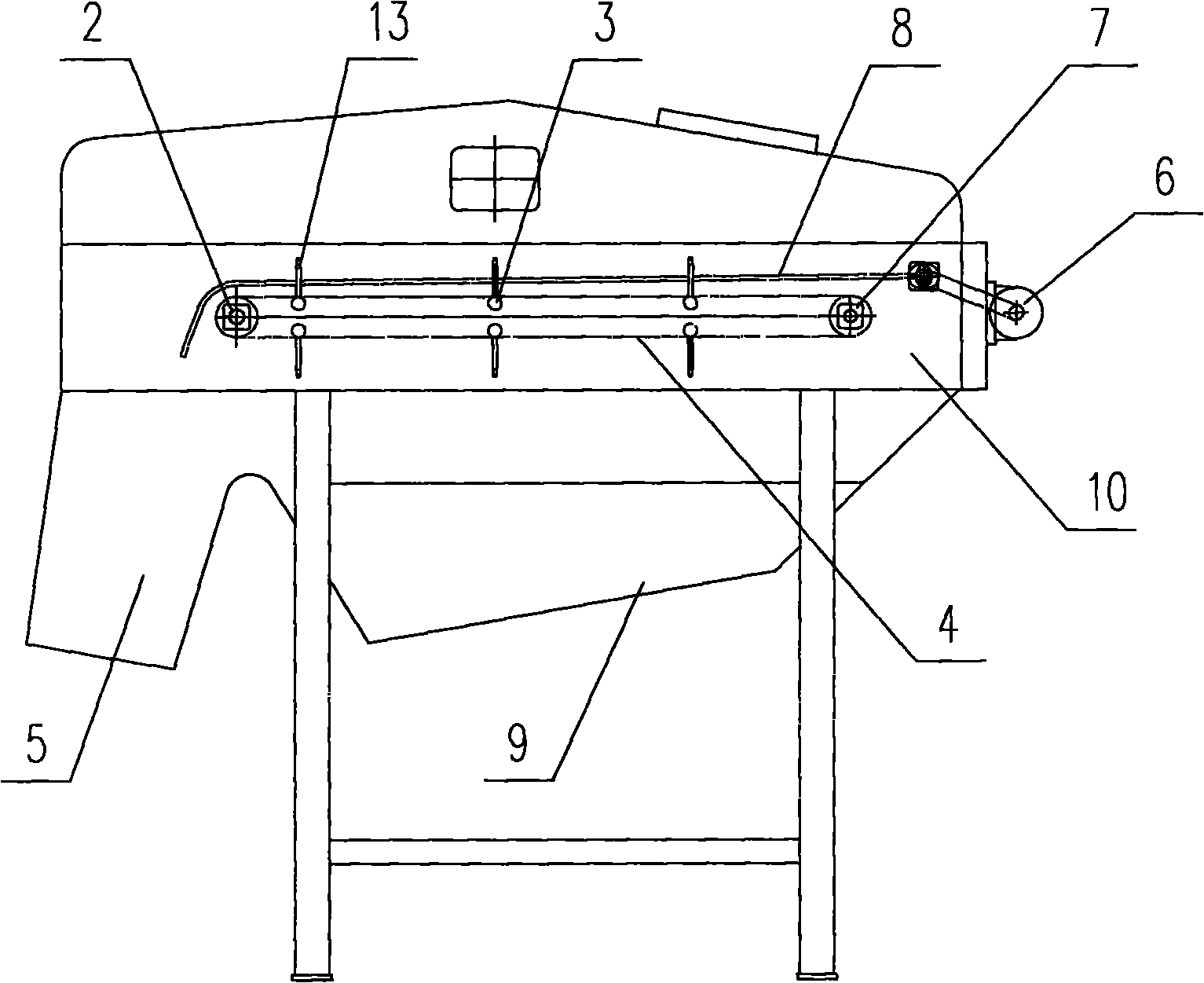

[0015] Example 1: See figure 1 and figure 2 , a kitchen waste vibrating screening machine, comprising a frame 10, a first driving shaft 11 and a first driven shaft 12 are installed on the frame 10, the first driving shaft 11 is driven by a motor reducer 1, and the first driving shaft A driving sprocket 2 is respectively installed at the two ends of 11, and a driven sprocket 7 is respectively installed at the two ends of the first driven shaft 12, and is driven by two transmission chains 4 between the driving sprocket and the driven sprocket. A plurality of rake shafts 3 parallel to each other are fixed between the transmission chains, and rake teeth 13 are welded on the rake shafts 3; a plurality of grid bars 8 are arranged on the rake shaft 3, and the grid bars 8 are connected with the drive chain 4 parallel to the rake teeth 13, one end of the grid bar 8 is a free end, and the other end is fixed to a separate connecting sleeve 14, and the connecting sleeve 14 is set on a s...

Embodiment 2

[0018] The connection sleeve fixedly connected with each grid bar forms a continuous integral connection sleeve, and the eccentric sleeve also forms a continuous integral eccentric sleeve. Other structures are the same as in Embodiment 1. The screening machine adopts this structure, and the bars cannot be staggered with each other. The effect of screening is worse than that of Example 1.

Embodiment 3

[0020] Same as Example 1, the connecting sleeve adopts a split structure, and the eccentric sleeve also adopts a split structure, but the installation method of the eccentric sleeve is the same, that is, the orientation of the large diameter ends of all eccentric sleeves is the same, and other structures are the same as in Embodiment 1. The screening machine adopts this structure, and the grid bars cannot be staggered with each other. The effect of screening is worse than that of Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com