Resource recovery method of lithium iron phosphate waste materials

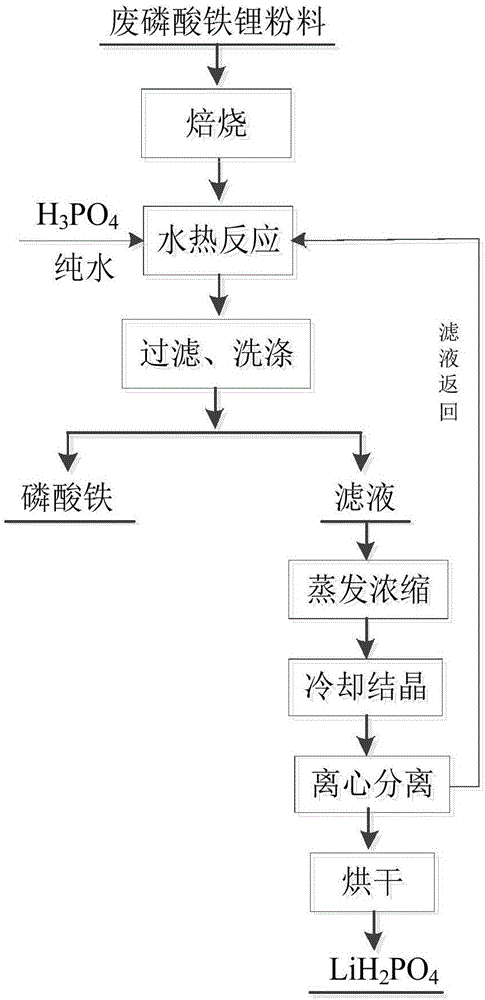

A lithium iron phosphate and resource recovery technology, applied in chemical instruments and methods, phosphorus compounds, inorganic chemistry and other directions, can solve the problems of large consumption of reagents, large amount of Fe waste residue, complicated process steps, etc., and achieve high resource recovery and utilization, The effect of short process flow and less reagent consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] Step 1, roasting: take 500g of lithium iron phosphate waste and put it into a roasting furnace at 300°C for 3 hours, put it into a ball mill after cooling, mill it at 200r / min for 10min, and pass through a 100-mesh sieve to obtain sieved lithium iron phosphate waste. Standby, wherein the reaction principle is: 6LiFePO 4 +3 / 2O 2 =2Li 3 Fe 2 (PO 4 ) 3 +Fe 2 o 3 ;

[0030] Step 2, preparation of phosphoric acid solution: take 250ml of concentrated phosphoric acid with a mass fraction of 85%, dilute it to 750ml with pure water to make a phosphoric acid solution, and set aside;

[0031] Step 3, hydrothermal reaction: Take 250g of sieved lithium iron phosphate waste and 500ml of phosphoric acid solution into the hydrothermal reaction kettle, seal the lid of the kettle, set the reaction temperature program, heat to 100°C, and stir at 200r / min heat preservation reaction 1h, control the internal pressure of the reactor during the reaction process to be 0.2MPa (pay atten...

Embodiment 2

[0036] Step 1, roasting: take 500g of lithium iron phosphate waste and put it into a roaster at 400°C for 4 hours, put it into a ball mill after cooling, mill it at 500r / min for 20min, and pass through a 150-mesh sieve to obtain sieved lithium iron phosphate waste. spare;

[0037] Step 2, preparation of phosphoric acid solution: take 250ml of concentrated phosphoric acid with a mass fraction of 85%, dilute it to 1000ml with pure water to make a phosphoric acid solution, and set aside;

[0038]Step 3, hydrothermal reaction: Take 250g of sieved lithium iron phosphate waste and 1000ml of phosphoric acid solution into the hydrothermal reaction kettle, seal the lid of the kettle, set the reaction temperature program, heat to 150°C, and stir at 500r / min heat preservation reaction 2h, control the internal pressure of the reactor to 1MPa during the reaction (pay attention to venting and pressure relief during the process);

[0039] Step 4, Filtration: After the reaction is finished,...

Embodiment 3

[0044] Step 1, roasting: take 500g of lithium iron phosphate waste and put it into a roasting furnace at 500°C for 4 hours, put it into a ball mill after cooling for 30 minutes at 700r / min, and pass through a 200-mesh sieve to obtain sieved lithium iron phosphate waste. spare;

[0045] Step 2, preparation of phosphoric acid solution: take 250ml of concentrated phosphoric acid with a mass fraction of 85%, dilute it to 1250ml with pure water to make a phosphoric acid solution, and set aside;

[0046] Step 3, hydrothermal reaction: Take 250g of sieved lithium iron phosphate waste and 1250ml of phosphoric acid solution into the hydrothermal reaction kettle, seal the lid of the kettle, set the reaction temperature program, heat to 200°C, and stir at 500r / min heat preservation reaction 3h, control the internal pressure of the reactor to 1MPa during the reaction (pay attention to venting and pressure relief during the process);

[0047] Step 4, Filtration: After the reaction is fin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com