Sludge dewatering high-alkalinity tail water treatment device and method

A treatment device and high-alkaline technology, which is applied in water/sewage treatment, neutralized water/sewage treatment, multi-stage water/sewage treatment, etc., can solve the large variation of sludge dewatering tail water and the secondary pollution of ions to the environment , pH adjustment and control are difficult to achieve the effect of promoting clean production, environmental protection, obvious economic benefits, and low process operation costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

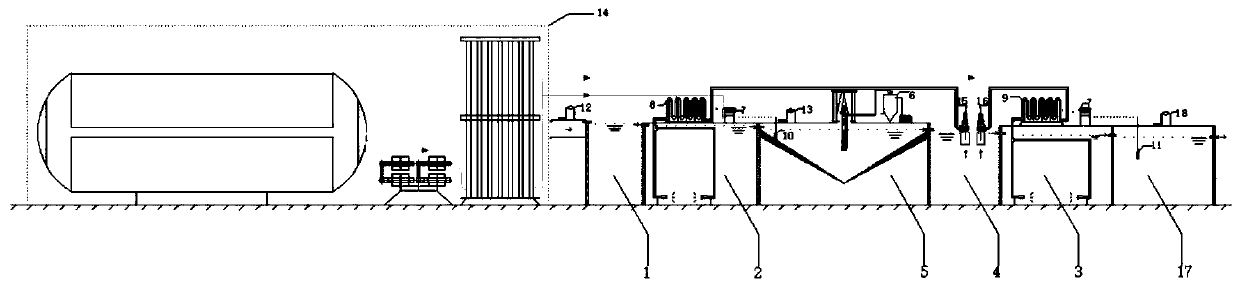

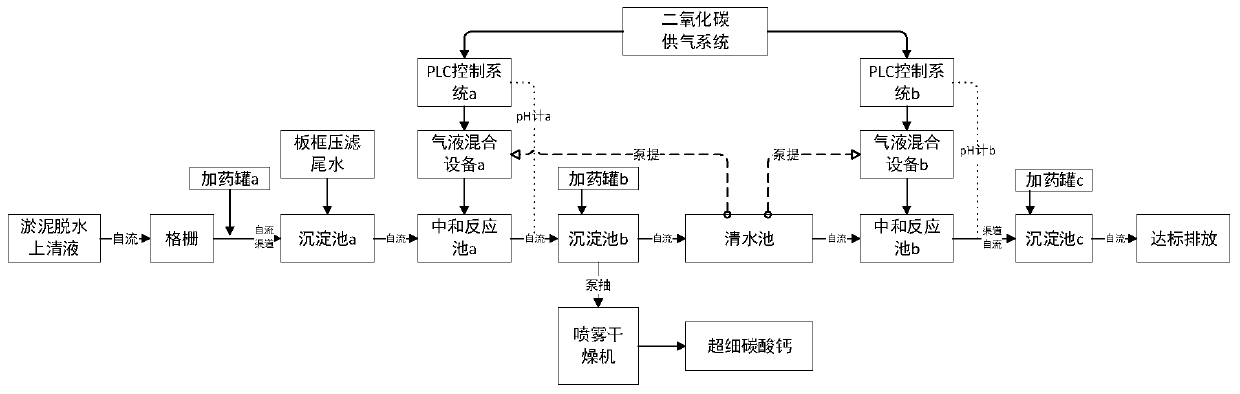

[0034] Example 1, such as figure 1 , figure 2 As shown, a sludge dehydration highly alkaline tail water treatment device includes a sedimentation tank a1, a neutralization reaction tank a2, a clear water tank 4, a sedimentation tank b5, a spray dryer 6, a PLC control system 7, a gas-liquid mixing equipment a8, Dosing tank a12, dosing tank b13, screw pump, CO 2 The supply system 14 and the submerged pump a15, the sedimentation tank a1, the neutralization reaction tank a2, the sedimentation tank b5 and the clean water tank 4 are connected in sequence; the screw pump is set on the sedimentation tank b5, and the outlet of the screw pump is connected to the spray dryer 6 through a pipeline ; The gas-liquid mixing equipment a8 is connected with the neutralization reaction pool a2, CO 2 The supply system 14 is connected to the PLC control system 7; the PLC control system 7 is connected to the gas-liquid mixing equipment a8; the gas-liquid mixing equipment a8 is connected to the cl...

Embodiment 2

[0035] Example 2, such as figure 1 , figure 2 As shown, the present embodiment is a further optimization carried out on the basis of embodiment 1, which is specifically as follows:

[0036]The sludge dehydration highly alkaline tail water treatment device also includes neutralization reaction tank b3, gas-liquid mixing equipment b9, submerged pump b16, sedimentation tank c17 and dosing tank c18, neutralization reaction tank b3 is connected with clear water tank 4, sedimentation tank c17 is connected with the neutralization reaction tank b3, the gas-liquid mixing equipment b9 is connected with the PLC control system 7, the PLC control system 7 is connected with the gas-liquid mixing equipment b9, the gas-liquid mixing equipment b9 is connected with the clear water tank 4 through the submerged pump b16, and Medicine tank c18 is filled with cationic polyacrylamide flocculant, and medicine adding tank c18 is used to add cationic polyacrylamide flocculant to sedimentation tank c1...

Embodiment 3

[0037] Example 3, such as figure 1 , figure 2 As shown, the present embodiment is a further optimization carried out on the basis of embodiment 1 or 2, which is specifically as follows:

[0038] The sludge dehydration and highly alkaline tail water treatment device also includes a position adjustment mechanism, which is arranged on the sedimentation tank b5, and the screw pump is arranged on the position adjustment mechanism, and the position adjustment mechanism is used to adjust the position of the screw pump in the sedimentation tank b5.

[0039] In this embodiment, the position adjustment mechanism includes a slideway and a pulley, the slideway is arranged on the sedimentation tank b5, the pulley is arranged on the slideway, the screw pump is arranged on the pulley, and the pulley can slide on the slideway to adjust the screw pump. s position.

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com