Wax dyeing dye, vegetable tanned leather wax dyeing product and vegetable tanned leather wax dyeing method

A vegetable tanning and dye technology, applied in the field of dyeing, can solve problems such as low dye fastness, and achieve the effect of increasing individual factors, facilitating resource recycling, and simplifying the process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

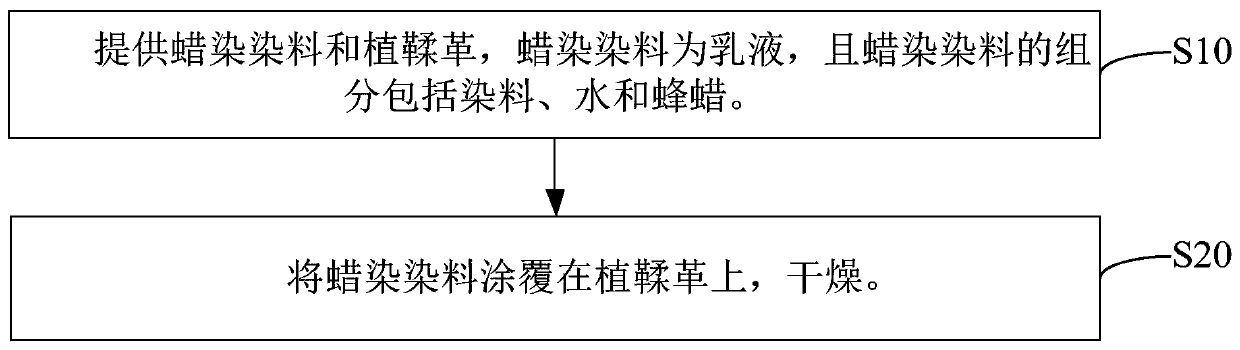

Method used

Image

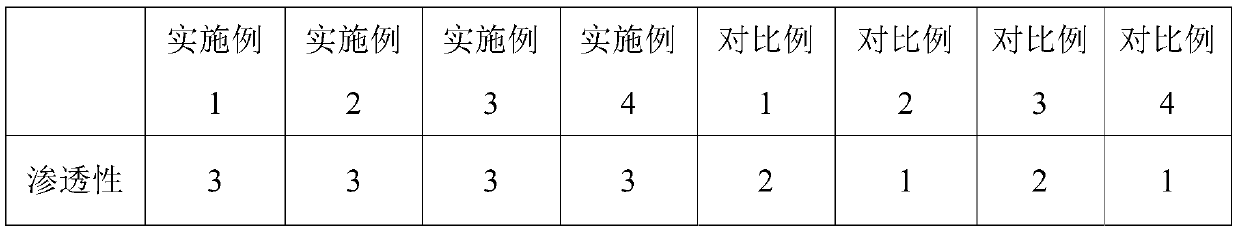

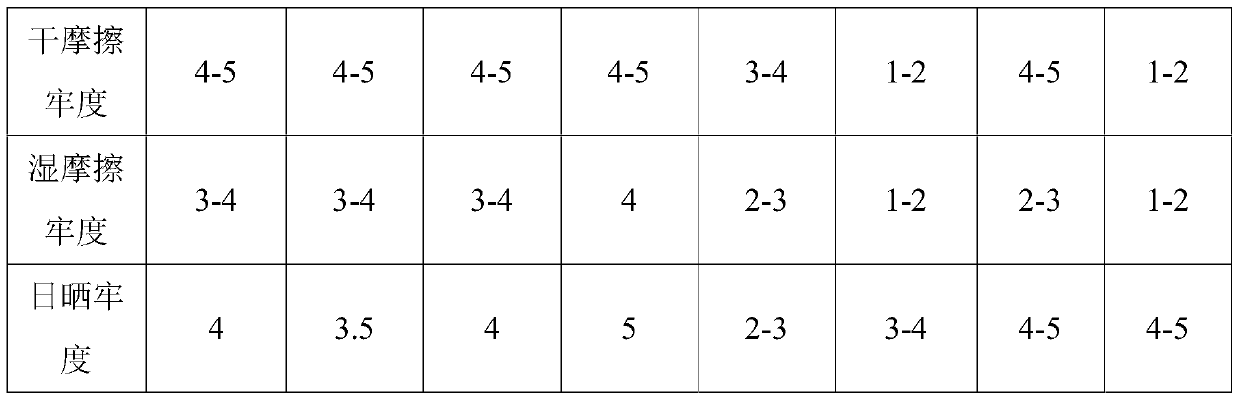

Examples

Embodiment 1

[0043] Get 10g of natural dye sorghum red and place it in 1L of water to prepare 1L of 10g / L sorghum red solution. Take 1g of sorghum red solution and place it in 20g of molten beeswax, and stir it at 8000r / min for 15min to make sorghum red batik emulsion.

[0044] Heat the sorghum red batik emulsion to 72°C, and use the sorghum red batik emulsion to draw patterns on the primary color vegetable tanned leather. Afterwards, the vegetable tanned leather with the pattern is blown for 30s at 70° C. with a hot air dryer. Paint the area not batiked with colorless beeswax, and blow it with a hot air dryer at 70°C for 30s. Finally, the sorghum red dye remaining on the vegetable tanned leather is collected.

Embodiment 2

[0046] Take 20g of natural dye copper chlorophyllin sodium salt and place it in 1L of water to prepare a 20g / L copper chlorophyllin sodium salt solution. Take 1g of copper chlorophyllin sodium salt solution and place it in 20g of molten beeswax, and stir for 30min at 10000r / min to prepare copper chlorophyllin sodium salt batik emulsion.

[0047] Heat the sodium copper chlorophyllin batik emulsion to 70°C, and use the sodium copper chlorophyllin batik emulsion to draw patterns on the primary color vegetable tanned leather. Afterwards, the vegetable tanned leather with the pattern is blown for 60s at 75° C. with a hot air dryer. Paint the area not batiked with colorless beeswax, and blow it with a hot air dryer at 70°C for 60s. Finally, the copper chlorophyllin sodium salt dye remaining on the vegetable tanned leather was collected.

Embodiment 3

[0049] Take a total of 40 g of natural dye copper chlorophyllin sodium salt and pomegranate peel mixed dye, put it in 1 L of water, and prepare a 40 g / L mixed dye solution. Take 1g of the mixed dye solution and place it in 20g of melted beeswax, and stir it for 40min at 12000r / min to prepare the mixed dye batik emulsion.

[0050] Heat the mixed dye batik emulsion to 74°C, and use the mixed dye batik emulsion to draw patterns on the primary color vegetable tanned leather. Afterwards, the vegetable tanned leather with pattern is blown for 90s at 78° C. with a hot air dryer. Use colorless beeswax liquid to paint the area that has not been wax painted, and blow it with a hot air dryer at 70°C for 120s. Finally, the residual copper chlorophyllin sodium salt and pomegranate peel mixed dyes were collected on the vegetable tanned leather.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com