Flame-retardant polypropylene plastic composition and preparation method thereof

A technology for polypropylene plastics and compositions, which is applied in the field of preparing polypropylene plastic compositions, can solve the problems of poor flame retardant effect of flame retardant polypropylene, poor environmental protection, toxic gas generation, etc. Conducive to environmental protection and improved flame retardancy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0034] The preparation method of the above-mentioned flame-retardant polypropylene plastic composition specifically comprises the following steps:

[0035] Get each raw material that prepares flame-retardant type polypropylene plastic composition according to above-mentioned prescription;

[0036] Add the waste melamine plastic powder into the high-speed mixer, add the ethanol solution of the coupling agent (that is, add the coupling agent to ethanol to form the ethanol solution of the coupling agent), and mix at a stirring speed of 750-1500 for at least 1 minute Finally, place it for 5-10 minutes, then mix it at a stirring speed of 750-150 for 1 minute, then place it for 5-10 minutes;

[0037] Then add other components into the high-speed mixer, mix at a stirring speed of 750-1500 for 1-2 minutes, and then discharge, and the obtained mixture is a flame-retardant polypropylene plastic composition.

[0038] The above method may also include the following steps:

[0039] After...

Embodiment 1

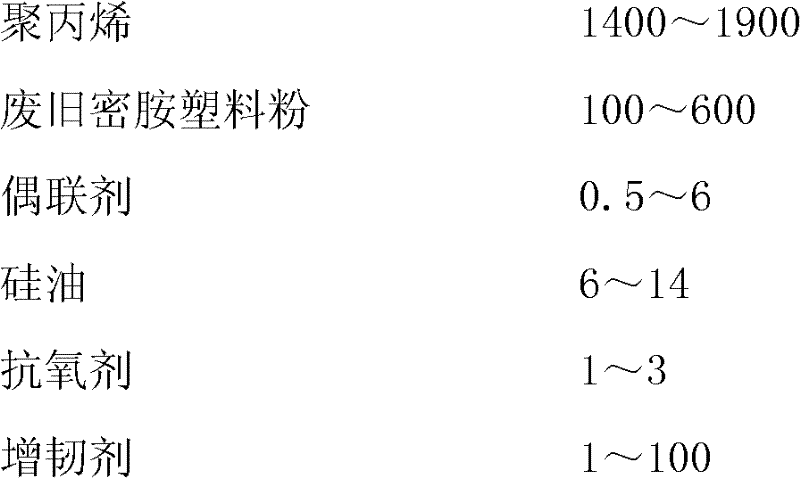

[0055] This embodiment provides a kind of flame-retardant polypropylene plastic composition, and each raw material is taken according to the following formula:

[0056]

[0057] The preparation method of the above-mentioned flame-retardant polypropylene plastic composition is as follows: first, the waste melamine plastic powder obtained by crushing the waste melamine plastic tableware is weighed into a high-speed mixer according to the formula ratio, and the coupling agent ethanol solution is added, After mixing for 1 minute, place it for 5-10 minutes, then mix it at high speed for 1 minute, and leave it for 5-10 minutes; then add other components into the high-speed mixer, mix it at high speed for 1-2 minutes, and then discharge, the obtained mixture is The flame-retardant polypropylene plastic composition; the discharged mixture can be added to a parallel co-rotating screw extruder (screw diameter: Φ32mm, screw aspect ratio 32:1, screw combination mode is medium and low sh...

Embodiment 2

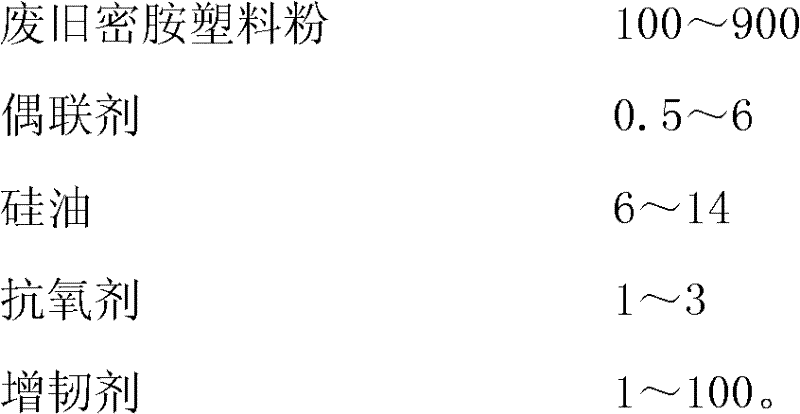

[0061] This embodiment provides a kind of flame-retardant polypropylene plastic composition, and each raw material is taken according to the following formula:

[0062]

[0063] The preparation method of the flame-retardant polypropylene plastic composition in this example is basically the same as that in Example 1, and reference can be made to Example 1, which will not be repeated here.

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com