Process for treating amantadine bromination waste water and mineral acid and alkali recycling through bipolar membrane electrodialysis process

A technology of bipolar membrane electrodialysis and amantadine, applied in bromine/hydrogen bromide, general water supply conservation, sulfur trioxide/sulfuric acid, etc., can solve problems such as waste of recyclable resources, environmental pollution, etc., and achieve good governance effects , uncomplicated operation, good industrial application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

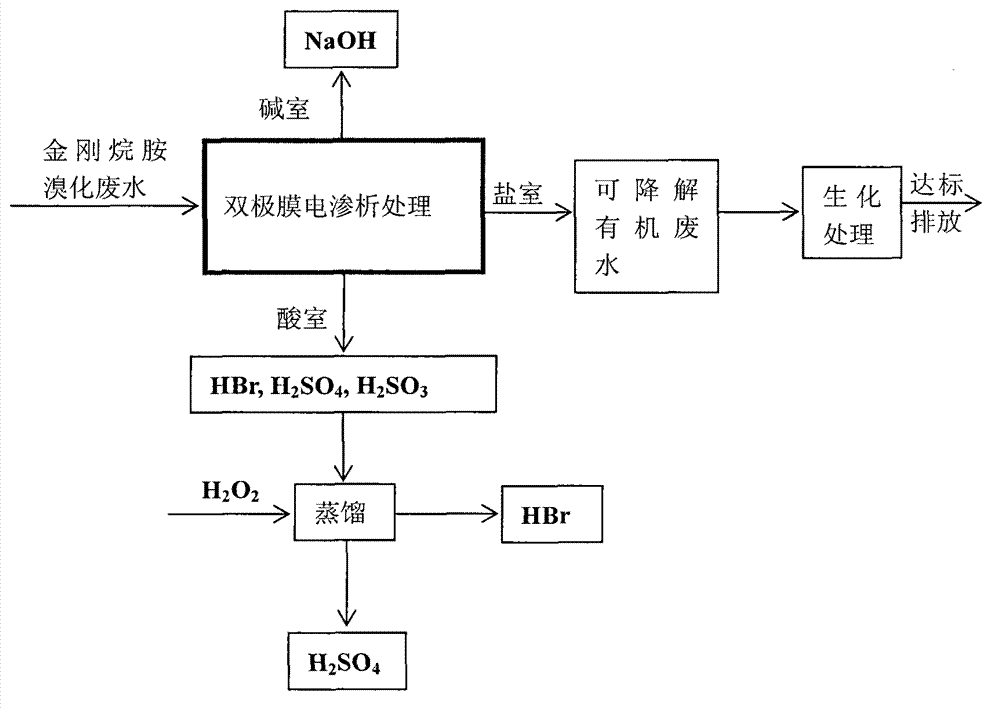

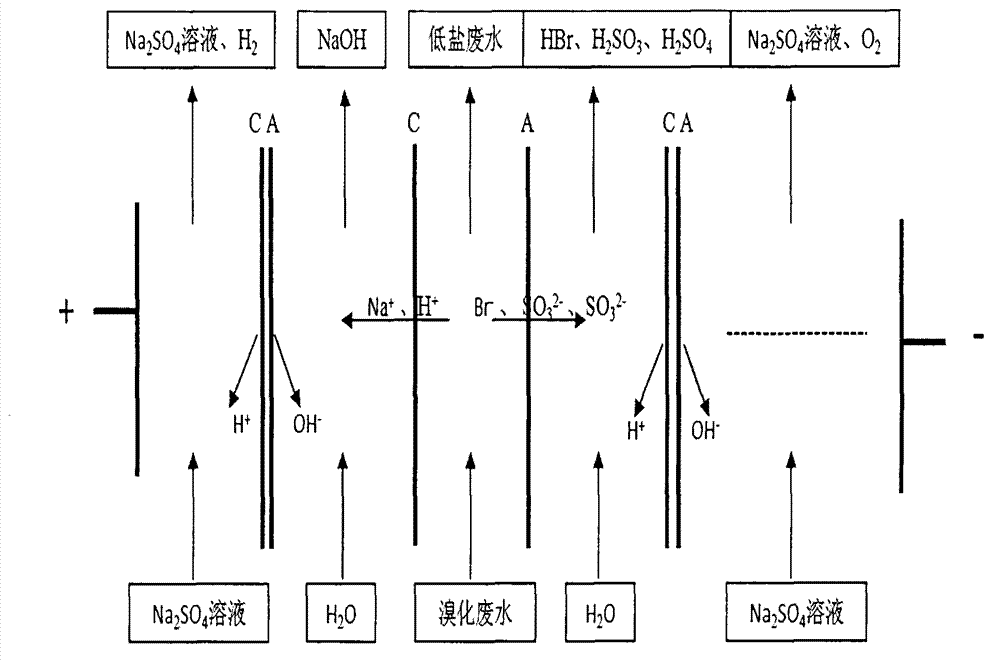

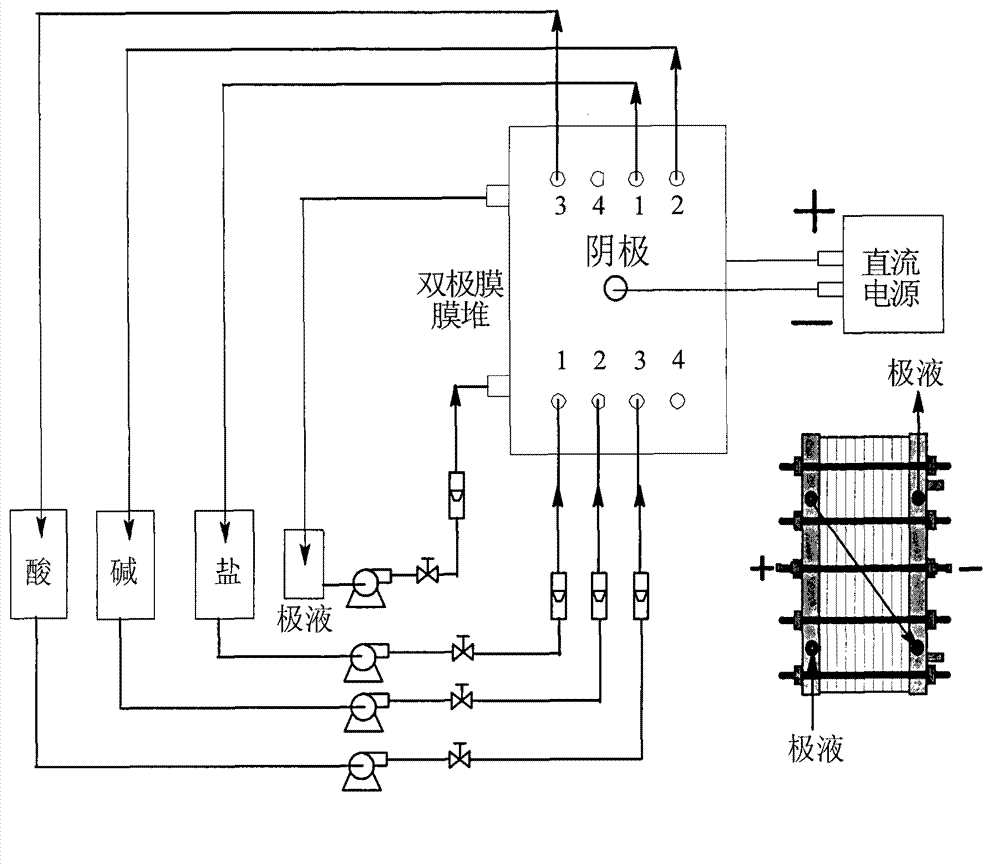

[0020] A method for treating amantadine bromination wastewater by bipolar membrane electrodialysis technology and recovering inorganic acids and bases is characterized by the following steps: filtering the bromination wastewater through a microporous membrane to remove suspended matter in the wastewater. When the hydrogen ion concentration of the brominated wastewater exceeds 1.5mol / L, it should be properly diluted to control the hydrogen ion concentration of the wastewater to be treated within 1.5mol / L. Pass the filtered bromination wastewater into the salt chamber of the bipolar membrane electrodialysis device, and the feed water of the acid chamber and alkali chamber of the bipolar membrane electrodialysis device is general tap water, and the feed water of the polar liquid is 1mol / L Na 2 SO 4 Solution; current density is 50-500A / m 2 , The membrane surface velocity is 2-8cm / s. The acid solution recovered by bipolar membrane electrodialysis can be further separated by disti...

Embodiment 2

[0023] Adopt 10 sets of bipolar membrane-positive membrane-negative membrane three-electrode chamber structure unit, circulate water, the salt chamber starts with brominated wastewater, the acid chamber and alkali chamber start with water, and the polar liquid is 1mol / LNa 2 SO 4 solution, the circulating water flow rate of the three-electrode chamber is 1L, the circulating water flow rate of the salt chamber is 20L / h, the circulating water flow rate of the acid chamber and alkali chamber is 15L / h, and the circulating water flow rate of the polar liquid is 40L / h. 200A / m 2 , the results are shown in Table 1.

Embodiment 3

[0025] 5 sets of bipolar membrane-positive membrane-cathode membrane three-electrode chamber structure unit are adopted, and the water is circulated. The salt chamber starts with brominated wastewater, the acid chamber and alkali chamber start with water, and the polar liquid is 1mol / LNa 2 S0 4 solution, the circulating water flow rate of the three-electrode chamber is 1L, the circulating water flow rate of the salt chamber is 15L / h, the circulating water flow rate of the acid chamber and alkali chamber is 10L / h, and the circulating water flow rate of the polar liquid is 30L / h. 200A / m 2 , the results are shown in Table 1.

[0026] Table 1 embodiment 1-3 result

[0027]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com