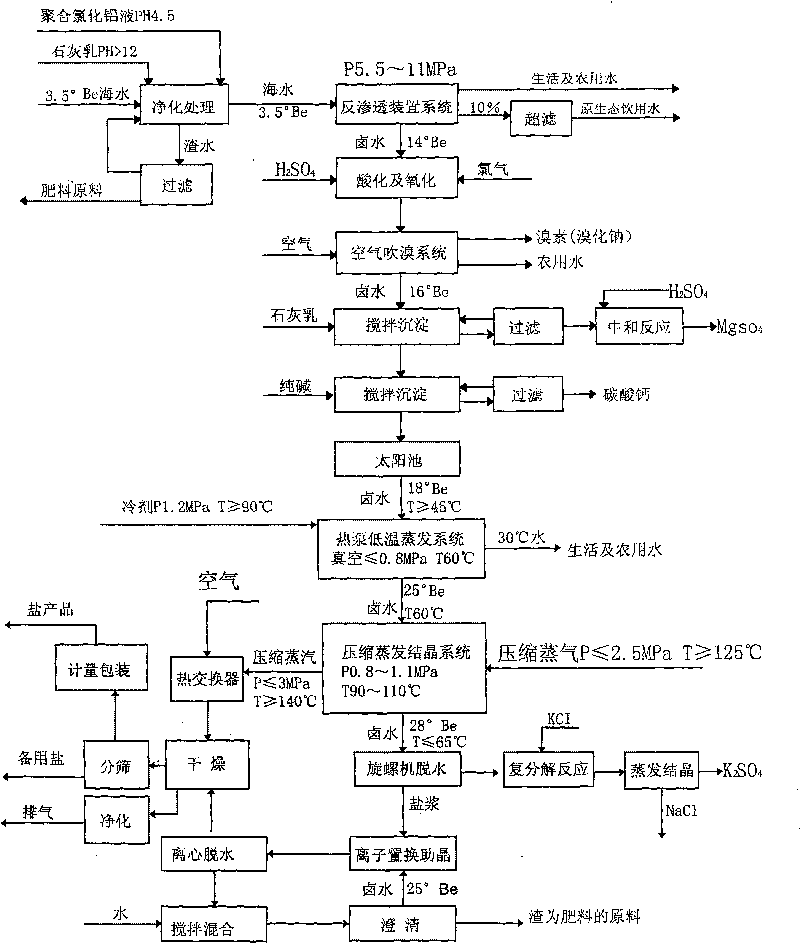

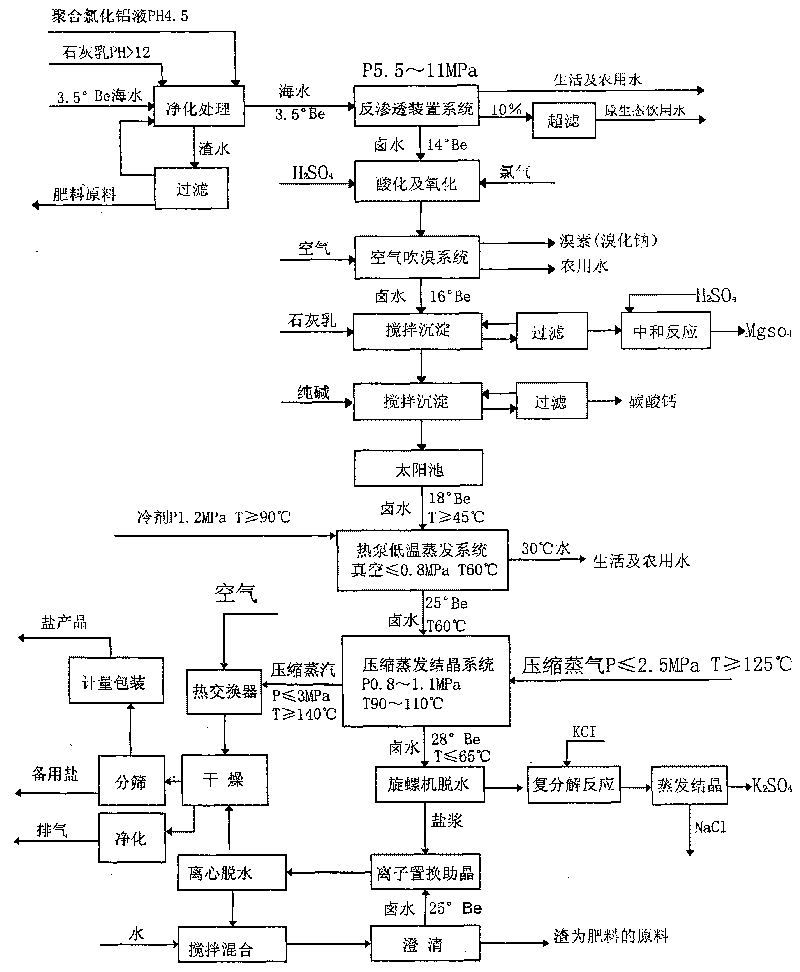

Technique for desalting sea water, making salt and comprehensively using by-products thereof by utilizing wind energy, solar energy and heat pump technologies

A heat pump technology, solar energy technology, applied in magnesium hydroxide, energy input, bromine/hydrogen bromide and other directions, can solve the problems of backward production technology, waste of resources, poor corporate efficiency, etc., to ensure production continuity and achieve material balance , the effect of cost reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] The process technology of the present invention can be implemented, and the selection of equipment is very important. The equipment selected for the process is all common at home and abroad, and is selected according to the specifications and models according to the process parameter requirements of production capacity and product quality standards. In addition, the main equipment driving energy is wind energy, solar energy is used as evaporation heat energy, heat pump technology is used for low-temperature evaporation, and compression evaporation is used for crystallization to produce salt.

[0040] (1) Utilization of wind energy

[0041] The southeast coast of my country is rich in wind energy, every m 2The average wind speed of m / s is 5000-7000 hours per year, and the utilization rate of wind energy is above 47%. Therefore, using wind energy to drive wind turbines to drive production equipment is the development direction of wind energy.

[0042] The technology of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com