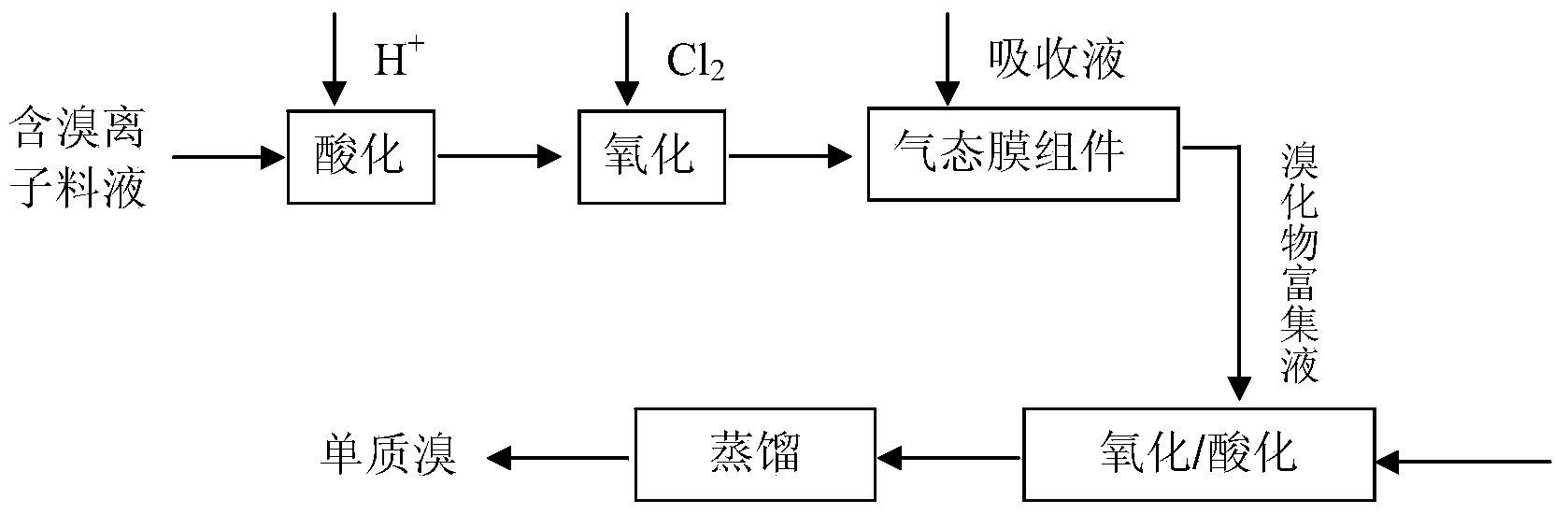

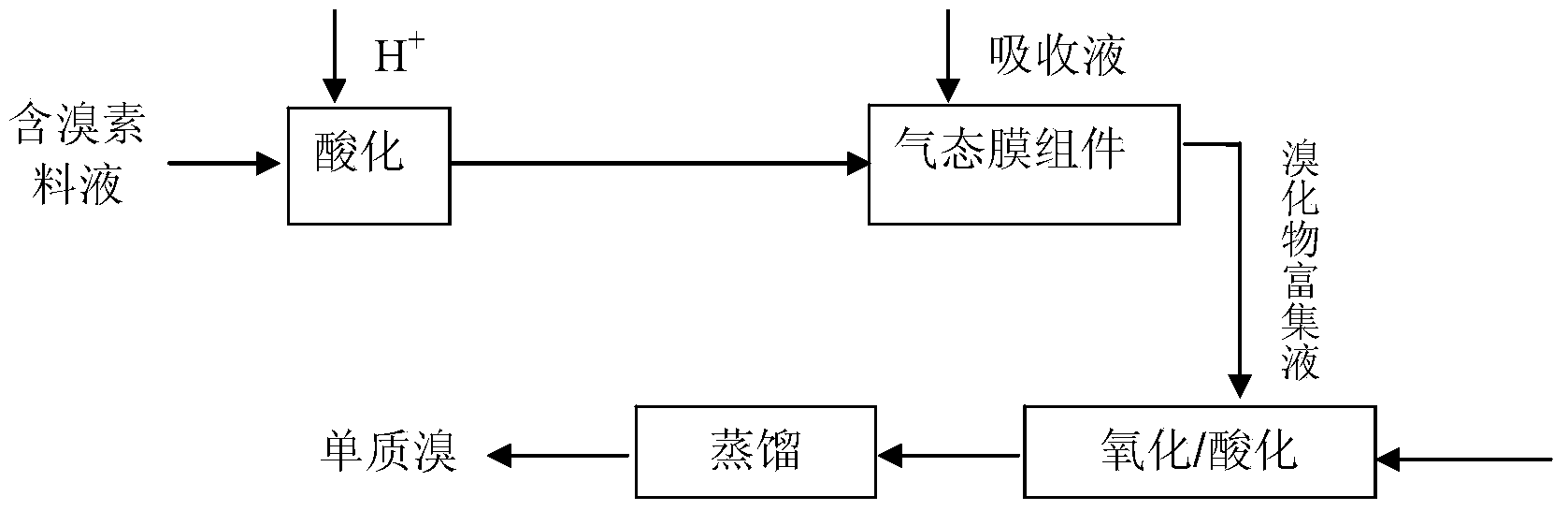

Method for preparing/gathering bromine from bromine-containing feed liquid or waste water

A technology for feed liquid and waste water, applied in the direction of bromine/hydrogen bromide, etc., can solve the problems of not being able to provide large-scale membrane modules with high specific surface area and high mass transfer performance, and difficulty in making them, so as to increase bromine output rate and prolong The effect of long service life and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0067] A seawater desalination plant produces 5-6°Bé concentrated seawater with a bromine content of 108mg / L. After sulfuric acid acidification (pH value 3.5) and chlorine gas oxidation, it enters the PTFE hollow fiber gaseous membrane module tube side (single membrane module, effective membrane area 2.0m 2 , the inner diameter of the membrane is 0.6mm, the wall thickness is 100μm, the average pore size is 0.2μm, and the porosity is 65%). The absorption liquid is 45g / L sodium formate solution, and sodium formate and bromine undergo a redox reaction:

[0068] Br 2 +HCOONa=HBr+NaBr+CO 2 ↑

[0069] The sodium formate solution and the bromine-containing feed solution after acidification and oxidation flow through the shell side of the gaseous membrane module in reverse, and then flow through the tube side of another gaseous membrane module with the same specification (the shell side of the module is connected to the atmosphere) to release the produced of carbon dioxide gas.

...

Embodiment 2

[0077] A 9.0°Bé underground brine with a bromine content of 155mg / L, after being acidified with hydrochloric acid (pH value 3.5) and oxidized by chlorine gas, enters the tube pass of a polytetrafluoroethylene hollow fiber gaseous membrane module (single membrane module, effective membrane area 2.0 m 2 , the inner diameter of the membrane is 0.4mm, the wall thickness is 250μm, the average pore size is 1.0μm, and the porosity is 75%). The absorption liquid is 80g / L sodium sulfite solution, which flows through the shell side of the gaseous membrane module countercurrently with the acidified and oxidized bromine-containing feed liquid. Redox reaction between sodium sulfite and bromine:

[0078] Br 2 +Na 2 SO 3 +H 2 O=2HBr - +Na 2 SO 4

[0079] The flow rate of the bromine-containing feed liquid is 20L / h, the temperature is 30°C; the flow rate of the absorption liquid is 5L / h, the temperature is 30°C, and the pH value is 8.9. After the bromine is extracted by the gaseous ...

Embodiment 3

[0085] A 9.0°Bé underground brine with a bromine content of 237mg / L, after being acidified with sulfuric acid (pH value 3.5) and oxidized by chlorine, enters the tube pass of a polytetrafluoroethylene hollow fiber gaseous membrane module (single membrane module, effective membrane area 2.0 m 2 , the inner diameter of the membrane is 0.4mm, the wall thickness is 250μm, the average pore size is 1.0μm, and the porosity is 75%). The absorption liquid is a sodium hydroxide solution with an initial concentration of 20g / L, which flows through the shell side of the gaseous membrane module in countercurrent to the acidified and oxidized bromine-containing feed liquid. Disproportionation reaction between sodium hydroxide and bromine:

[0086] 3Br 2 +6NaOH - =5NaBr - +NaBrO 3 +3H 2 o

[0087] The flow rate of the bromine-containing feed liquid is 20L / h, and the temperature is 30°C; the flow rate of the absorption liquid is 15L / h, and the temperature is 30°C. After the bromine is ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com