Method for recovering bromine tail gas and chlorine gas in bromine production

A recovery method and a bromine technology are applied in the recovery field of bromine tail gas and chlorine gas, which can solve problems such as environmental pollution, and achieve the effects of solving environmental pollution, saving throughput and improving utilization rate.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

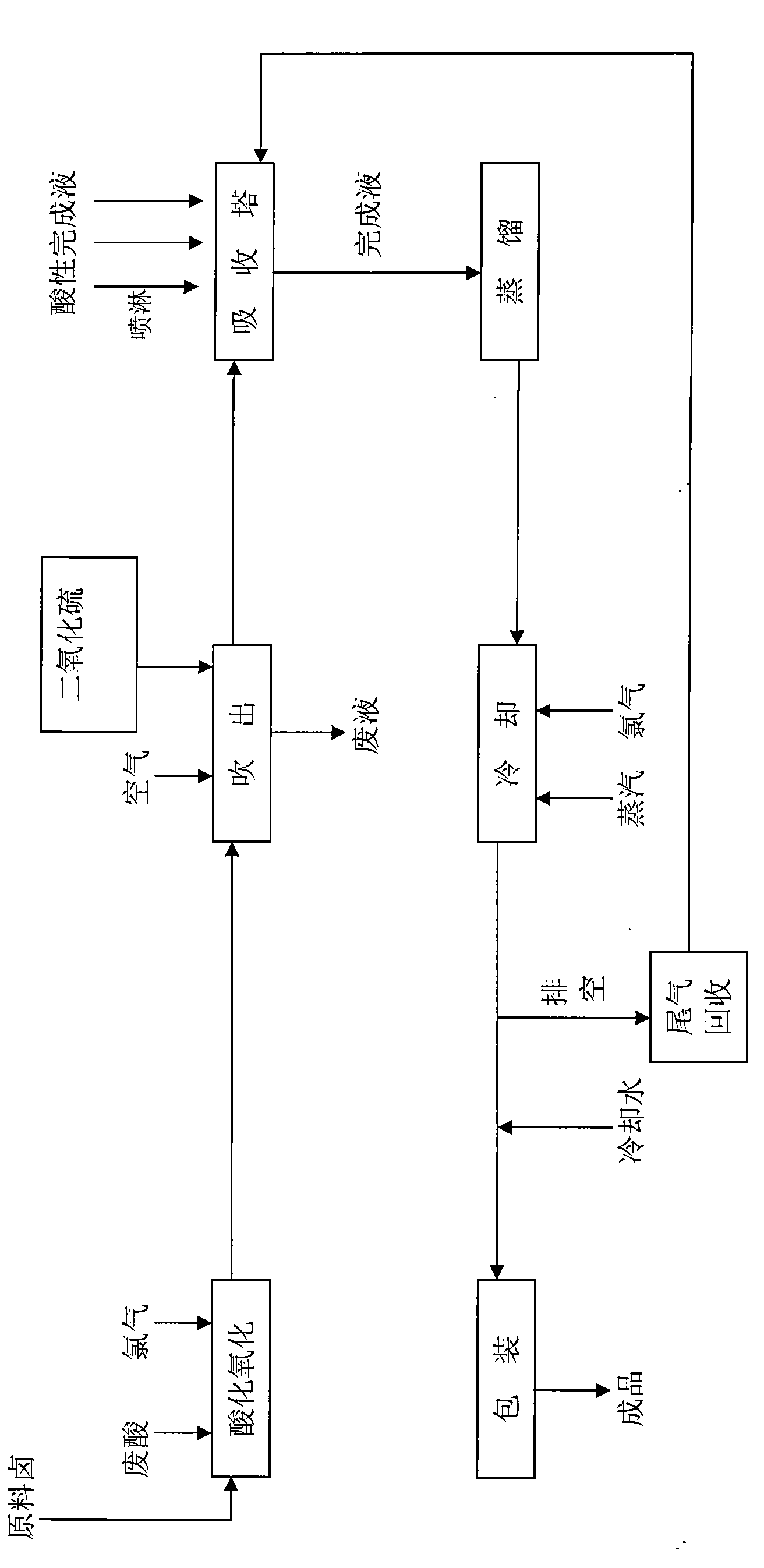

Image

Examples

Embodiment Construction

[0009] Below in conjunction with preferred embodiment, the specific implementation mode provided according to the present invention is described in detail as follows:

[0010] A method for recovering bromine tail gas and chlorine gas in bromine production, which uses acidic liquid as an absorbent to absorb chlorine gas and bromine in the tail gas. The acidic liquid uses the absorbed liquid in the bromine production process as an absorbent to absorb chlorine and bromine in the tail gas. The absorption process route for absorbing tail gas is to recover the tail gas and send it to the bottom of the absorption tower through a pipeline, and the tail gas is sprayed with the secondary acidic finishing liquid from bottom to top in the absorption tower, so that the chlorine in the tail gas is dissolved in the finishing liquid, Then the finished product bromine is formed after secondary distillation and cooling of the finished liquid. The finished liquid is a mixed liquid of hydrobromi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com