Ecological optimization production process for all-seawater industry

A production process and seawater technology, applied in chemical instruments and methods, seawater treatment, boron oxides, etc., can solve problems such as polluting the sea, reducing cholesterol and neutral fat content, and marine life death, so as to eliminate pollution and improve health. The effect of high quality and rich economic benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

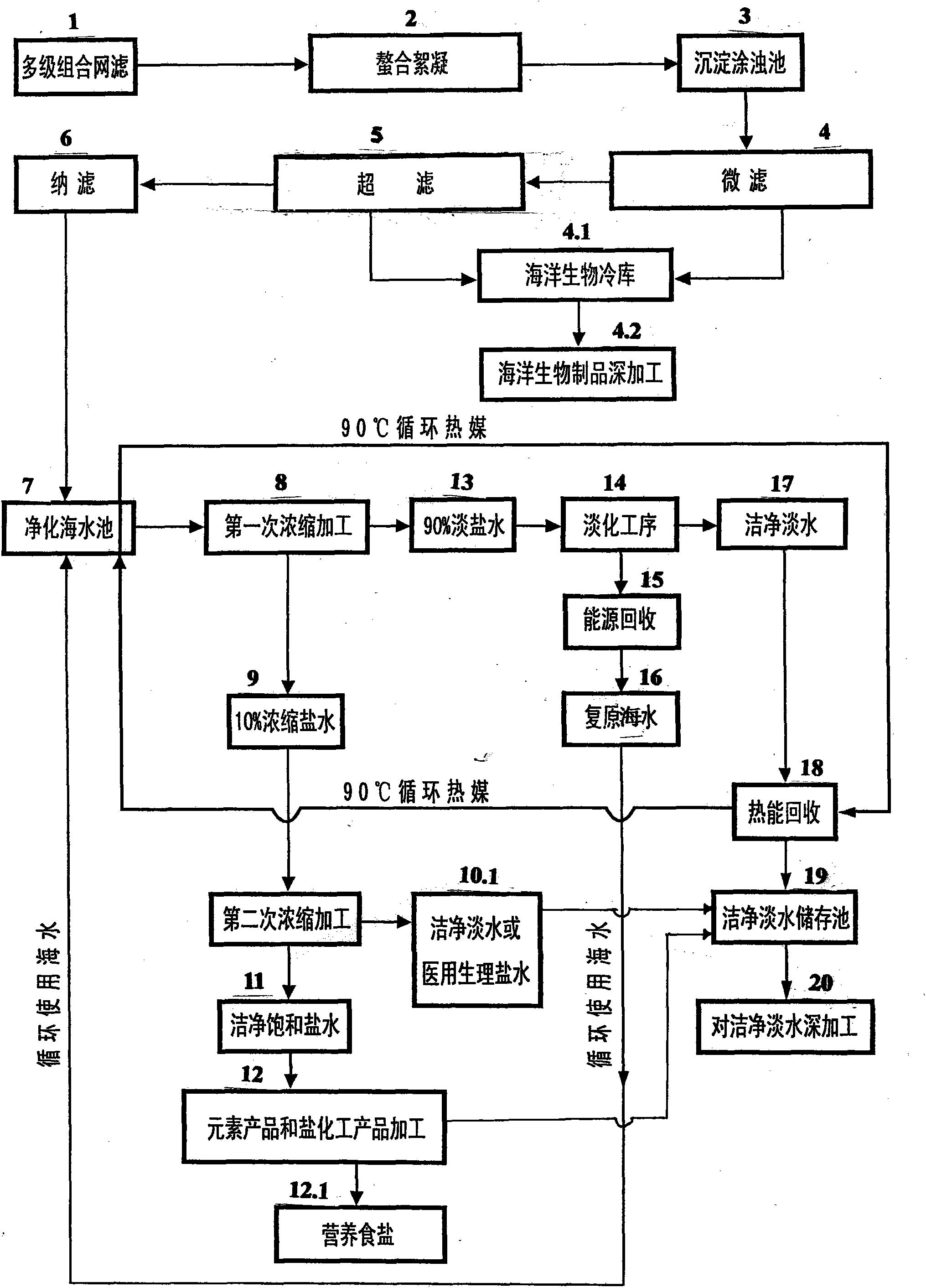

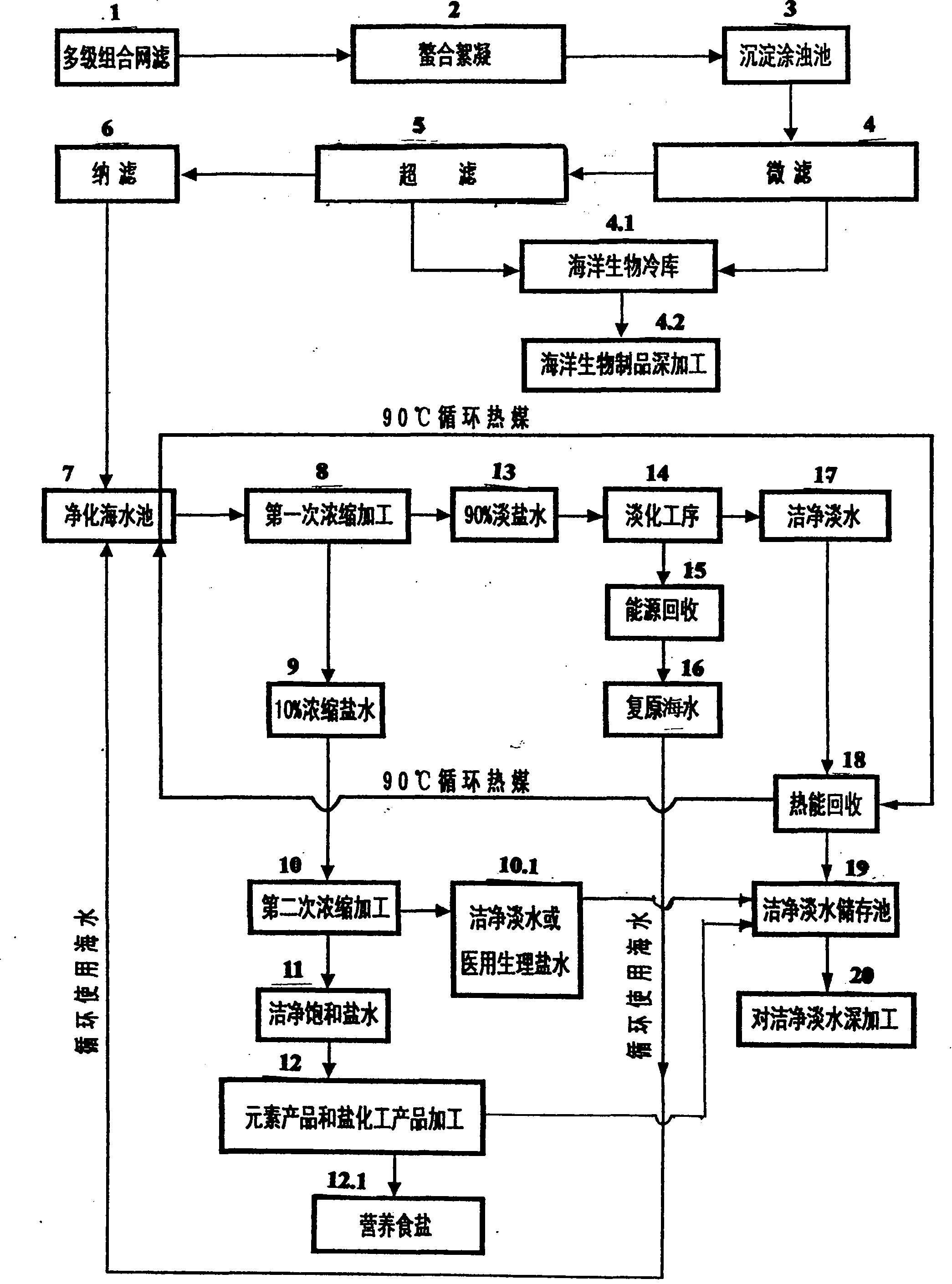

[0050] In the following, in conjunction with the accompanying drawings and preferred embodiments, the specific implementation, features, and effects of the ecologically optimized combined production process for the entire seawater industry proposed according to the present invention will be described in detail below.

[0051] Please refer to figure 1 As shown, the present invention includes in the ecological optimization combined production process of the whole seawater industry: multi-stage combined screen filter 1, chelation flocculation 2, sedimentation and turbidity removal tank 3, microfiltration 4, marine biological cold storage 4.1, deep processing of marine biological products 4.2, ultrafiltration 5, nanofiltration 6, seawater pool purification 7, first concentration processing 8, 10% concentrated brine 9, second concentration processing 10, clean fresh water or medical normal saline 10.1, clean saturated brine 11, marine elements Product and Salt Chemical Product Proc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com