Method for treating wastewater produced by methylation reaction in metribuzin synthesis

A technology of methylation and mezotrione is applied in the field of treating wastewater generated by methylation reaction in the synthesis of methitrione, can solve problems such as no literature reports on wastewater treatment, achieve good practical value, reduce environmental pollution, The effect of reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0012] The method for treating the wastewater produced by the methylation reaction in the synthesis of mecitrione in this embodiment has the following steps:

[0013] ①The 500ml three-necked bottle is equipped with a return tube, and a gas absorption device is connected to the outlet of the return tube. The gas absorbing device comprises a glass tube and an inverted funnel connected in sequence, and also includes a beaker, which is filled with a 10wt% NaOH solution. Add 350 g of waste water produced by the methylation reaction in the synthesis of mecitrione into the three-necked flask, add 4 mL of sulfuric acid with a concentration of 98 wt % under stirring, and then raise the temperature to 105° C. for reflux to deodorize and decolorize. The gas generated and volatilized by the waste water during heating passes through the return pipe, then passes through the glass tube and funnel, and is absorbed by the NaOH solution in the beaker to remove the odor.

[0014] Continue to re...

Embodiment 2~ Embodiment 4

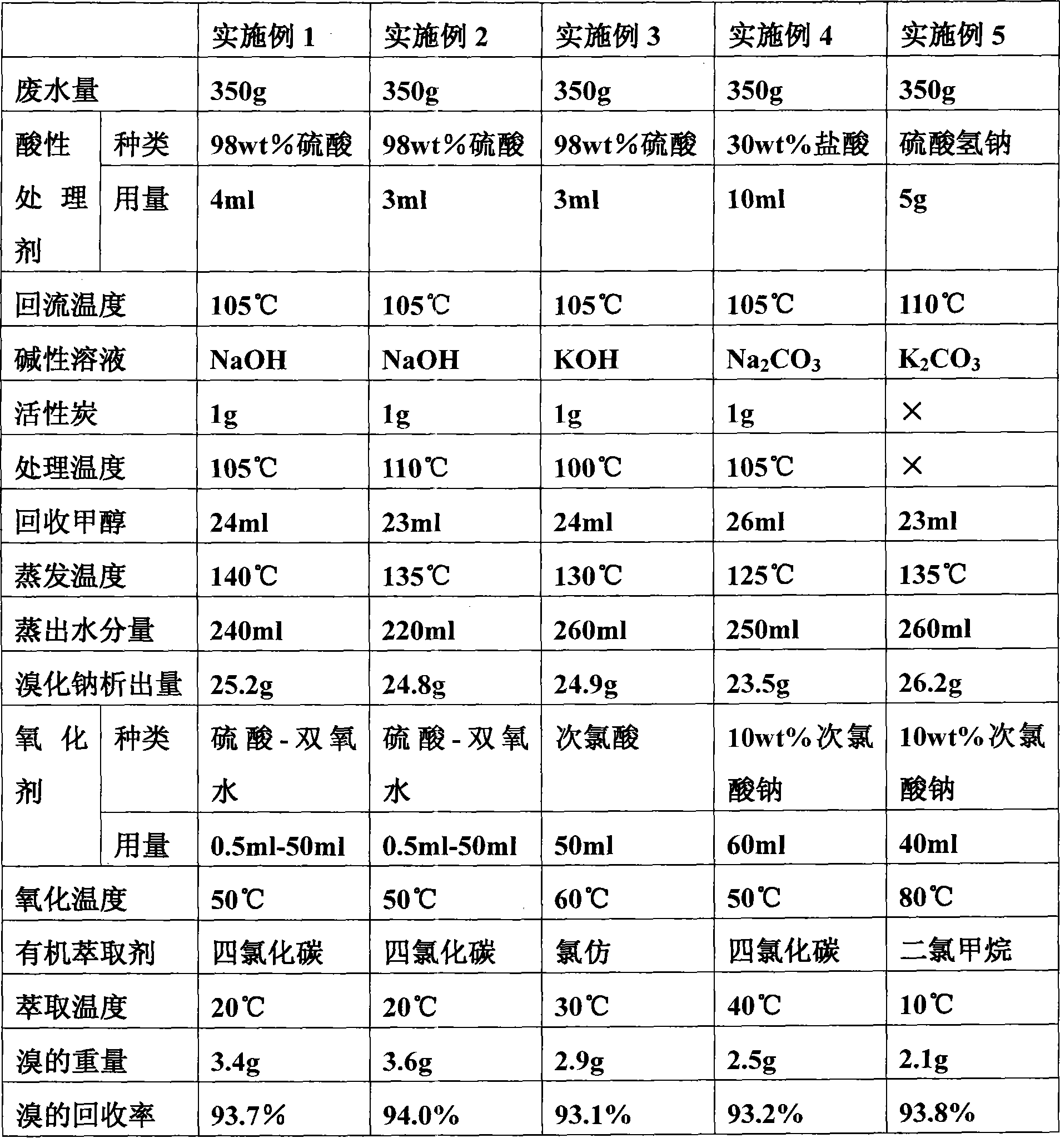

[0020] The processing method of each embodiment is basically the same as that of Embodiment 1, and the differences are shown in Table 1.

Embodiment 5

[0022] The treatment method of the present embodiment is basically the same as that of Example 1, the difference being that: in step 1., during reflux for 1.5 hours, the color of the waste water in the there-necked bottle gradually changes from brown to lavender, and then gradually becomes almost colorless, Then this step does not need to add activated carbon, and directly proceed to step ②. In step ②, directly remove the return pipe on the three-necked bottle, then install the packed tower, and then recover the methanol in the waste water by batch rectification. See Table 1 for other differences.

[0023] Table 1

[0024]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com