Thick seawater comprehensive utilization technique after seawater desalination

A technology of concentrated seawater and process, applied in the directions of magnesium hydroxide, bromine/hydrogen bromide, alkali metal chlorides, etc., can solve the problems such as the inability to remove the negative impact of salt production, and achieve the reduction of the amount of bittern and the increase of the concentration of bittern , the effect of improving yield and quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

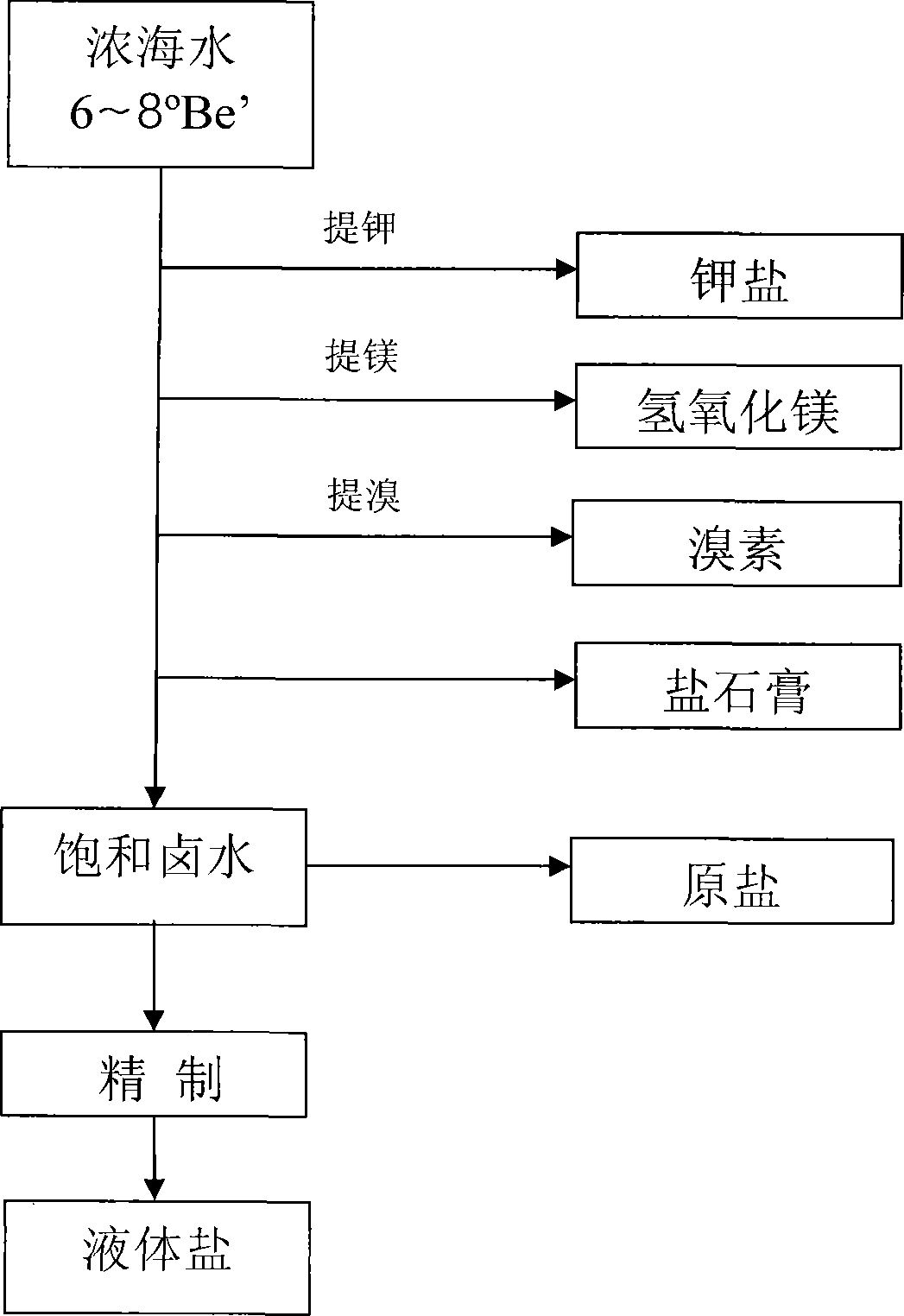

[0013] The comprehensive utilization process of desalinated concentrated seawater of the present invention will be described in conjunction with the accompanying drawings and embodiments.

[0014] The invention belongs to a new salinization co-production process, and its basic principle is to use concentrated seawater with 6-8°Bé after seawater desalination as raw material, go through the processes of extracting potassium, magnesium, and bromine, and then mix a small amount of ammonia distillation waste liquid of the same concentration , so that calcium sulfate dihydrate is basically precipitated to obtain "salt gypsum" products, and a large amount of sulfate ions in brine are precipitated, and this brine is used to produce solar salt or liquid salt after further refining. This process can be applied to the comprehensive utilization industry of producing sun-dried industrial salt and concentrated seawater discharged after seawater desalination with seawater and underground brin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com