Device and method for continuously back extracting penicillin

A penicillin and equipment technology, applied in the field of online automatic control continuous stripping penicillin, can solve the problems of organic phase product entrainment, unstable degradation of penicillin, emulsification, instability, etc., and achieve the effect of ensuring clarification time and inhibiting product degradation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

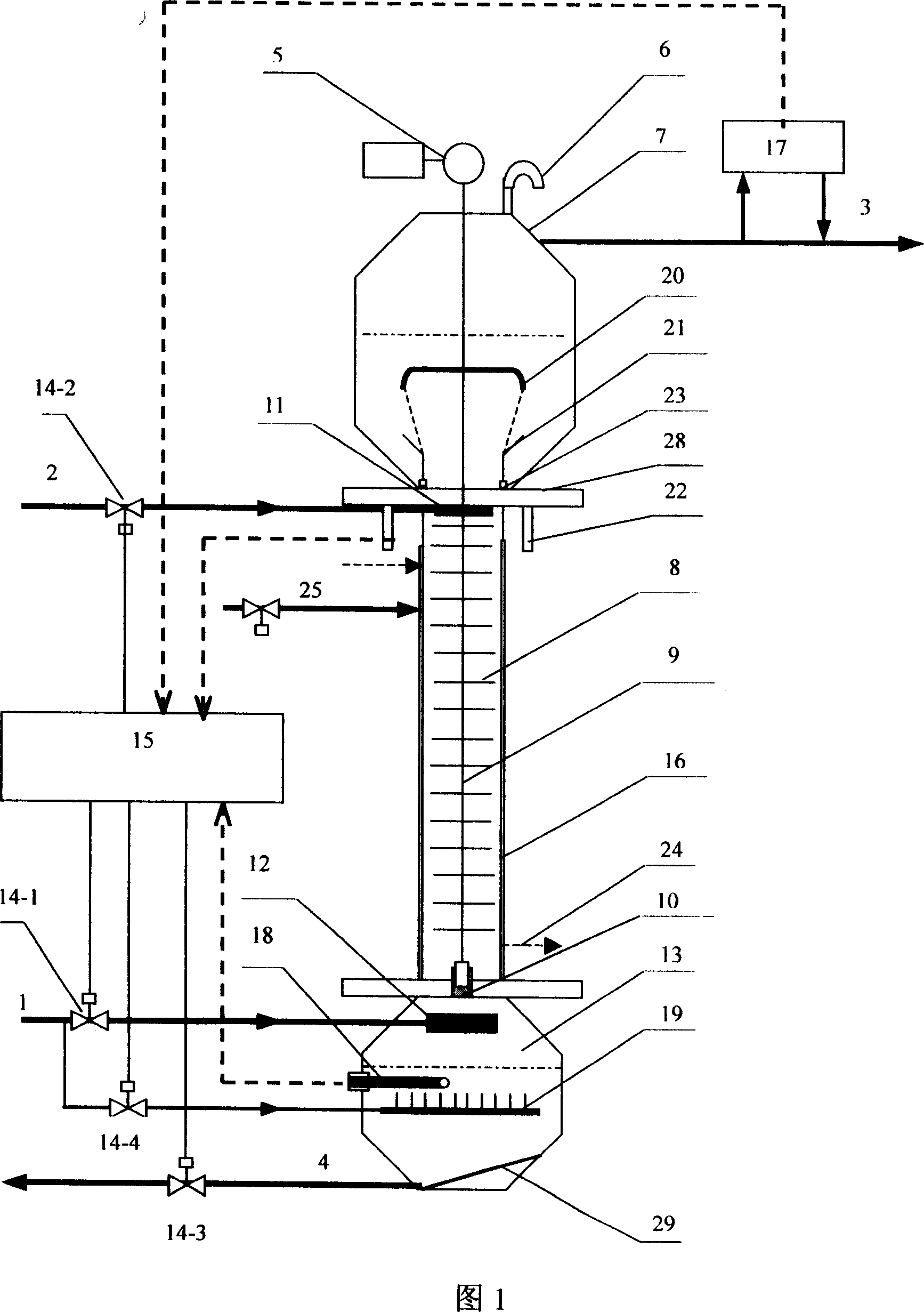

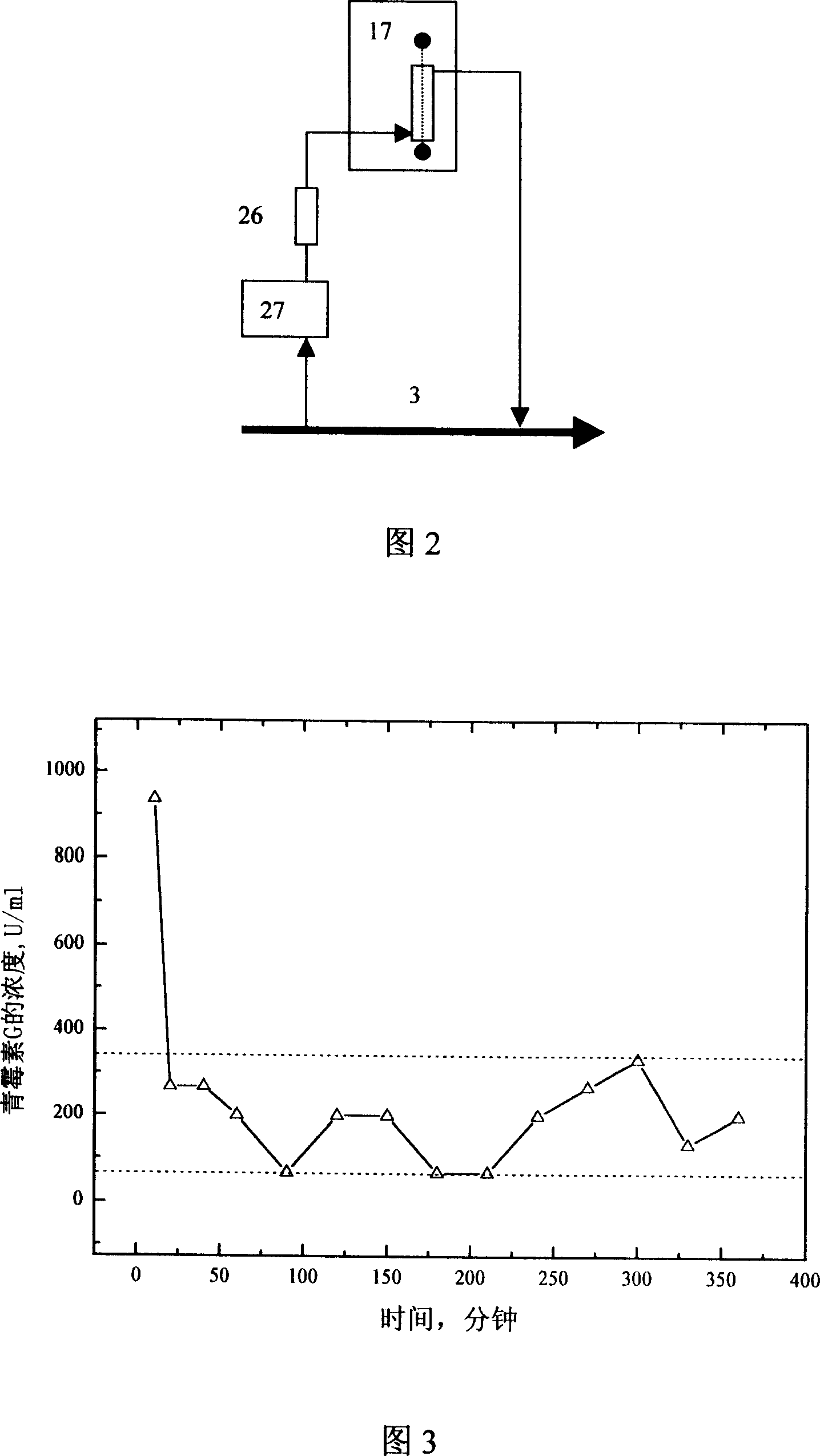

[0057] See Figure 1 and Figure 2. The equipment includes: eccentric wheel 5, exhaust valve 6, upper clarification section container 7, tray 8, central shaft 9, central shaft groove 10, heavy phase distributor 11, light phase distributor 12, lower clarification section container 13, electromagnetic Valves 14-1, 14-2, 14-3, 14-4, computer control system 15, cooling water jacket layer 16, polarimeter 17, pH meter probe 18, light phase distributor 19 in heavy phase clarification area, arc shaped baffle plate 20, tower body extension 21, laser particle size analyzer 22, return hole 23, injection pipe 25, filter 26, peristaltic pump 27, flange 28, inclined plate 29.

[0058] The two ends of a tower body are respectively the extraction tower of clarification section container, and its cylindrical tower body reaction extraction section adopts jacket layer 16 structure, and the clarification section container 7 of tower body upper end is larger than the clarification section container ...

Embodiment 2

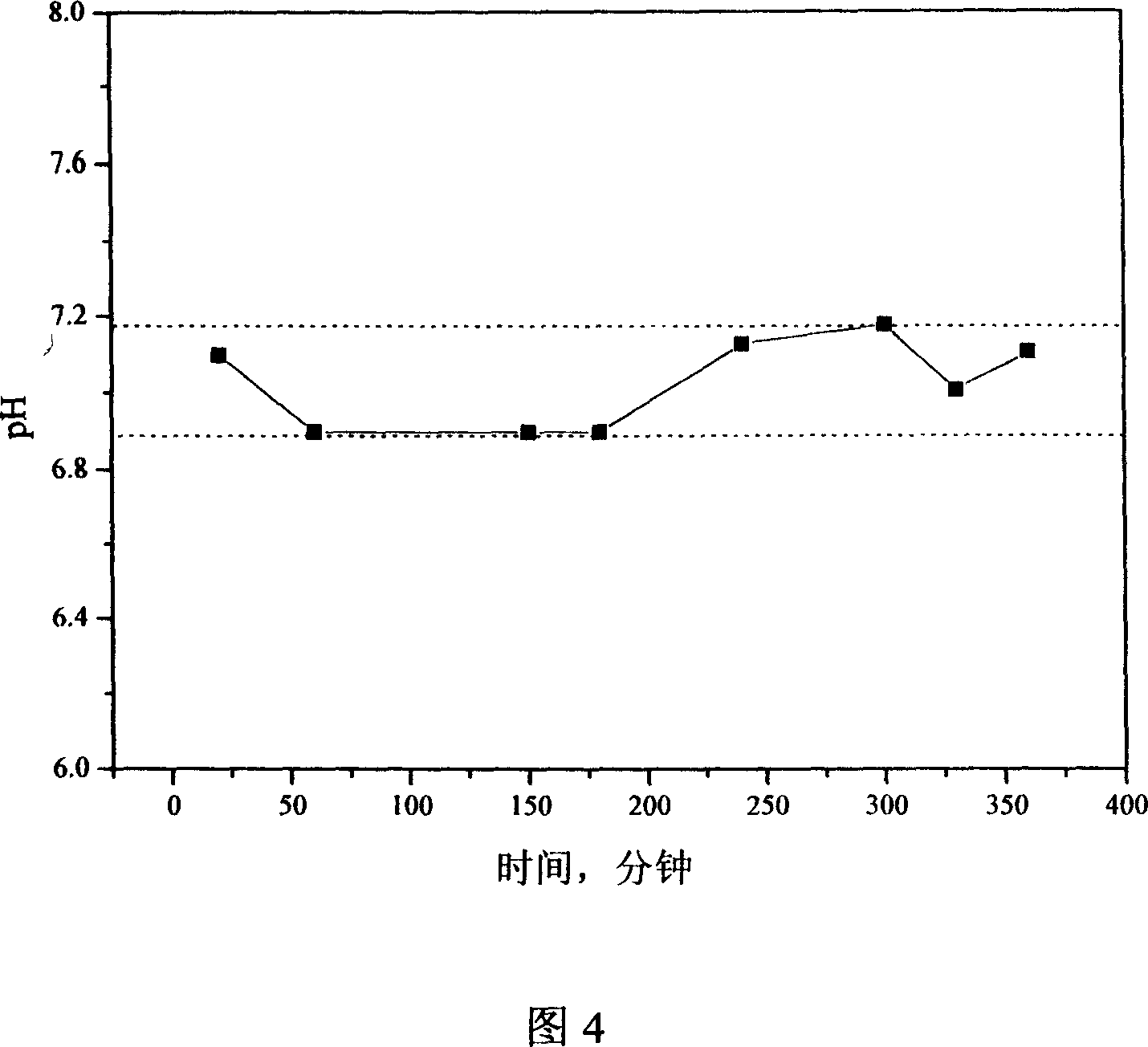

[0069] The equipment of Example 1 was used. Concentration is 69010U / ml penicillin G organic solution and concentration is 25wt% potassium carbonate solution with 200l / h and 8.05l / h respectively under the condition of embodiment 1. The organic raffinate phase continuously flows out of the tower through the clarification section at the top of the tower and enters the intermediate storage tank for collection. The heavy phase rich in penicillin enters the collection tank continuously through the clarification section at the bottom of the tower controlled by a solenoid valve. The experimental results showed that there was no entrainment in the heavy phase and the organic raffinate phase; the potency of penicillin in the organic raffinate phase was 200-500 U / ml, and the pH of the heavy phase was 6.6-7.0; the yield of penicillin G was 90.6%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com