Method for adjusting product composition during coked crude benzene refining

A technology for coking crude benzene and products, which is applied in the fields of chemical instruments and methods, bulk chemical production, organic chemistry, etc., can solve the problems of no mixed aromatics alkylation technology and low efficiency of desulfurization technology, and achieve easy mass production , low price, simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

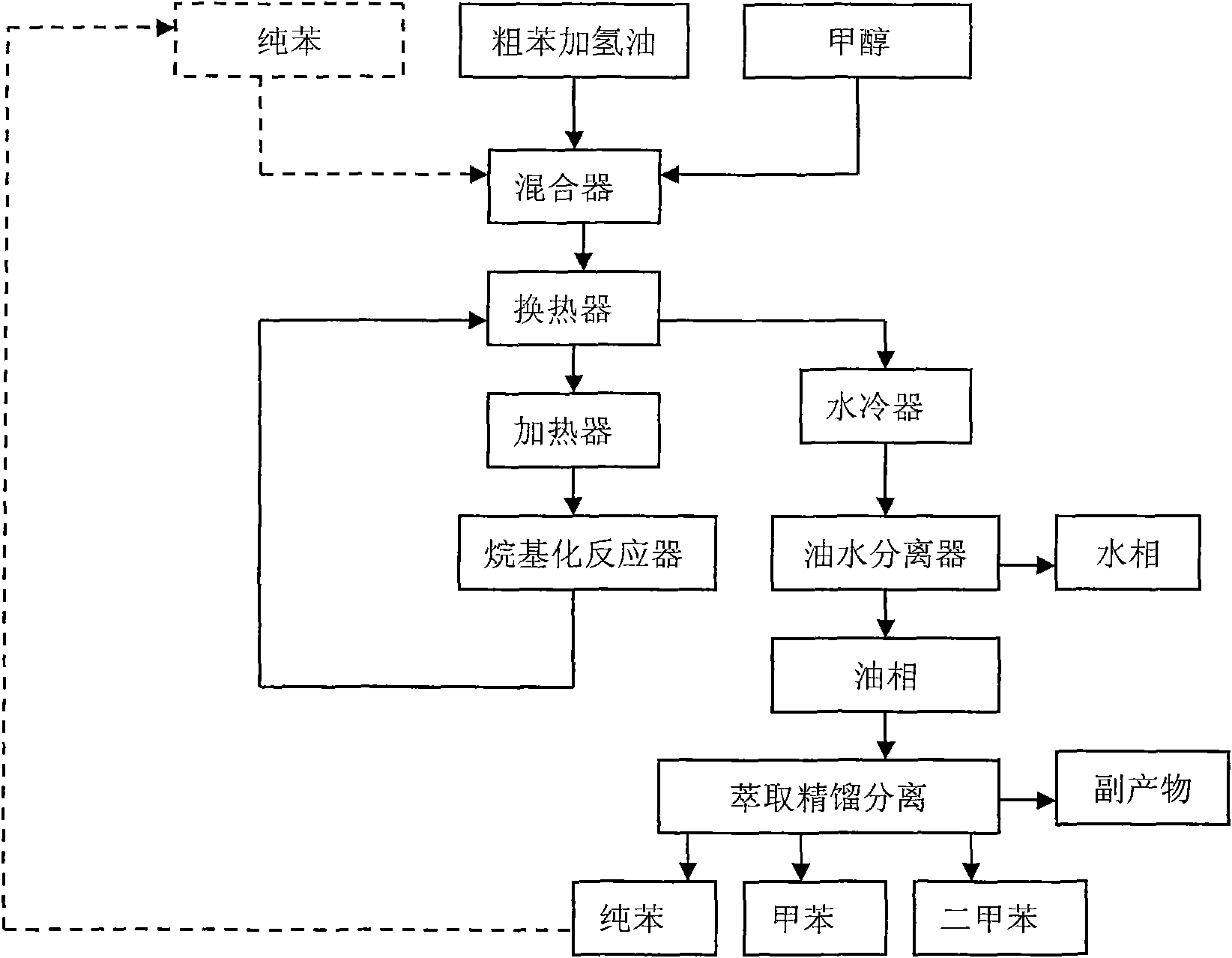

Method used

Image

Examples

Embodiment 1

[0034] In a small fixed-bed reactor, 5ml HZSM-5 molecular sieve is packed, and the crude coking benzene hydrogenation oil and methanol are used as raw materials. The main process parameters are as follows:

[0035] Benzene / alcohol molar ratio 4:1 (calculated based on pure benzene in crude benzene hydrogenated oil)

[0036] The total space velocity of the weight of raw materials is 2h -1

[0037] Reaction temperature 400℃

[0038] Reaction pressure 0.1MPa

[0039] After 24 hours of reaction, the reaction product was sampled and calculated, and the following reaction results were obtained:

[0040] Methanol conversion rate: 100%.

[0041] The composition of crude benzene hydrogenated oil and alkylation products is as follows:

[0042] Benzene Toluene Xylene Other

[0043] Crude benzene hydrogenated oil wt% 69 19 9 3

[0044] Alkylation reaction product wt% 37.76 44.03 13.06 4.75

Embodiment 2

[0045] Example 2: On the basis of Example 1, benzene was additionally recycled as a common raw material. The ratio of recycled benzene to hydrogenated oil is 1:1, and all other conditions are the same as in Example 1.

[0046] After 24 hours of reaction, the following reaction results were obtained:

[0047] Methanol conversion rate: 100%.

[0048] The composition of crude benzene hydrogenated oil and alkylation products is as follows:

[0049] Benzene Toluene Xylene Other

[0050] Crude benzene hydrogenated oil + recycled benzene wt% 86.32 9.13 3.52 1.03

[0051] Alkylation reaction product wt% 55.70 35.46 7.33 1.51

Embodiment 3-6

[0053] Process parameters are shown in Table 1. The raw material composition is the same as in Example 1 Table 1

[0054] Example 3-6 Process Parameters

[0055] Process parameters

Benzene / alcohol molar ratio (Note)

Weight of raw materials, total space velocity h -1

Reaction pressure MPa

Example 3

10:1

5

400

0.1

Example 4

6:1

3

400

0.1

Example 5

2:1

2

400

0.1

Example 6

1:1

1

400

0.1

[0056] Note: The benzene / alcohol molar ratio is calculated based on the pure benzene in crude benzene hydrogenated oil

[0057] After 24 hours of reaction, methanol conversion rate: 100%. The composition of crude benzene hydrogenated oil and alkylation products is shown in Table 2

[0058] Table 2 Example 3-6 Reaction Results

[0059] Product composition

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com