Heavy hydrocarbon removing process and device of natural gas

A natural gas and heavy hydrocarbon removal technology, applied in the petroleum industry, gas fuel, fuel, etc., can solve the problem that resources cannot be transported by pipelines for long distances

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

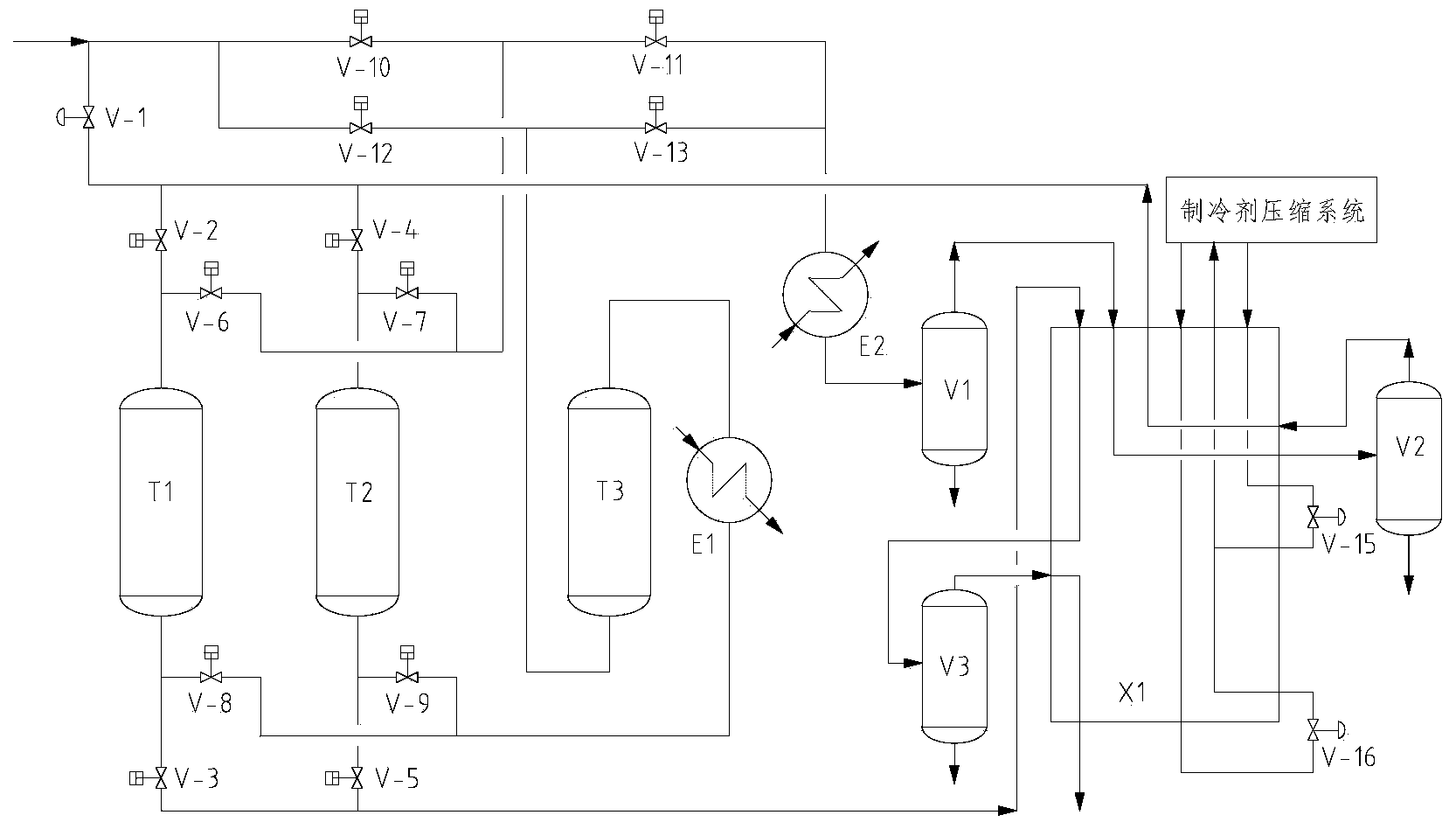

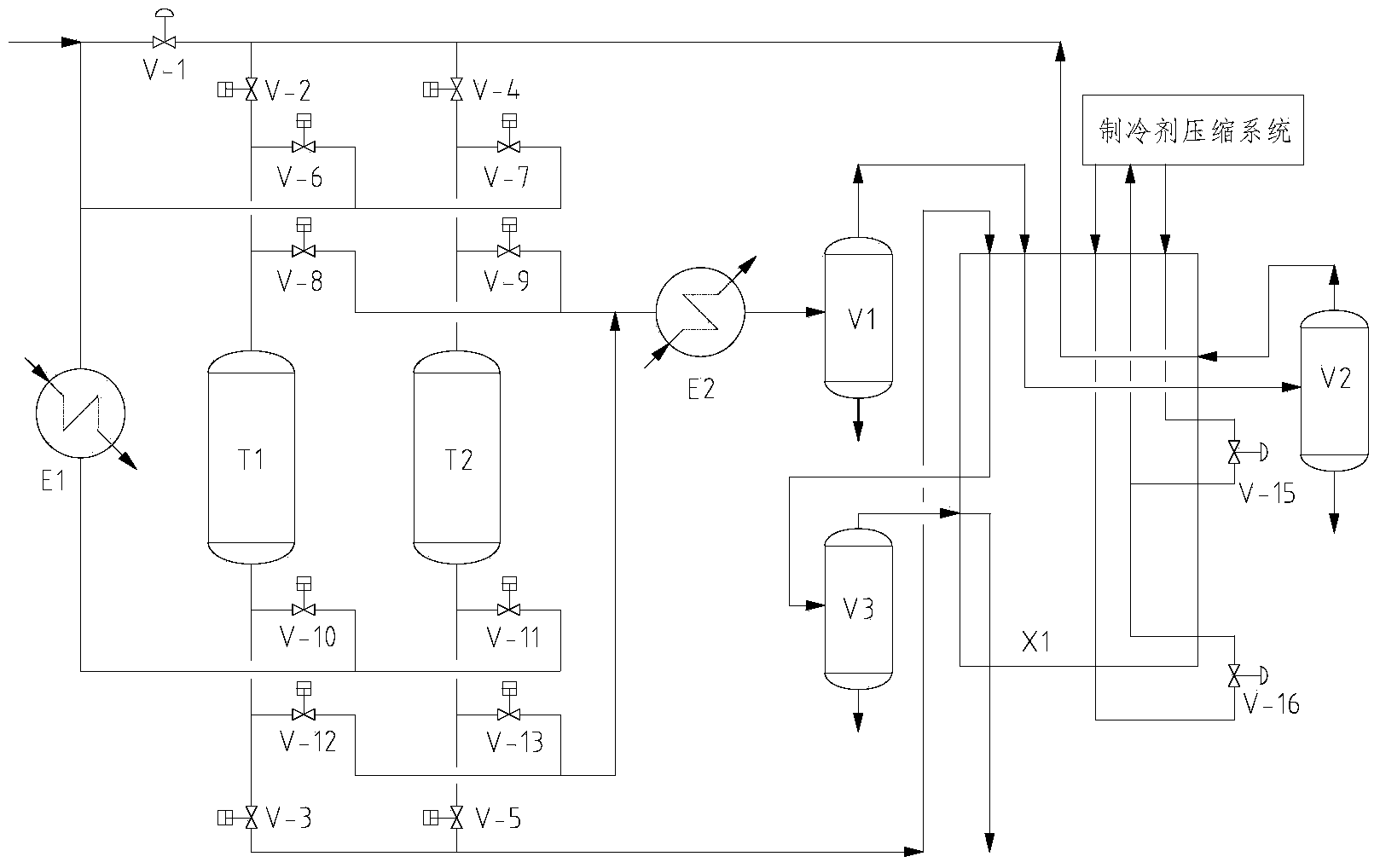

[0059] The heavy hydrocarbon removal process of natural gas provided by the invention adopts the heavy hydrocarbon removal process combining adsorbent and low-temperature separation; the natural gas after deacidification and dehydration treatment first uses the heavy hydrocarbon adsorbent bed to remove most of the heavy hydrocarbons in the gas. hydrocarbons, and then enter the cold box to separate and remove the remaining heavy hydrocarbons at low temperature. After the treatment, the C in the natural gas 6 and C 6 + The heavy hydrocarbon components are removed to the extent that LNG is soluble; part of the natural gas is used as the regeneration gas, and the regeneration gas is pre-cooled, liquid-separated, low-temperature cooled, and liquid-separated to complete the regeneration step, and this part of the regeneration gas is returned to the process gas of the system.

[0060] Refer to attached figure 1 , the natural gas deheavy hydrocarbon device of the present invention c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com