Method and equipment for preparing aromatic sulfonic acid by gas-phase sulphonation of aromatic organic compound

An organic and aromatic technology, applied in the gas-phase sulfonation of aromatic organics to prepare aromatic sulfonic acids and equipment, can solve problems such as side reactions, affecting product quality, unfavorable circulation and injection, and achieve small heat release and enhanced contact effect , improve the effect of selectivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

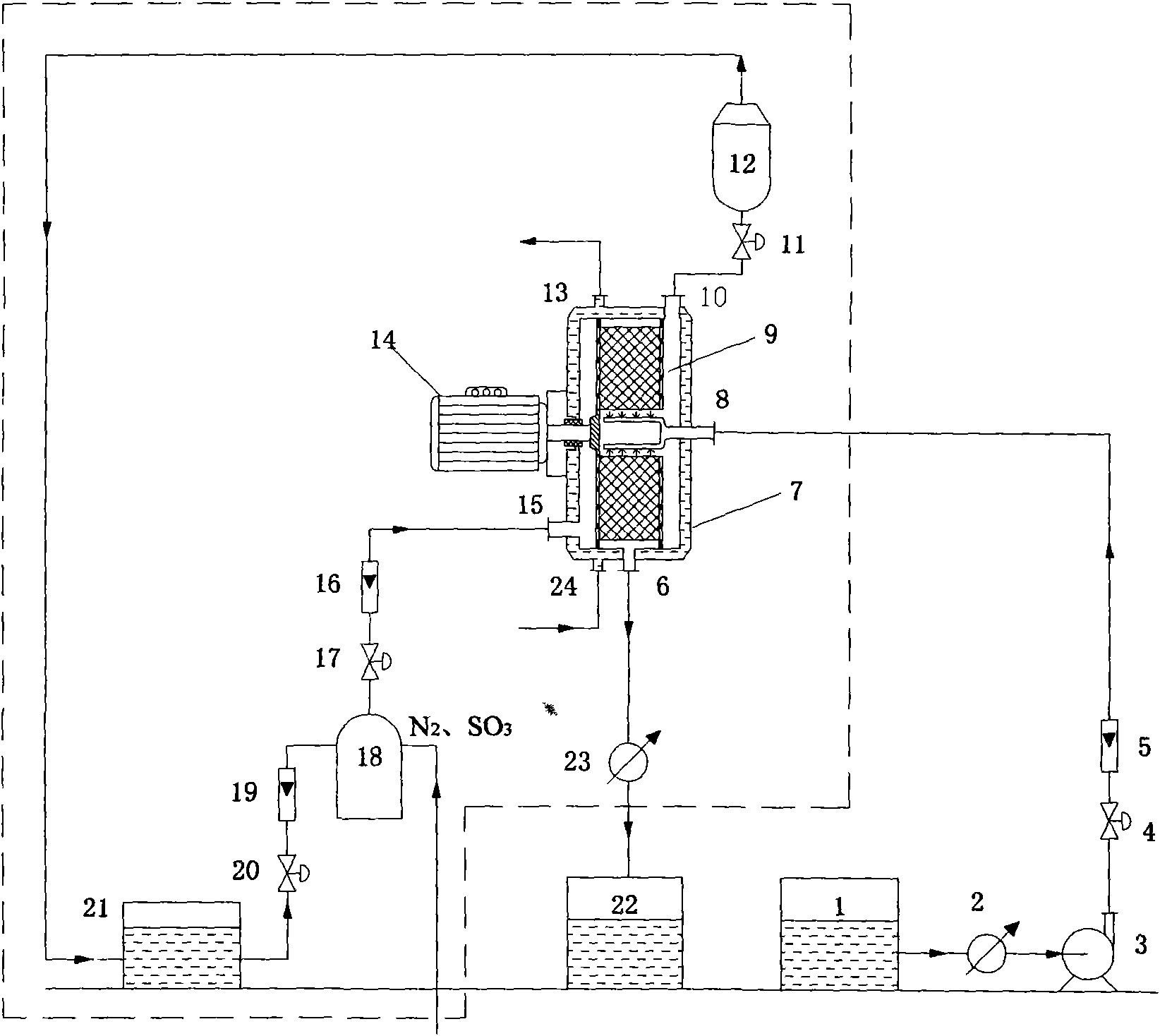

[0032] Embodiment 1: the sulfonation of toluene

[0033]use figure 1 The plant scheme shown performs the sulfonation of toluene. Adjust the rotational speed of the rotating packed bed 9 to 3000r / min, and the raw material toluene is cooled to -5°C to 0°C through the heat exchanger 2 before entering the rotating packed bed 9, and the flow rate of the toluene entering the system is 6kg / h, containing 6 kg of sulfur trioxide % (v / v) of mixed gas (the rest is dry air) flow rate is 7Nm 3 / h, the two raw materials react quickly in the rotating packed bed 9 and then enter the tube heat exchanger 23 through the liquid outlet 6, and cool down to maintain the temperature at 0°C to 10°C, and the reacted product enters the product storage tank 22. The sulfur trioxide and toluene are added into the reaction system at a molar ratio of 0.3:1. The para-isomer content in the toluenesulfonic acid produced by the reaction accounts for 87%-90%, while the meta-isomer content is not more than 1.0%...

Embodiment 2

[0034] Example 2: Sulfonation of Benzene

[0035] use figure 1 The plant scheme shown carries out the sulfonation of benzene. Adjust the rotating speed of the rotating packed bed 9 to be 500r / min, the flow of the benzene entering the system is 5kg / h, and the flow of the mixed gas (all the rest are dry air) containing sulfur trioxide 8% (v / v) is 9N m 3 / h, the two raw materials react quickly in the rotating packed bed 9 and then enter the external heat exchanger 23 through the liquid outlet 6, cool down and maintain the temperature at 20°C to 60°C, and the reacted product enters the product storage tank 22. The molar ratio of the sulfur trioxide and the benzene added to the reaction system is 0.5:1.

Embodiment 3

[0036] Example 3: Sulfonation of Benzene

[0037] use figure 1 The plant scheme shown carries out the sulfonation of benzene. Adjust the rotating speed of rotating packing bed 9 to be 1500r / min, the flow of the benzene that enters the system is 5kg / h, the flow that contains the mixed gas of sulfur trioxide 4% (v / v) (all the other are dry air) is 36Nm 3 / h, the two raw materials react rapidly in the rotating packed bed 9 and then enter the external heat exchanger 23 through the liquid outlet 6, cool down and maintain the temperature at 20°C to 30°C, and the reacted product enters the product storage tank 22. The molar ratio of the sulfur trioxide and the benzene added into the reaction system is 1:1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com