Complexing centrifugal extraction method of high-concentration phenolic wastewater

A high-concentration technology for phenol wastewater, applied in the direction of extraction water/sewage treatment, water pollutants, chemical instruments and methods, etc., can solve the problems of low phenol distribution coefficient, unsatisfactory treatment effect, secondary pollution, etc., and achieve solvent The effect of small retention, compact equipment and high production capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

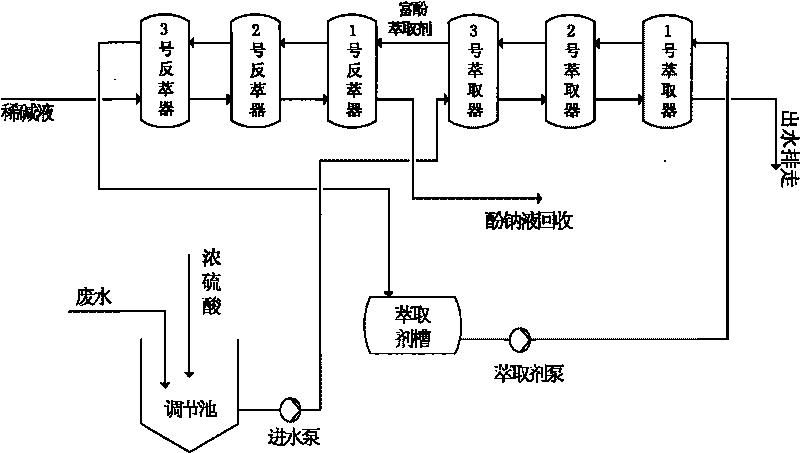

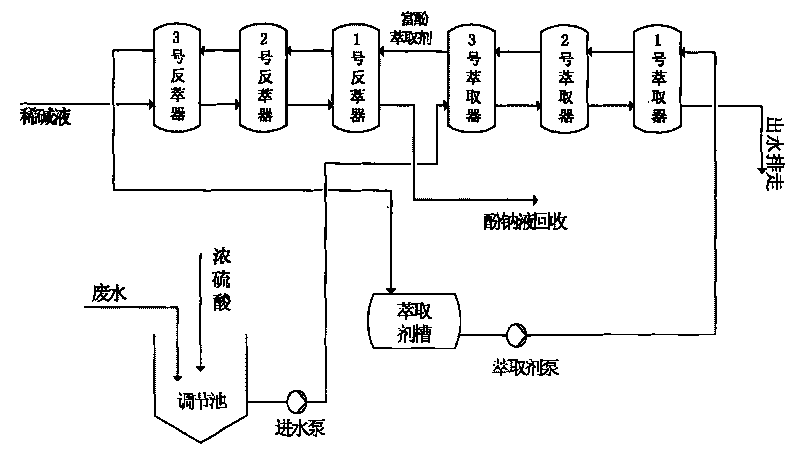

[0022] like figure 1 , Pass the high-concentration phenol-containing wastewater containing 15,000 ppm of phenol into the adjustment tank, add concentrated sulfuric acid for pretreatment, and adjust the pH value to 4.

[0023] The extractant N in the extractant tank 503 The extractant pump flows to No. 1, No. 2, and No. 3 extractors in sequence; the phenol-containing wastewater with a pH value of 4 after pretreatment flows into No. 3 and No. 2 in reverse order through the inlet pump, and No. 1 has already flowed into the extractant In the extractor, the extraction reaction takes place in the extractor.

[0024] The waste water after dephenolization was discharged from No. 1 extractor, and the phenol content was detected to be 154ppm. The phenol-rich extractant after the extraction reaction is discharged from No. 3 extractor.

[0025] The phenol-rich extractant flows into No. 1, No. 2 and No. 3 strippers in sequence, and the 5% sodium carbonate dilute alkali solution is rever...

Embodiment 2

[0028] like figure 1 , Pass the high-concentration phenol-containing wastewater containing 17000ppm phenol into the adjustment tank, add concentrated sulfuric acid for pretreatment, and adjust the pH value to 5.

[0029] The extractant heavy benzene in the extractant tank flows to No. 1, No. 2, and No. 3 extractors in turn through the extractant pump; the phenol-containing wastewater with a pH value of 5 after pretreatment flows into No. 3 in reverse order through the inlet pump , No. 2, and No. 1 have flowed into the extractor of the extractant, and the extraction reaction occurs in the extractor.

[0030] The waste water after dephenolization was discharged from the No. 1 extractor, and the detected phenol content was 166ppm. The phenol-rich extractant after the extraction reaction is discharged from No. 3 extractor.

[0031] The phenol-rich extractant flows into No. 1, No. 2 and No. 3 strippers in sequence, and the 10% sodium bicarbonate dilute alkali solution is reversel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com