Patents

Literature

33results about "Sulfo/sulfonyldioxy group formation/introduction" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

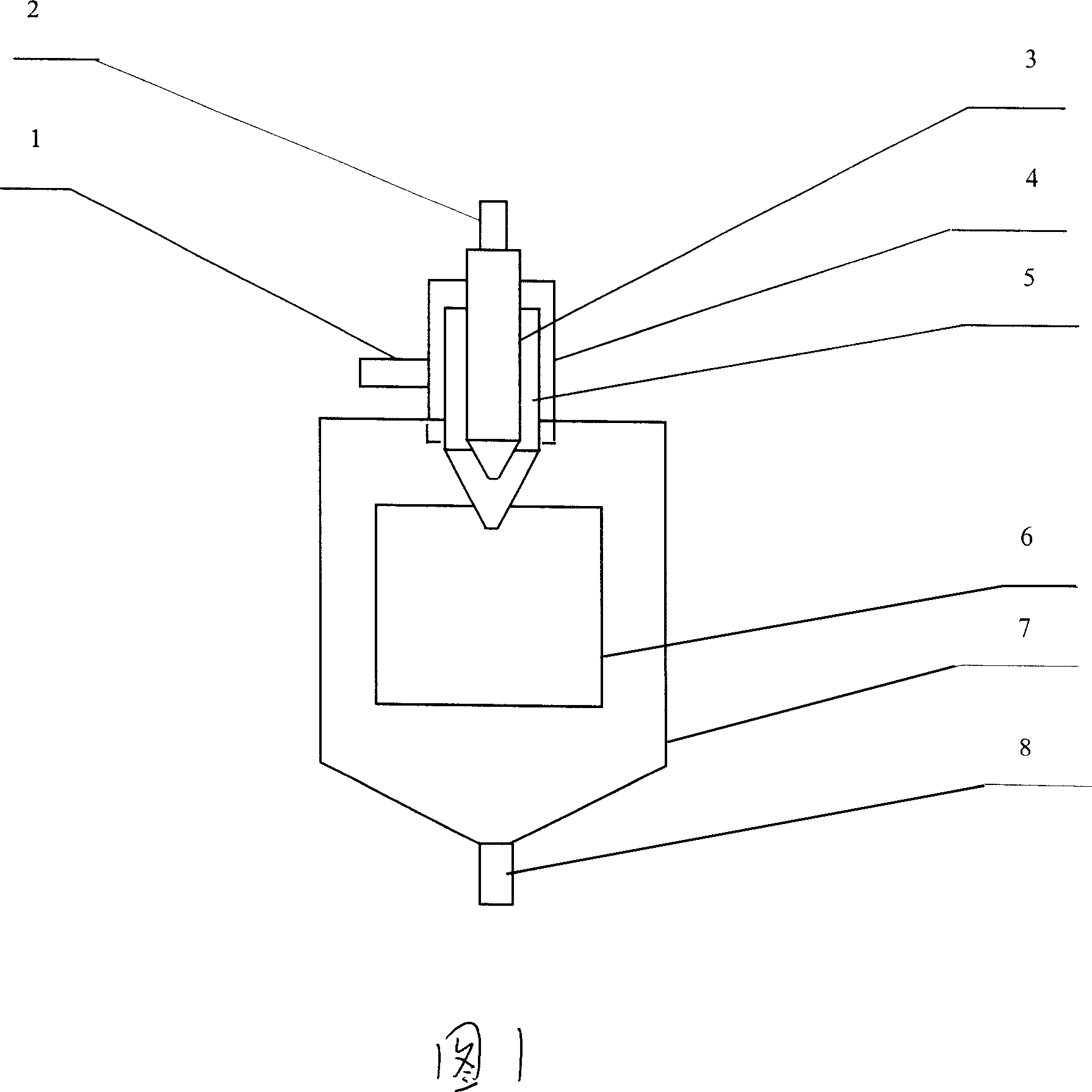

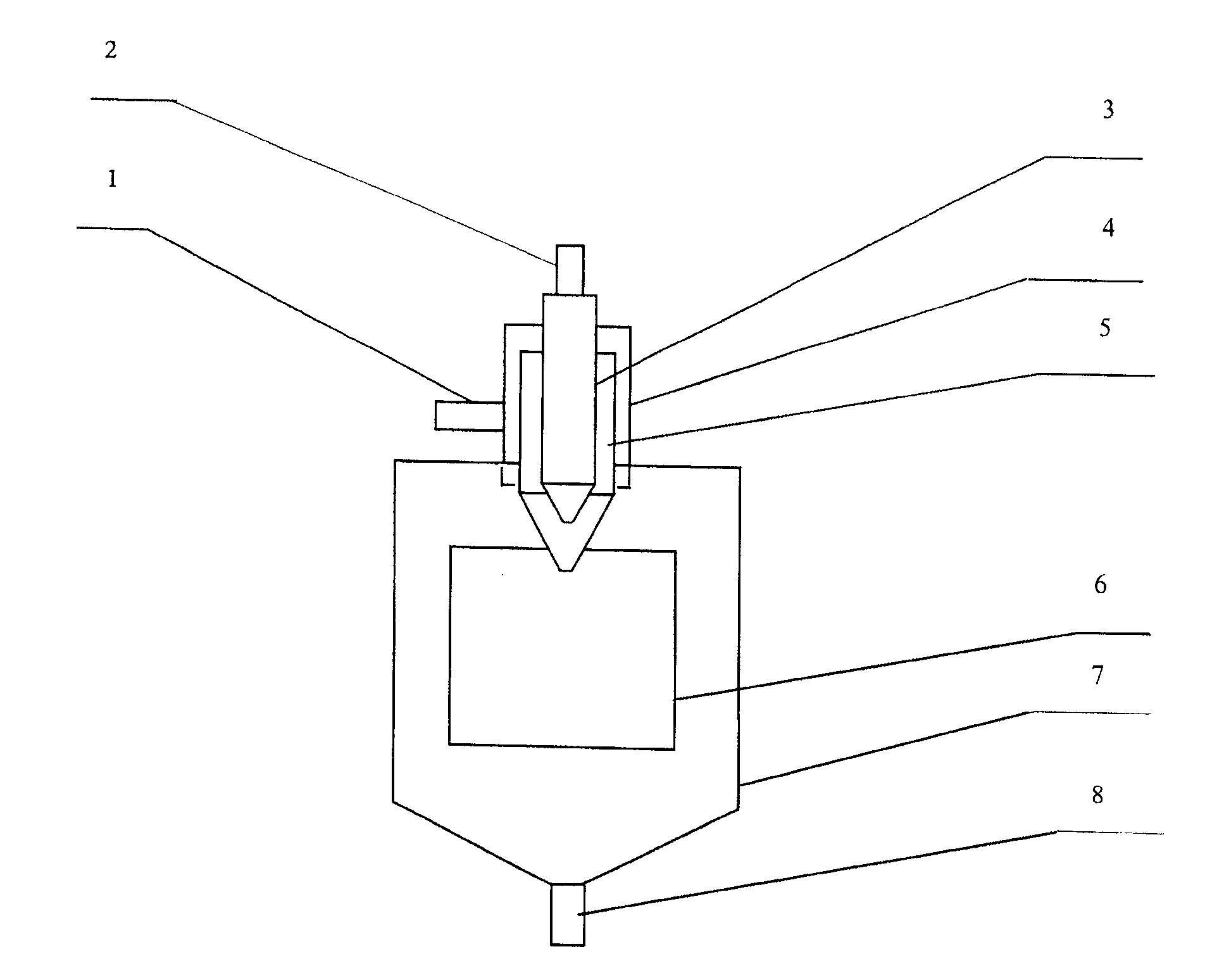

SO3 gas jetting sulfonation reactor and process

ActiveCN1973989AReasonable structureFlexible and easy to operateChemical/physical/physico-chemical nozzle-type rreactorsLiquid-gas reaction processesProduct gasProcess engineering

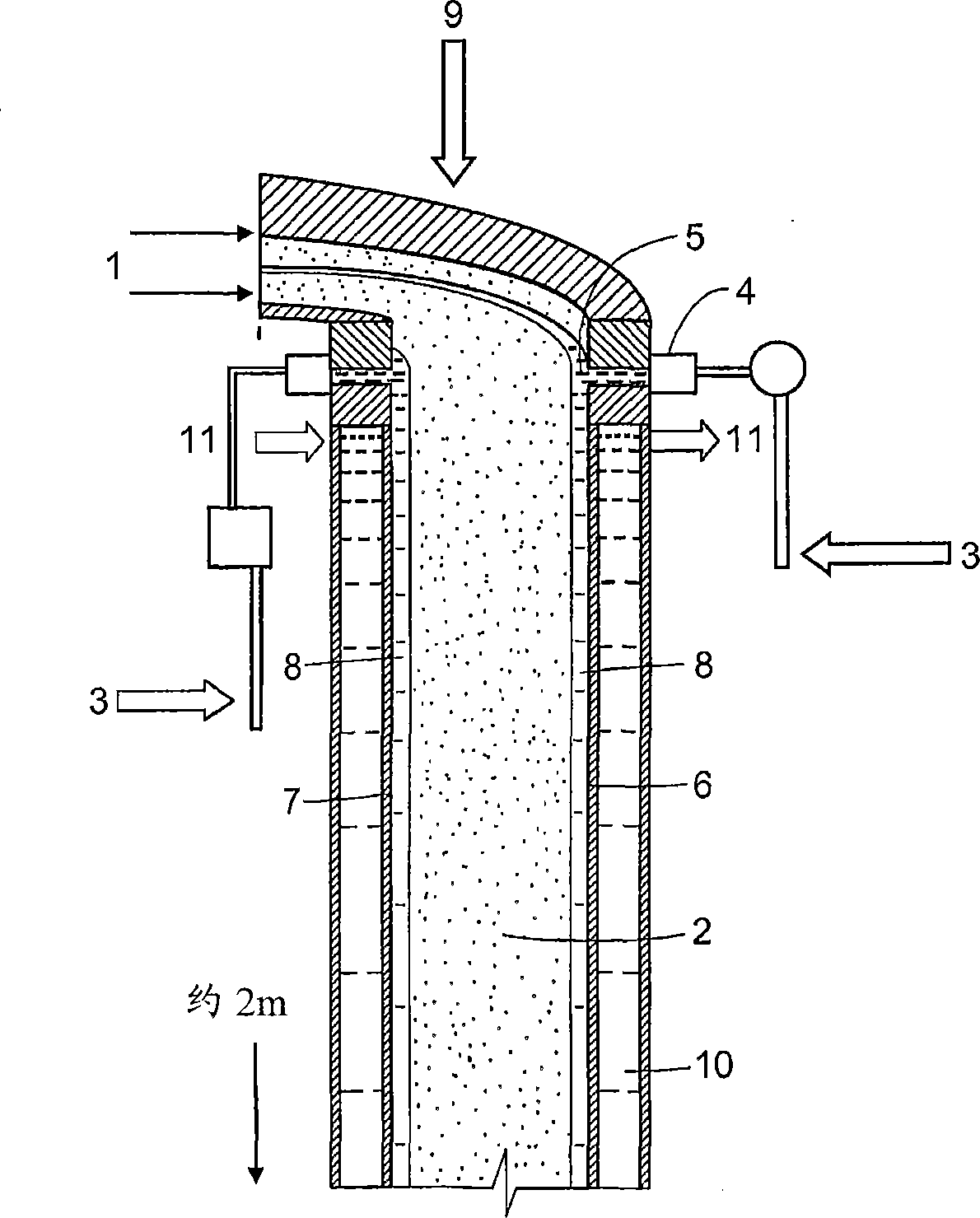

The SO3 gas jetting sulfonation reactor consists of a nozzle and a reactor kettle. The nozzle includes a gas jet, a liquid distributing cavity, an atomizing jet, a liquid material inlet and a gas mixture inlet. The nozzle is fixed in the top of the reactor kettle, the atomizing jet is stretched into inside of the reactor kettle, and the reactor kettle has product outlet in the lower end. The present invention is suitable for sulfonating different kinds of organic material, and has the advantages of reasonable structure, great operation flexibility, simple operation, easy material replacement, stable product quality, etc.

Owner:中轻化工绍兴有限公司

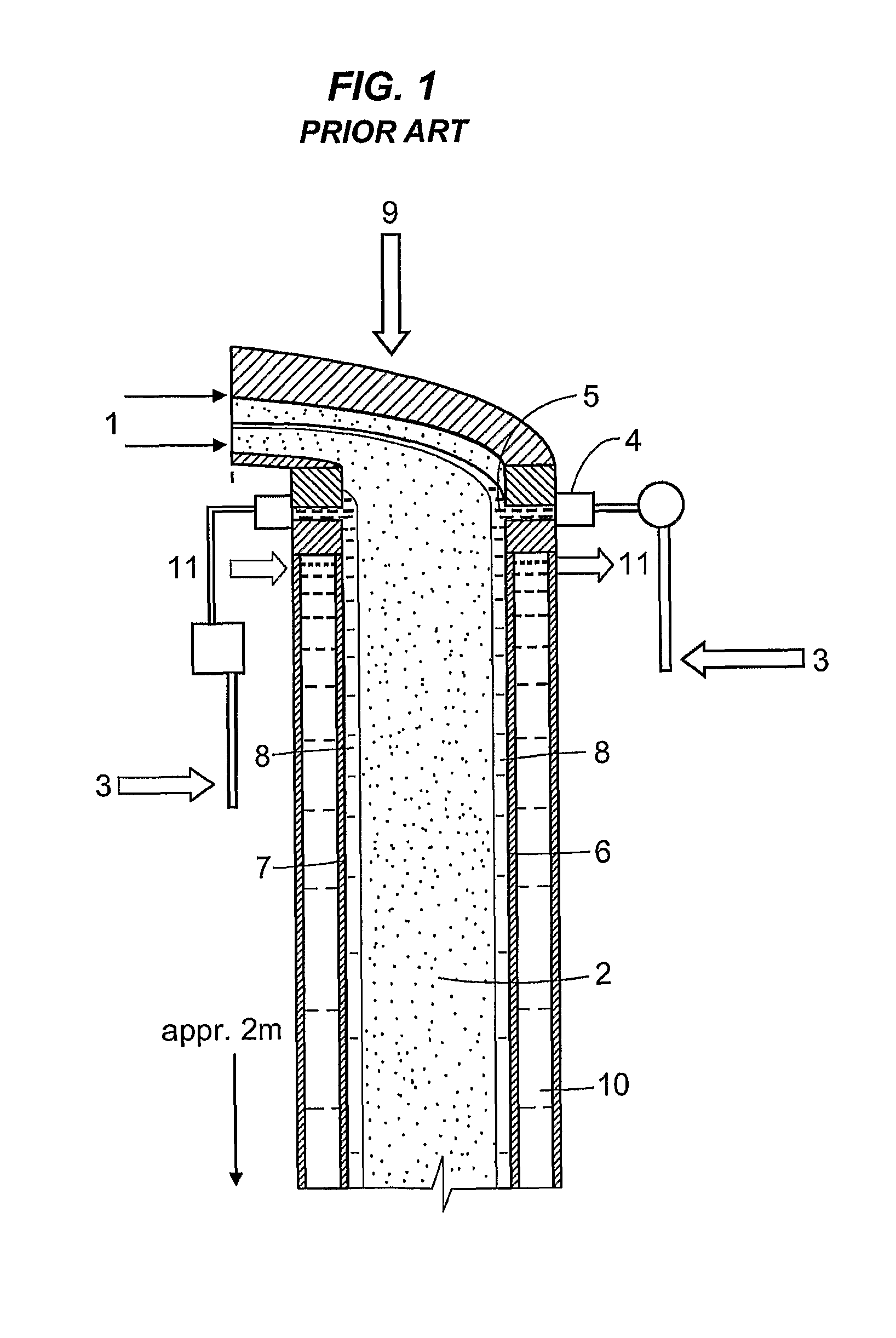

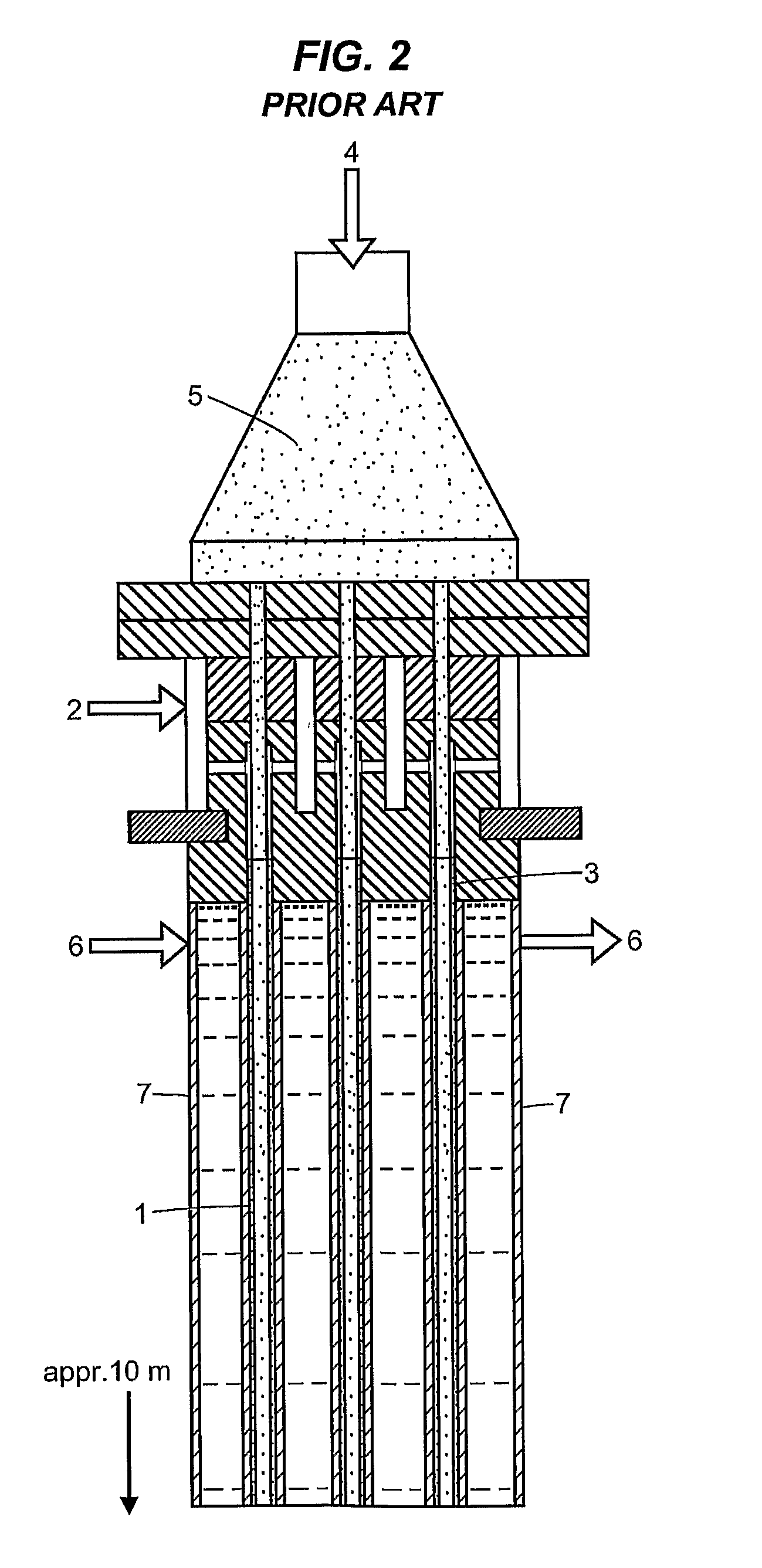

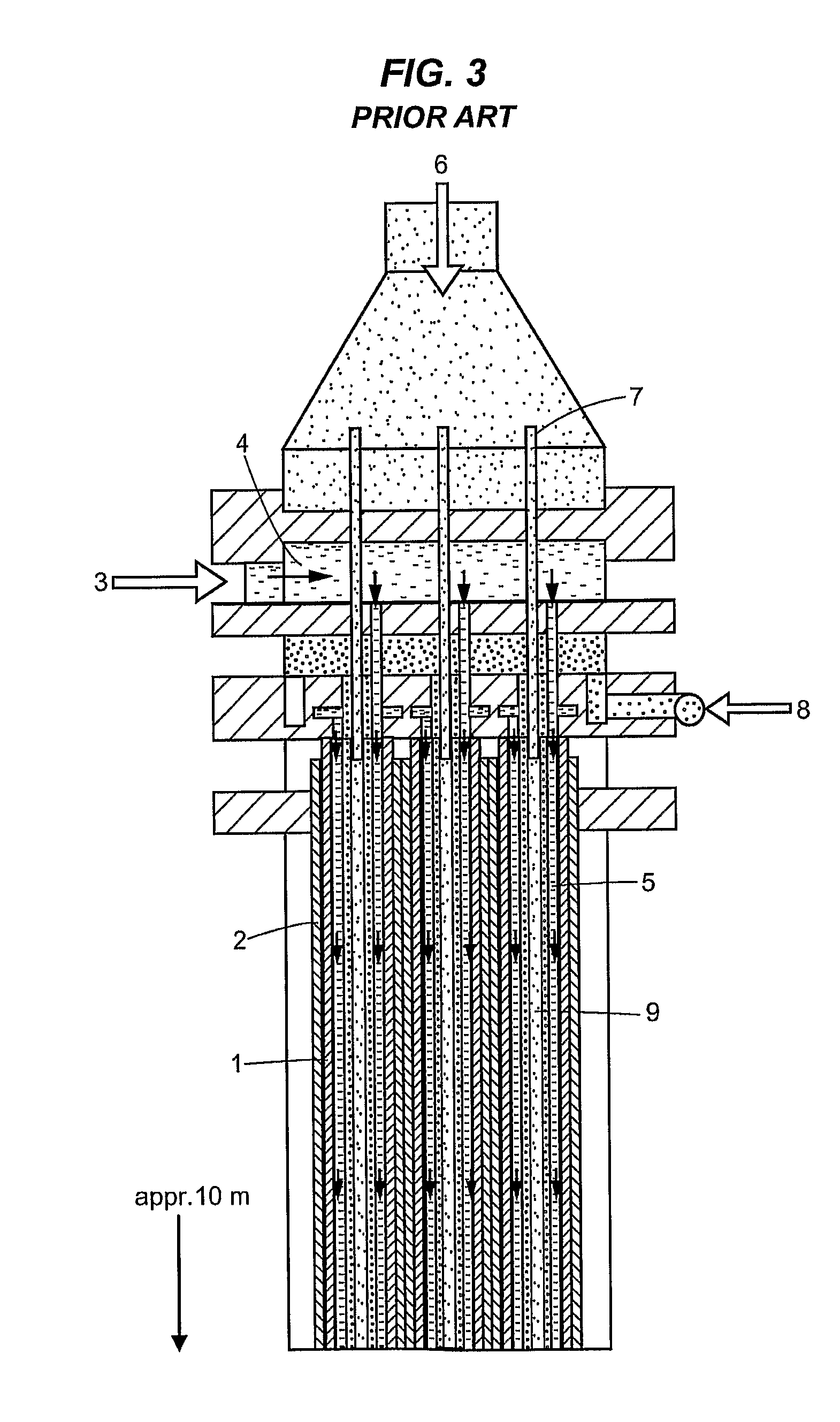

Method and device for the sulfonation or sulfation of sulfonatable or sulfatable organic substances and for performing faster, strongly exothermic gas/liquid reactions

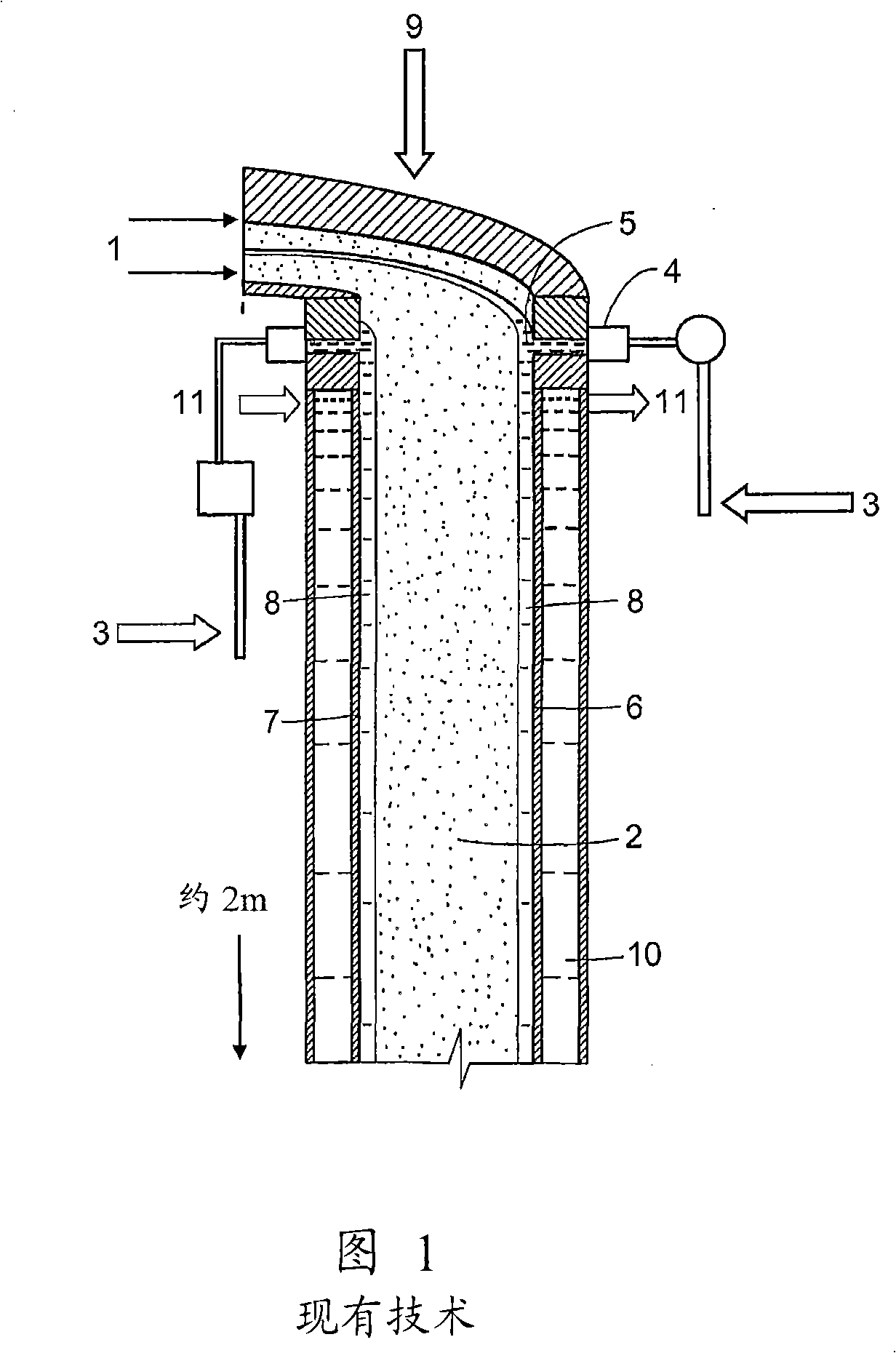

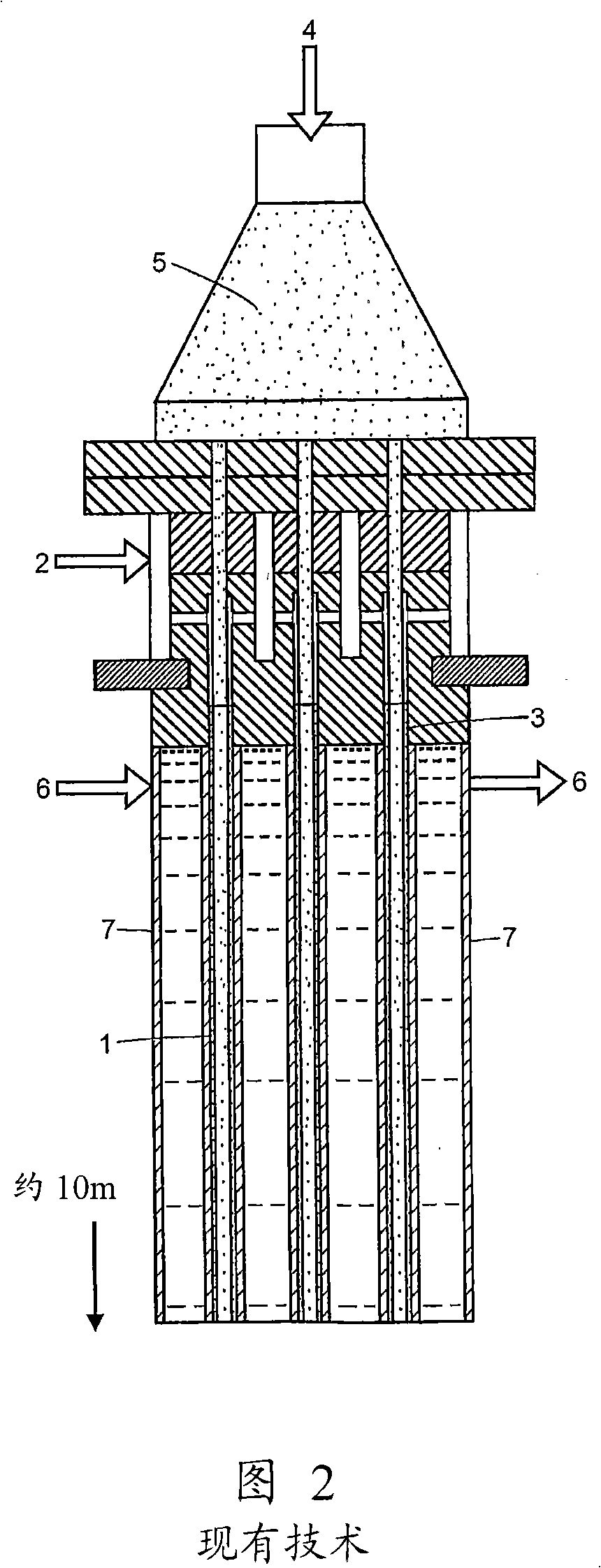

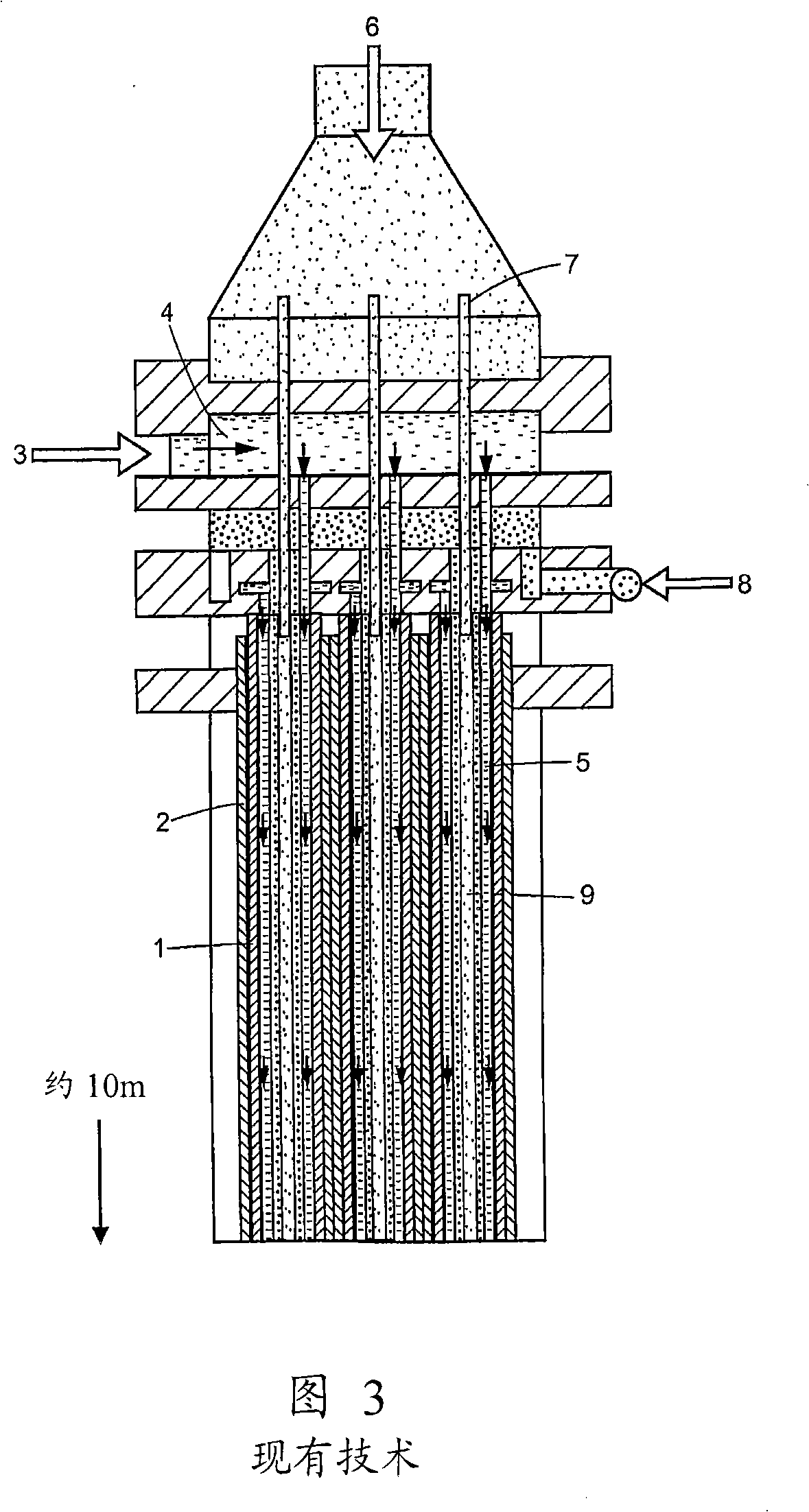

InactiveUS7968742B2Rapid and highly exothermic gas/liquid reactionProcess control/regulationPhysical/chemical process catalystsSulfationGas liquid reaction

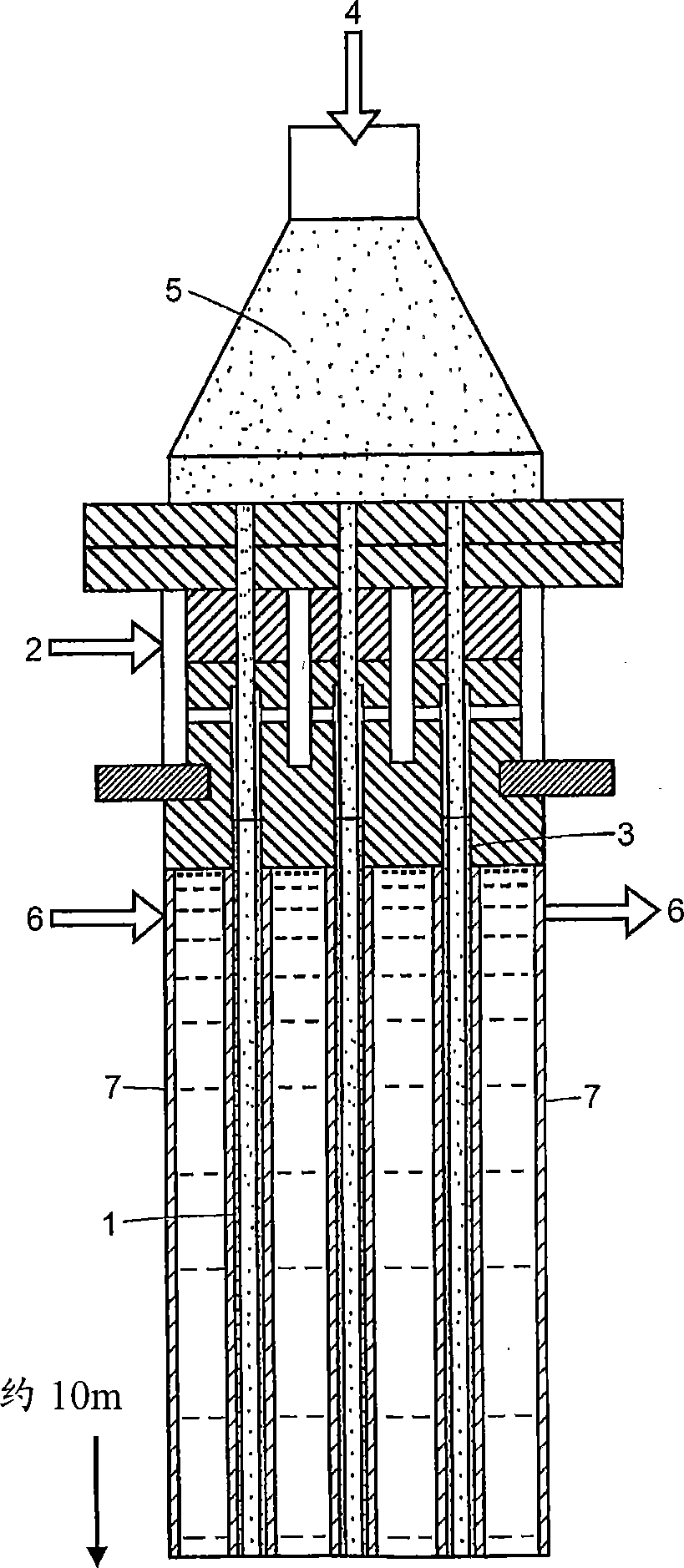

A method and a device for the sulfonation or the sulfation of organic liquid raw materials with an SO3 / air mixture and other reaction gases in order to perform rapid, highly exothermic gas-liquid reactions in conventional thin-layer falling-film reactors are disclosed. The introduction of the SO3 / air mixture occurs through several feed locations, which are located within (along) the reaction tube or reaction tubes or in the annular gap of annular-gap falling-film reactors. High peak temperatures, undesirable byproducts, worsening of the color and local oversulfation or oversulfonation, which leads to side reactions, are largely avoided.

Owner:CHEMITHON

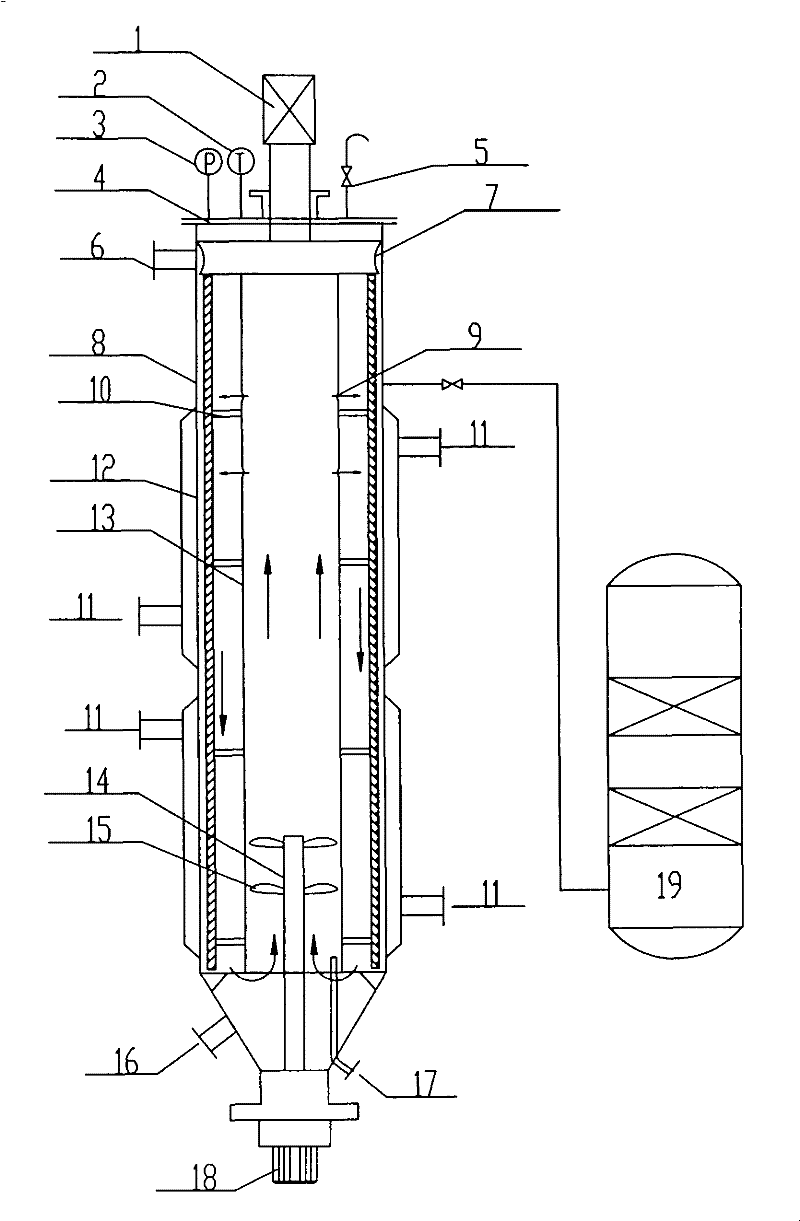

Gas phase SO3 film-scrapping sulfonating technology

InactiveCN101445418ALess investmentReduce energy consumptionLiquid-gas reaction of thin-film typeSulfo/sulfonyldioxy group formation/introductionGas phaseProduct gas

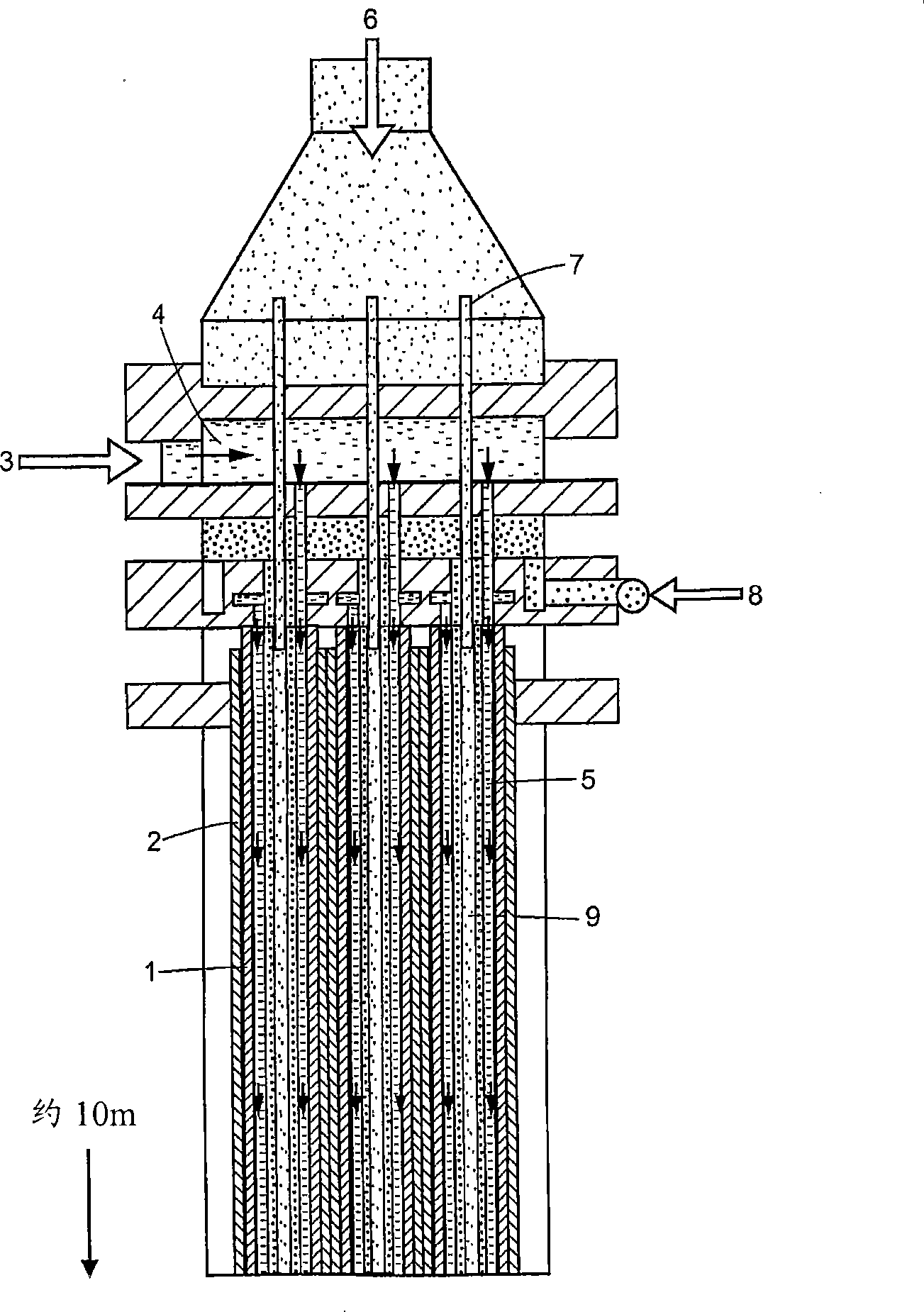

The invention relates to a gas phase SO3 film-scraping sulfonating technology which belongs to the technical field of production technology which prepares anionic surfactant by using gas phase SO3 film-scraping sulfonating liquid organic materials. The invention is carried out according to the following steps: A: liquid SO3 is vaporized to gas phase SO3, the gas phase SO3 is sucked in a mixer shaft through a turbo-blower, the gas phase SO3 is mixed with inert gases recycled in a sulfonating reactor to reaction gas with the volume concentration being 0.1 to 10 percent, and then the reaction gas goes into a reaction cylinder body through reaction gas distribution holes on the upper part of the scraping plate shaft; B: the organic materials go into the sulfonating reactor and downwards flow along the inner wall of the reaction cylinder body, a scraping plate is rotated along with the mixer shaft under the action of a transmission system, the organic materials are continuously suffered with film scaping-spread coating-film scaping in the inner wall of the reaction cylinder body, the organic material are alternately updated and uniformly coated on the inner wall of the reaction cylinder body, and the organic materials are completely contacted and reacted with the reaction gas which goes from the reaction gas distribution holes to form reaction products. The design of the technology is reasonable, and the invention can be suitable for sulfonating or sulphating materials with various viscosities.

Owner:ZANYU TECH GRP CO LTD

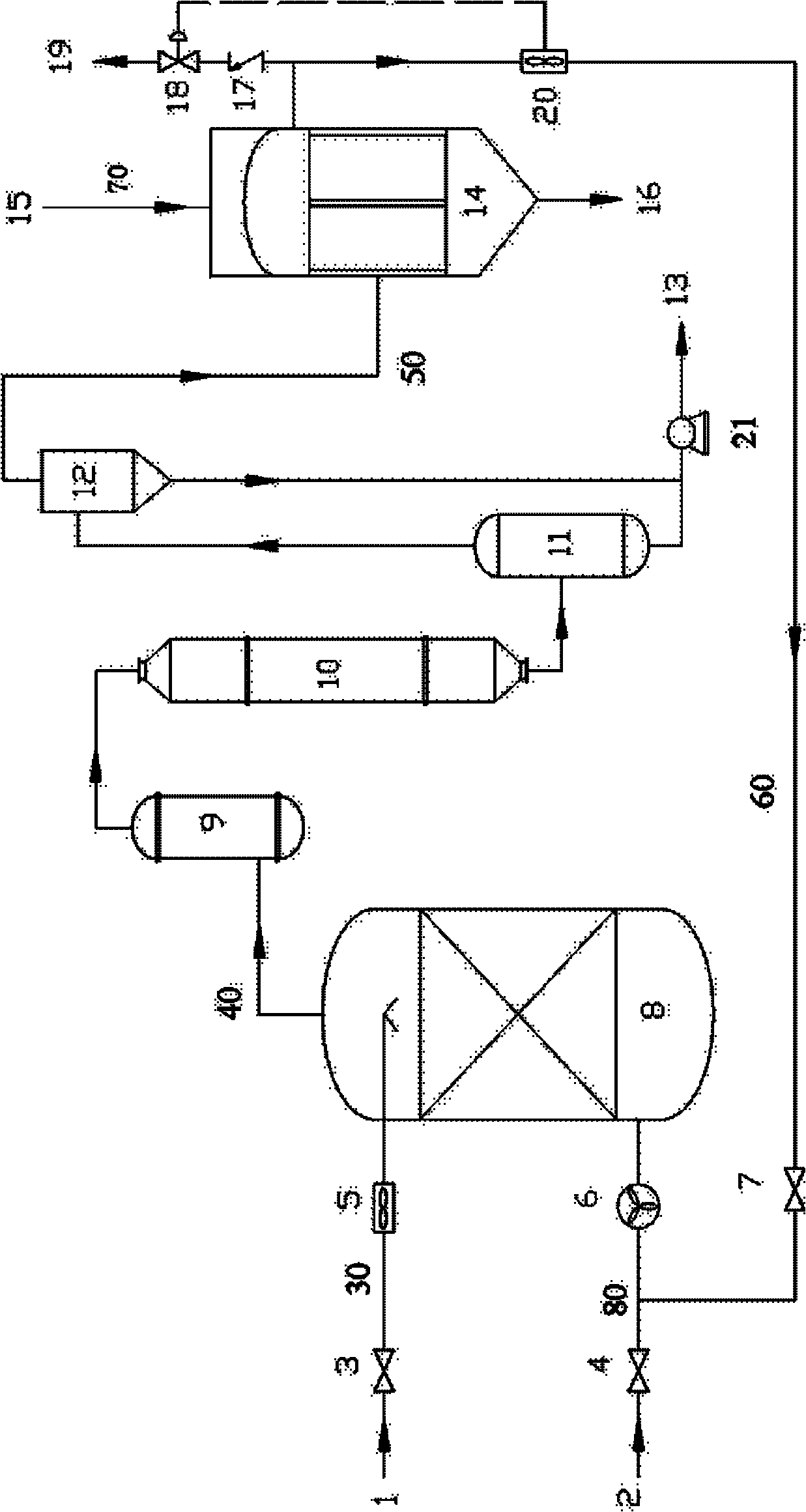

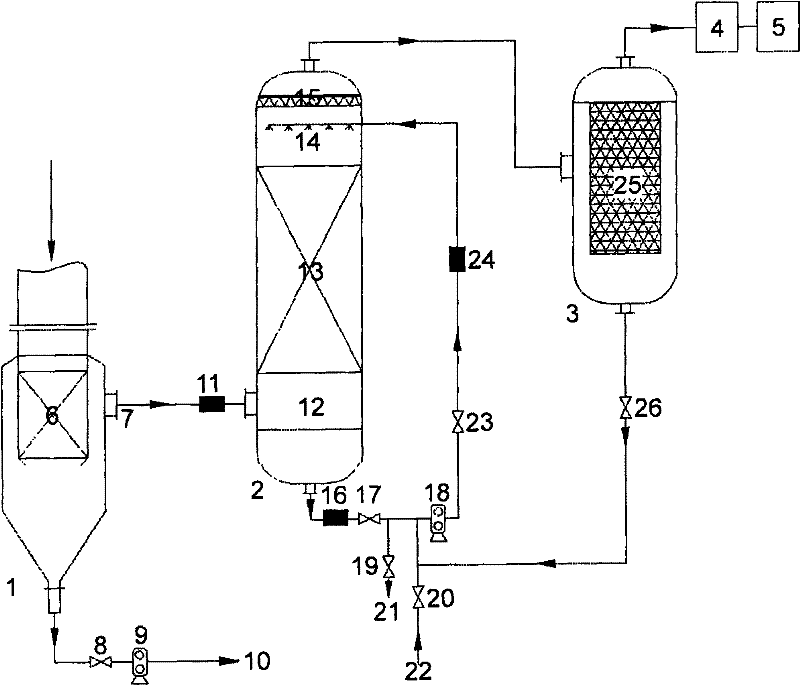

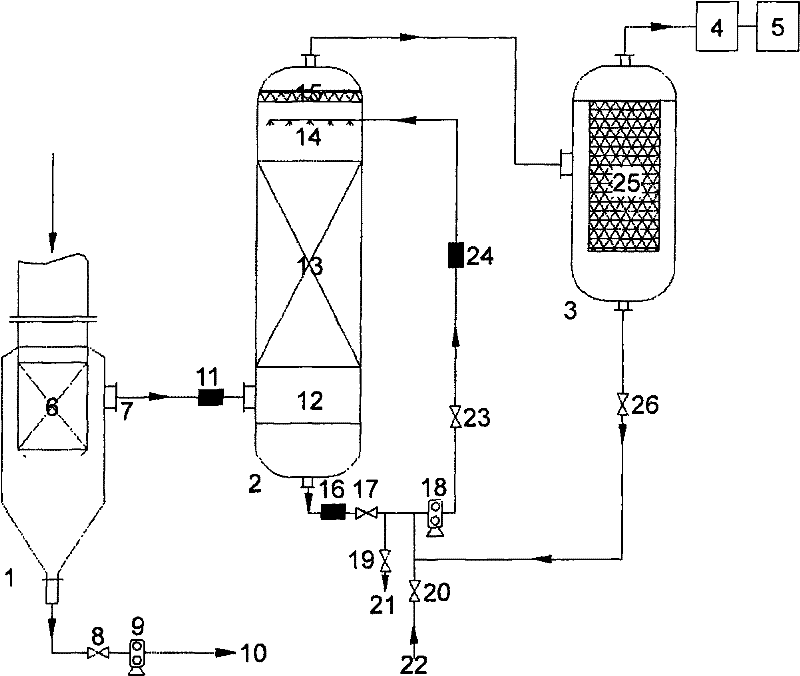

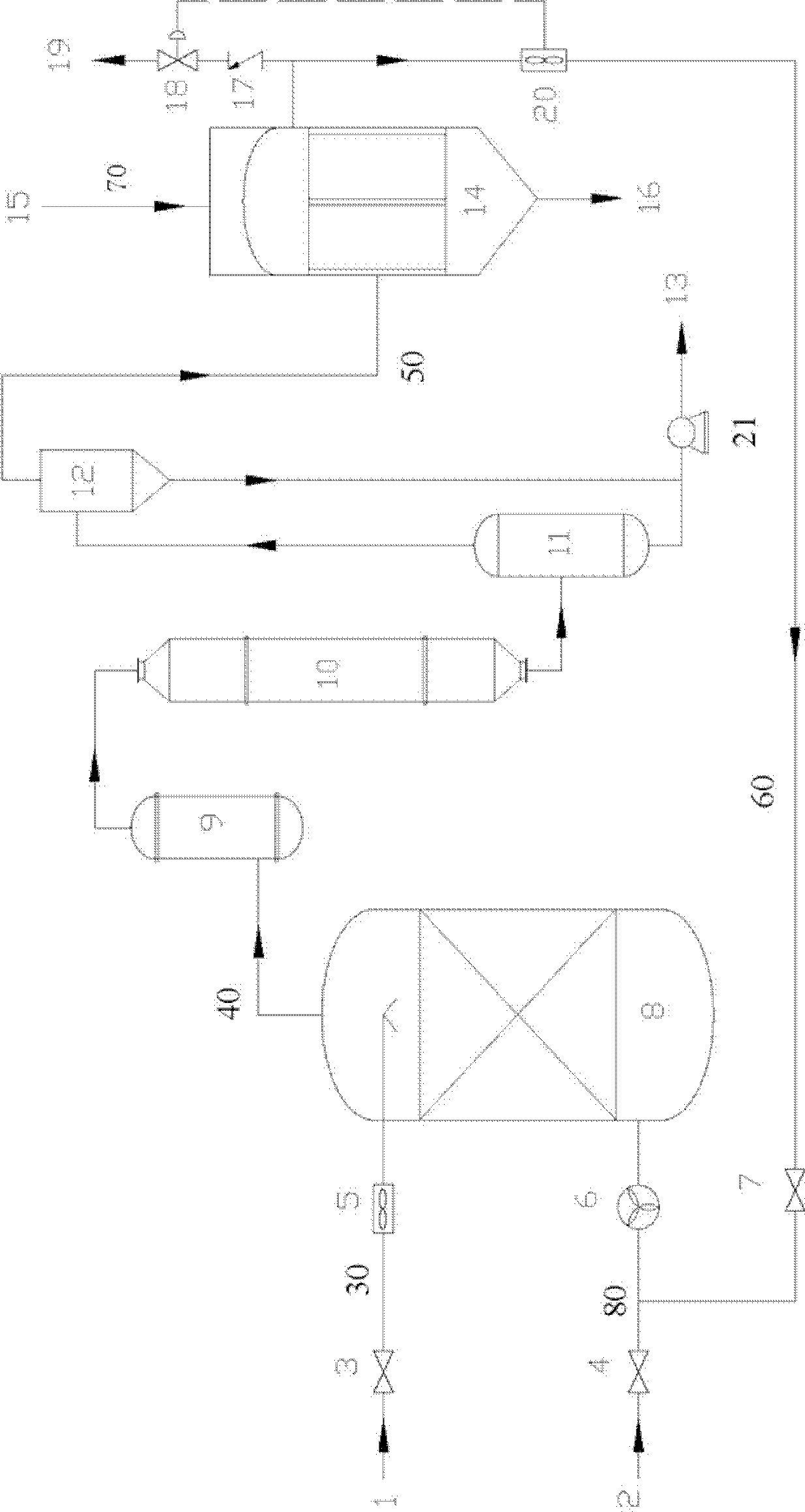

Sulfonated tail gas recycling method and sulfonated tail gas recycling system

ActiveCN102513039AEmission reductionLow investment costCombination devicesLiquid-gas reaction processesProcess engineeringSulfur trioxide

The present invention relates to a sulfonated tail gas recycling method and a sulfonated tail gas recycling system. The purpose of the present invention is to provide the method and the system, wherein the method and the system have characteristics of less waste gas discharge and less wastewater discharge, and the system has characteristics of reasonable structure, easy manufacture, and low cost. The technical scheme is that: the sulfonated tail gas recycling method comprises the following steps that: dry air enters the lower part of a sulfur trioxide evaporator, and is subjected to counter current contact with liquid sulfur trioxide entering the upper part of an vaporizing mixer so as to evaporate into the sulfur trioxide gas; the sulfur trioxide gas is cooled, enters a sulfonator, is subjected to a contact reaction with an organic material in the sulfonator, and then is output; the sulfonated tail gas is separated from the liquid, wherein the separated liquid material is output and enters a neutralization system, the separated sulfonation tail gas enters an electrostatic demister to carry out a demisting treatment, the partial discharged sulfonated tail gas enters an alkali washing processing system, and the remaining sulfonated tail gas is conveyed to the lower part of the sulfur trioxide mixing evaporator to recycle. The pipeline system of the sulfonated tail gas recycling system is arranged according to the method.

Owner:JIAXING ZANYU TECH DEV CO LTD

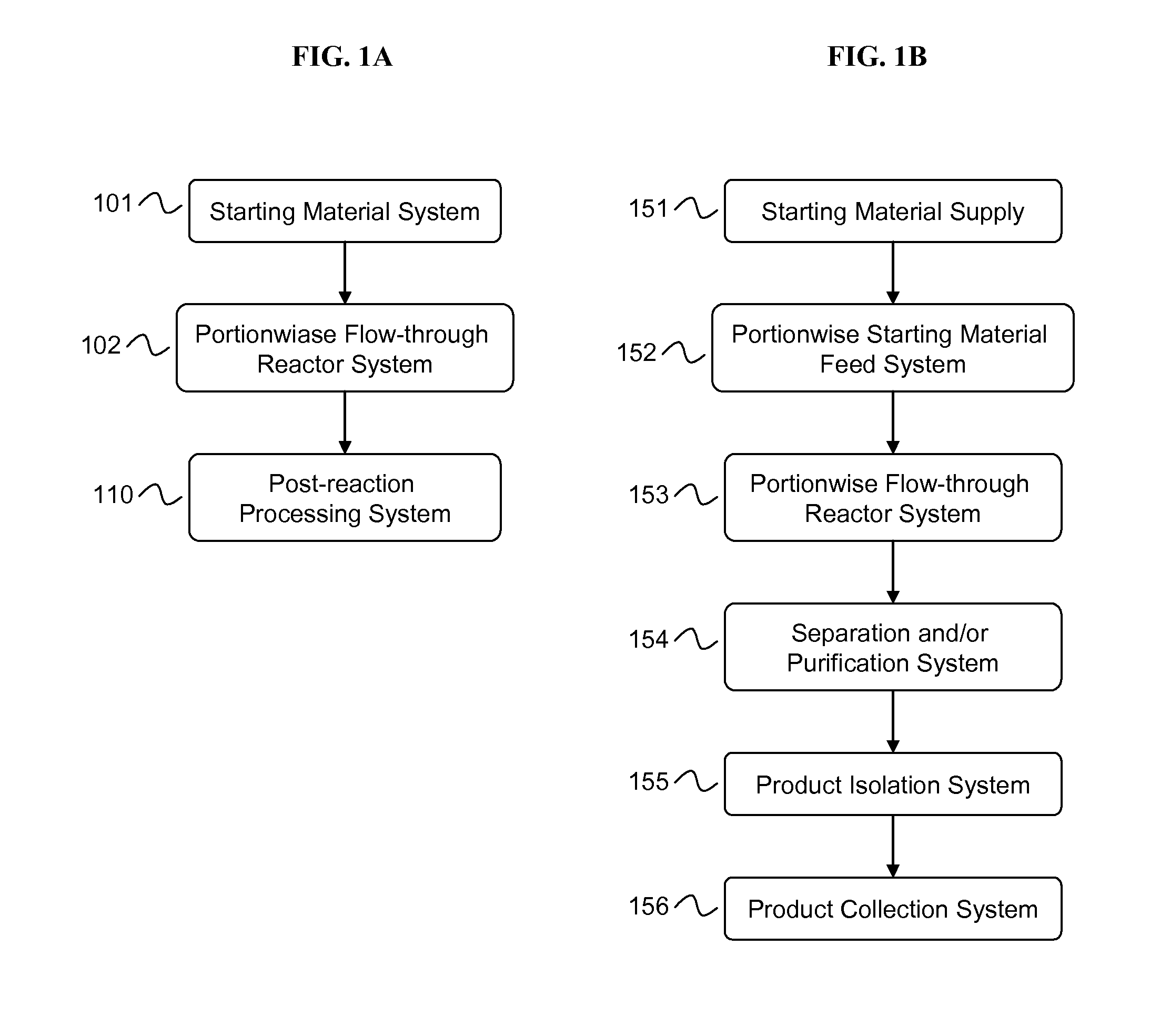

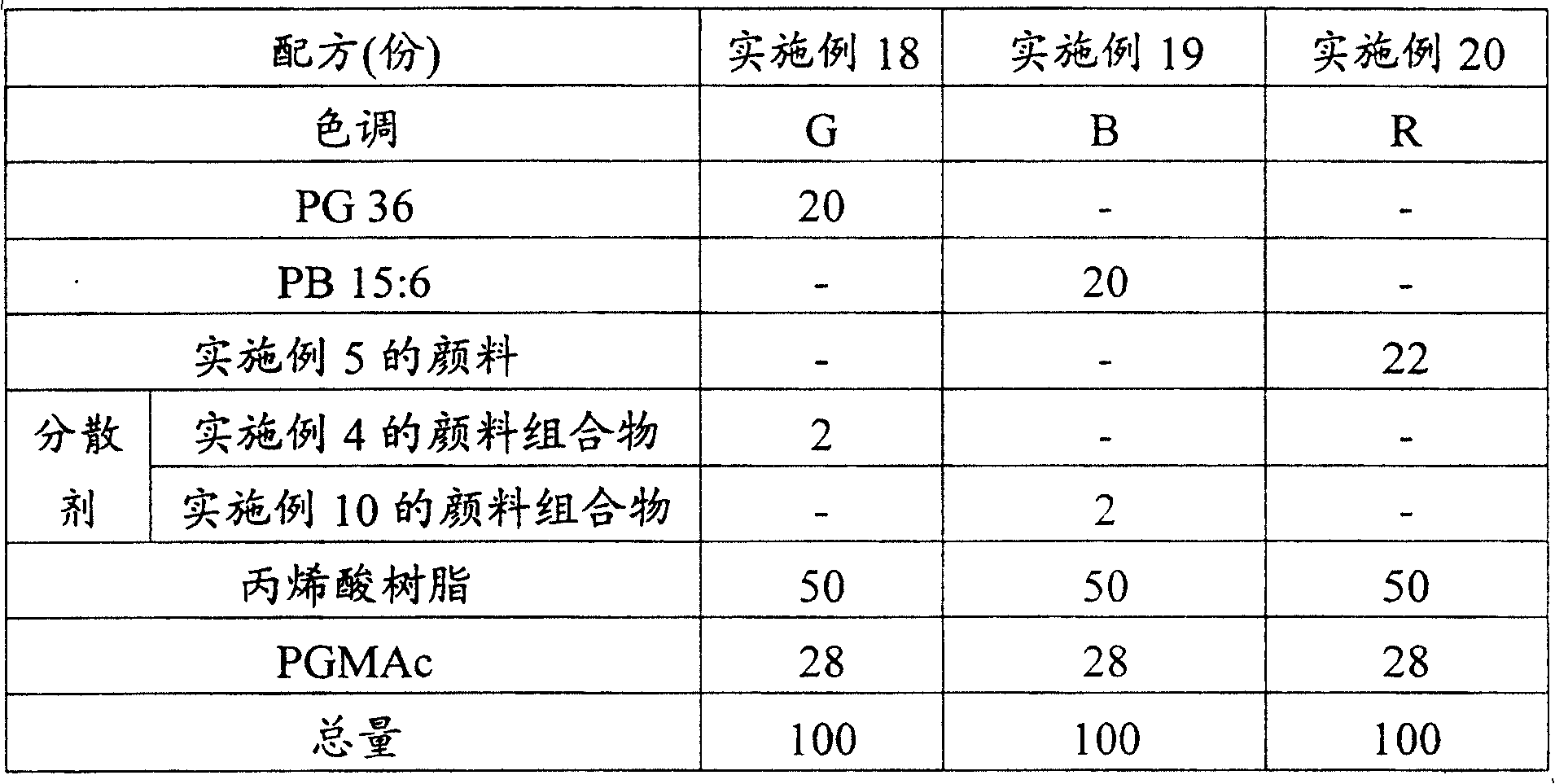

Manufacturing process for cyclodextrin derivatives

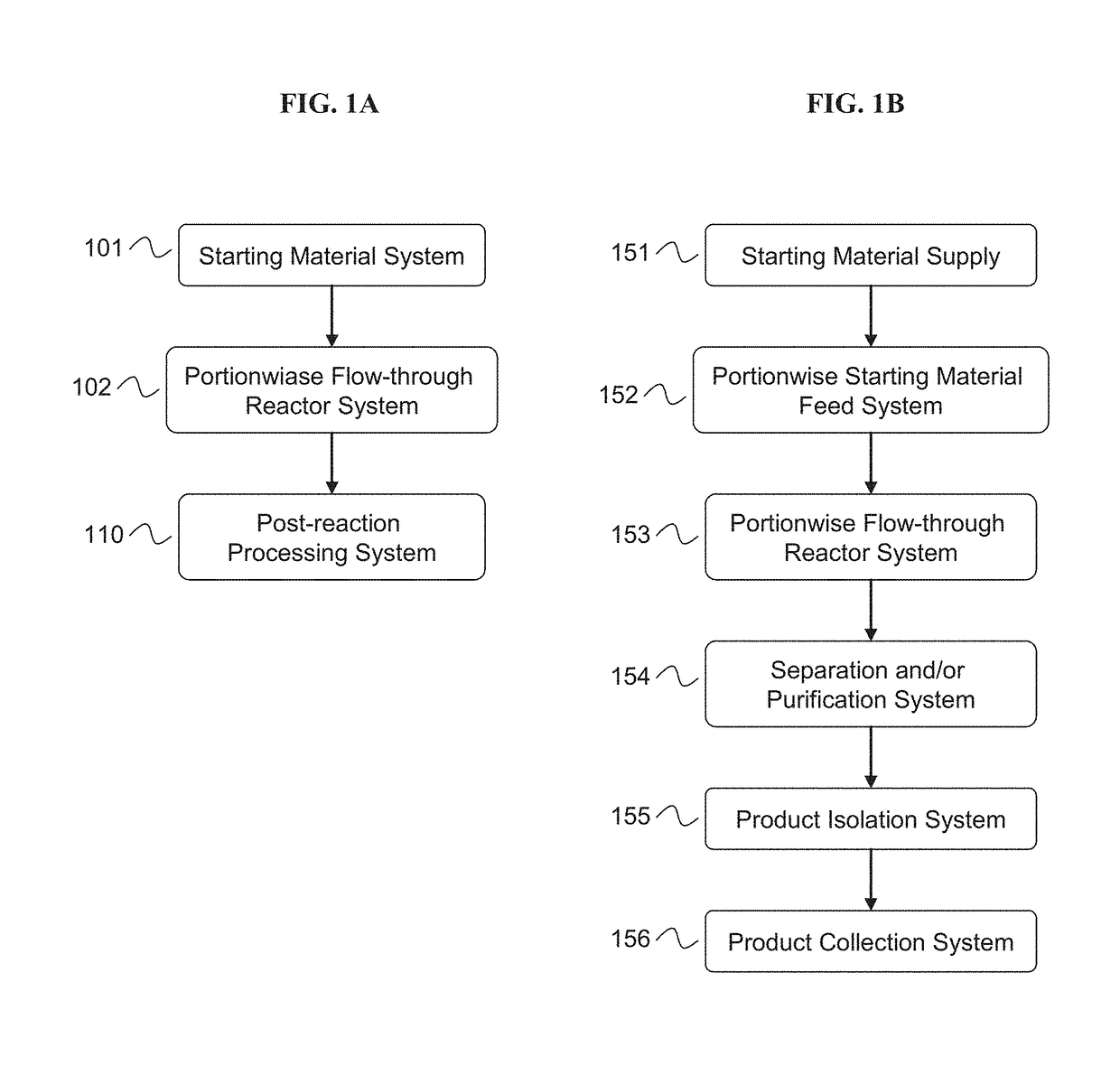

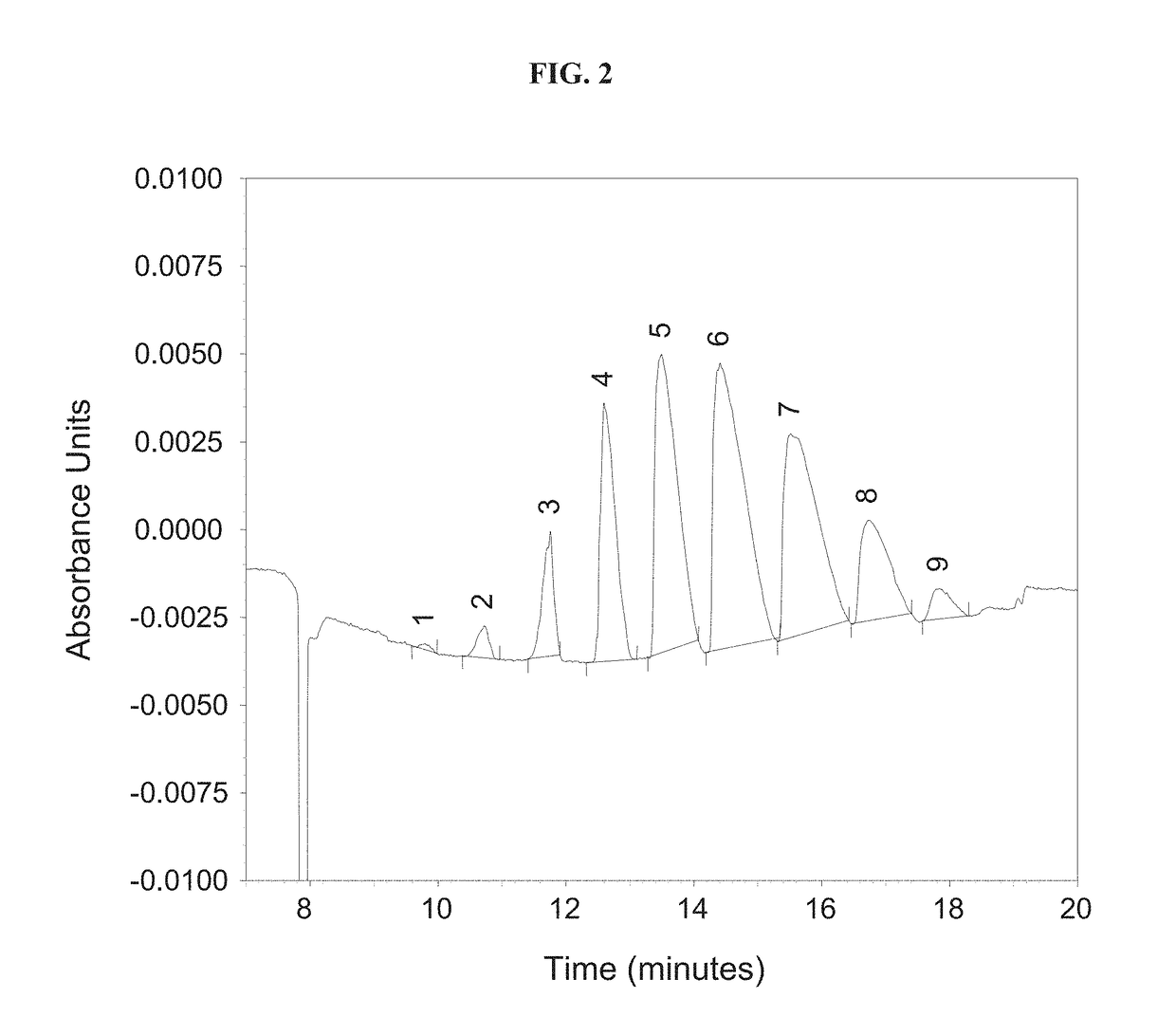

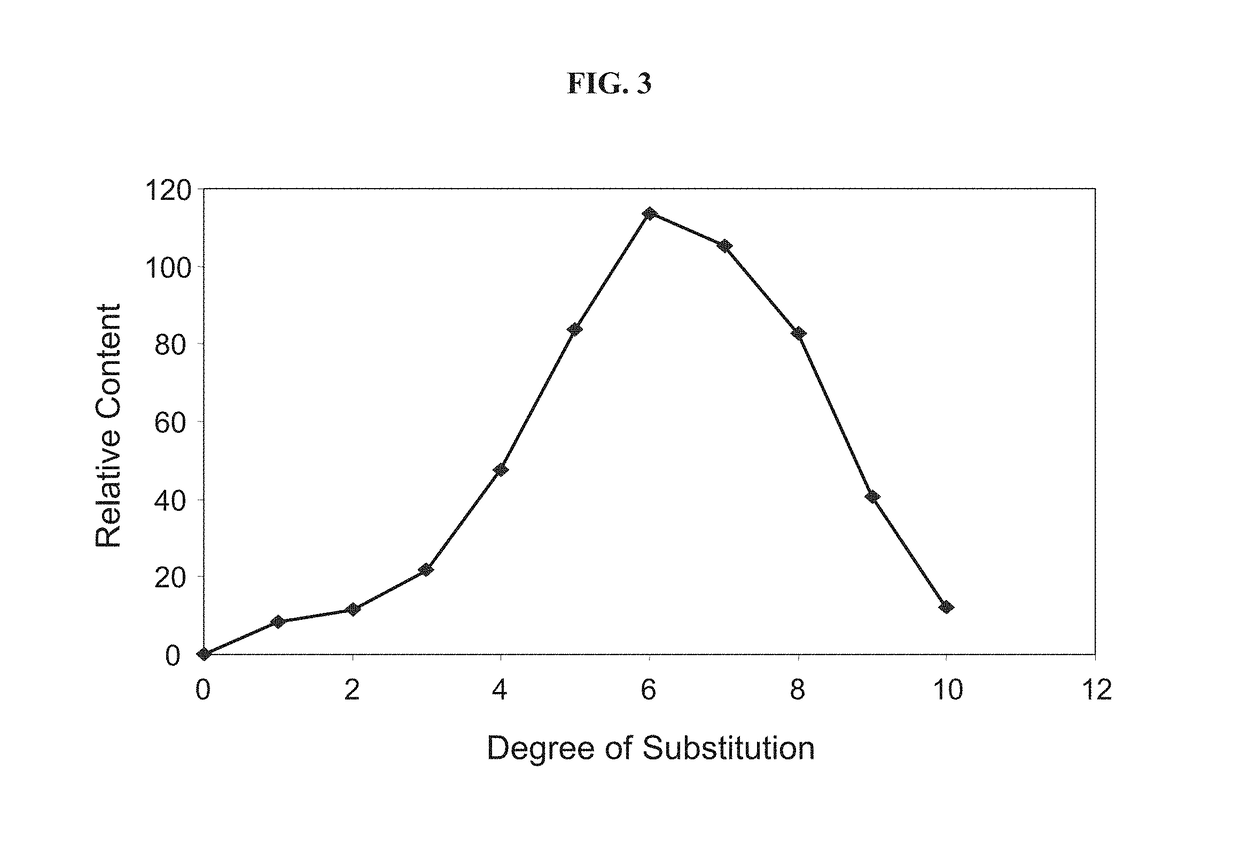

ActiveUS20160009826A1Rapid responseMinimize formationEther/acetal/ketal group formation/introductionSulfo/sulfonyldioxy group formation/introductionCyclodextrin DerivativesSide product

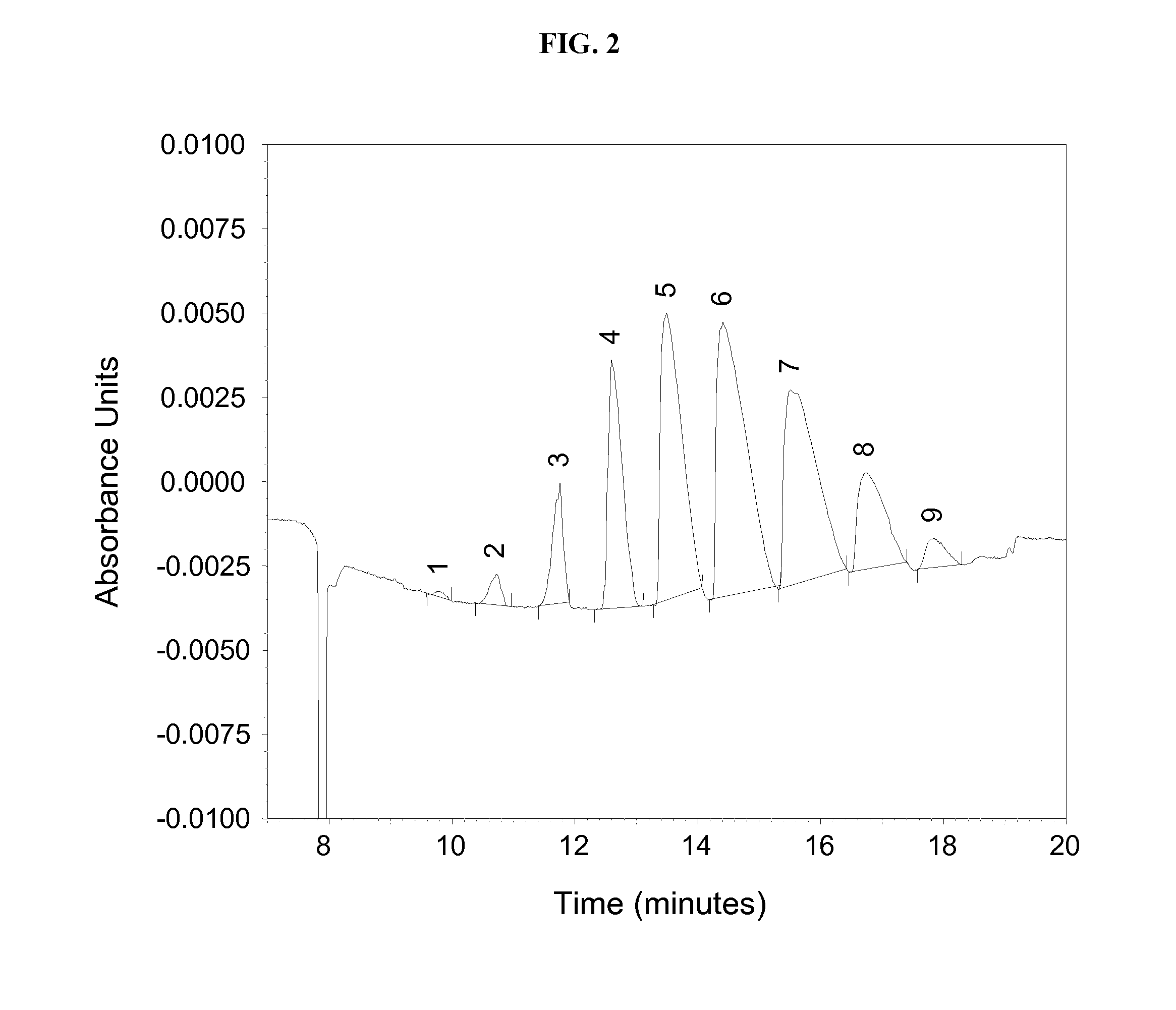

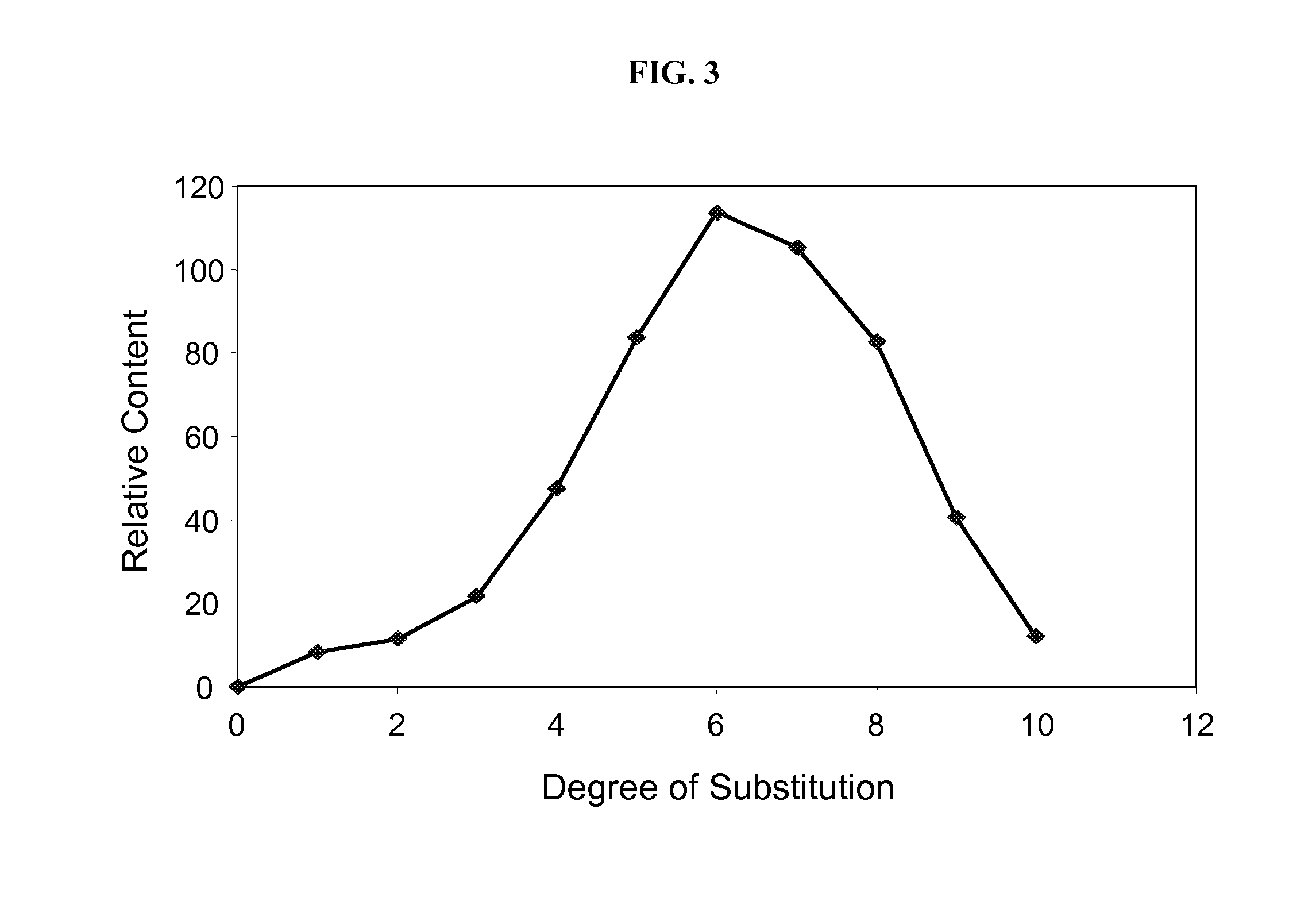

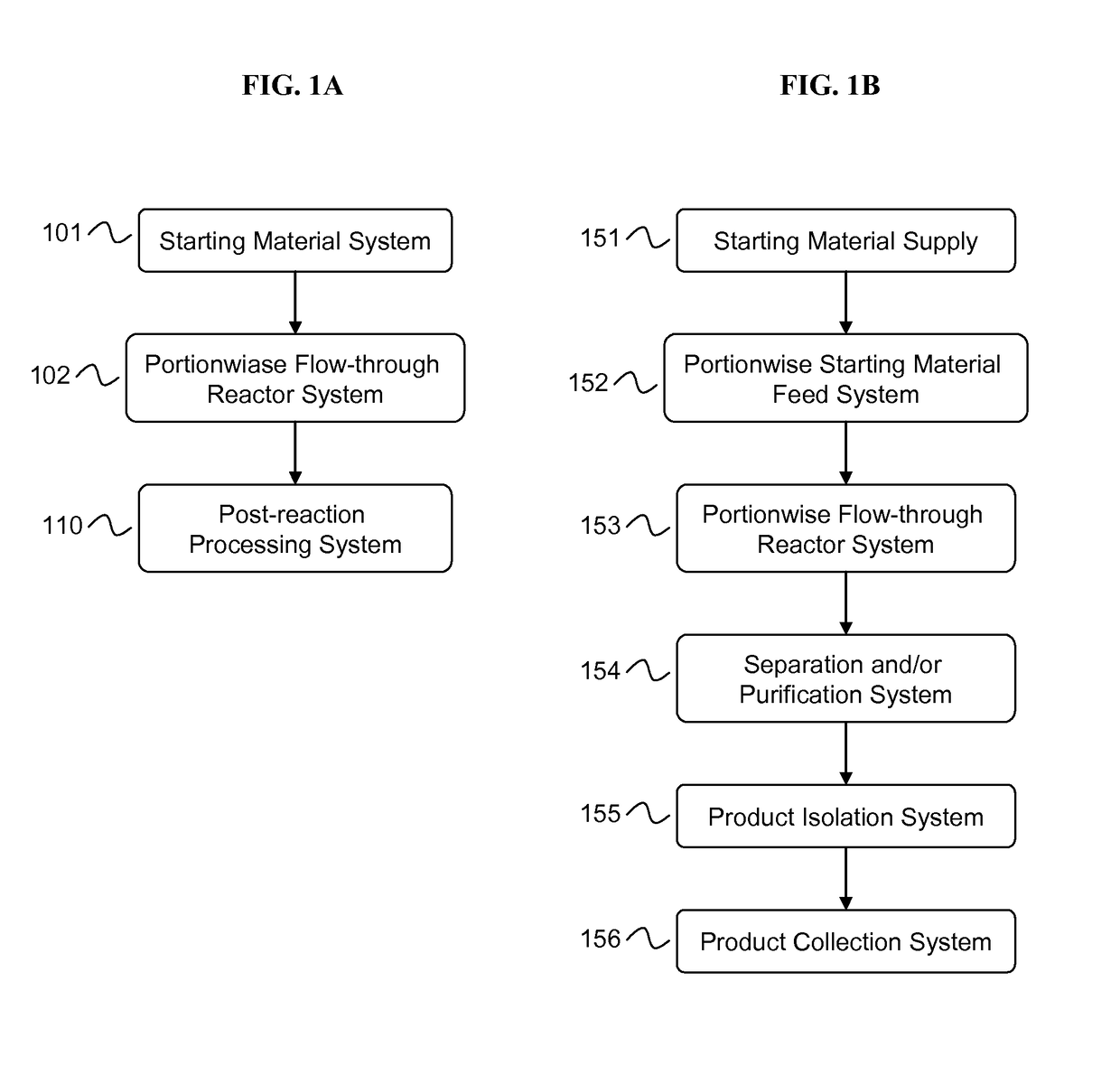

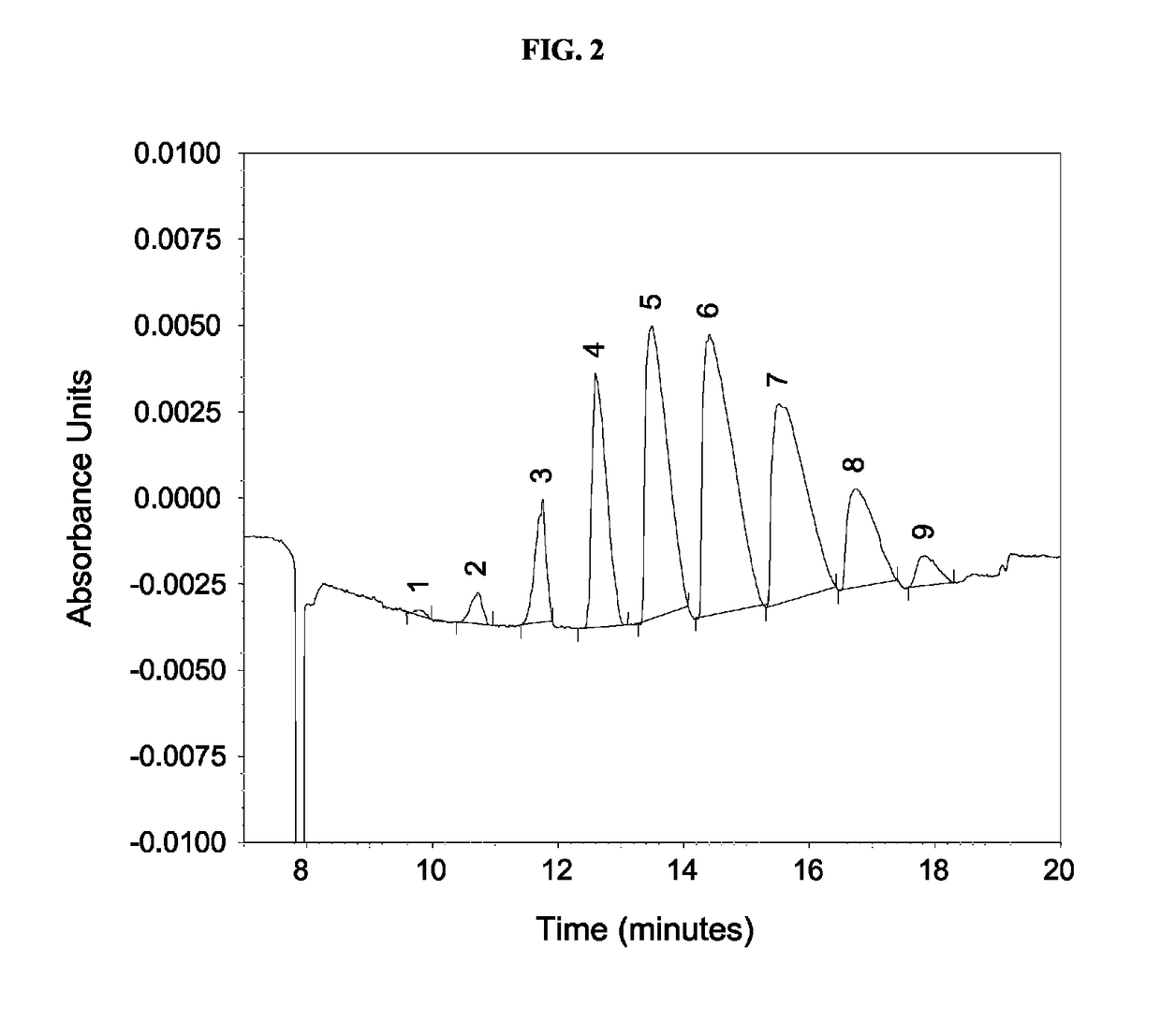

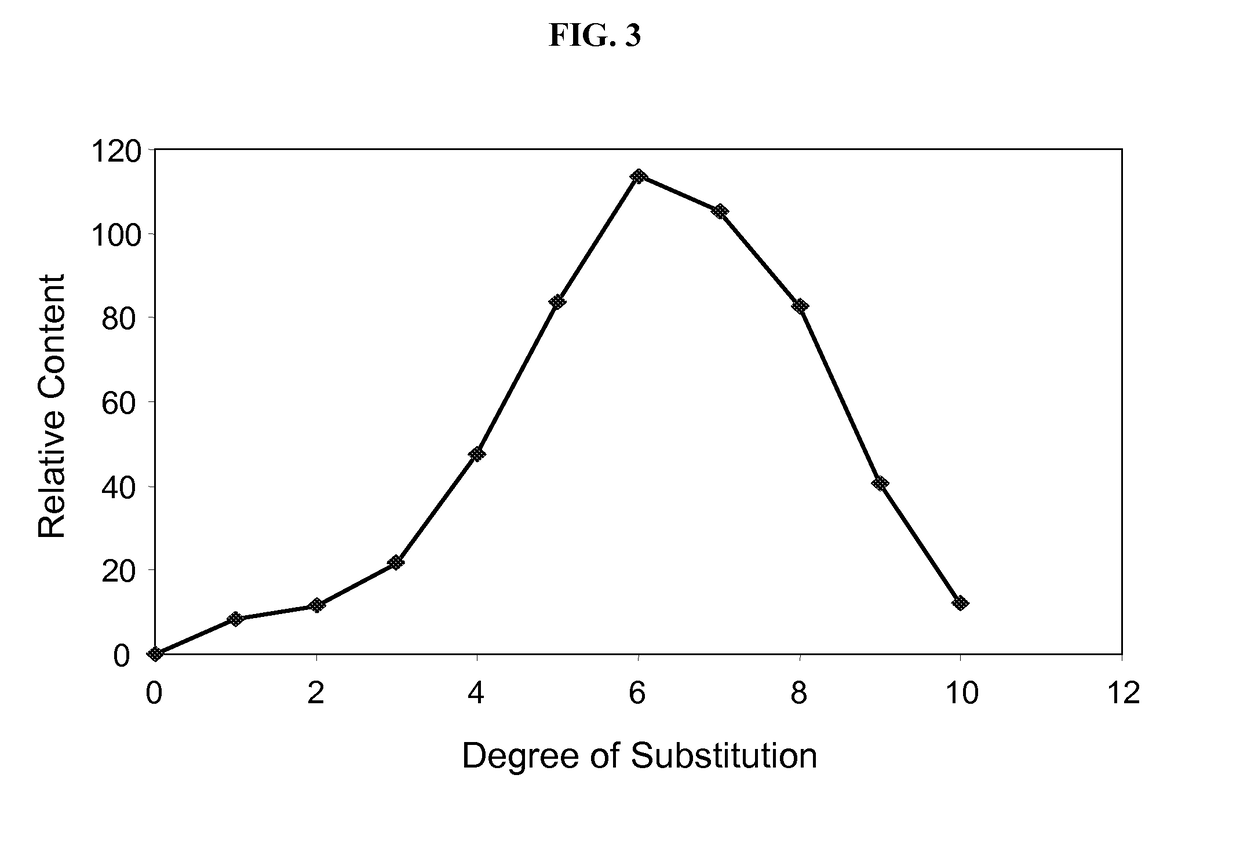

A process and equipment assembly for reacting a substituent precursor with a cyclodextrin starting material to provide a raw product comprising a cyclodextrin derivative and 1% or less of an initial amount of the substituent precursor is provided, The process of the present invention provides cyclodextrin derivatives in substantially shorter time and with fewer side products than previous processes that utilize substantially the same starting materials.

Owner:CYDEX PHARMACEUTICALS INC

Manufacturing process for cyclodextrin derivatives

ActiveUS9751957B2Rapid responseMinimize formationEther/acetal/ketal group formation/introductionSulfo/sulfonyldioxy group formation/introductionCyclodextrin DerivativesSide product

A process and equipment assembly for reacting a substituent precursor with a cyclodextrin starting material to provide a raw product comprising a cyclodextrin derivative and 1% or less of an initial amount of the substituent precursor is provided. The process of the present invention provides cyclodextrin derivatives in substantially shorter time and with fewer side products than previous processes that utilize substantially the same starting materials.

Owner:CYDEX PHARMA INC

Method and device for the sulfonation or sulfation of sulfonatable or sulfatable organic substances and for preforming faster, strongly exothermic gas7liquid reactions

InactiveCN101321582AProcess control/regulationOrganic compound preparationSulfationGas liquid reaction

A method and a device for the sulfonation or the sulfation of organic liquid raw materials with an S03 / air mixture and other reaction gases in order to perform rapid, highly exothermic gas-liquid reactions in conventional thin-layer falling-film reactors are disclosed. The introduction of the S03 / air mixture occurs through several feed locations, which are located within (along) the reaction tube or reaction tubes or in the annular gap of annular-gap falling-film reactors. High peak temperatures, undesirable byproducts, worsening of the color and local oversulfation or oversulfonation, which leads to side reactions, are largely avoided.

Owner:CHEMITHON

Preparation method of heparinoid

ActiveCN104877042AThe synthesis process is simpleProduction operation is easy to controlSulfo/sulfonyldioxy group formation/introductionHeparinoidsSulfur trioxide

The invention discloses a preparation method of heparinoid. The preparation method comprises the following steps : adopting chondroitin sulfate as a raw material, and treating to obtain heparinoid after sulfonation reaction. In the sulfonation reaction, the adopted solvent is formamide and the adopted sulfonating agent is free sulfur trioxide, fuming sulfuric acid or pyridine sulfur trioxide. The preparation method of heparinoid, disclosed by the invention, has the advantages that the synthesis process is simple, the production and the operation are easily controlled, no special requirement exists for production equipment, the molecular weight range of a product is stable, the physicochemical indexes of the product are controlled in the quality standard range, and simultaneously the product is high in yield and the method is suitable for large-scale industrial production.

Owner:ZHEJIANG SANMEN HYGECON PHARMA CO LTD

Manufacturing process for cyclodextrin derivatives

ActiveUS20180051098A1Rapid responseMinimize formationEther/acetal/ketal group formation/introductionSulfo/sulfonyldioxy group formation/introductionCyclodextrin DerivativesSide product

A process and equipment assembly for reacting a substituent precursor with a cyclodextrin starting material to provide a raw product comprising a cyclodextrin derivative and 1% or less of an initial amount of the substituent precursor is provided. The process of the present invention provides cyclodextrin derivatives in substantially shorter time and with fewer side products than previous processes that utilize substantially the same starting materials.

Owner:CYDEX PHARMA INC

Preparation process of sulfonated solid particle

A process produces a sulfonated solid particle by burning sulfur to yield gaseous sulfur dioxide, subjecting the gaseous sulfur dioxide to catalytic oxidation to yield gaseous sulfur trioxide, and sulfonating a dry powdery or granular solid particle with the gaseous sulfur trioxide in a gas phase-solid phase reaction.

Owner:DAINICHISEIKA COLOR & CHEM MFG CO LTD

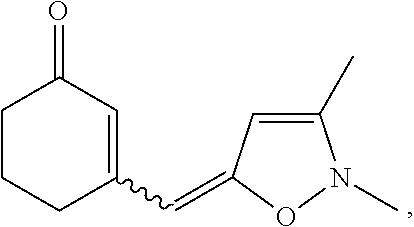

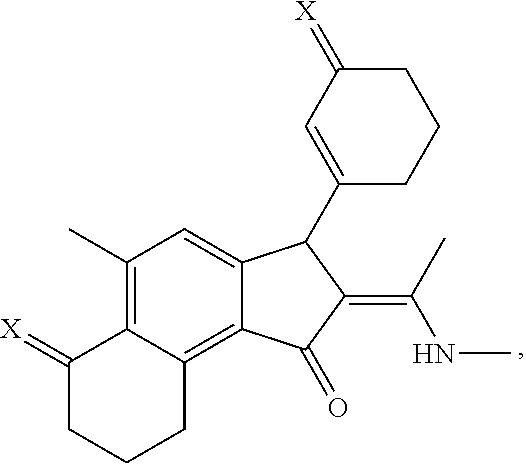

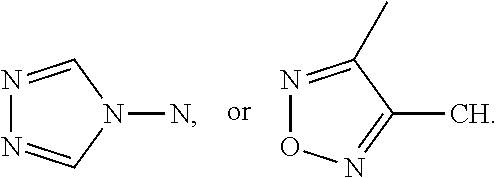

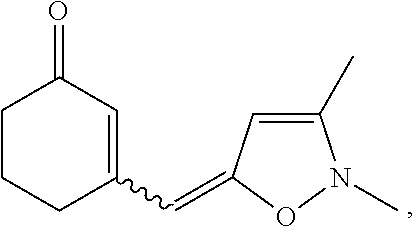

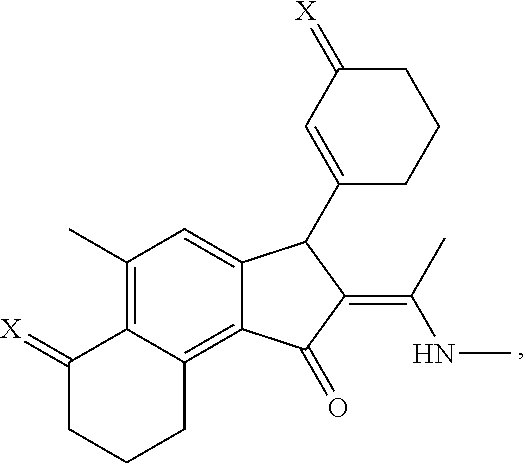

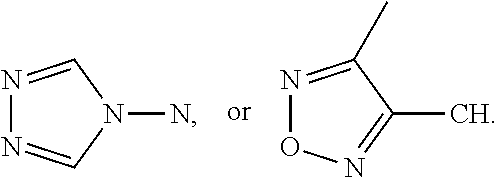

Azasteroidal Mimics

ActiveUS20180155299A1Useful biological propertyAmino group formation/introductionEndocrine system disorderHydrazoneCyclohexenone

An azasteroid mimic or an intermediate for the preparation of an azasteroid and azasteroid mimic is formed via an oxocycloalkenyl isoxazolium anhydrobase and its dimer. The dimer can be used to form mono- and dihydrazones, which can be an azasteroid mimic or an intermediate for the preparation of an azasteroid and azasteroid mimic. A method of preparation of the dimer and the azasteroid mimic or an intermediate for the preparation of an azasteroid and azasteroid mimic occurs with hydrazonation and, optionally, a subsequent dehydrazonation. The dimer can be converted by inserting a nitrogen atom into the six membered ring of to a C-17 position cyclohexenone moiety of the dimer to yield a reduced tetrazolo[1,5-a]azepin-8-yl group. A subsequent hydrozone formation at a benzylic ketone can be carried out to generate an azasteroid mimic with a (triazol-4-yl)imino substituent. Monohydrazones can be converted to their thione equivalents.

Owner:FLORIDA INTERNATIONAL UNIVERSITY

Method for detecting process and end point of sulfur trioxide sulfonation

InactiveCN101692063AAccurate judgmentEasy to solveMaterial resistanceSulfonic acid preparationSulfur trioxideReagent

The invention discloses a method for detecting process and end point of sulfur trioxide sulfonation. The method comprises the following steps that: (1) a conductance-detecting electrode is inserted into reactant subjected to sulfonation; the conductance of the reactant is detected and displayed in real time; the conductance of the reactant decreases along with the process of sulfonation; and sulfur dioxide gas is adopted as a sulfonating agent in the sulfonation; and (2) when the conductance of the reactant is detected to decrease to zero, the sulfonation reaches the end for sure. The method has the advantages of tracking the process of the sulfonation in real time through the conductance change of sulfonation solution, accurately judging the end point of the sulfonation, reminding operators in real time, ensuring that reaction cannot exceed the end point, leaving out the trouble of chemical sampling detection and avoiding the phenomenon that the chemical sampling detection is not timely and accurate enough in results.

Owner:WUHAN QINGJIANG CHEM IND

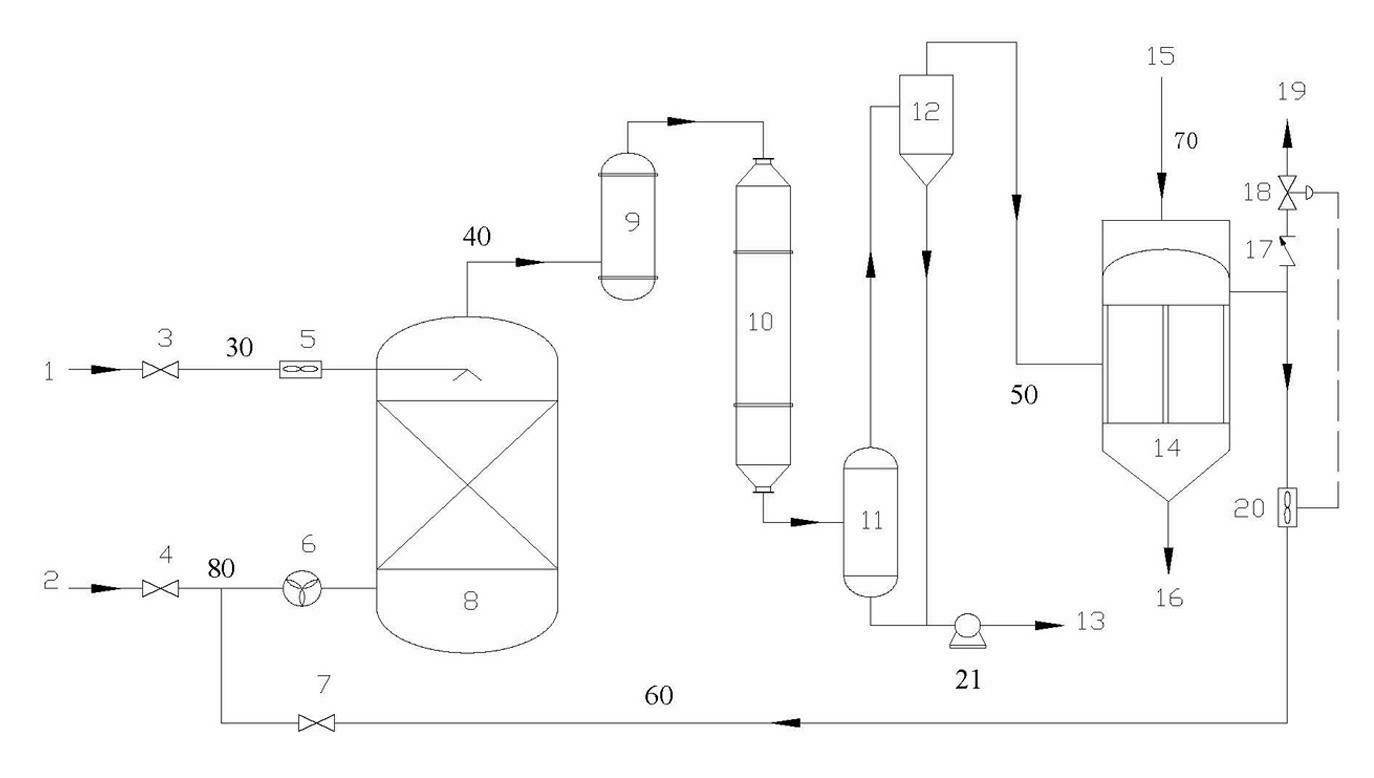

Sulfonated tail gas cycle-absorption method and cycle-absorption system

ActiveCN101670225BSmooth entryAvoid it happening againDispersed particle separationSulfo/sulfonyldioxy group formation/introductionSURFACTANT BLENDContact reaction

The invention relates to a novel process for cycle-absorbing and reusing sulfonated tail gas, belonging to the technical field of surfactant producing processes and aiming at providing a method which has reasonable design and simple operation and is suitable for the cycle-absorption and recovery of various sulfonated SO3 tail gases and a relative processing system. The technical solution of the invention comprises the following steps: A. mixture material resulted from the contact reaction of SO3 and organic material 1 in a sulfonator enters a gas liquid separation device; B. after the supplementary heating, the separated SO3 gas reacts with the organic material, and then a corresponding sulfonated product is generated; C. the sample of the generated sulfonated product is output for test; material discharge can be carried out upon the qualification, and the residual SO3 gas is discharged after the demisting; otherwise, the sulfonated product and the SO3 gas are subjected to a contact reaction again; and D. the residual SO3 gas output to a demister is output by the demister after being demisted, and then discharged after tail gas treatment.

Owner:ZANYU TECH GRP CO LTD

SO3 gas jetting sulfonation reactor and process

ActiveCN100584443CReasonable structureFlexible and easy to operateChemical/physical/physico-chemical nozzle-type rreactorsLiquid-gas reaction processesProduct gasProcess engineering

The SO3 gas jetting sulfonation reactor consists of a nozzle and a reactor kettle. The nozzle includes a gas jet, a liquid distributing cavity, an atomizing jet, a liquid material inlet and a gas mixture inlet. The nozzle is fixed in the top of the reactor kettle, the atomizing jet is stretched into inside of the reactor kettle, and the reactor kettle has product outlet in the lower end. The present invention is suitable for sulfonating different kinds of organic material, and has the advantages of reasonable structure, great operation flexibility, simple operation, easy material replacement, stable product quality, etc.

Owner:中轻化工绍兴有限公司

Method of improving sulfonation reaction efficiency and production method of dispersant MF

ActiveCN106810412AImprove reaction efficiencyLess quantityOrganic compound preparationTransportation and packagingOrganic chemistrySodium sulfate

The invention discloses a method of improving the sulfonation reaction efficiency. Sulfonation is promoted by removing water generated in a sulfonation reaction. The method is characterized by comprising the step: in a sulfonation reaction process, keeping constant pressure or vacuum, and introducing gas into a reaction system, wherein water in the reaction system is taken away as gas flows out. The invention also discloses a production method of a dispersant MF. With adoption of the sulfonation method, the dispersant MF product is obtained by means of condensation and neutral reactions. In the whole process, unmanageable solid wastes are not generated, the content of sodium sulfate of the obtained product is lower than 5%, and the product can resist 150 DEG C and meets the first grade standard.

Owner:ZHEJIANG QICAI ECO TECH CO LTD

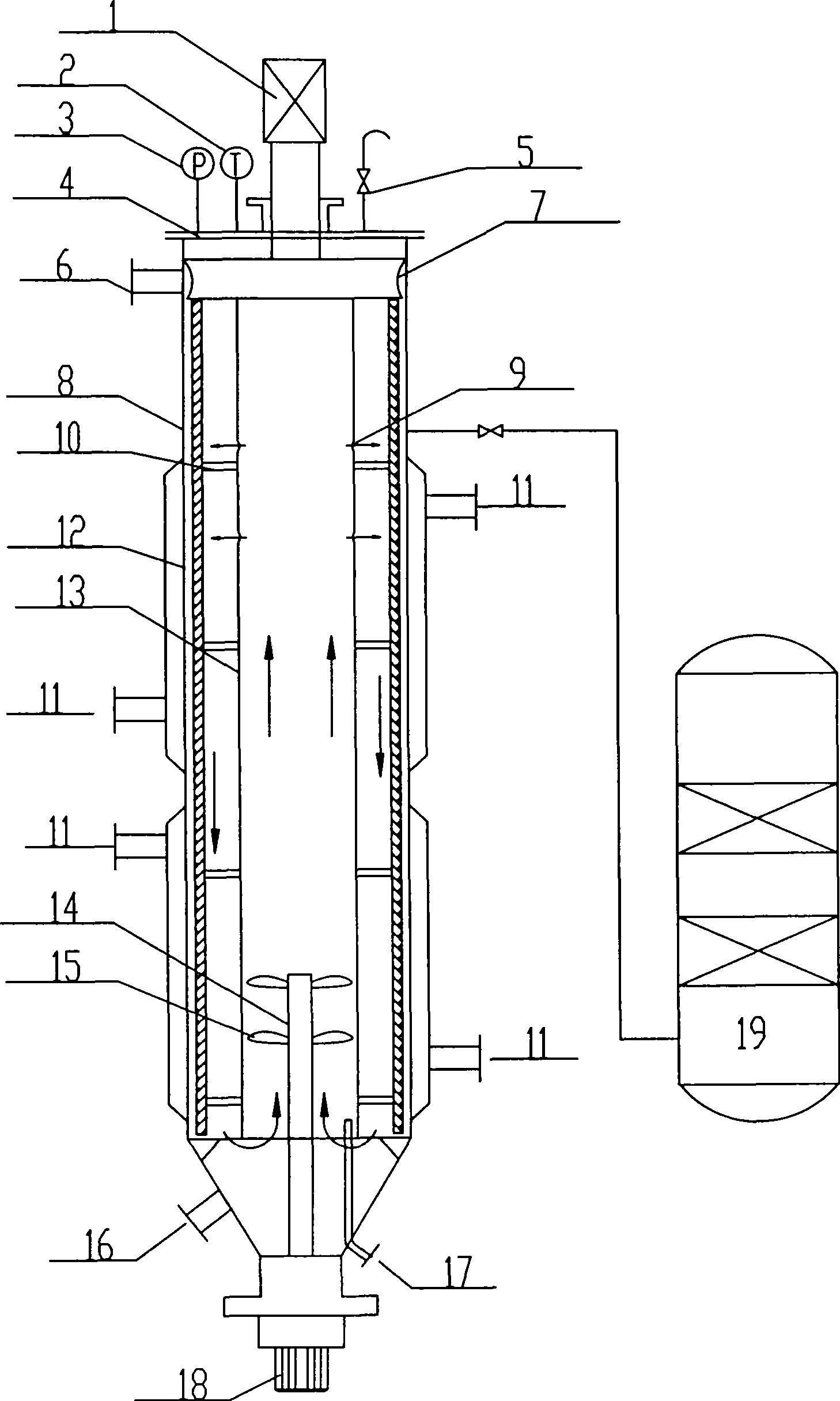

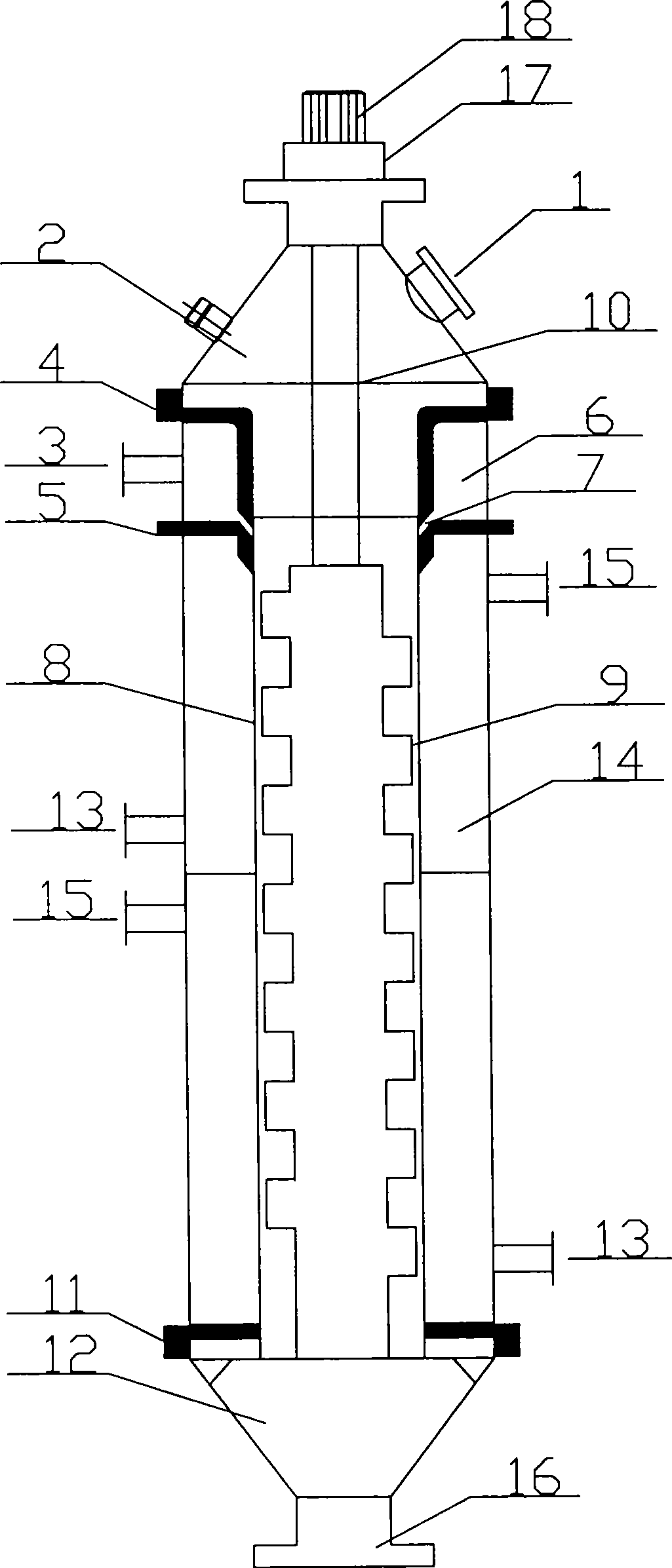

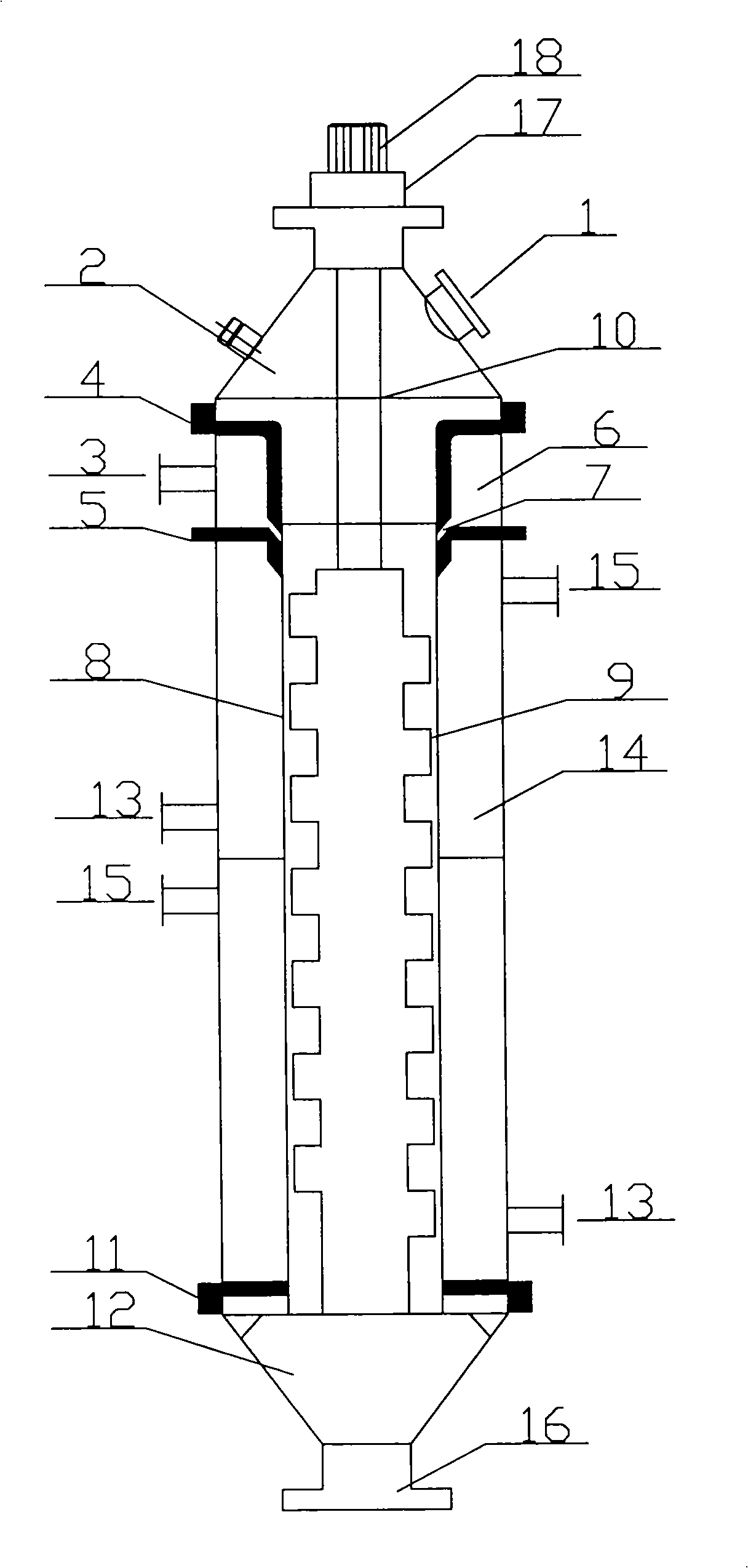

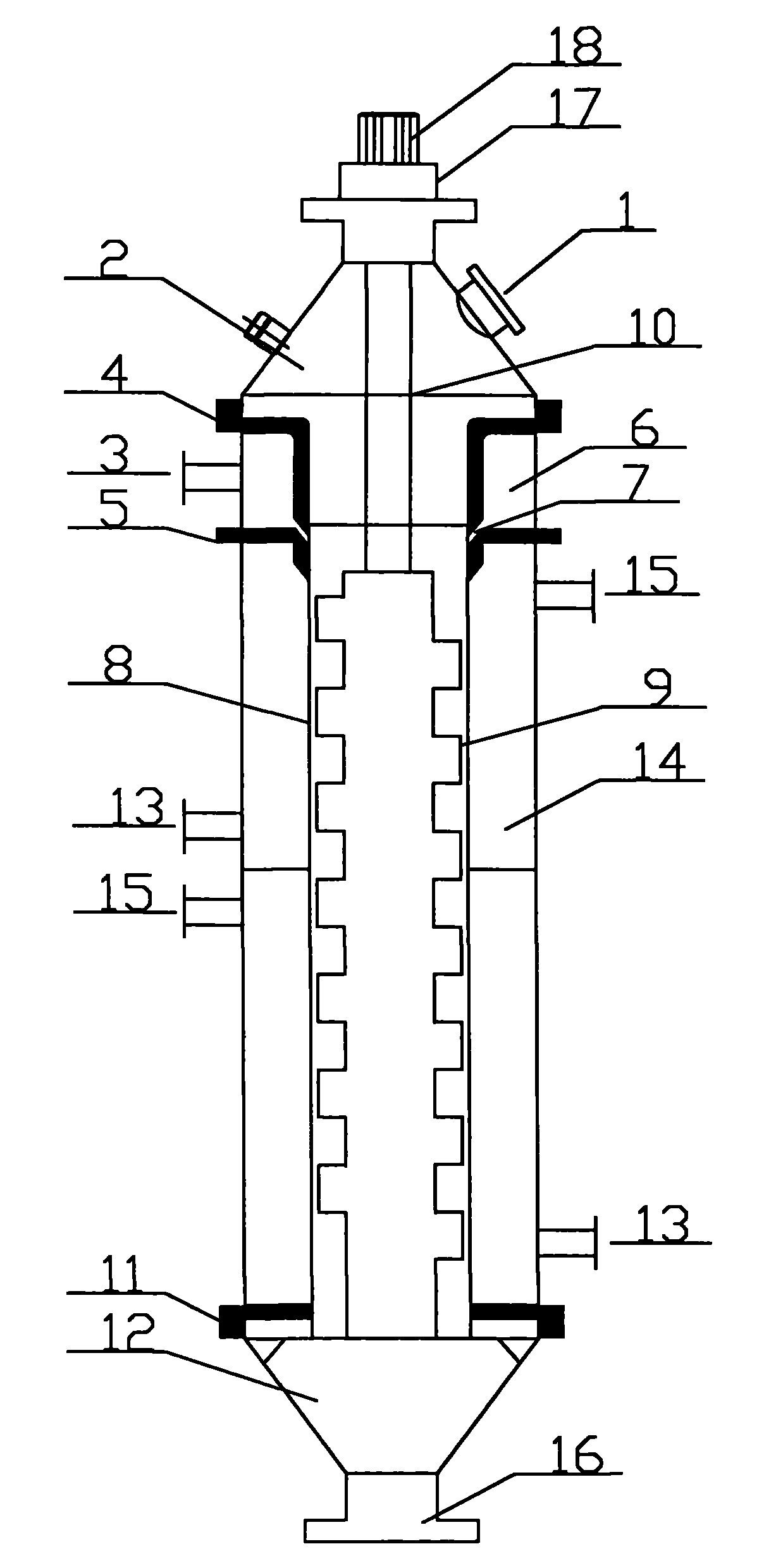

Scraped film type sulfonator

InactiveCN101474548AUniform responseAdequate responseLiquid-gas reaction of thin-film typeSulfonic acid preparationActive agentEngineering

The invention relates to a wiped-film sulfonator, belonging to the manufacturing technical field for a reaction device for producing an anion active agent through sulphonation or sulphation of gas SO3. The device comprises an orthostatic reaction cylinder body (8), a stirring shaft (10) with a scraping plate (9) arranged in the orthostatic reaction cylinder body (8), a lower tube plate (11) and an upper plate(5) with a sealed tube plate (4) which are arranged at the two ends of the orthostatic reaction cylinder body; an upper head (2) with a SO3 gas inlet (1) which is arranged at the upper part of the sealed tube plate, a lower head (12) with a reactant outlet (16) arranged at the lower part of the lower tube plate (11), a motor (18) with a reducer (17) which is connected with the stirring shaft (10) and fixed at the upper head (2) or the lower head (12) and 1-3 section cooling jackets (14) with a cooling water inlet (13) and a cooling water outlet (15) which is arranged at the periphery of the orthostatic reaction cylinder body (8), etc. The general structure is designed reasonably, the operation is flexible, the manufacture is easy and the investment is small.

Owner:ZANYU TECH GRP CO LTD

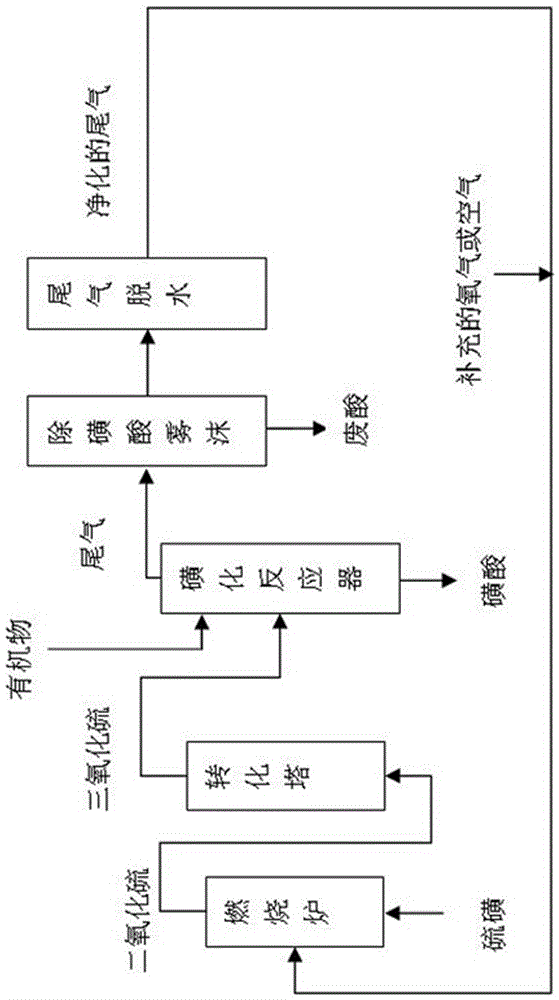

Method for recycling sulfonation tail gas

InactiveCN106044721AReduce pollutionReduce energy consumptionSulfur compoundsSulfo/sulfonyldioxy group formation/introductionCombustion systemSulfur

The invention relates to the technical field of sulfonation tail gas treatment, in particular to a method for recycling sulfonation tail gas, comprising the following steps: removing acidic oil mist carried in sulfonation-produced tail gas, dewatering, feeding the dewatered tail gas with supplemented oxygen or air into a sulfur combustion system to produce tail gas mainly composed of sulfur dioxide, further oxidizing the tail gas to obtain tail gas mainly composed of sulfur trioxide, and feeding the tail gas mainly composed of sulfur trioxide into a sulfonation system for sulfonation. The method for recycling sulfonation tail gas provided herein need not use alkaline liquid to absorb and remove sulfur dioxide in the tail gas, no waste liquid is produced, new pollution source due to the absorption by the alkaline is avoided, the tail gas may be recycled without emission, energy consumption is thereby reduced, environmental pollution is greatly reduced, and operation expenditure is also reduced; the method for treating sulfonation tail gas is more applicable to existing sulfonation production modes and has a promising application prospect.

Owner:新疆金塔投资(集团)有限公司

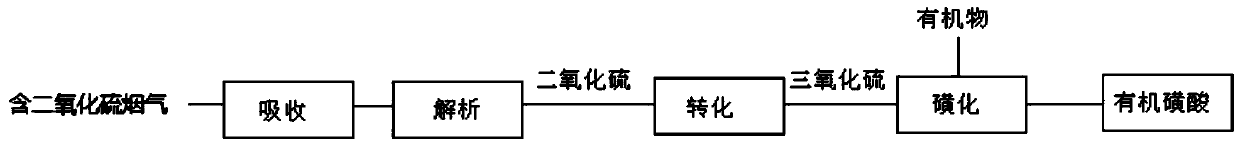

Method for preparing organic sulfonic acid by utilizing sulfur-containing fuel combustion flue gas

InactiveCN110606795AGreenEasy to industrializeGas treatmentDispersed particle separationOrganic sulfonic acidCombustion

The invention relates to a preparation method of organic sulfonic acid, in particular to a method for preparing organic sulfonic acid by utilizing sulfur-containing fuel combustion flue gas. Accordingto the method for preparing the organic sulfonic acid from the sulfur-containing fuel combustion flue gas, sulfur dioxide in the sulfur-containing fuel flue gas serves as a main raw material, the organic sulfonic acid is prepared through the processes of recovery, conversion and sulfonation. The method has the advantages of being economical, environmentally friendly and easy to industrialize.

Owner:孔繁昇 +1

Gas phase SO3 film-scrapping sulfonating technology

InactiveCN101445418BLess investmentReduce energy consumptionLiquid-gas reaction of thin-film typeSulfo/sulfonyldioxy group formation/introductionGas phaseProduct gas

The present invention relates to a gas phase SO3 film-scraping sulfonating technology which belongs to the technical field of production technology which prepares anionic surfactant by using gas phase SO3 film-scraping sulfonating liquid organic materials. The invention is carried out according to the following steps: A: liquid SO3 is vaporized to gas phase SO3, the gas phase SO3 is sucked in a mixer shaft through a turbo-blower, the gas phase SO3 is mixed with inert gases recycled in a sulfonating reactor to reaction gas with the volume concentration being 0.1 to 10 percent, and then the reaction gas goes into a reaction cylinder body through reaction gas distribution holes on the upper part of the scraping plate shaft; B: the organic materials go into the sulfonating reactor and downwards flow along the inner wall of the reaction cylinder body, a scraping plate is rotated along with the mixer shaft under the action of a transmission system, the organic materials are continuously suffered with film scaping-spread coating-film scaping in the inner wall of the reaction cylinder body, the organic material are alternately updated and uniformly coated on the inner wall of the reaction cylinder body, and the organic materials are completely contacted and reacted with the reaction gas which goes from the reaction gas distribution holes to form reaction products. The design of the technology is reasonable, and the invention can be suitable for sulfonating or sulphating materials with various viscosities.

Owner:ZANYU TECH GRP CO LTD

Preparation process of sulfonated solid particle

A process produces a sulfonated solid particle by burning sulfur to yield gaseous sulfur dioxide, subjecting the gaseous sulfur dioxide to catalytic oxidation to yield gaseous sulfur trioxide, and sulfonating a dry powdery or granular solid particle with the gaseous sulfur trioxide in a gas phase-solid phase reaction.

Owner:DAINICHISEIKA COLOR & CHEM MFG CO LTD

Sulfonated tail gas recycling method and sulfonated tail gas recycling system

ActiveCN102513039BEmission reductionLow investment costCombination devicesLiquid-gas reaction processesWastewaterProcess engineering

The present invention relates to a sulfonated tail gas recycling method and a sulfonated tail gas recycling system. The purpose of the present invention is to provide the method and the system, wherein the method and the system have characteristics of less waste gas discharge and less wastewater discharge, and the system has characteristics of reasonable structure, easy manufacture, and low cost. The technical scheme is that: the sulfonated tail gas recycling method comprises the following steps that: dry air enters the lower part of a sulfur trioxide evaporator, and is subjected to counter current contact with liquid sulfur trioxide entering the upper part of an vaporizing mixer so as to evaporate into the sulfur trioxide gas; the sulfur trioxide gas is cooled, enters a sulfonator, is subjected to a contact reaction with an organic material in the sulfonator, and then is output; the sulfonated tail gas is separated from the liquid, wherein the separated liquid material is output and enters a neutralization system, the separated sulfonation tail gas enters an electrostatic demister to carry out a demisting treatment, the partial discharged sulfonated tail gas enters an alkali washing processing system, and the remaining sulfonated tail gas is conveyed to the lower part of the sulfur trioxide mixing evaporator to recycle. The pipeline system of the sulfonated tail gas recycling system is arranged according to the method.

Owner:JIAXING ZANYU TECH DEV CO LTD

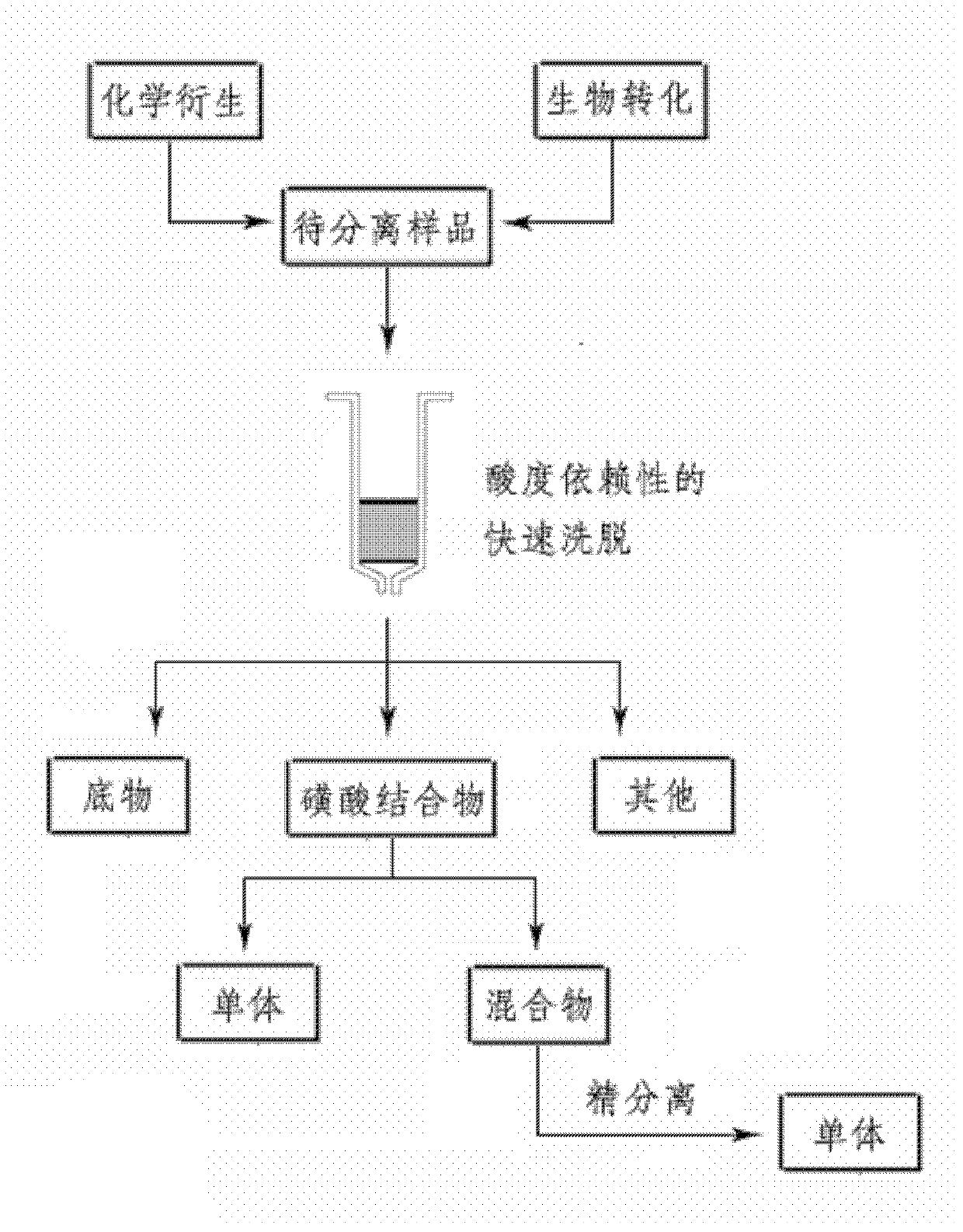

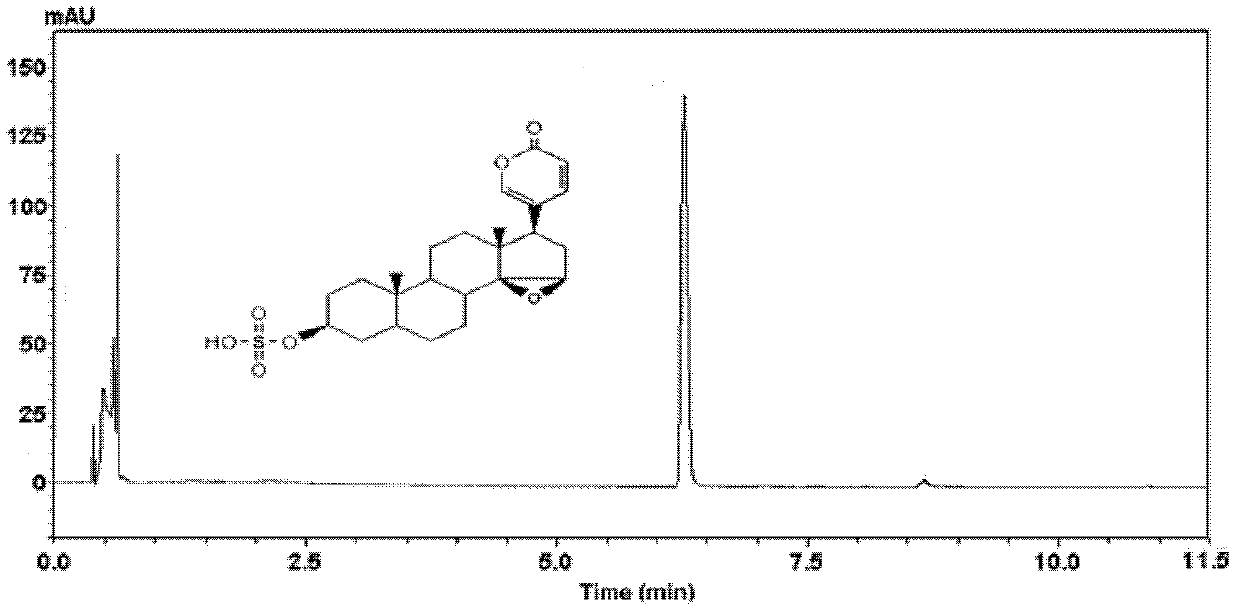

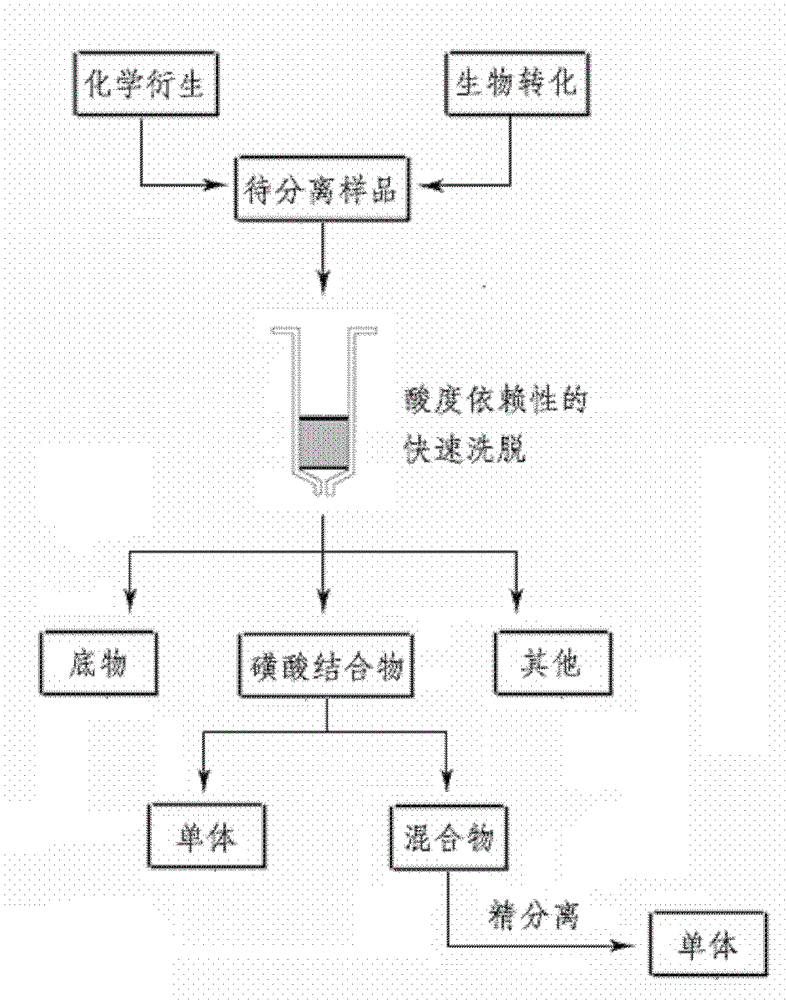

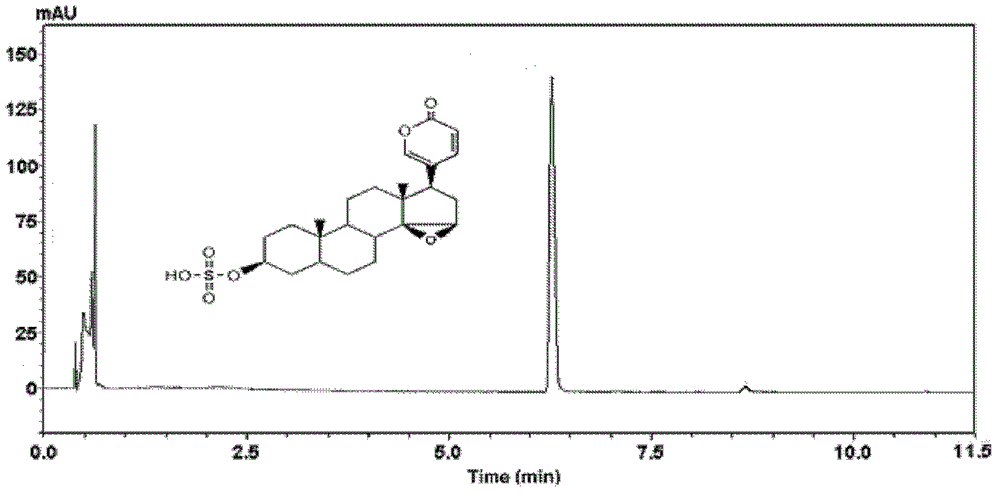

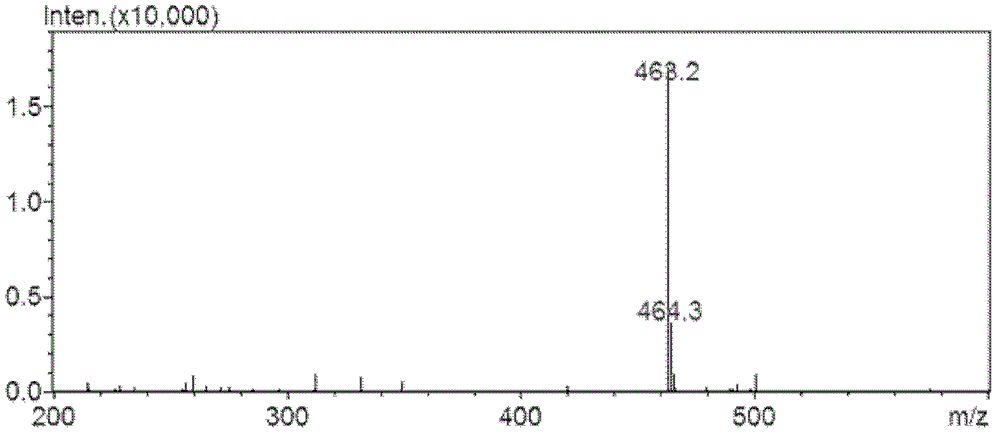

Separation method of sulfonic acid combination

ActiveCN103301653AEasy accessEasy to separateOrganic compounds purification/separation/stabilisationSolid sorbent liquid separationAlcoholChromatographic column

The invention discloses a separation method of a sulfonic acid combination. The separation method of the sulfonic acid combination comprises the following step of: separating the acidity dependence of a hydroxy compound as well as a sulfonic acid combination thereof rapidly by taking a mixture of a substrate of the hydroxy compound (containing phenolic hydroxyl group and alcoholic hydroxyl group) after chemical derivation or biological conversion as raw materials in virtue of chromatographic columns filled by composite materials, and meanwhile through utilizing eluents with different pH values. The separation method of the sulfonic acid combination provided by the invention has wide application in preparing the sulfonic acid combination, and is suitable for the purification and preparation of all sulfonic acid combinations which contain phenolic (alcohol) hydroxyl group, but not contain acidity groups.

Owner:ZHANGJIAGANG IND TECH RES INST CO LTD DALIAN INST OF CHEM PHYSICS CHINESE ACADEMY OF SCI

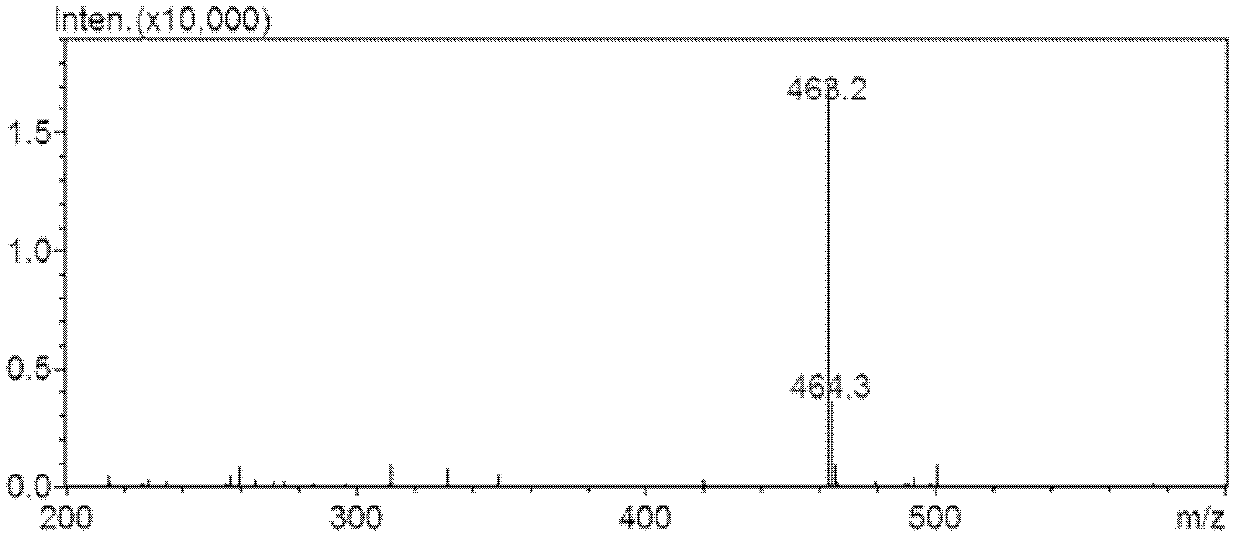

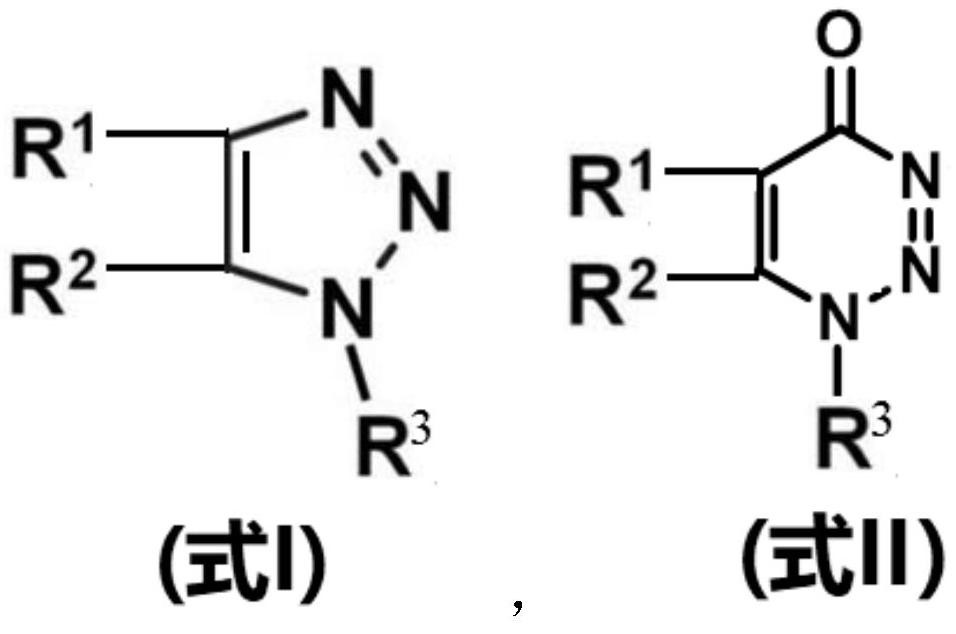

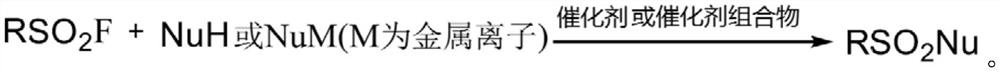

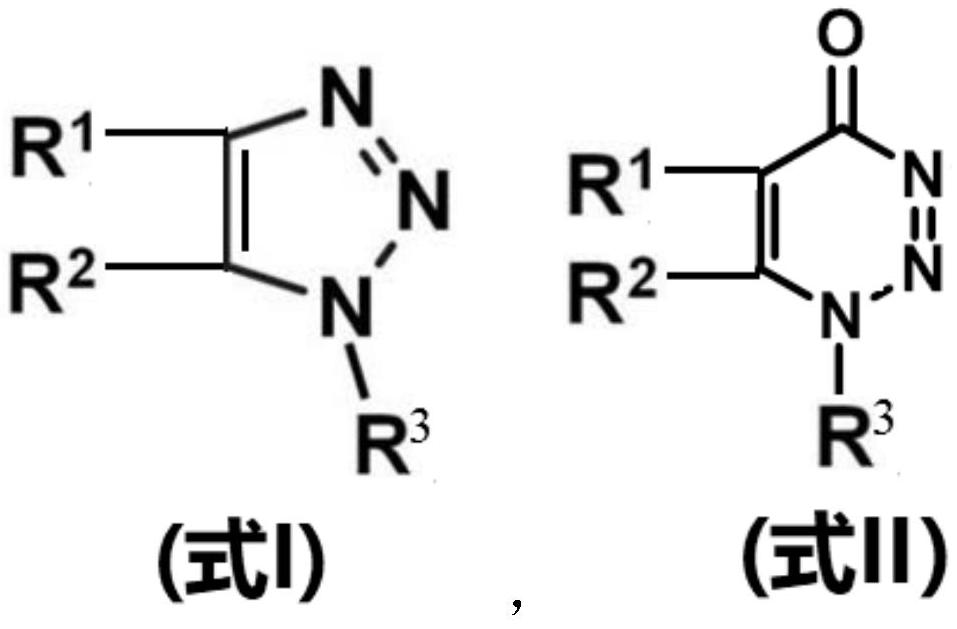

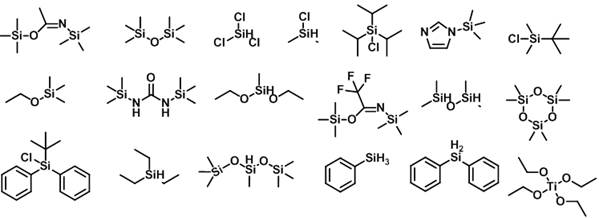

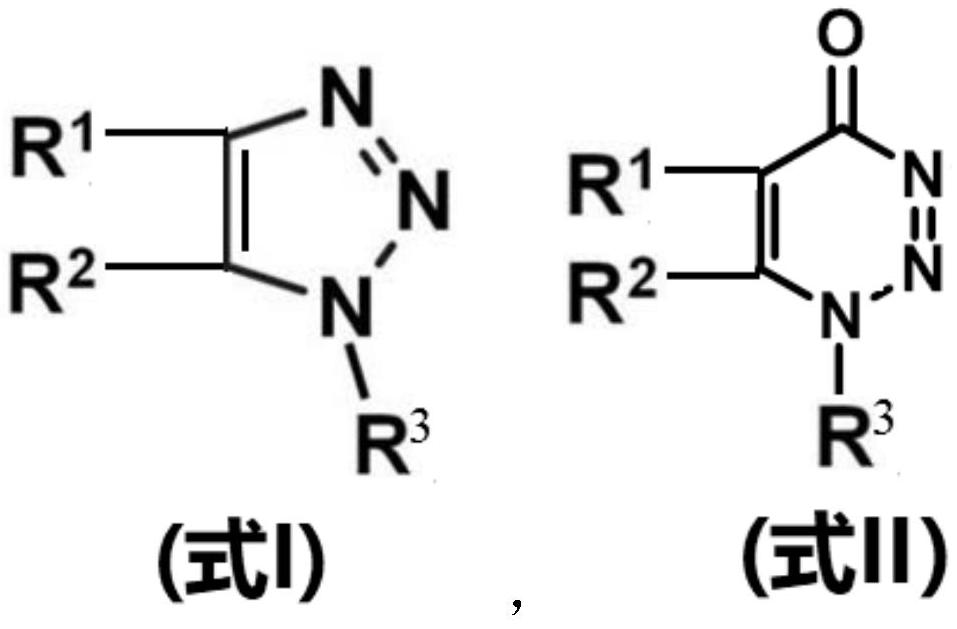

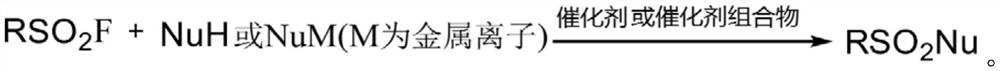

Catalyst composition and use of catalyst composition or catalyst for catalyzing nucleophilic substitution reaction

ActiveCN112121852AHigh reactivityWide range of substratesSulfonyl/sulfinyl group formation/introductionGroup 5/15 element organic compoundsPtru catalystCombinatorial chemistry

The present invention provides a catalyst composition comprising: (a) at least one catalyst, (b) at least one silicon additive, and (c) an optional base. The invention also provides a use of the catalyst composition or catalyst according to the invention for catalyzing a nucleophilic substitution reaction of a SO2F group-containing compound with a nucleophilic agent. The catalyst or the catalyst composition according to the present invention is capable of sufficiently activating a SO2F group-containing compound and a nucleophilic reagent, thereby enabling the compound and the nucleophilic reagent to efficiently perform a nucleophilic substitution reaction. In addition, the nucleophilic substitution reaction using the catalyst composition or the catalyst is simple and convenient to operate,the yield is high, and the catalyst composition or the catalyst is suitable for large-scale production.

Owner:SUN YAT SEN UNIV

Method and device for the sulfonation or sulfation of sulfonatable or sulfatable organic substances and for performing faster, strongly exothermic gas/liquid reactions

InactiveCN101321582BProcess control/regulationOrganic compound preparationSulfationGas liquid reaction

A method and a device for the sulfonation or the sulfation of organic liquid raw materials with an S03 / air mixture and other reaction gases in order to perform rapid, highly exothermic gas-liquid reactions in conventional thin-layer falling-film reactors are disclosed. The introduction of the S03 / air mixture occurs through several feed locations, which are located within (along) the reaction tube or reaction tubes or in the annular gap of annular-gap falling-film reactors. High peak temperatures, undesirable byproducts, worsening of the color and local oversulfation or oversulfonation, which leads to side reactions, are largely avoided.

Owner:CHEMITHON

A kind of preparation method of heparin

ActiveCN104877042BThe synthesis process is simpleProduction operation is easy to controlSulfo/sulfonyldioxy group formation/introductionOleumBiochemical engineering

Owner:ZHEJIANG SANMEN HYGECON PHARMA CO LTD

Method for detecting process and end point of sulfur trioxide sulfonation

InactiveCN101692063BAccurate judgmentEasy to solveMaterial resistanceSulfonic acid preparationSulfur trioxideReagent

Owner:WUHAN QINGJIANG CHEM IND

A kind of separation method of sulfonic acid conjugate

ActiveCN103301653BSimple and efficient operationSuitable for separationOrganic compounds purification/separation/stabilisationSolid sorbent liquid separationAlcoholChromatographic column

The invention discloses a separation method of a sulfonic acid combination. The separation method of the sulfonic acid combination comprises the following step of: separating the acidity dependence of a hydroxy compound as well as a sulfonic acid combination thereof rapidly by taking a mixture of a substrate of the hydroxy compound (containing phenolic hydroxyl group and alcoholic hydroxyl group) after chemical derivation or biological conversion as raw materials in virtue of chromatographic columns filled by composite materials, and meanwhile through utilizing eluents with different pH values. The separation method of the sulfonic acid combination provided by the invention has wide application in preparing the sulfonic acid combination, and is suitable for the purification and preparation of all sulfonic acid combinations which contain phenolic (alcohol) hydroxyl group, but not contain acidity groups.

Owner:ZHANGJIAGANG IND TECH RES INST CO LTD DALIAN INST OF CHEM PHYSICS CHINESE ACADEMY OF SCI

Scraped film type sulfonator

InactiveCN101474548BUniform responseAdequate responseLiquid-gas reaction of thin-film typeSulfonic acid preparationActive agentEngineering

Owner:ZANYU TECH GRP CO LTD

Azasteroidal mimics

Owner:FLORIDA INTERNATIONAL UNIVERSITY

Catalyst composition and use of catalyst composition or catalyst for catalyzing nucleophilic substitution reactions

ActiveCN112121852BHigh reactivityWide range of substratesSulfonyl/sulfinyl group formation/introductionOrganic-compounds/hydrides/coordination-complexes catalystsPtru catalystCombinatorial chemistry

The present invention provides a catalyst composition comprising: (a) at least one catalyst, (b) at least one silicon additive, and (c) optionally a base. The present invention also provides the catalyst composition or catalyst according to the present invention for catalyzing 2 Use of a nucleophilic substitution reaction of a compound of the F group with a nucleophile. Catalyst or catalyst composition according to the present invention can fully activate the 2 F group compounds and nucleophiles, so that they can efficiently carry out nucleophilic substitution reactions. In addition, the nucleophilic substitution reaction using the catalyst composition or catalyst according to the present invention is easy to operate, has high yield, and is suitable for large-scale production.

Owner:SUN YAT SEN UNIV

Popular searches

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com