Preparation process of sulfonated solid particle

A solid particle, sulfonation technology, applied in the formation/introduction of sulfonic acid group/dihydroxysulfonyl group, dyeing low molecular organic compound treatment, thin material treatment, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0058] A total of 100 parts of powdered carbon black pigment (average particle diameter: 0.013 μm) was predried in a drier at 150° C. for 1 hour, and then placed in a reactor. The sulfur is burned separately to produce gaseous sulfur dioxide, which is catalytically oxidized to produce gaseous sulfur trioxide. A mixture of dry air and gaseous sulfur trioxide heated at 80° C. to 110° C. was fed into the reactor, wherein the concentration of gaseous sulfur trioxide was 8% relative to the dry air, followed by sulfonation for 2 hours. The reaction mixture was cooled, and the sulfonated carbon black was placed in ion-exchanged water, stirred, and then filtered. This washing step is repeated until the pH becomes constant. These filtrates were neutralized with 10% aqueous sodium hydroxide, which required 16.9 parts of sodium hydroxide, based on pure substance. This shows that the content of sulfur trioxide adsorbed by the sulfonated pigment is 20.7 parts in terms of sulfuric acid. ...

Embodiment 2

[0061] A sulfonated pigment was prepared in the same manner as in Example 1, except that 100 parts of C.I. Pigment Red 122 (hereinafter "C.I." in the pigment name will be omitted) (average particle diameter: 0.1 μm) was used instead of carbon black paint. In this method, after sulfonation, 24 parts of sodium hydroxide need to be neutralized and washed. This indicates that the content of sulfur trioxide adsorbed by the sulfonated pigment was 29.4 parts in terms of sulfuric acid. After drying, 104.5 parts of sulfonated pigment were obtained. The unit mass of sulfonated pigment contains 3.9% sulfo groups, which means that about 0.15 sulfo groups are incorporated into each molecule of pigment.

Embodiment 3~13

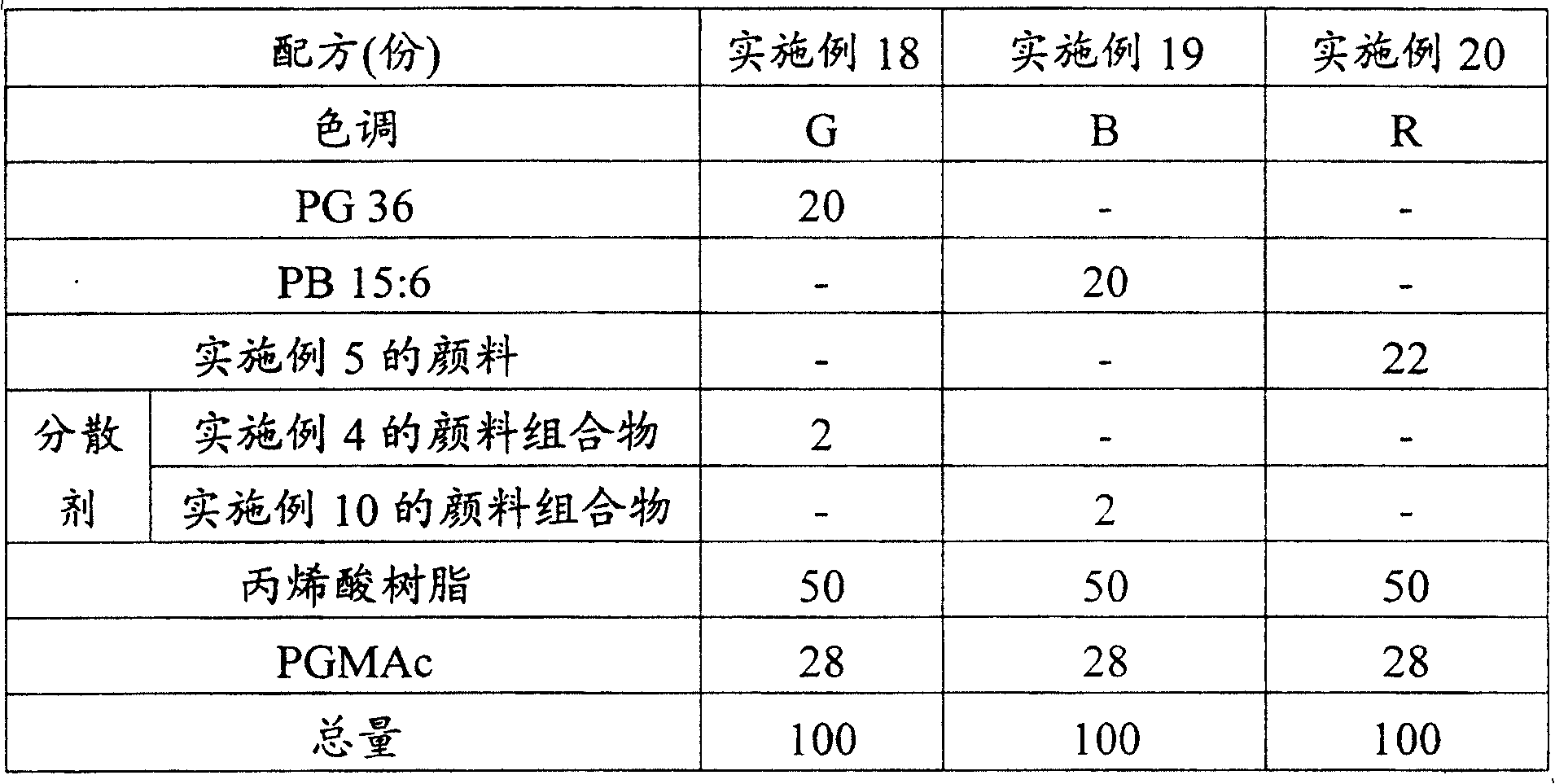

[0063] In the same manner as in Example 1, the yellow pigments, red pigments, blue pigments, purple pigments and black pigments listed in Table 1 were sulfonated. Table 1 lists the sulfonation results. For organic pigments other than carbon black pigments, the number of sulfo groups per molecule of pigment is also given.

[0064] Table 1

[0065] Example

[0066] *: Commercially available from Dainchiseika Color & Chemicals Mfg. Co., Ltd.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com