Patents

Literature

65results about How to "Suitable for separation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

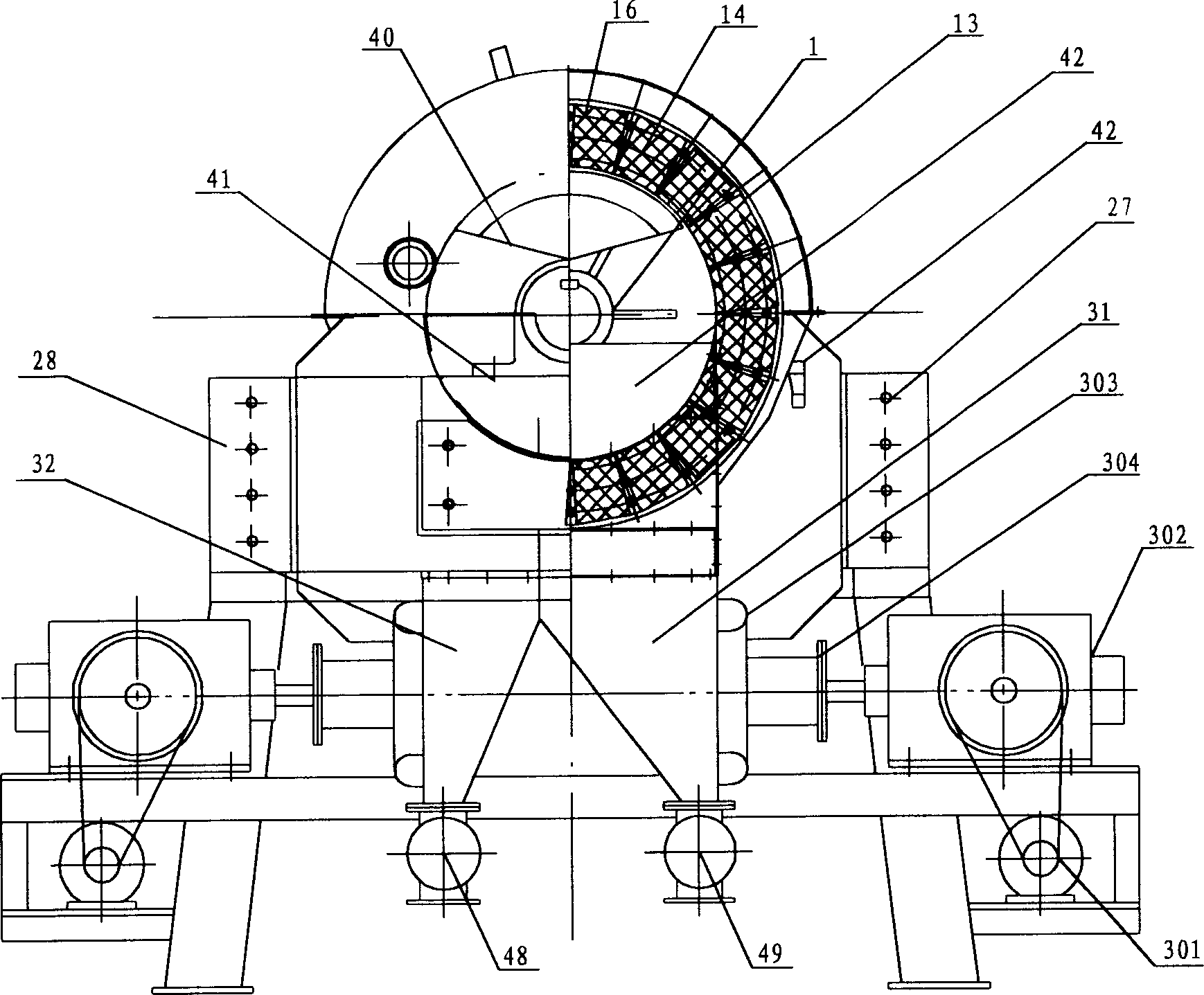

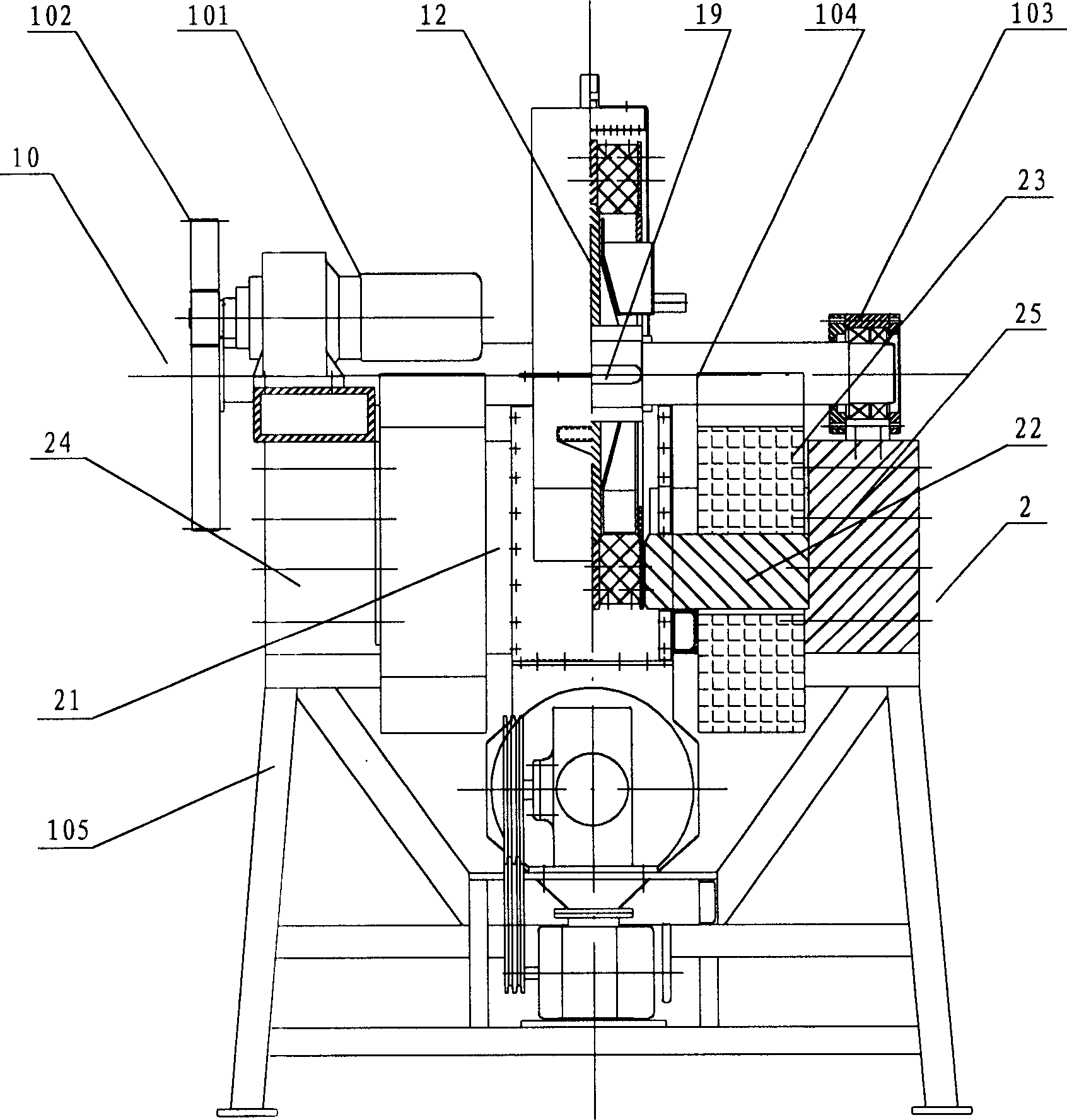

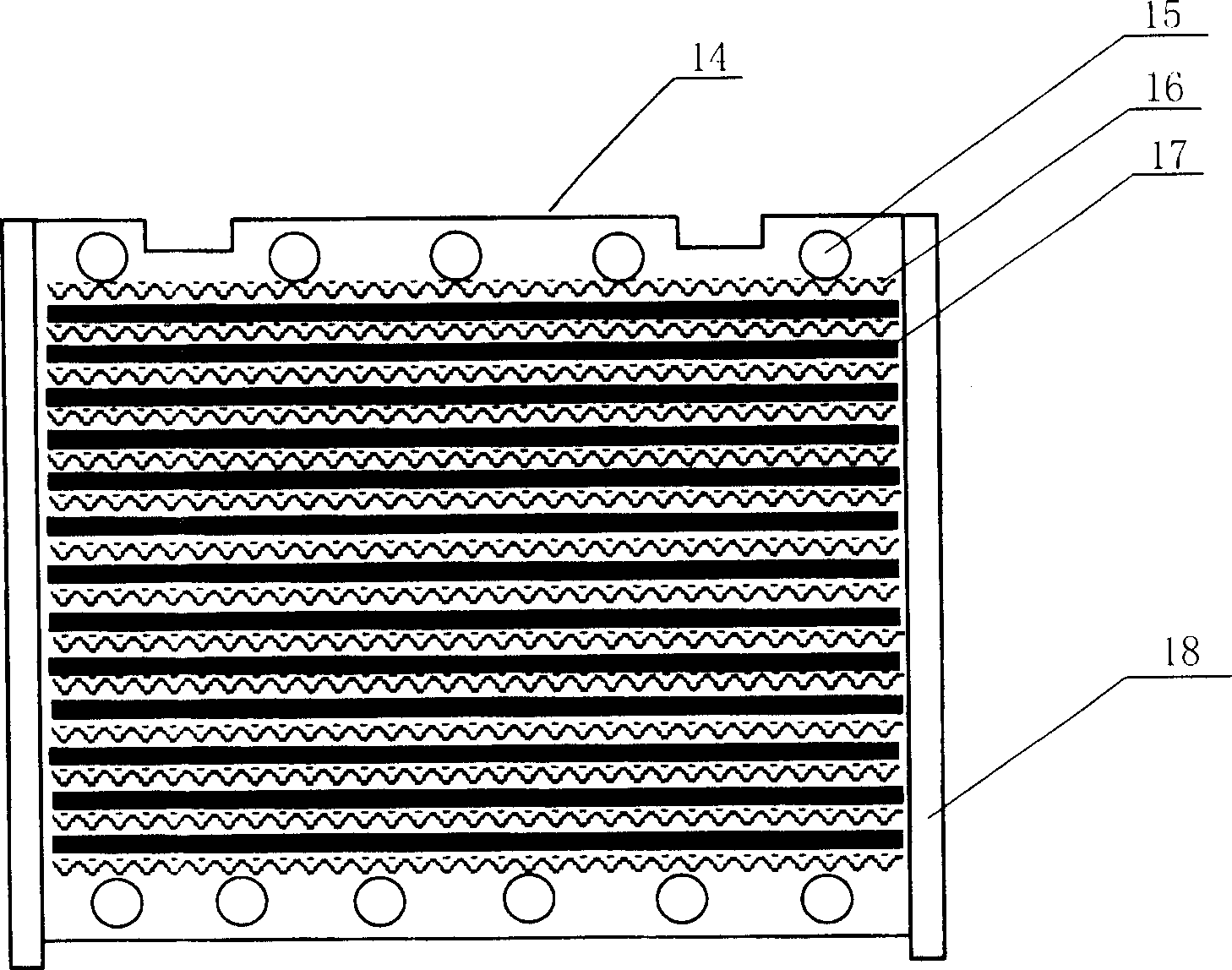

Double-frequency pulse and double-vertical ring high-gradient magnetic separator

InactiveCN1387958AImprove sorting effectTaking into account the quality of concentrateHigh gradient magnetic separatorsMagnetic separatorReciprocating motion

The magnetic separator includes separating ring and magnetic field unit, the magnetic field unit is distributed beside the separating ring to produce magnetic force lines penetrating the separating ring, and the separating ring is provided with at least one pulse device to make ore pulp move in the direction perpendicular to the magnetic force lines. Owing to the combined closed magnetic field unit to produce horizontal magnetic force lines and unique double-pulse device, the particles adsorbed to the surface of the medium exist only in the side in magentic force line direction and the ore pulp reciprocates to produce fluid motion tangent to the particle side and shear and clean the particles, so that the included non-magnetic and weak magnetic adherant particles are washed out resulting in greatly raised separating effect.

Owner:广东省资源综合利用研究所

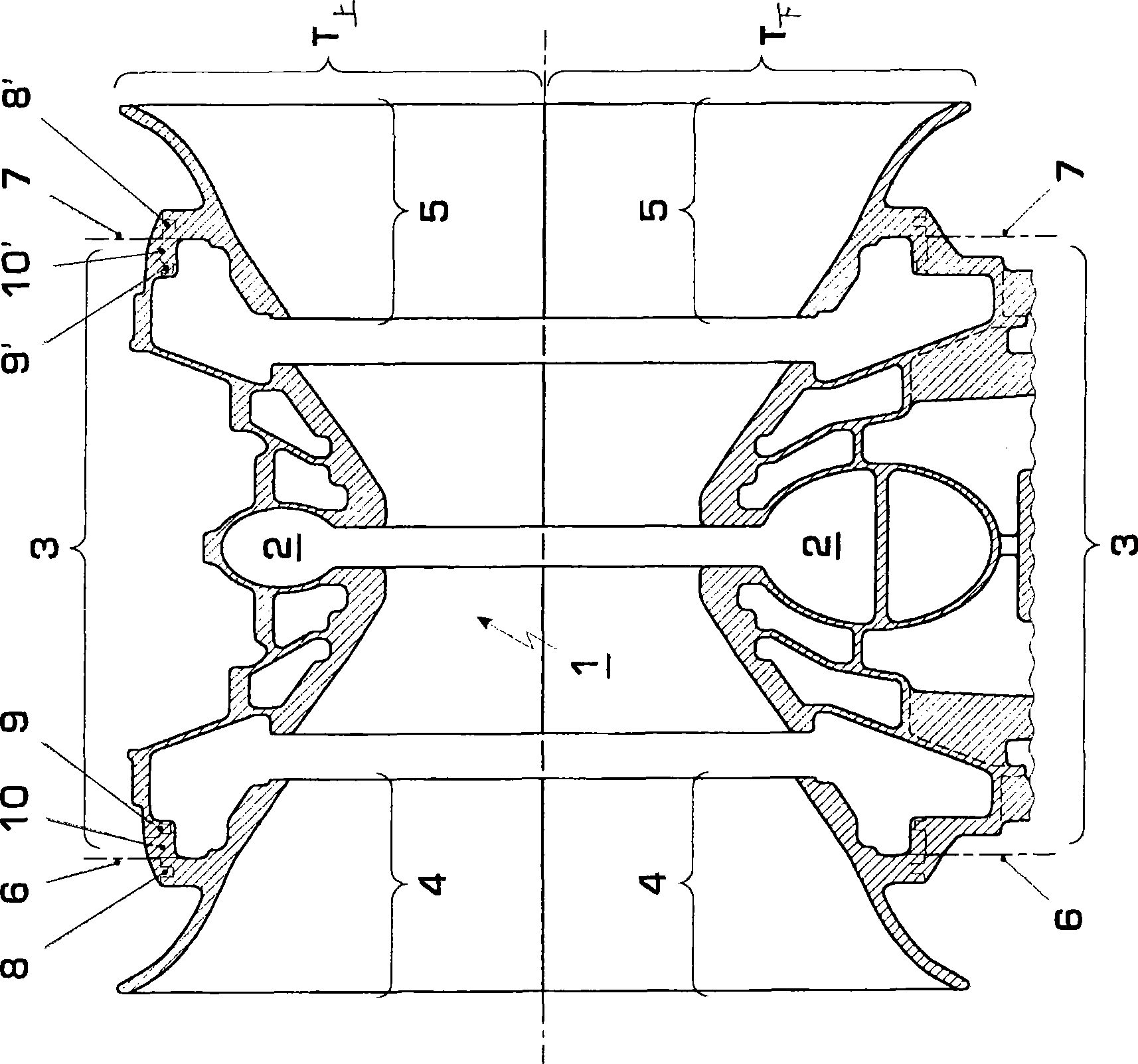

Method for producing a turbine casing

InactiveCN101480705AFast and unified quality checksCutting costsEngine manufactureFoundry mouldsTurbine

A method for producing a turbine casing for a rotating machine is provided. The casing is manufactured by a casting process, and is cast in two casing halves which are separated by a parting plane which passes axially through the turbine casing. Each casing half is first cast in one piece in each case, and each casing half is separated into at least two casing sections which are joined together for forming a casing half in each case.

Owner:GENERAL ELECTRIC TECH GMBH

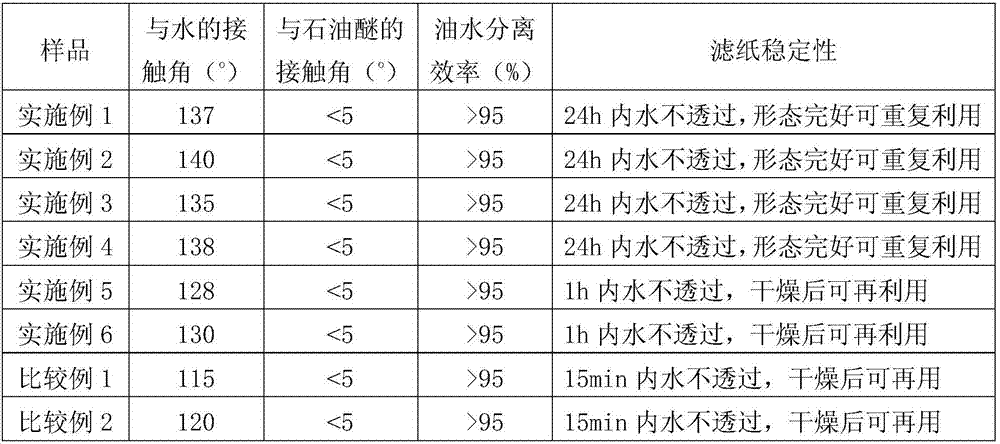

Filter paper having function of oil-water separation, and simple preparation method and application of filter paper

InactiveCN106868948ALow costGood stabilityFatty/oily/floating substances removal devicesNon-macromolecular organic additionChemistrySilane coupling

The invention discloses filter paper having a function of oil-water separation, and a simple preparation method and application of the filter paper. The filter paper takes common experimental filter paper as substrate, and an organic / inorganic compound hydrophobic layer is loaded on the substrate, wherein the organic / inorganic compound hydrophobic layer is prepared from the following components: nano-silica, a silane coupling agent, a catalyst, ethanol and water, and the weight ratio of the nano-silica to the silane coupling agent to the catalyst to the ethanol to the water is equal to (2-5):(2-10):(2-10):(80-100):(5-20). The filter paper is prepared by adopting a dip-coating method; the preparation method of the filter paper comprises the steps of evenly dispersing the nano-silica, the silane coupling agent and the catalyst in mixed liquid of the ethanol and the water, dipping the filter paper into the dispersed liquid, taking out the dipped filter paper, and then naturally drying the filter paper in the air to obtain the filter paper having the function of oil-water separation. The filter paper is simple in preparation method, good in stability, reusable and convenient to dispose, and has a good application prospect in the fields such as oil-water separation and oily sewage treatment.

Owner:SHANDONG JIAOTONG UNIV

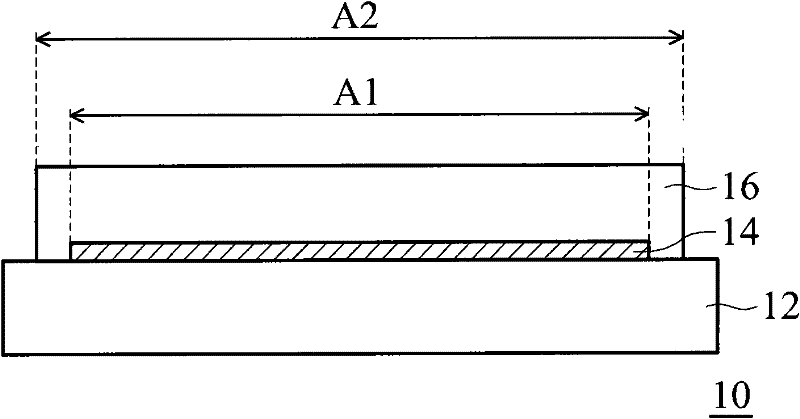

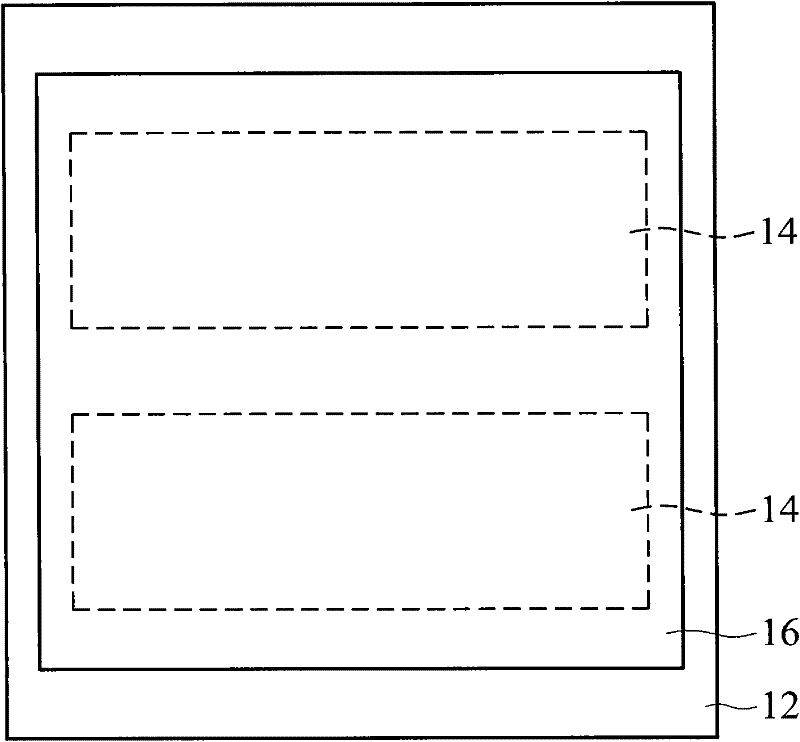

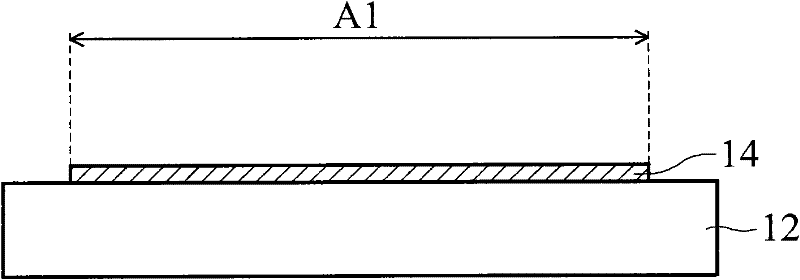

Substrate structure and manufacturing method thereof

ActiveCN102194829ASuitable for separationSolid-state devicesSemiconductor/solid-state device manufacturingEngineeringElectronic component

Owner:IND TECH RES INST

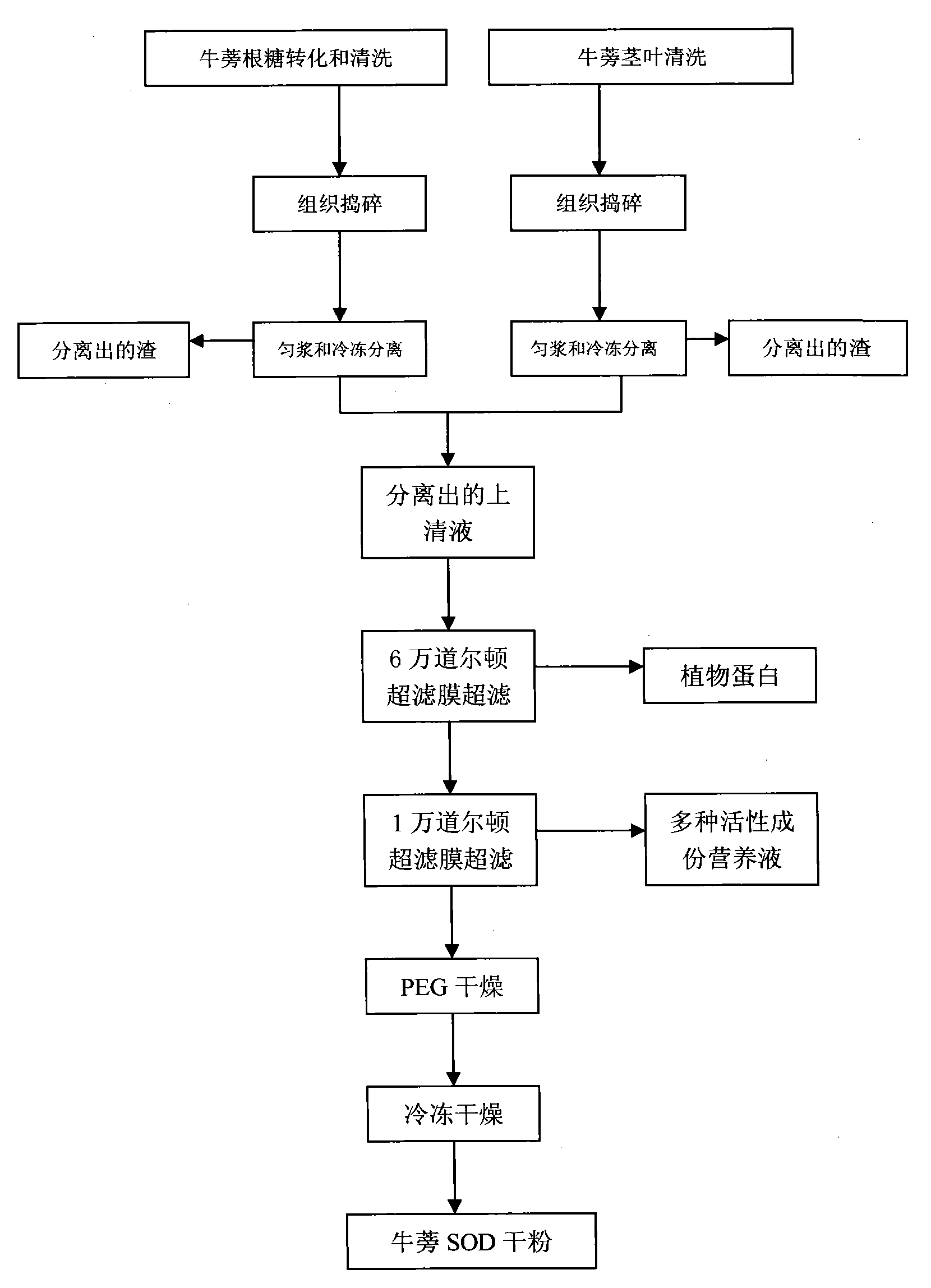

Process method for extracting superoxide dismutase from root, stem and leaf of burdock

ActiveCN102586200AGreat tastePrevent oxidationClimate change adaptationBioloigcal waste fertilisersUltrafiltrationPolyethylene glycol

The invention relates to a process method for extracting superoxide dismutase from a root, a stem and a leaf of a burdock, which comprises the following steps of: cleaning the root, the stem and the leaf of the burdock, organizing, smashing, homogenating and carrying out frozen separation; successively ultra-filtering separated supernate for two times; intercepting above sixty thousands of daltons of matters in the primary ultrafiltration and intercepting above ten thousands of daltons of matters in the secondary ultrafiltration; and intercepting solution passing through the primary ultrafiltration into ten thousands-sixty thousands of solution containing SOD (Superoxide Dismutase) by the secondary ultrafiltration, and after the solution containing the SOD intercepted in the secondary ultrafiltration is dried by PEG (Polyethylene Glycol), drying in a freeze drier to obtain a solid SOD matter.

Owner:龚森淼

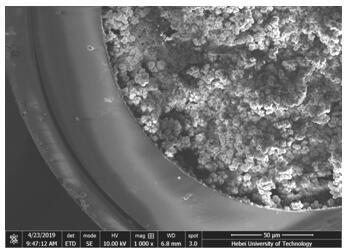

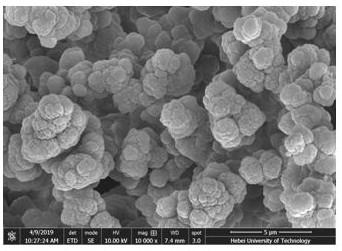

Novel hydrophilic alkyl bonded silica gel filler preparation method

InactiveCN109092275AReduce dosageAvoid multiple filter dryingOther chemical processesSolid sorbent liquid separationSolventSilica gel

The invention discloses a novel hydrophilic alkyl bonded silica gel filler preparation method. The method comprises the steps that alkylchlorosilane is used as silica gel to introduce bonded alkyl, polymethylcyclopolysiloxane is supported on the silica gel, finally, a conventional micromolecule endcapping agent is used for masking residual silicon hydroxyl, and the hydrophilic alkyl bonded silicagel filler is obtained; due to the fact that for the prepared chromatographic filler, the preparation technology adopts a one-pot multi-step reaction, multiple times of filtering and drying are avoided, and the solvent dosage is reduced; the filler contains rich silyl ether bonds, it can be ensured that the filler can be fully infiltrated in water, and the method is more suitable for separation ofmacromolecules such as polypeptide and protein.

Owner:JIANGSU HANBON SCI & TECH CO

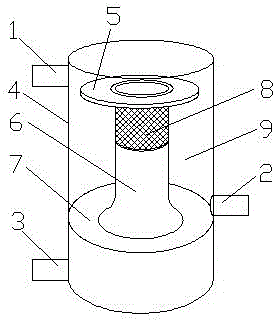

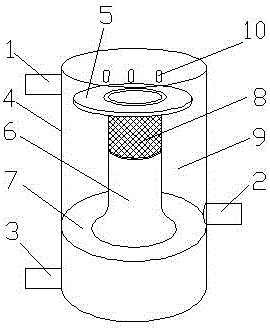

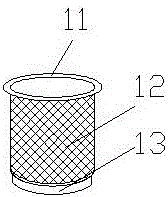

Mud-and-water auto-separating pipeline apparatus

InactiveCN106039804ARealize automatic separationSuitable water for irrigationStationary filtering element filtersAgricultural irrigationWater flow

The invention discloses a mud-and-water auto-separating pipeline apparatus and belongs to the technical field of water conservancy transportation pipelines. The pipeline apparatus includes a water inlet pipe, a water outlet pipe and a drainage pipe and also includes a mud-and-water auto-separating part. The mud-and-water auto-separating part includes a cylindrical pipe body, wherein annular steps are formed on an inner side wall of the cylindrical pipe body. An inner fixing base is arranged under the annular steps. An annular groove is formed by the inner fixing base and the inner side wall of the cylindrical pipe body. An annular filter screen is disposed on the annular steps, wherein the top end of the annular filter screen is connected to the annular steps and the bottom end of the annular filter screen is connected to the inner fixing base. A clear water chamber is formed by the inner side wall of the cylindrical pipe body and an outer side wall of the annular filter screen. The water outlet pipe is communicated with the clear water chamber. The water inlet pipe is arranged on the side wall of the cylindrical pipe body and is arranged above the annular steps. The pipeline apparatus can automatically separate mud from water, wherein clear water flows out through the water outlet pipe while a mud and sand mixture is discharged through the drainage pipe. The pipeline apparatus is free of extra kinetic energy, is low in energy consumption and is suitable for agricultural irrigation.

Owner:张铁耀

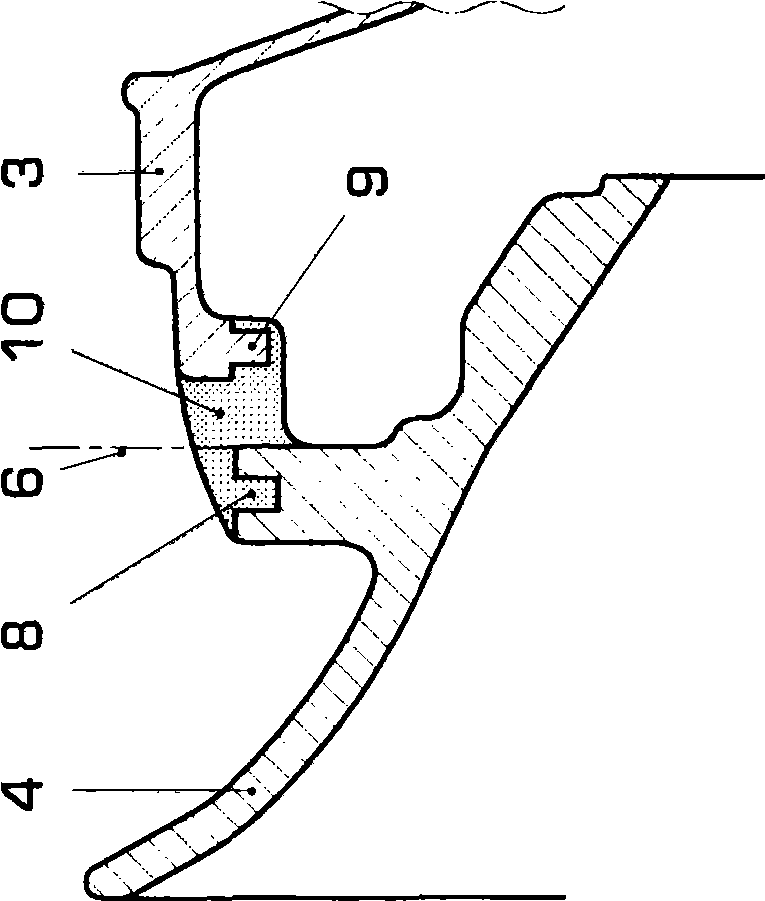

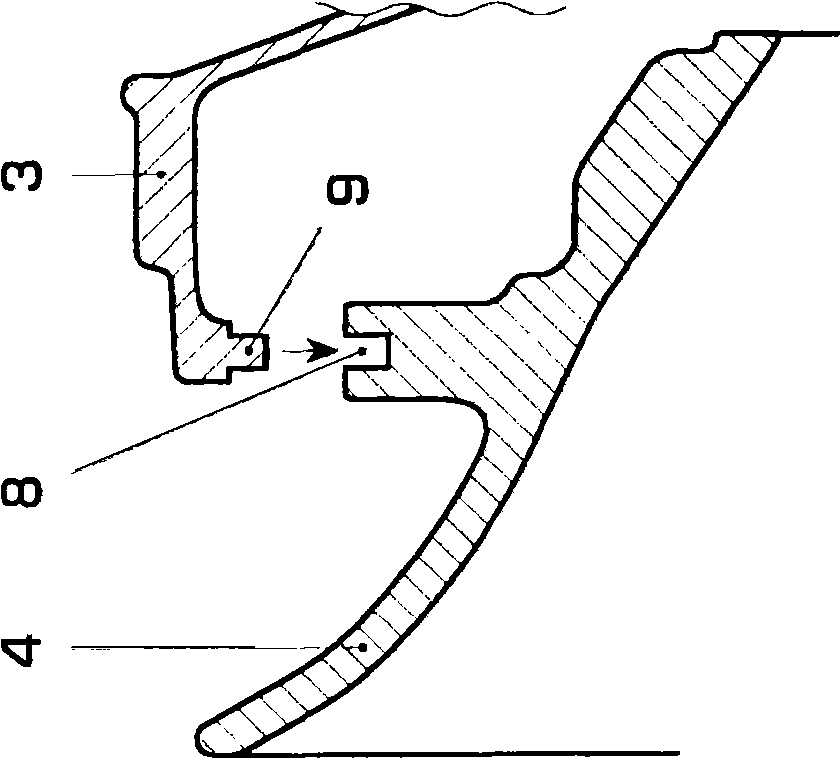

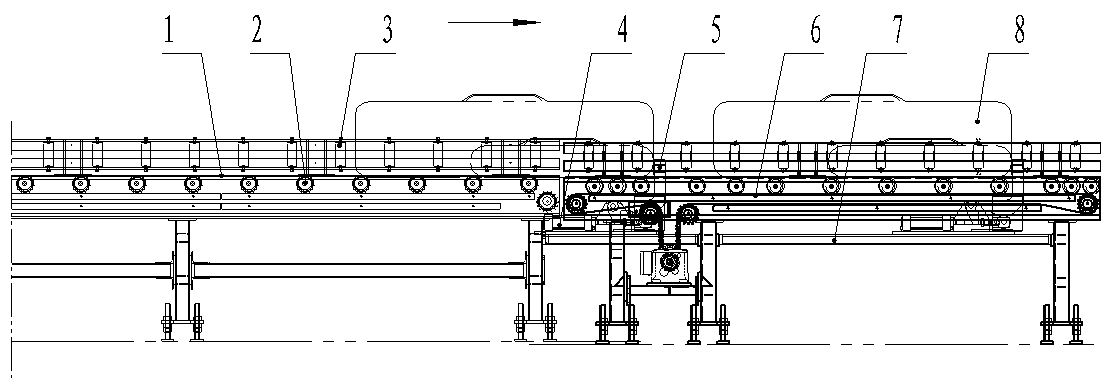

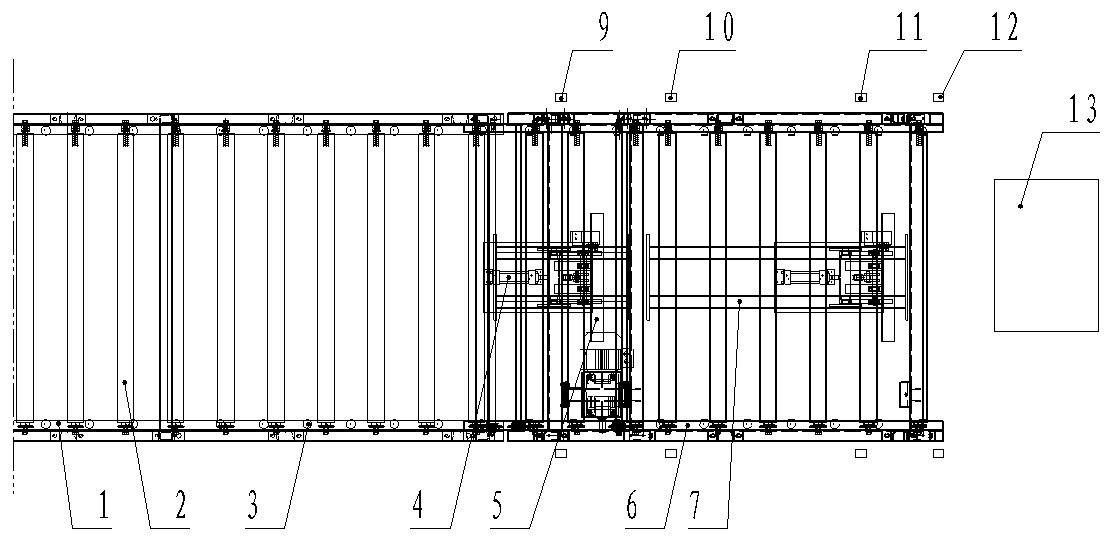

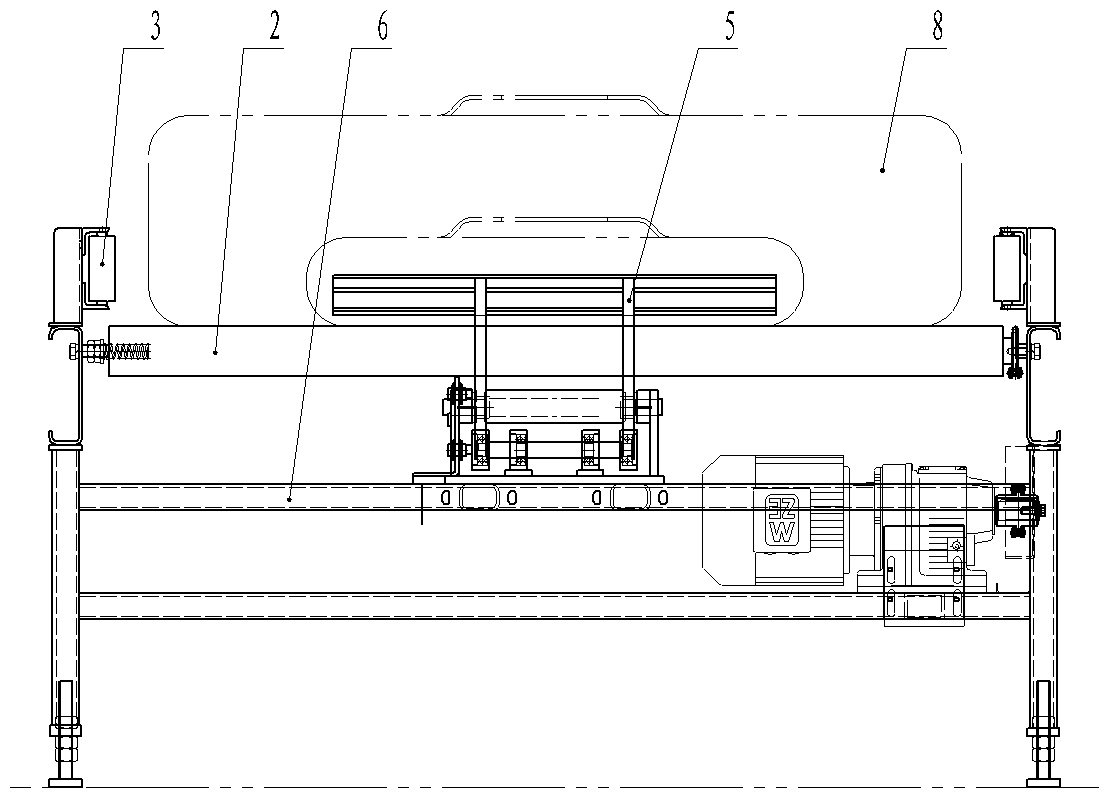

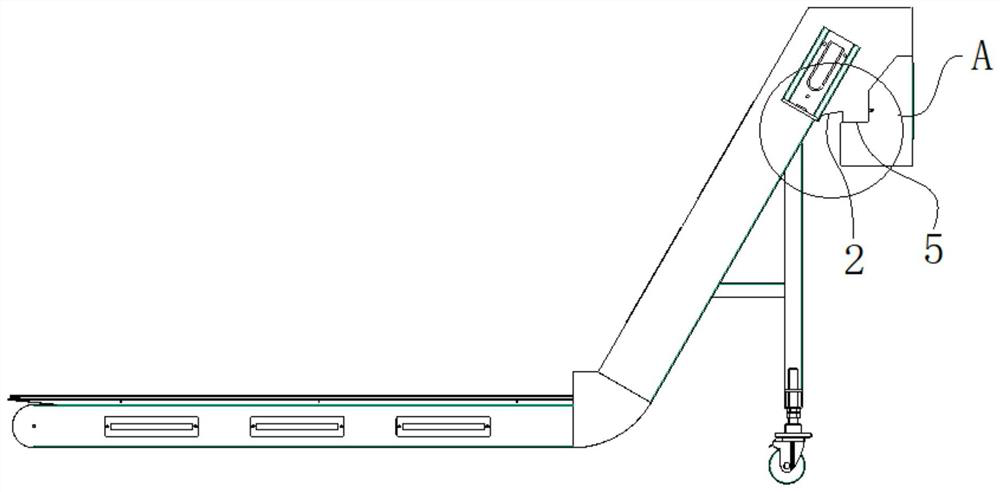

Tyre separation device of tyre transportation line

ActiveCN108639657ASuitable for separationSimple structureConveyor partsRoller-waysElectricityEngineering

The invention discloses a tyre separation device of a tyre transportation line and relates to the technical field of automatic production. The tyre separation device of the tyre transportation line comprises a main rollgang, wherein a high speed roller bed for transporting single tyres is hinged to the output end of the main rollgang, hook type stoppers are separately arranged at the feed inlet and the discharge end of the high speed roller bed, each hook type stopper is provided with a barrier arm part rotatably connected to a rack, and a power cylinder which drives the barrier arm part to stretch out of the transportation surface of the high speed roller bed is mounted on the rack; a first stand-out switch and a first occupied switch are separately arranged on front and back sides of thebarrier arm part located at the feed inlet, a second stand-out switch and a second occupied switch are separately arranged on front and back sides of the barrier arm part located at the discharge end, and the power cylinder, the first occupied switch, the second occupied switch, the first stand-out switch and the second stand-out switch are electrically connected to a control box. Compared with the prior art, the tyre separation device can separate tyres, the diameters phi of which are 750mm to 1300mm on the transportation line, and the tyre separation device is suitable for transporting andseparating tyres, the diameter difference of which is relatively great.

Owner:DONGFENG LIUZHOU MOTOR

Hydrogen generating bacteria and its screening method

InactiveCN1644679AImprove hydrogen production performanceStrong acid resistanceBacteriaGenetic engineeringMicroorganismHydrogen

This invention relates to a hydrogen generating bacteria and its screening method. It is named Ethanologyenbacterium hit B49 with preserving no. CGMCC No.1153. It is cultured in a special medium and has high efficiency of hydrogen generation. The said bacteria is of acid resistance.

Owner:HARBIN INST OF TECH

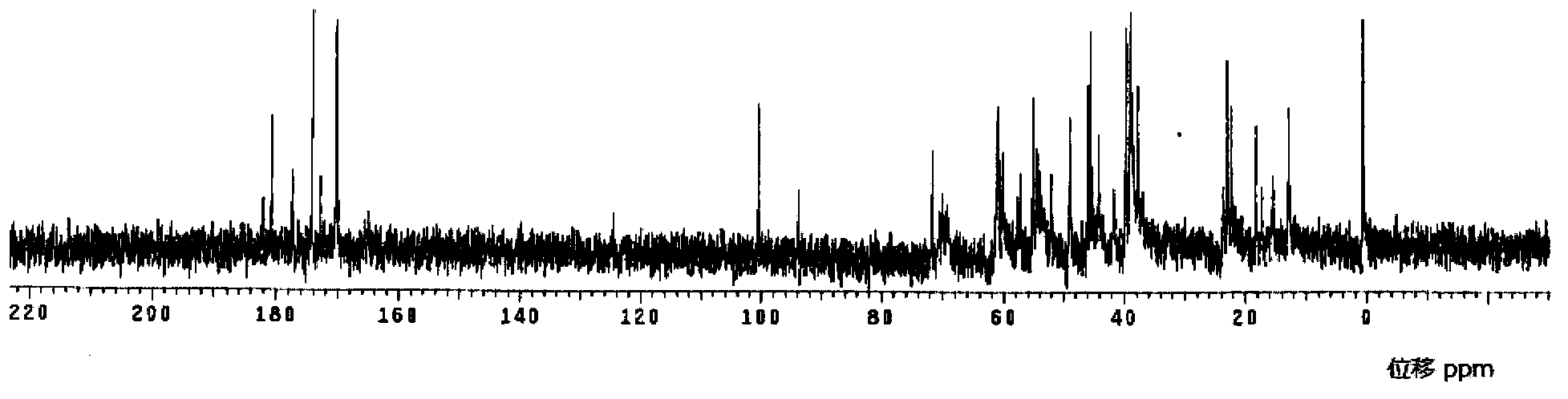

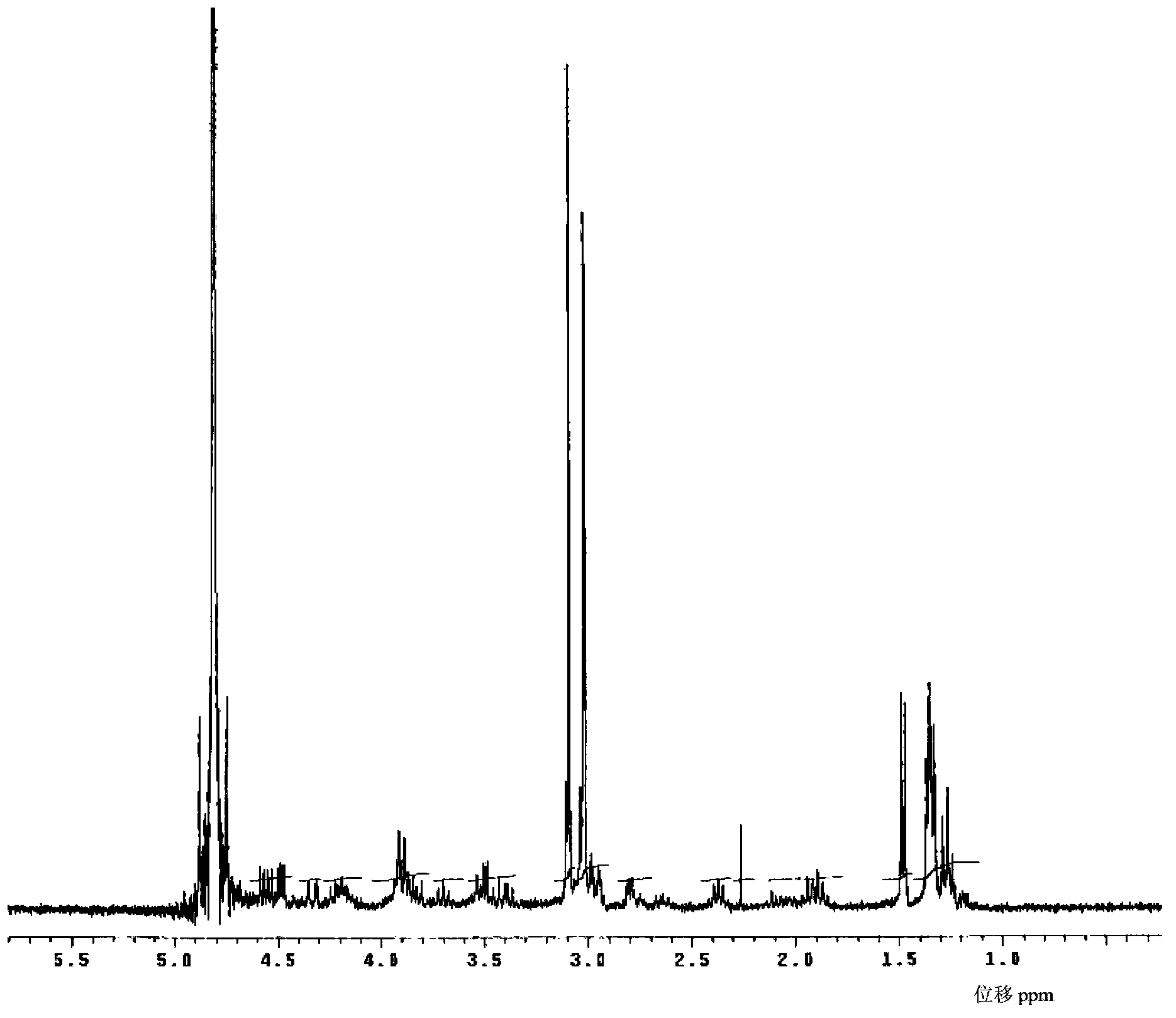

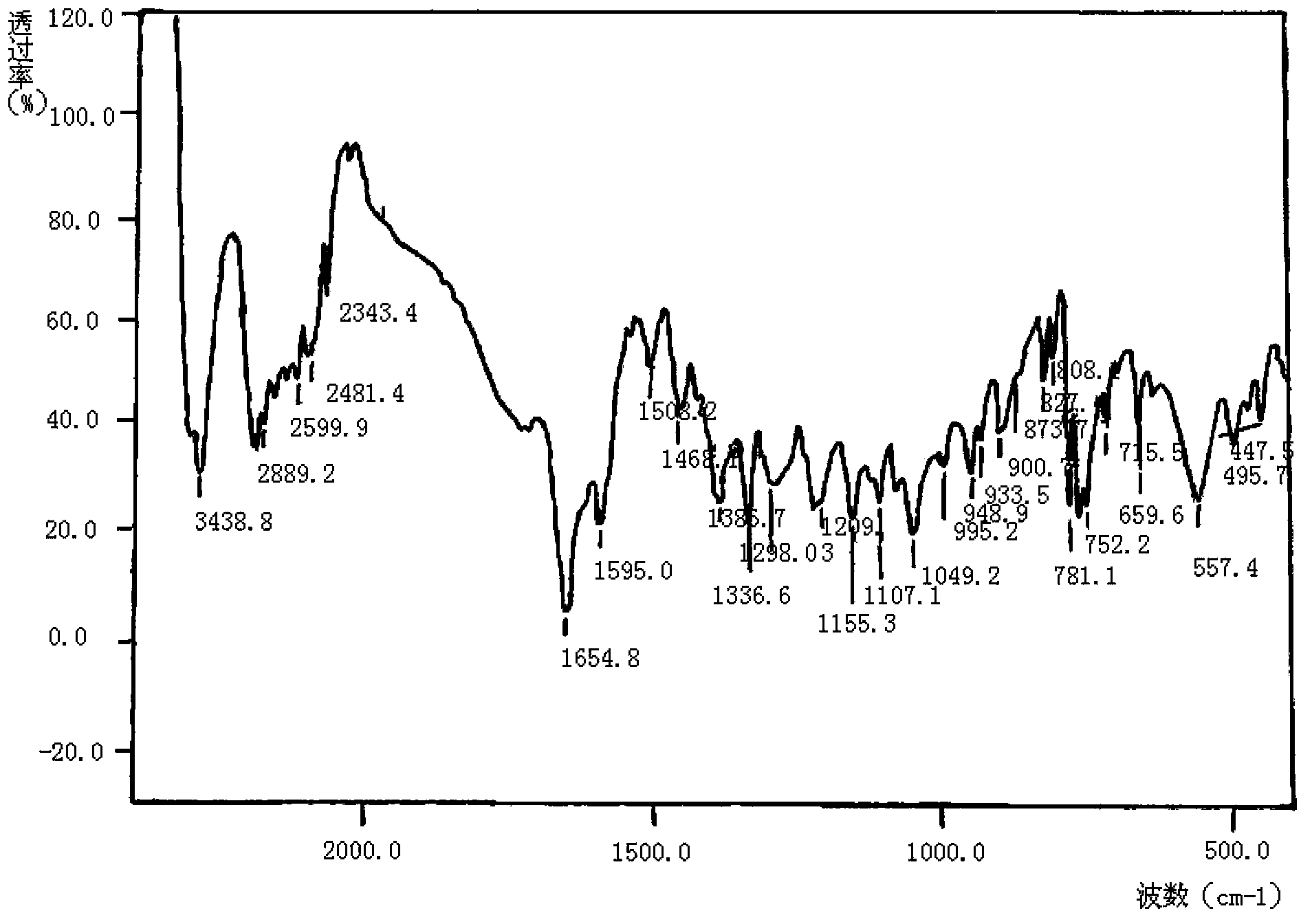

Meropenem raw medicine, preparation method thereof and pharmaceutical composition containing same

ActiveCN103570718AHigh purityThe status of impurities is clearAntibacterial agentsOrganic active ingredientsSolubilityMeropenem

The invention discloses a meropenem raw medicine which is characterized in that the content of meropenem in the raw medicine is 98.5-101.0% by weight based on anhydride; the content of the impurity A and impurity B in the related substances of the raw medicine is not greater than 0.25% respectively; the content of any unknown single impurity is not greater than 0.05%; the total content of other impurities except the A and B is not greater than 0.2%; the acetone residue is not greater than 400ppm and preferably not greater than 100ppm. The invention also discloses a meropenem pharmaceutical composition for injection, and the pharmaceutical composition takes the meropenem raw medicine provided by the invention as an active ingredient and has excellent stability. The meropenem raw medicine provided by the invention has the advantages of high purity, clear impurity condition, low solvent residue, good solubility and good long-term storage stability, and can guarantee the effectiveness and safety of the medicine. In the invention, the process is simple and compact, the cost is remarkably low, and the control is simple. The invention is suitable for industrial large-scale aseptic production of the meropenem raw medicine and pharmaceutical preparation.

Owner:SHENZHEN HAIBIN PHARMA +1

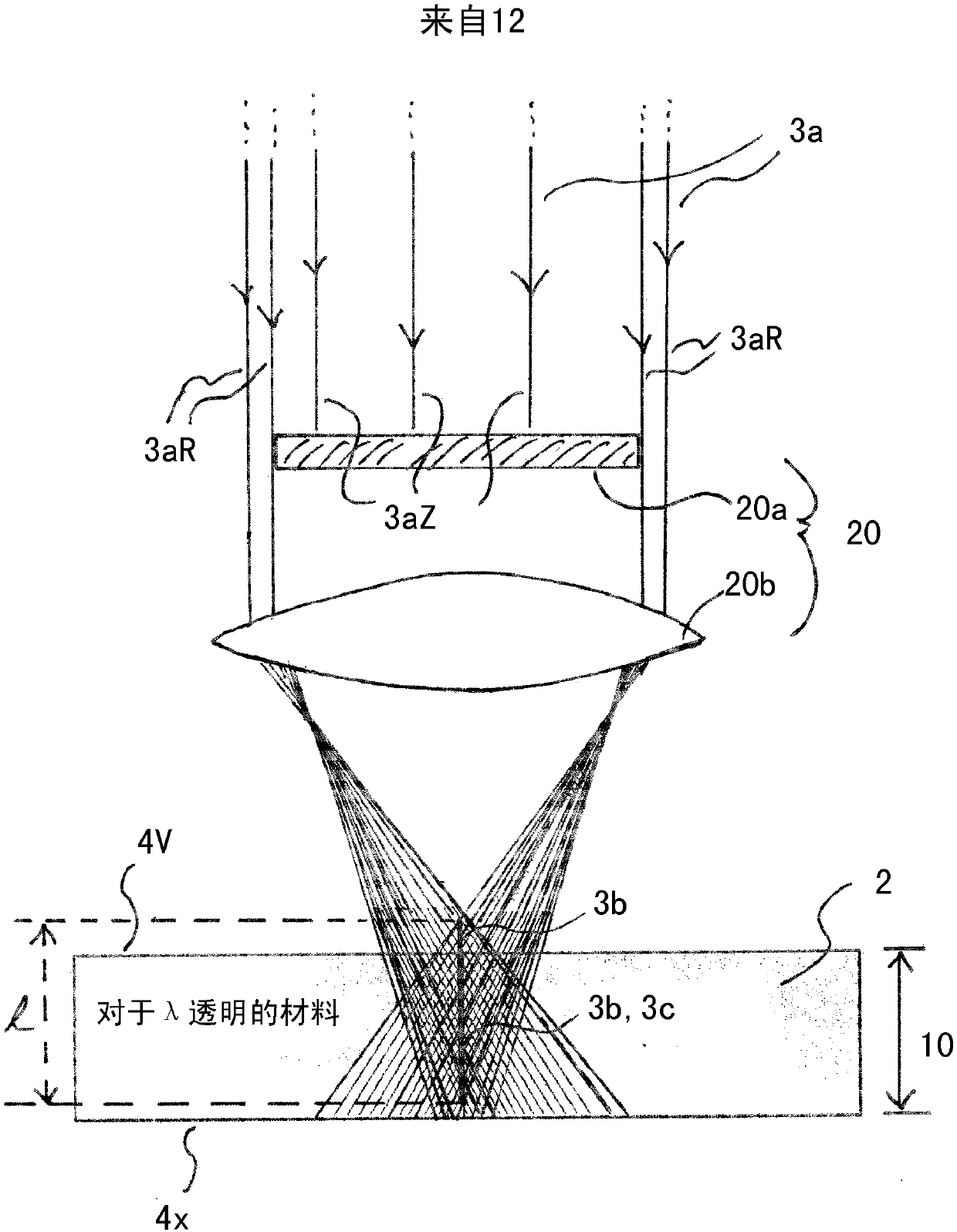

Device and method for cutting out contours from flat substrates using a laser

ActiveCN107755904AHigh precisionReduce roughnessGlass severing apparatusWelding/soldering/cutting articlesMaterial removalPlanar substrate

The invention relates to a method for producing a contour (5) in a planar substrate (5) and for removing the contour from the substrate, in particular for producing an internal contour in a planar substrate and for removing the internal contour from the substrate, wherein in a contour definition step, by means of a laser beam (3) guided over the substrate, a plurality of individual zones (5-1, 5-2,....) of internal damage is produced along a contour line in the substrate material marking the contour (5) to be produced; in a crack definition step, by means of a laser beam guided over the substrate, a plurality of individual zones (6-1, 6-2,...) of internal damage is produced along each of a plurality of crack line segments (6a, 6b,..) in the substrate material leading, as viewed from the contour line, away at an angle [alpha] > 0 and into the contour to be removed; and in a material removal step performed after the contour definition step and after the crack definition step, by means ofa material-removing laser beam (7) guided over the substrate, the substrate material is removed over the entire substrate thickness along a removal line, which extends along the contour line but at adistance from the contour line and in the contour to be removed and which also preferably crosses the crack line segments.

Owner:CORNING LASER TECH

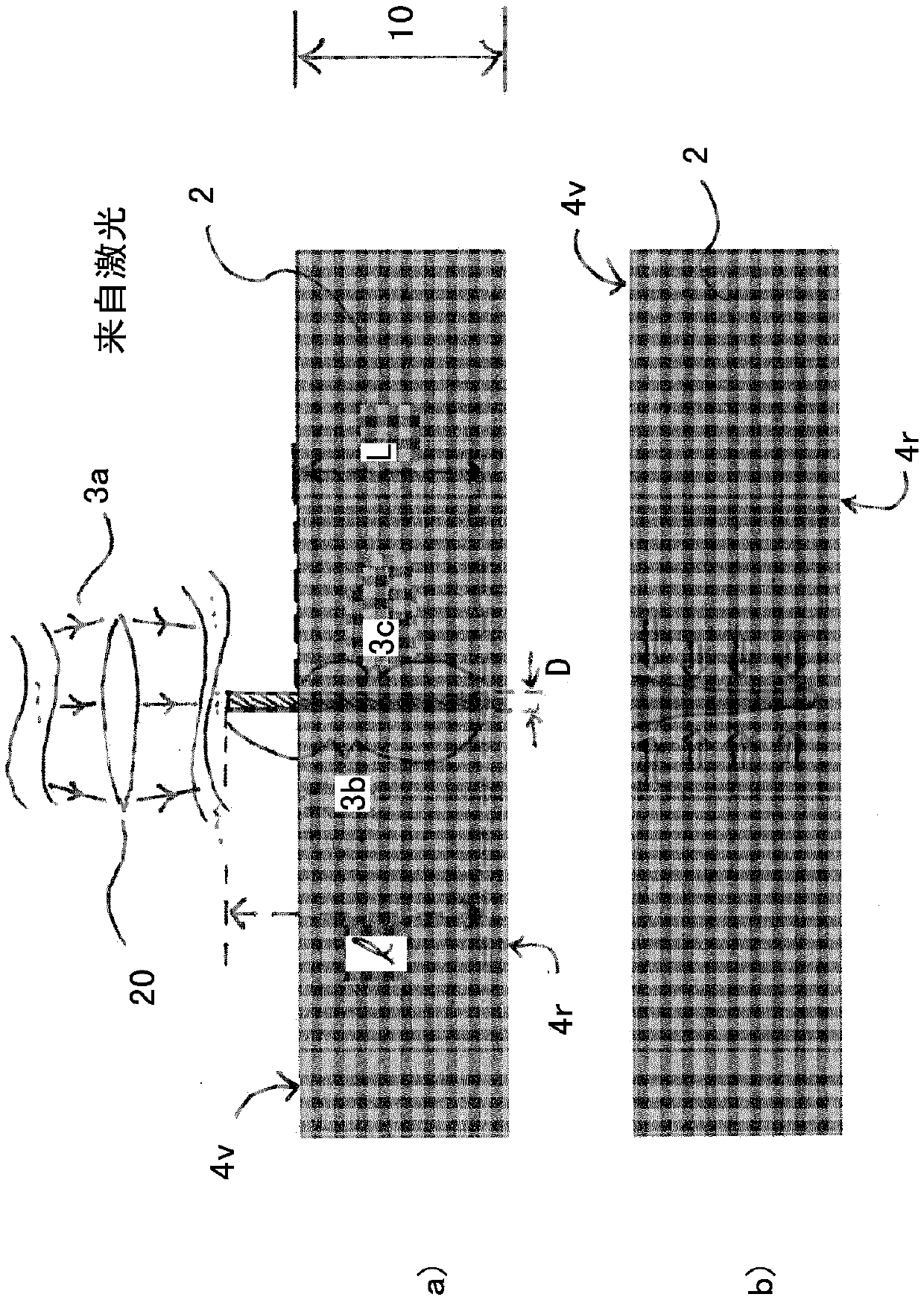

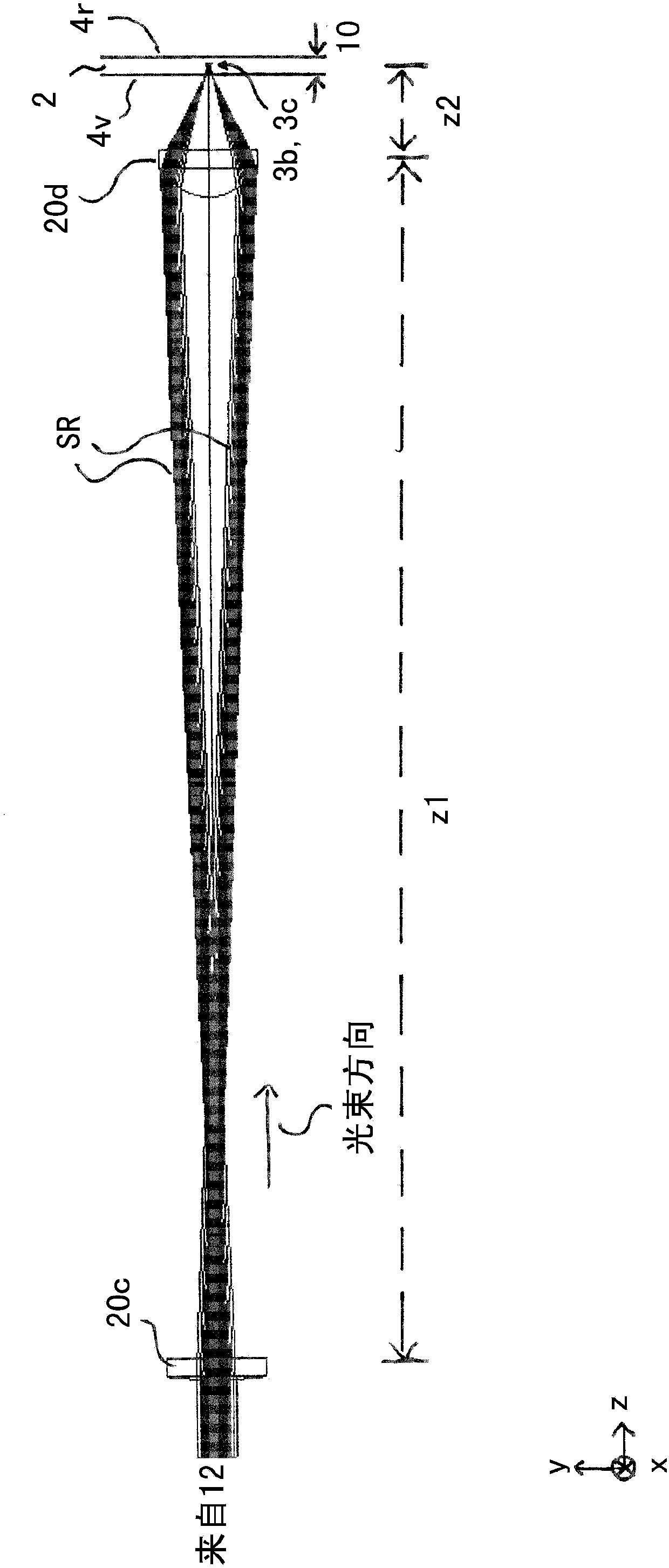

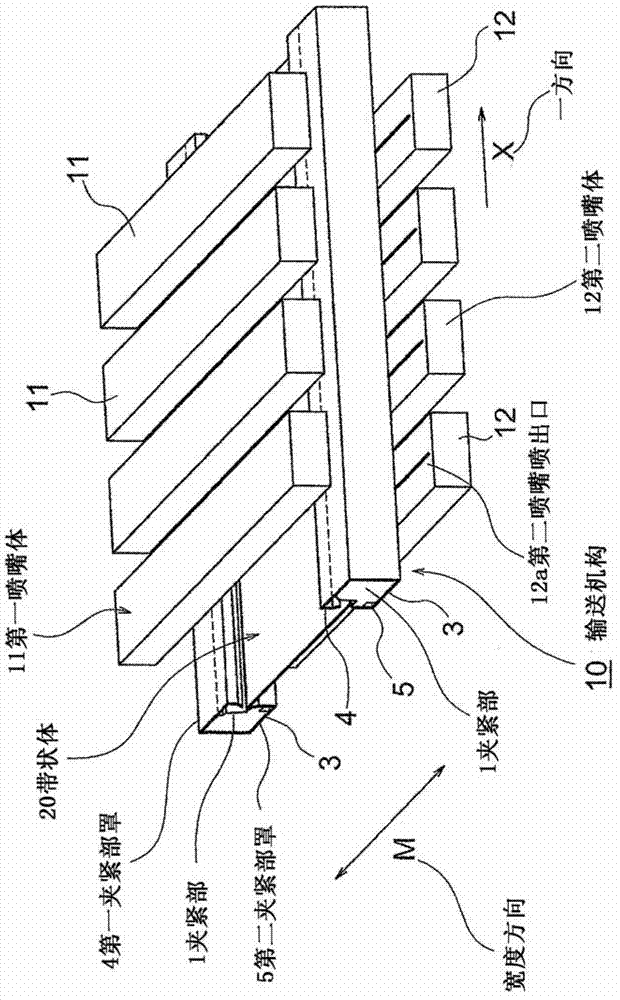

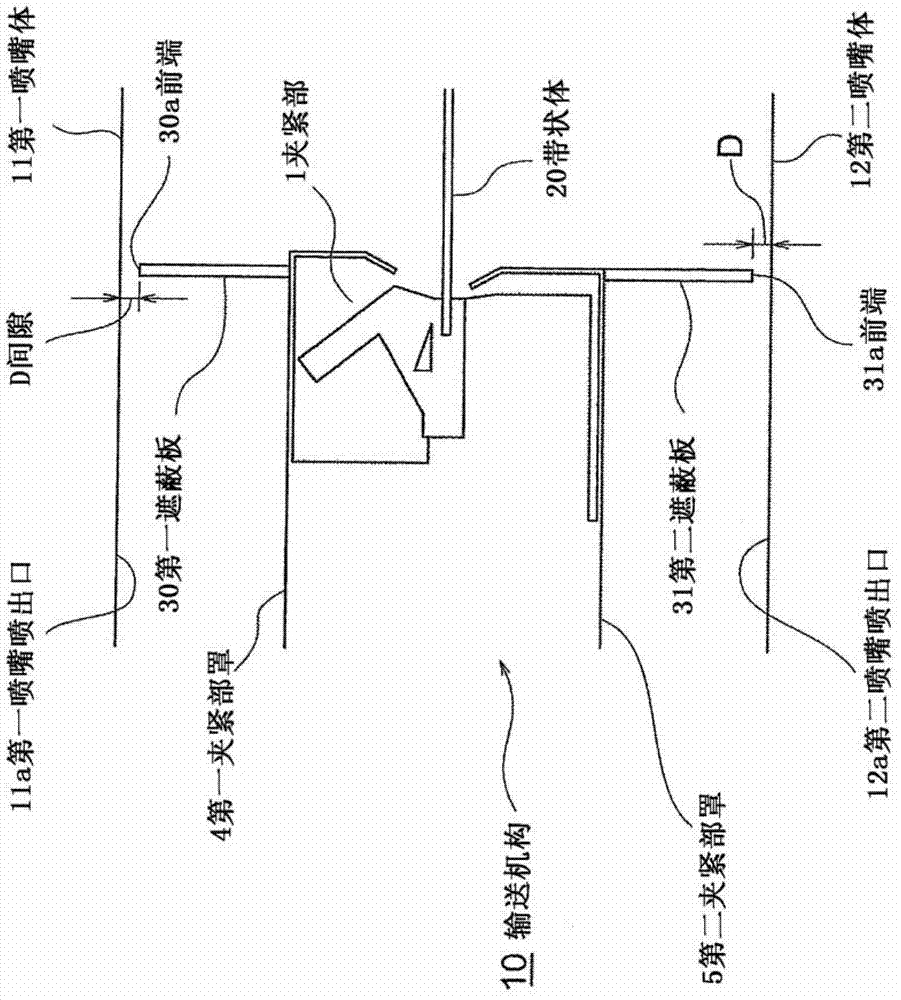

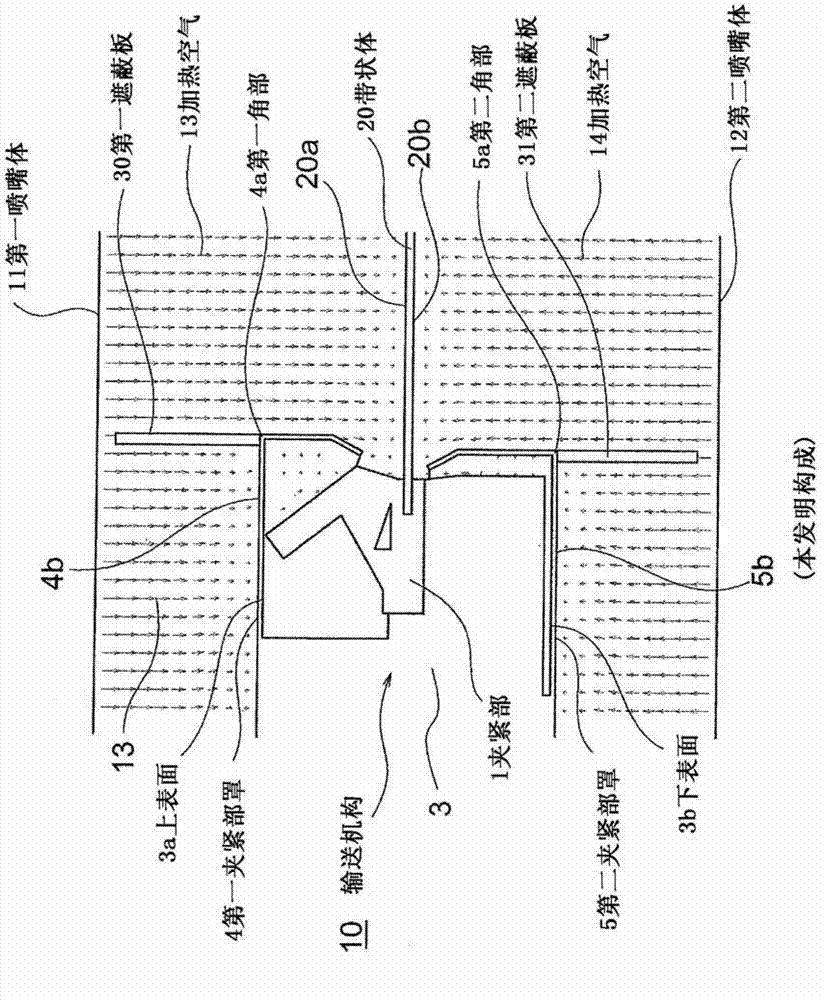

Transverse stretching method and device thereof

The present invention provides a transverse stretching method and a device thereof. The aim of the invention is to rectify flow of heating air and improve heating efficiency through equipped a shielding board on a conveying mechanism of a conveying belt-shaped member. According to the transverse stretching method and device of the invention, a first shielding board (30) and a second shielding board (31) which are equipped next to a clamping part (1) of a conveying mechanism (10) and are in a pair separate the heating air (13,14) that collide with the conveying mechanism (10) from the heating air (13,14) that collide with the belt-shaped member (20).

Owner:JAPAN STEEL WORKS LTD

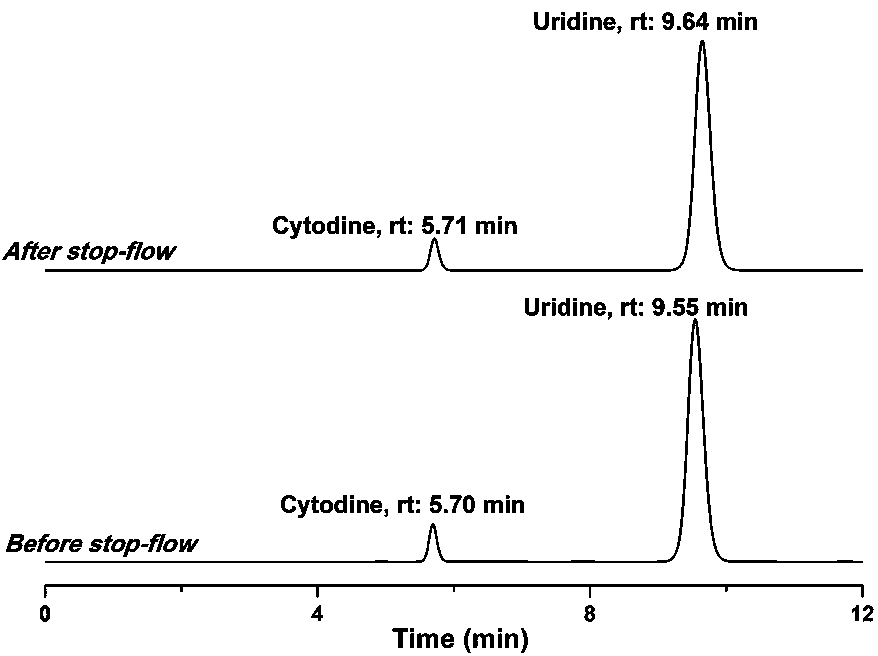

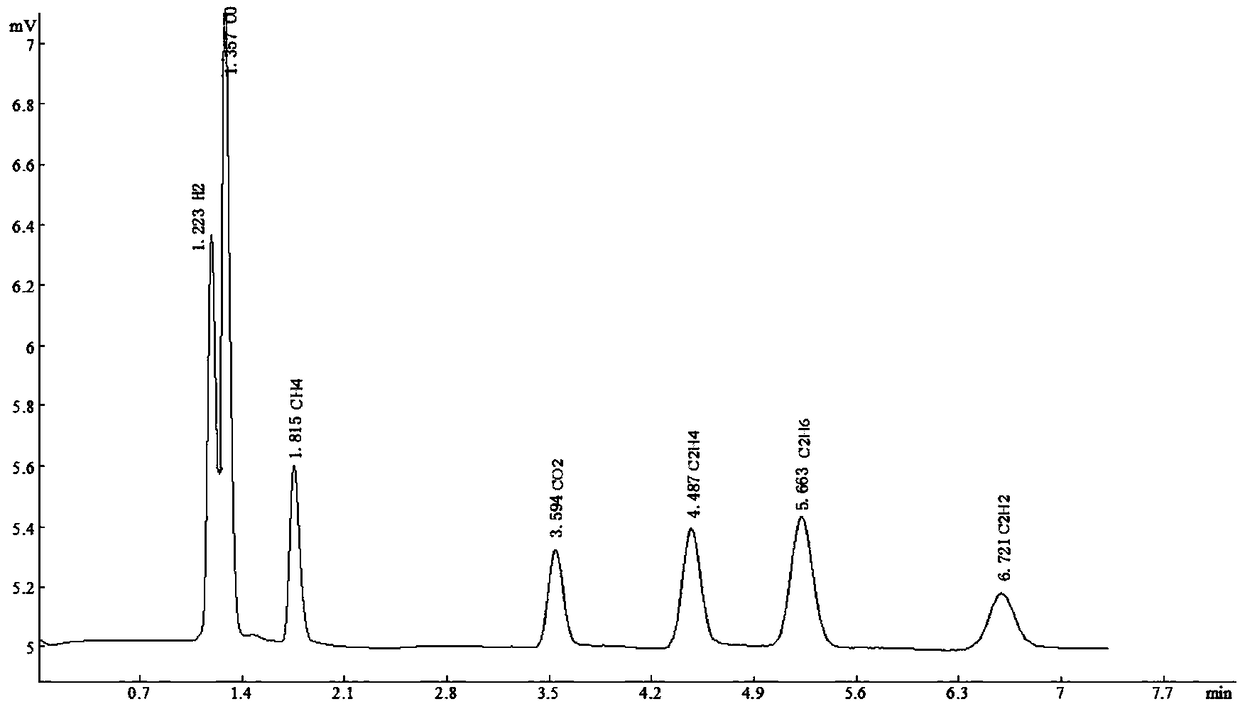

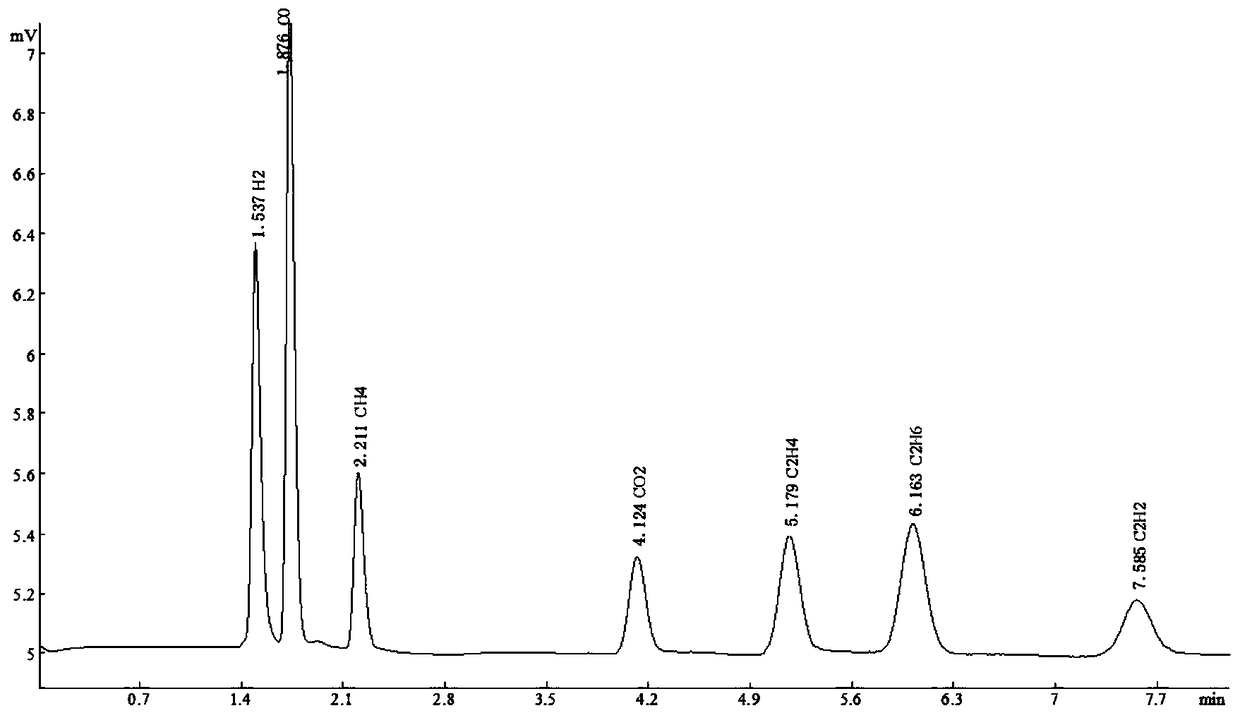

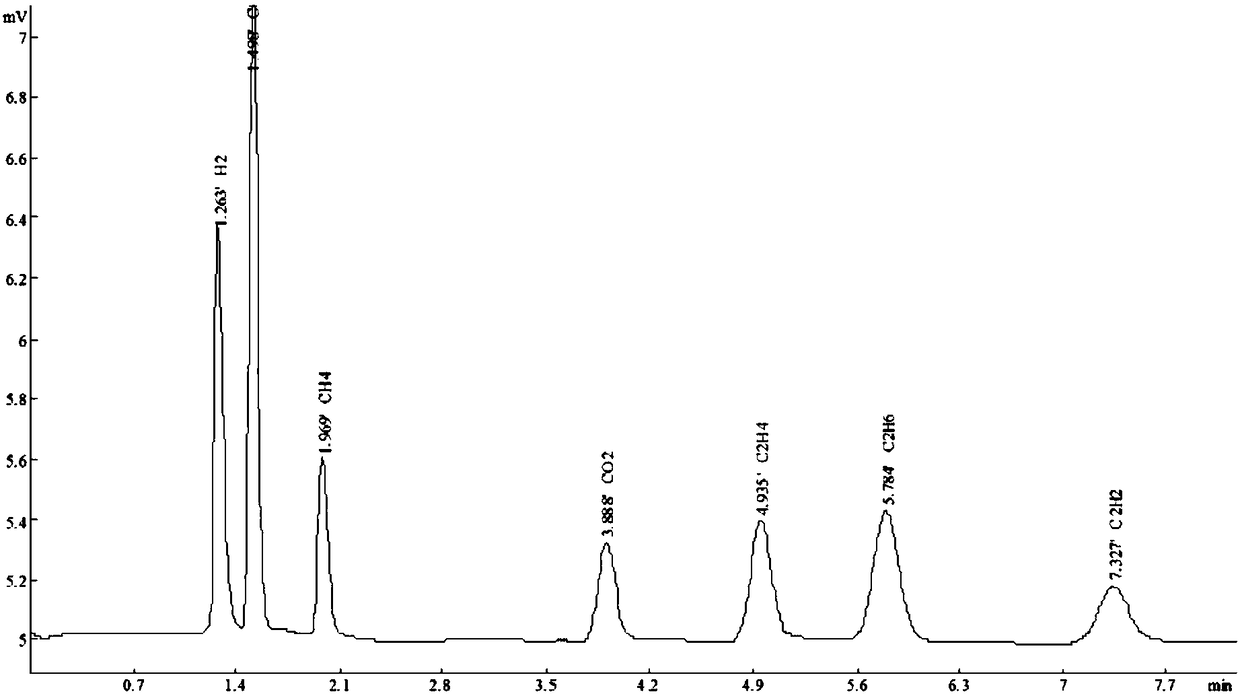

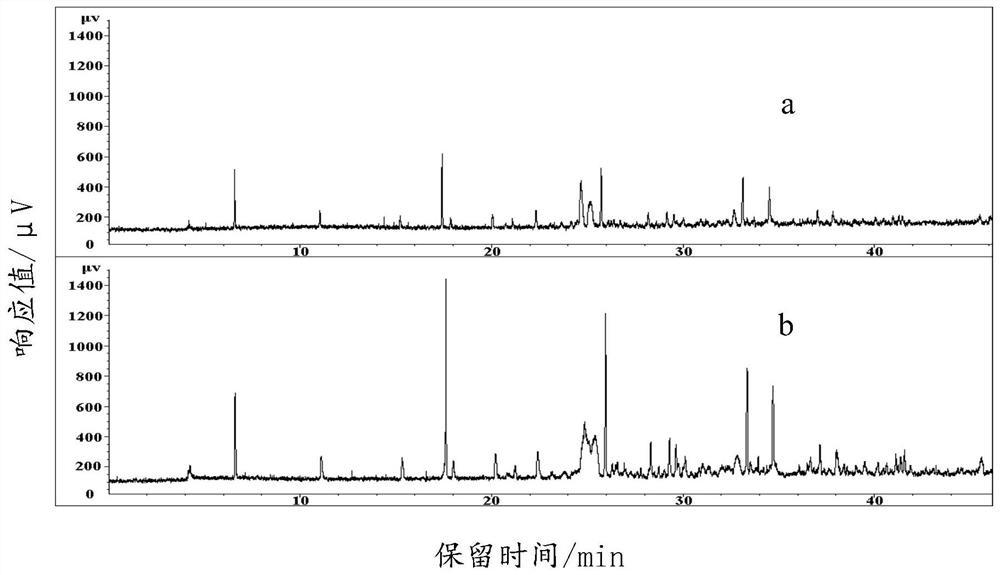

Gas chromatographic packed column, preparation method thereof and application of packed column

The invention provides a gas chromatographic packed column, a preparation method thereof and an application of the packed column. The gas chromatographic packed column comprises a packed column pipe and a packed column stationary phase, the packed column pipe is filled with the packed column stationary phase, the packed column stationary phase comprises a packed column filler, the packed column filler comprises attapulgite, and a preparation method of the packed column filler includes the steps: crushing the attapulgite, and screening the crushed attapulgite to obtain attapulgite powder with particle meshes no less than 200; adding binders into the attapulgite powder, uniformly mixing mixture to prepare small attapulgite balls, and drying the small attapulgite balls at the temperature of 250-350 DEG C; separating the small attapulgite balls in a screening manner to obtain uniform packed column filler with particle meshes of 40-140. According to the novel gas chromatographic packed column, kinds of the gas chromatographic packed column are enriched, the gas chromatographic packed column is applied to analysis of gas dissolved in transformer oil, and the gas dissolved in the transformer oil can be sensitively, rapidly and accurately detected by one chromatographic packed column.

Owner:兰州东立龙信息技术有限公司

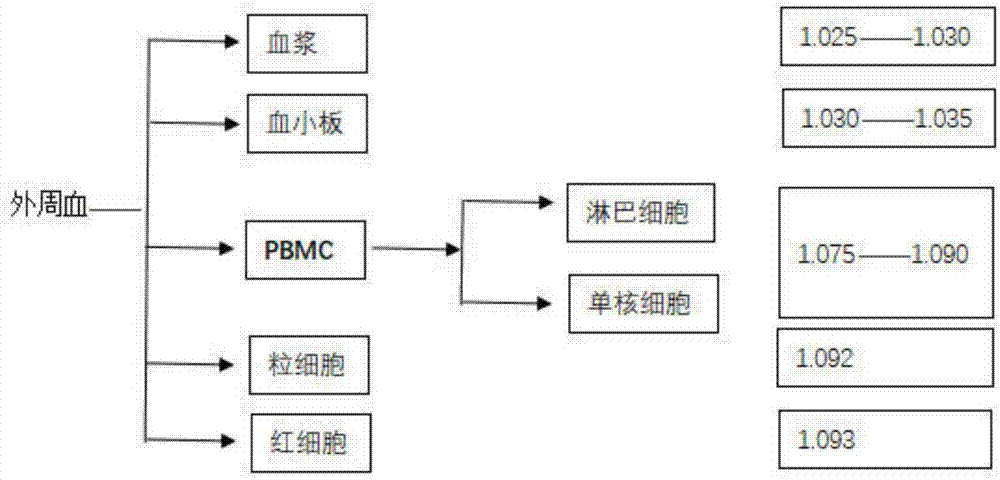

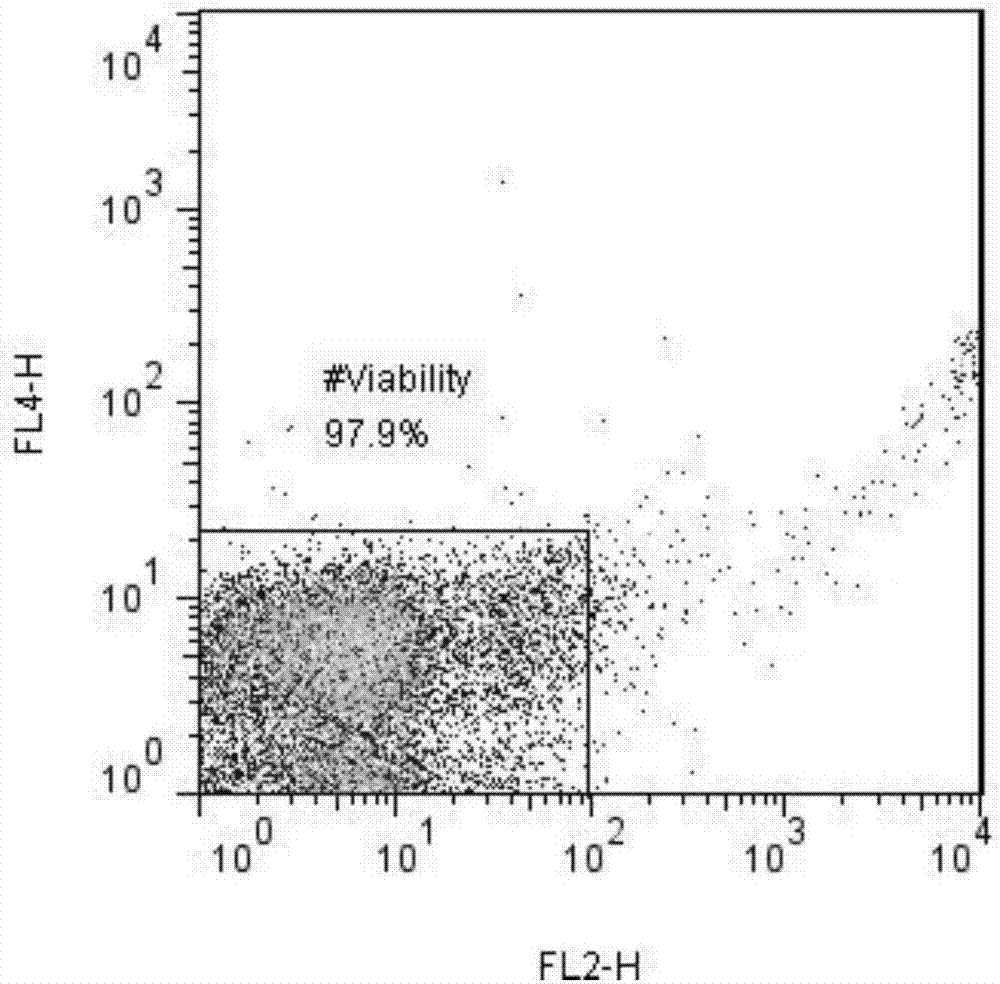

Separation method for peripheral blood mononuclear cell

InactiveCN107254438AAvoid damageHigh yieldCell dissociation methodsBlood/immune system cellsLymphocytic cellCell layer

The invention discloses a method for isolating peripheral blood mononuclear cells, which comprises the following steps: (1) mixing the peripheral blood with Duchenne's phosphate buffer to obtain diluted peripheral blood; placing the lymphocyte separation solution in a centrifuge tube and Store in shading; (2) Tilt the centrifuge tube containing the lymphocyte separation solution so that the liquid level of the lymphocyte separation solution is at an angle of 50°-70° to the horizontal plane; add the diluted peripheral blood to the lymphocyte along the side wall of the centrifuge tube. The mixed solution is obtained from the cell separation solution; the volume ratio of the diluted peripheral blood to the lymphocyte separation solution is 1-2:1; (3) centrifuge the centrifuge tube containing the mixed solution and take the buffy coat to obtain the peripheral blood mononuclear cell layer. The separation method is easy to operate and is suitable for the separation of a large number of samples; it can realize aseptic operation, and the obtained peripheral blood mononuclear cells are suitable for clinical application; the damage to the isolated peripheral blood mononuclear cells is small, and the cell yield is high. will not be disturbed.

Owner:MIAOSHUN SHANGHAI BIOTECH CO LTD

Preparation method of coal-based activated carbon for nitrogen/methane separation and prepared activated carbon

InactiveCN112919461AImprove adsorption capacityLittle change in adsorption performanceNitrogen purification/separationCarbon compoundsActivated carbonPtru catalyst

The invention discloses a preparation method of coal-based activated carbon for nitrogen / methane separation and the prepared activated carbon. The preparation method comprises the following steps: taking anthracite as a raw material, and crushing; uniformly mixing the pulverized coal obtained by crushing with a binder, an activated catalyst and water to obtain a mixture; carrying out pressure molding on the obtained mixture, and naturally airing molded strips to cure the molded strips; putting the cured molded strips into a carbonization furnace, and carbonizing the molded strips under the condition of air isolation; putting the obtained carbonized material into an activating furnace, and performing activating by adopting carbon dioxide gas as an activating agent to obtain the coal-based activated carbon for nitrogen / methane separation. By selecting suitable coal types, improving the production process and simplifying the preparation process, the preparation process of the coal-based activated carbon for nitrogen / methane separation suitable for large-scale production is successfully researched, and the purpose of preparing a high-performance activated carbon adsorbent at low cost is achieved.

Owner:CHINA ENERGY GRP NINGXIA COAL IND CO LTD

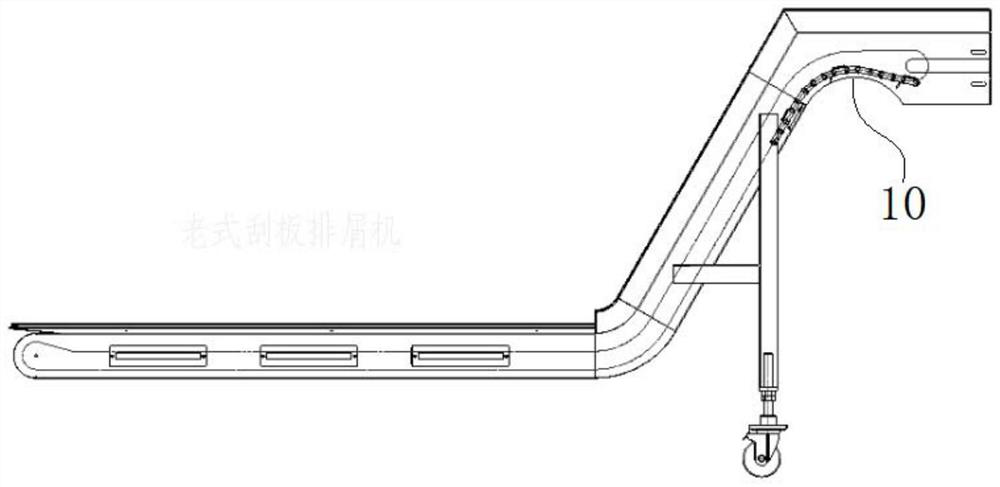

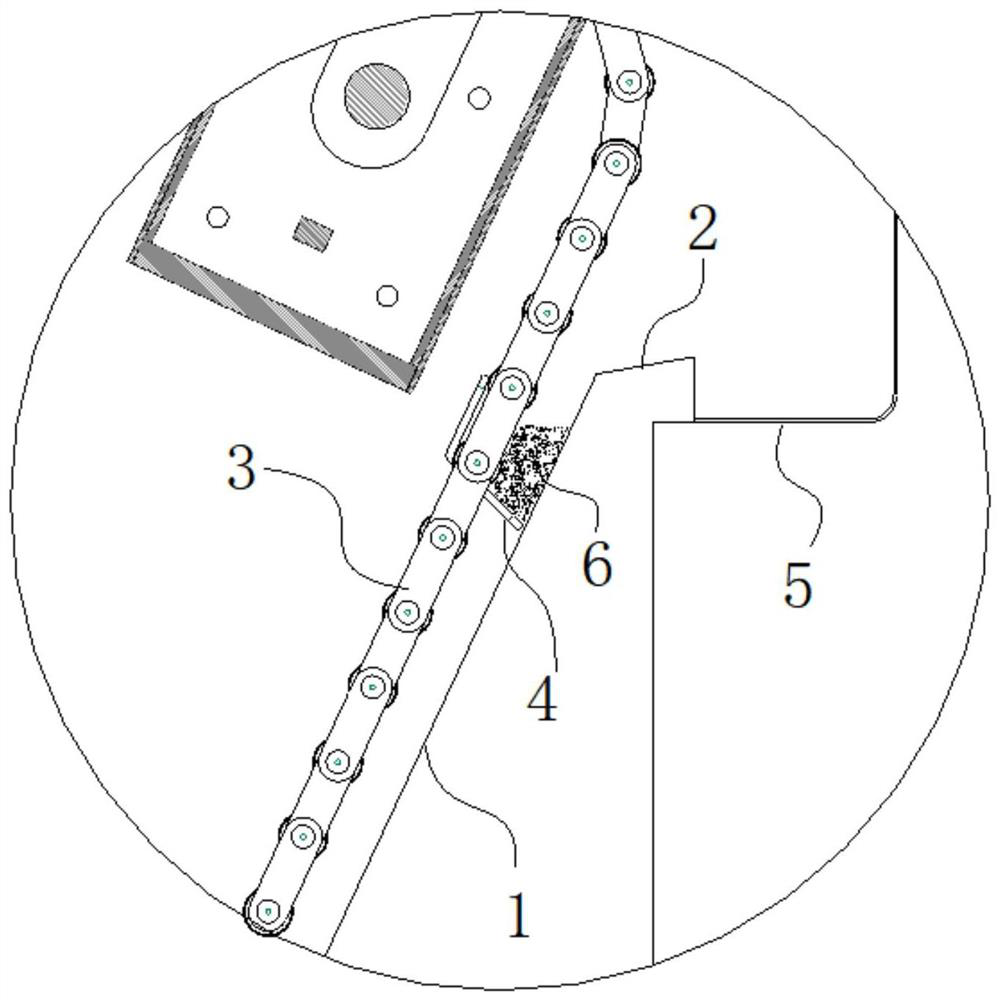

Scraper type chip removal device and chip removal method

PendingCN113103056AReduce carryAvoid churnMaintainance and safety accessoriesStructural engineeringProcess engineering

The invention discloses a scraper type chip removal device and a chip removal method, and belongs to the technical field of machine tool machining matched equipment. The scraping plate type chip removal device comprises a circulating type scraper chain and a plurality of scrapers, wherein one ends of the scrapers are fixedly connected to the circulating type scraper chain, and the other ends of the scrapers are tightly attached to a chip removal climbing section; and a chip removal retention section is arranged between the chip removal climbing section and a chip removal discharging port. By fully utilizing the poor adhesive force between cutting fluid and scrap iron and the inclination angle of the scrapers in the conveying process, the cutting fluid is separated from the scrap iron under the action of the gravity of the cutting fluid and then flows back into a cutting fluid pool along the chip removal climbing section, the carrying amount of the cutting fluid during scrap iron falling is reduced, and therefore loss and waste of the cutting fluid are avoided, and the pollution to soil or environment caused by chemical components contained in the cutting fluid is also avoided.

Owner:马鞍山昇工智能科技有限公司

Synthetic method of clinic effect of alendronate

ActiveCN101284848AOvercoming the disadvantages of solidification and inability to stirAvoid spontaneous combustion, dangerous problemsGroup 5/15 element organic compoundsSkeletal disorderPhosphorous acidOperability

The invention provides a method for synthesizing alendronic acid. According to the invention, 4-aminobutyric acid, phosphorous acid, phosphorus trichloride or phosphorus pentachloride are reacted in aprotic polar solvent, and then the mixture obtained through the reaction is hydrolyzed and crystallized to obtain the alendronic acid. The method has high safety and reliability, easily separated product, strong operability, high yield and low cost, and is particularly suitable for large-scale production.

Owner:CSPC OUYI PHARM CO LTD

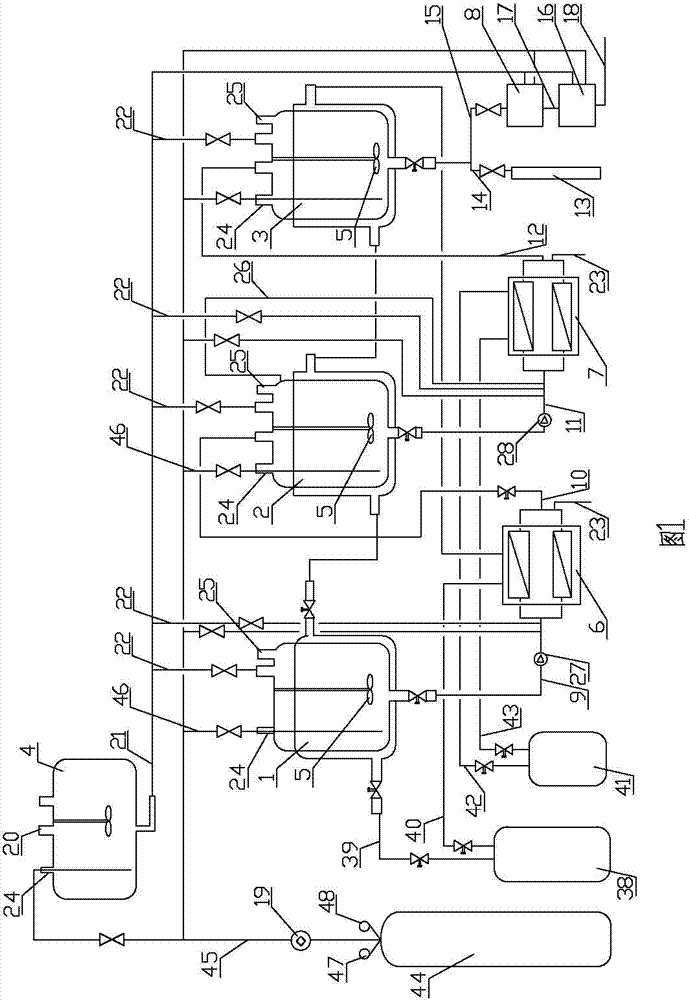

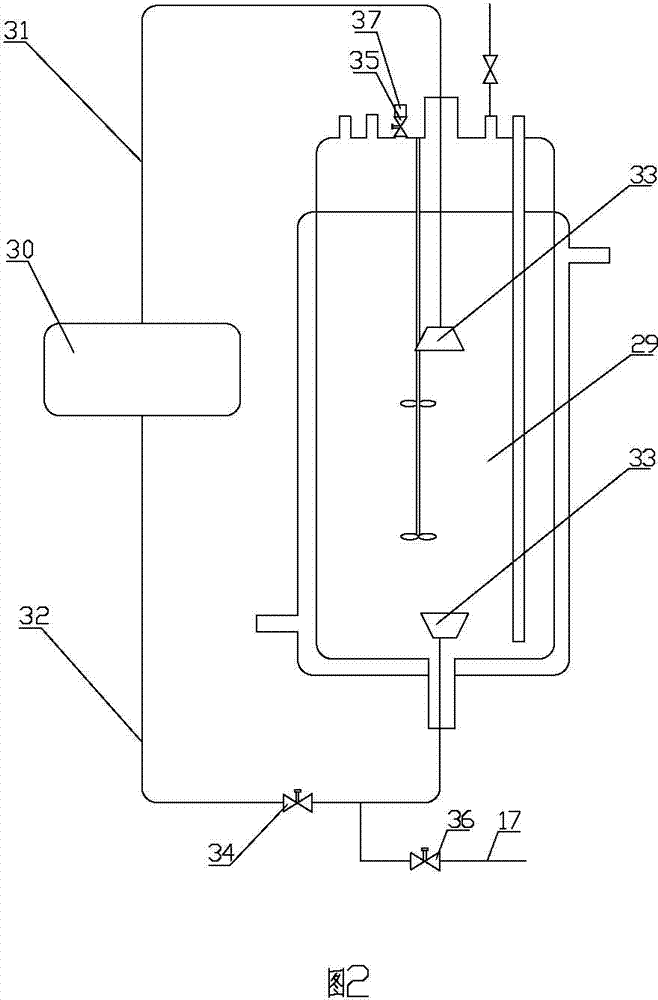

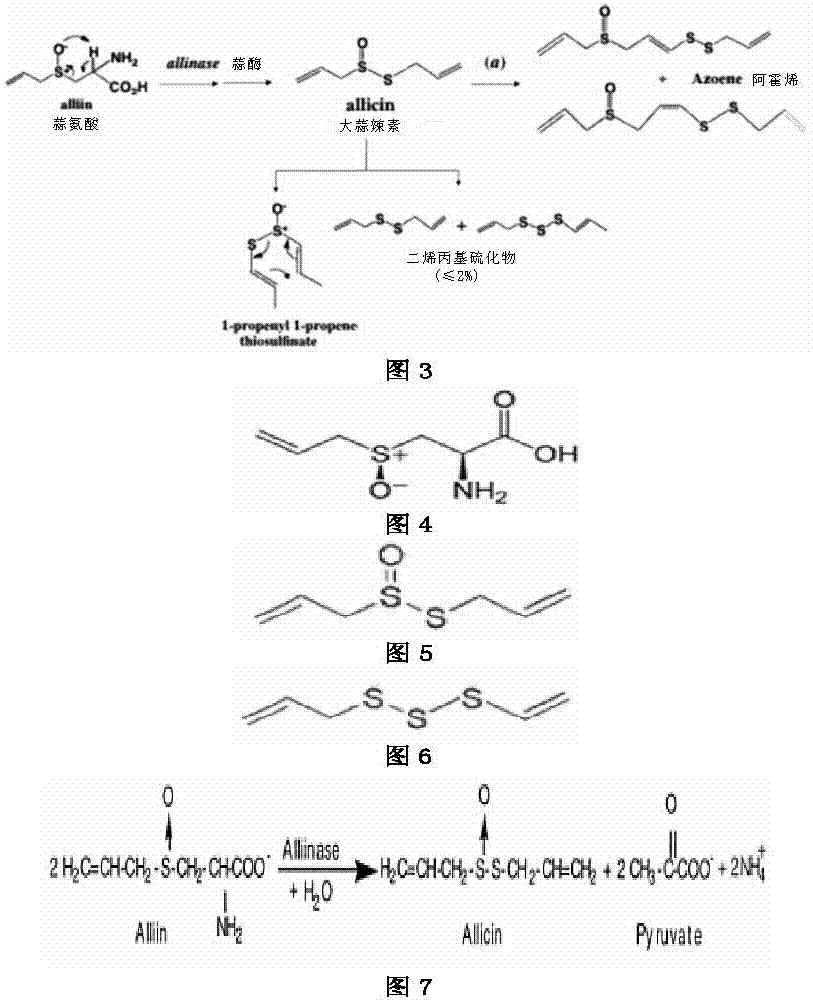

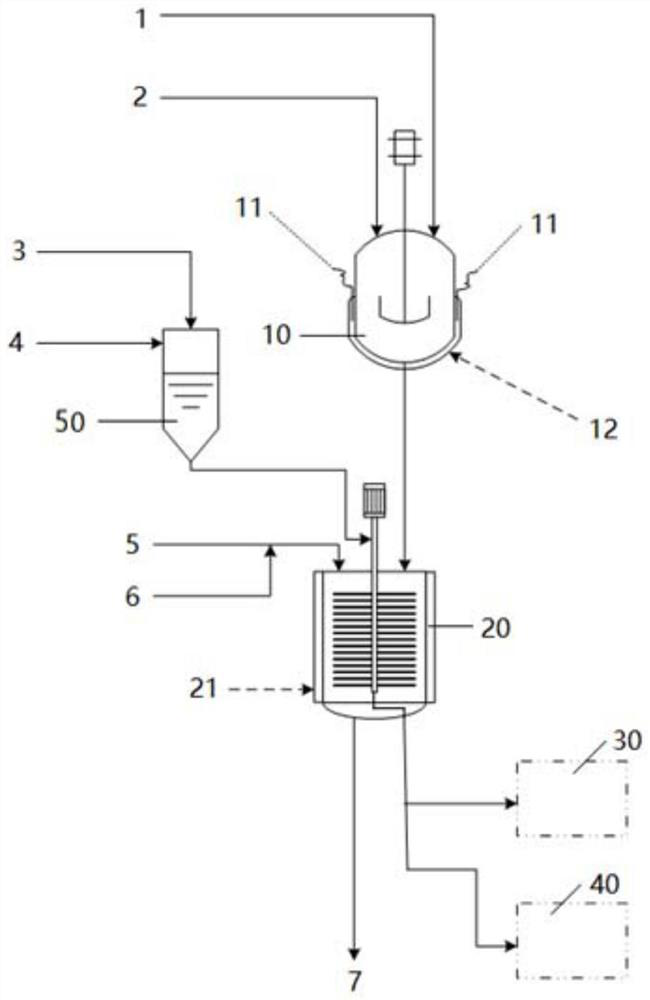

Low-temperature air-isolated allicin production apparatus and usage method thereof

ActiveCN104498351AMild conditionsEffective isolationBioreactor/fermenter combinationsOrganic chemistryLysisDistillation

The invention relates to the technical field of biosynthesis apparatuses, and relates to a low-temperature air-isolated allicin production apparatus and a usage method thereof. The production apparatus comprises a reaction tank, a first low-temperature aseptic tank, a second low-temperature aseptic tank, a microfiltration device, an ultrafiltration device, a cycled extraction device, an injection loading device, a molecular distillation device and an oxygen-removed water tank. Through current pharmaceutical new technologies such as alliinase catalyzing alliin lysis for biosynthesis of allicin, microfiltration and ultrafiltration for purifying allicin, cycled extraction and molecular distillation for realizing liquid-liquid separation, physical sterilization and argon-filling precharging and the like, the low-temperature air-isolated allicin production apparatus effectively isolates air, reduces the temperature of biologically synthesizing allicin and avoids allicin decomposition, and enables the allicin biological synthesis conditions to be mild, the yield to be high and the quality to be excellent. Also the low-temperature air-isolation allicin production apparatus is especially applicable to separation of heat-sensitive easily-oxidized substances, and is capable of effectively keeping the physical properties of natural substances.

Owner:新疆胡蒜研究院(有限公司)

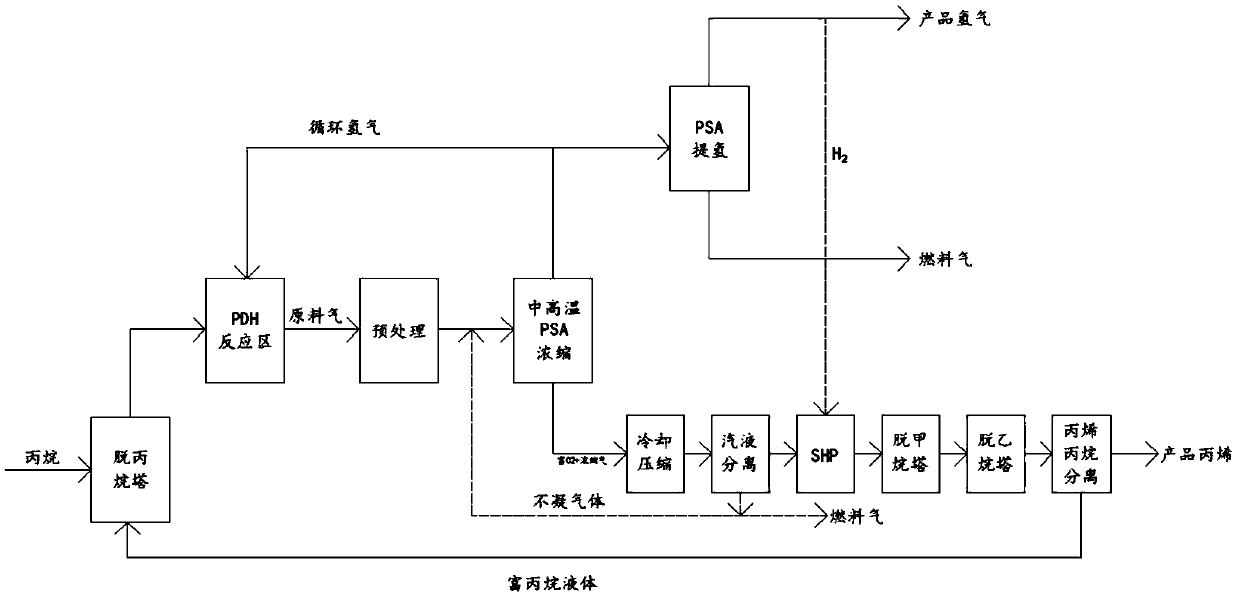

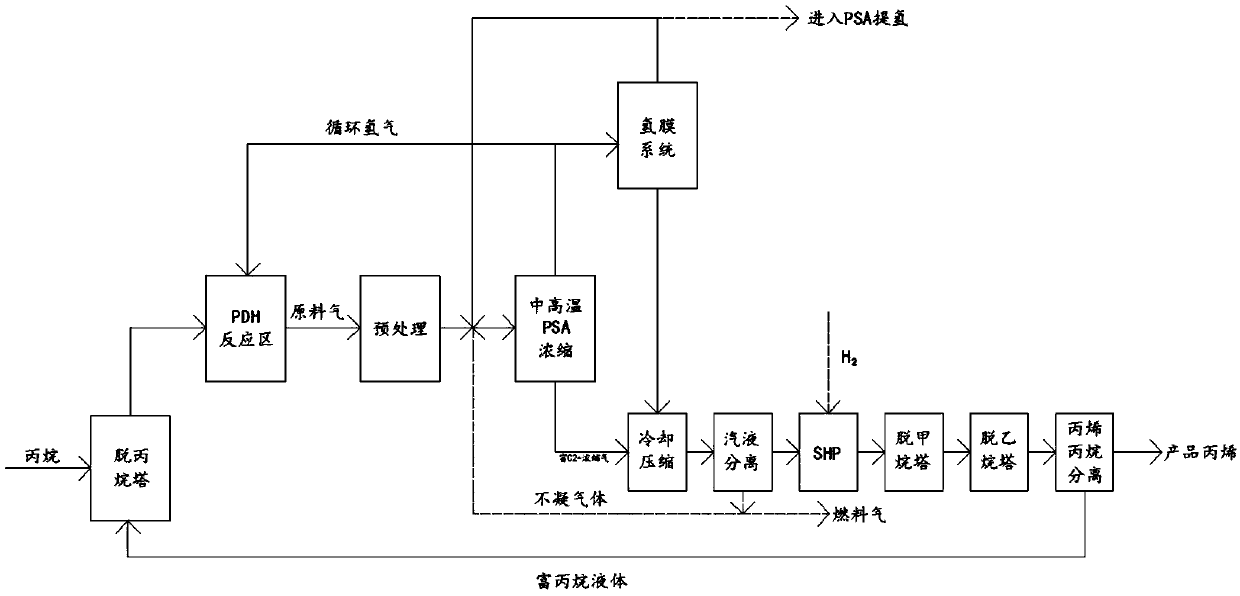

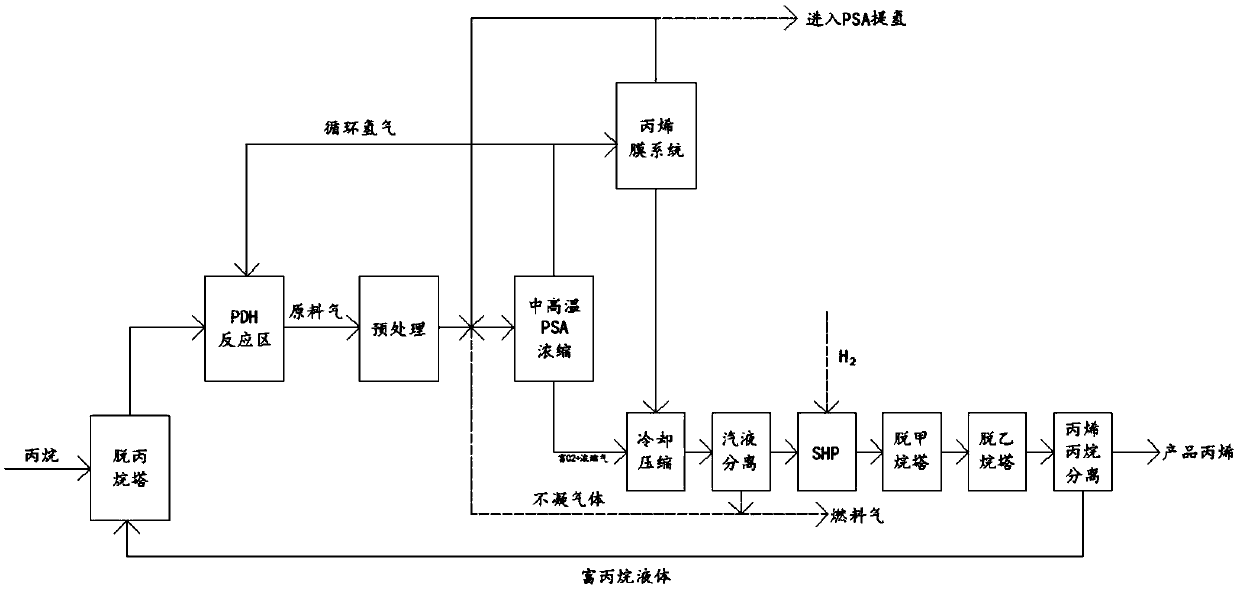

Method for separating mixed gas FTrPSA in reaction for preparing propylene by dehydrogenizing propane

InactiveCN109574787ASuitable for separationReduce contentHydrocarbonsAdsorption purification/separationHydrogenFractionation

The invention discloses a method for separating a mixed gas FTrPSA in a reaction for preparing propylene by dehydrogenizing propane. The method comprises the following steps: (1) taking a reactant mixed gas in a reaction zone for preparing the propylene by dehydrogenizing the propane as a raw gas, and performing pre-treatment to obtain a raw gas A; (2) enabling the raw gas A to enter a medium-hightemperature PSA concentrating system with the operating temperature of 30 to 160 DEG C and the operating pressure of 0.2 to 4.0 MPa to obtain a hydrogen-rich gas component and a C<2+>-rich concentrated gas; (3) directly using part of the hydrogen-rich gas component as circulating hydrogen required by a PDH reaction zone, and enabling the other part of the hydrogen-rich gas component to enter a PSA hydrogen extracting process to obtain a product, namely, the hydrogen, wherein desorbed gas of the hydrogen is directly output as fuel; and (4) after the C<2+>-rich concentrated gas is cooled, compressed and subjected to gas-liquid separation, recycling C<2+> and forming a liquid to enter a PDH product fractionation zone to obtain a propylene product, and returning the unreacted propane to propane raw gas to mix and enter the PDH reaction zone for reacting. Through the combination of the processes of performing pre-treatment, medium-high temperature PSA concentrating and PSA hydrogen extracting, the comprehensive energy consumption is low, and the equipment is low in investment cost and is safe.

Owner:SICHUAN TECHAIRS

Method of removing organic solvent from plant extract

InactiveCN108992966AImprove adsorption capacitySuitable for separationSolid solvent extractionMANGANESE ACETATEDesorption

The invention discloses a method of removing an organic solvent from plant extract. The method comprises the following steps: S1, preparation of ginkgo biloba extract; S2, removal of ginkgolic acid bymeans of an organic solvent method; S3, removal of ginkgolic acid by means of an organic solvent-macroporous resin method; and S4, removal of phenolic acid by means of an organic solvent-macroporousresin-coordinate method. The AB-8type macroporous resin adopted by the method is relatively high in adsorption and desorption rates to flavonoid compounds and is relatively suitable for separating active components and removing phenolic acid in initial ginkgo biloba extract by adopting the organic solvent method, the macroporous resin method and the coordinate method continuously. Ginkgolic acid can form a complex with metal salt. The content of phenolic acid can be reduced effectively by adopting manganese acetate and zinc chloride. The ginkgolic acid in the initial ginkgo biloba extract is removed favorably by means of the macroporous resin method and the organic solvent method matched with the coordinate method. The ginkgo biloba extract with extremely low phenolic acid content can be obtained. The method is simple in process, convenient to operate and good in phenolic acid removal effect.

Owner:安徽桧元素生物科技有限公司

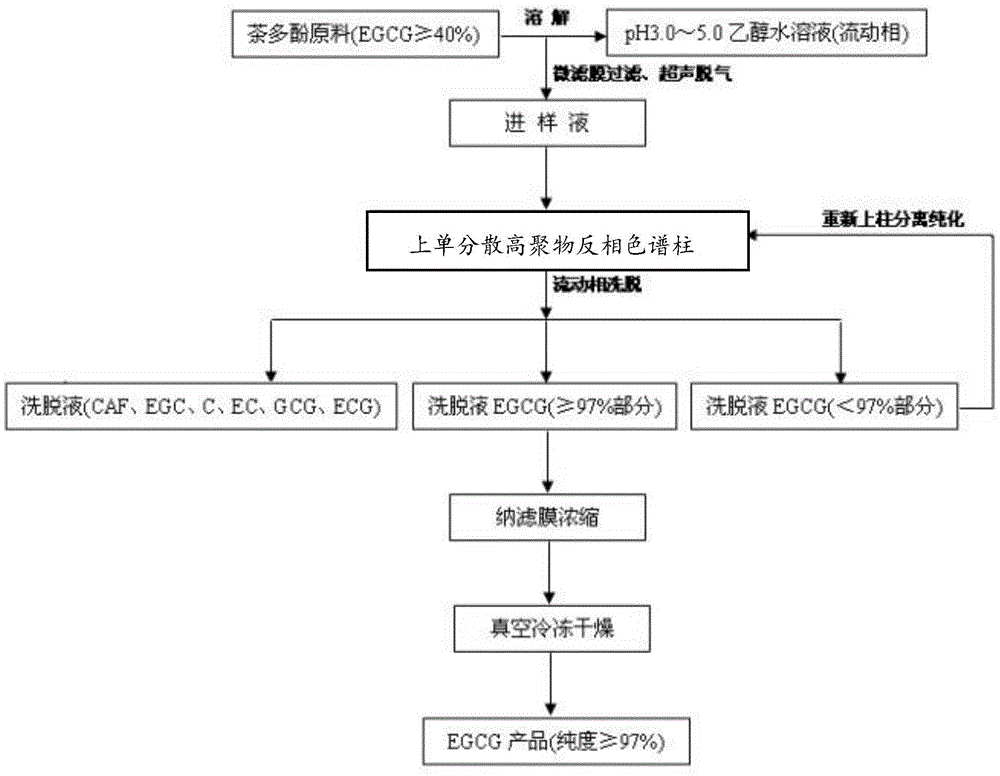

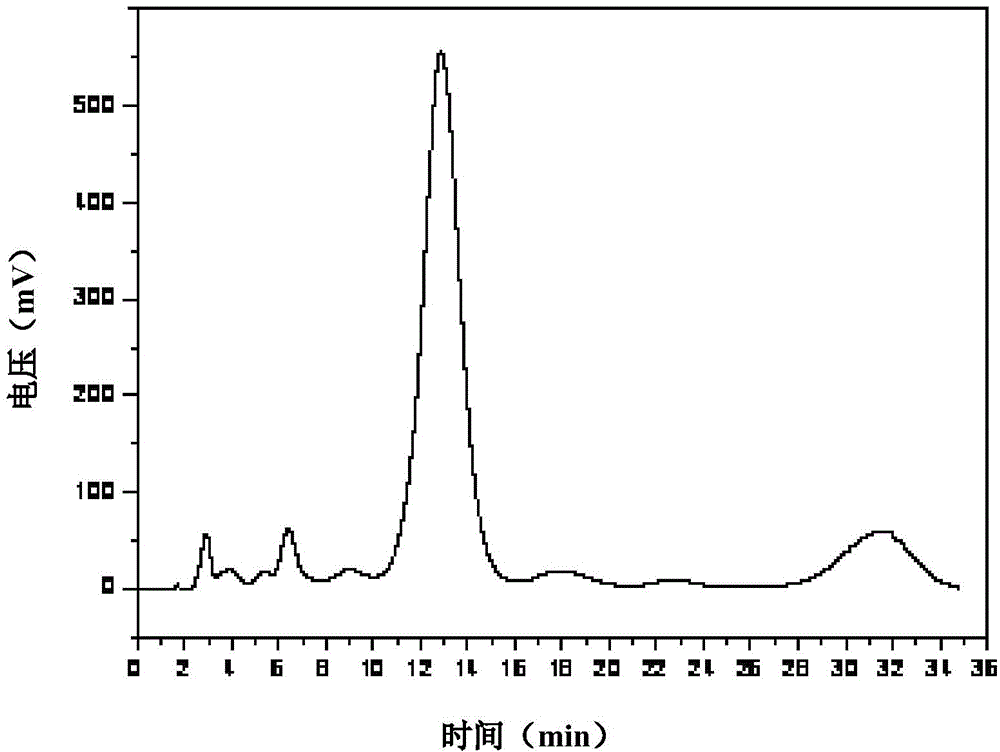

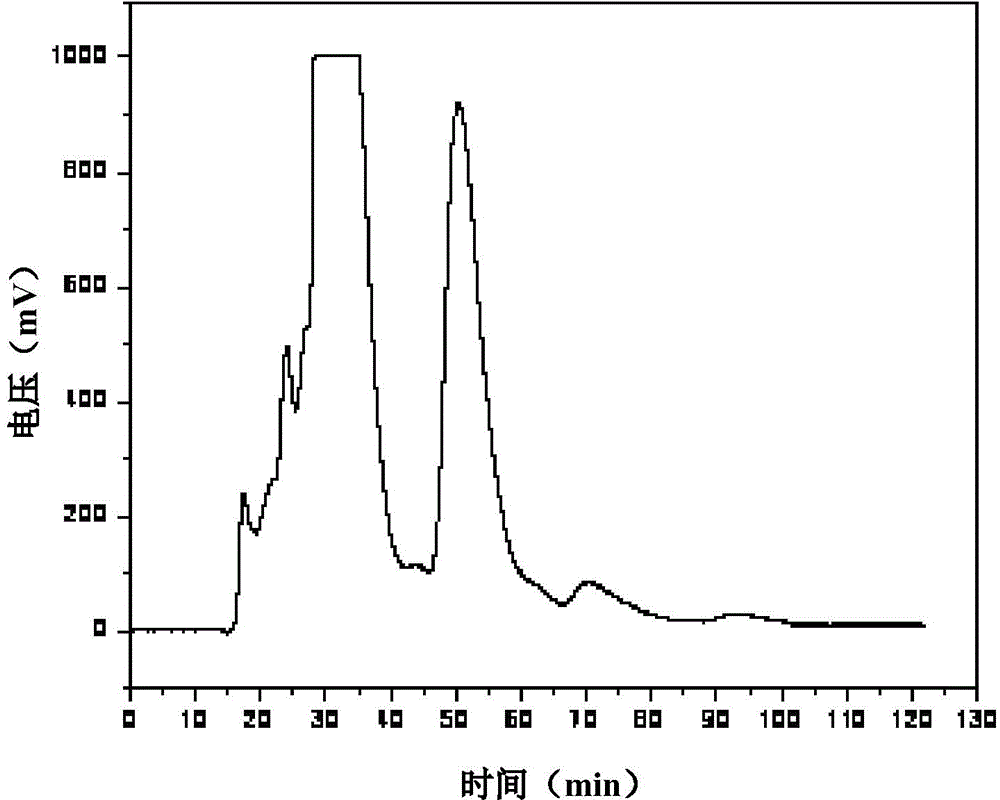

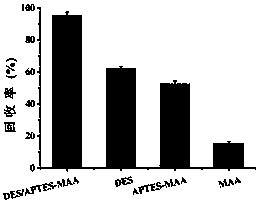

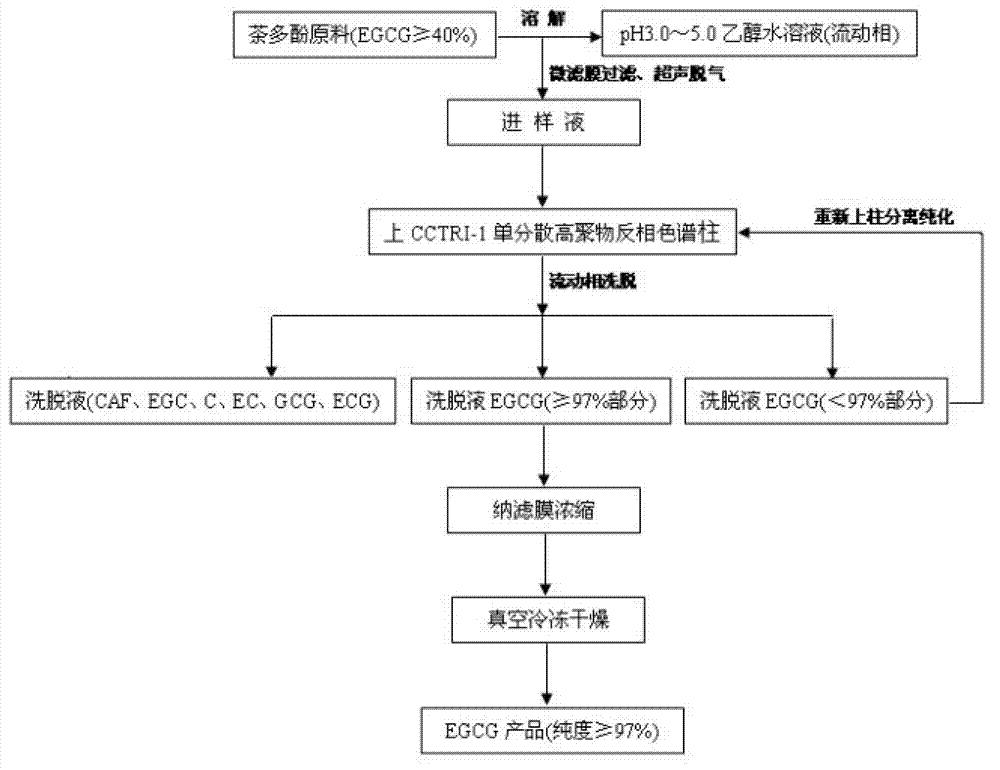

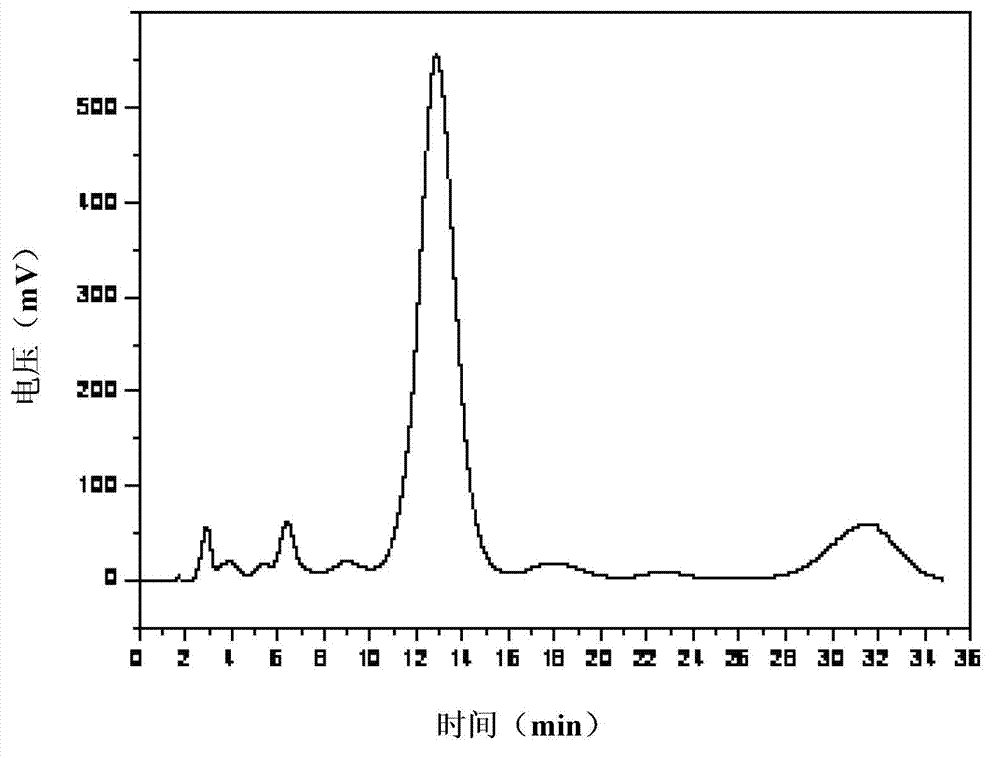

Method for separating and purifying EGCG (Epigallocatechin Gallate) by medium-pressure high polymer inversed phase chromatography

ActiveCN102964329BAvoid security issuesMaintain biological activityOrganic chemistryFiltration membraneSolvent

The invention discloses a method for separating and purifying EGCG (Epigallocatechin Gallate) by medium-pressure high polymer inversed phase chromatography. The method comprises the steps of dissolving a tea polyphenol raw material by taking acidified ethanol water with certain concentration as a mobile phase, filtering the acidified ethanol water by a micro-filtration membrane, then eluting the mobile phase by using a CCTRI-1 monodisperse high polymer inversed phase chromatographic column, collecting eluted cut fractions in a segmenting manner, concentrating the cut fractions to a certain concentration by a nanofiltration membrane, and drying the concentrate in a vacuum freeze drier to obtain a high-purity EGCG product. According to the method, the process is simple, the operation is convenient, the production cycle is short, the separating efficiency is high, the product purity is high, and a solvent used in the separation and purification process is ethanol solution which is non-toxic and can be recycled, so that the low carbon and environmental protection effect is realized, and the safety problem caused by the using of organic solvents can be effectively avoided.

Owner:HANGZHOU TEA RES INST CHINA COOP

Method for separating and preparing rumicin

InactiveCN102476986AHigh purityHigh recovery rateCarbonyl compound separation/purificationChromatographic separationEthyl acetate

The present invention discloses a method for separating and preparing rumicin. The method comprises subjecting sheep hooves to percolation extraction with dichloromethane, and recovering the solvent to obtain a dry crude extract; and selecting a two-phase solvent system, adopting high-speed countercurrent chromatography, dissolving the crude extract in a mixed solution of a top phase and a bottom phase, filling a stationary phase in a separation column, connecting the head end of the separation column with a sampling valve, collecting an isolate, concentrating, and drying to obtain the final product. The two-phase solvent system is a petroleum ether-ethyl acetate-ethanol-water system, the top phase is the stationary phase, and the bottom phase is a mobile phase. The prepared product has content of rumicin up to 98%.

Owner:苏州宝泽堂医药科技有限公司

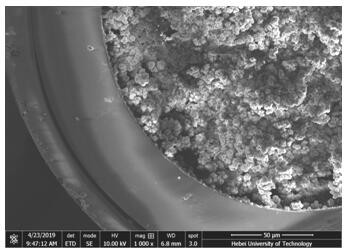

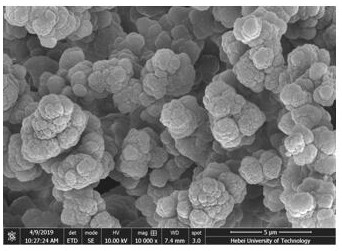

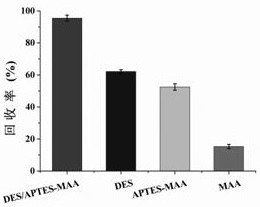

Monolithic Column Combining deep eutectic solvents Monomer and Hybrid Monomer

ActiveCN110124633AGood water solubilityImprove adsorption capacityMaterial analysis using wave/particle radiationOther chemical processesPolymer scienceFunctional monomer

The invention relates to an integral column combining a deep eutectic solvent monomer and a hybrid monomer. DES monomer (choline chloride-methacrylic acid) and hybrid monomer (3-aminopropyltriethoxysilane-methacrylic acid) as binary functional monomers, ethylene glycol dimethacrylate as a cross-linking agent, methanol and PEG 20000 as a binary porogen, and an in-situ thermal polymerization processare used to prepare the a novel monolithic column. The monolithic column has the advantages of low cost and simple synthesis process, and the prepared monolithic column has good permeability, strongmechanical strength and biocompatibility, and can successfully separate bovine serum albumin and cytochrome C, and simultaneously can achieve better enrichment of two proteins of the bovine serum albumin and the cytochrome C. The method provides a new idea for the separation and purification of proteins.

Owner:TIANJIN MEDICAL UNIV

Method for separating and purifying EGCG (Epigallocatechin Gallate) by medium-pressure high polymer inversed phase chromatography

ActiveCN102964329AImprove separation efficiencyEasy to separateOrganic chemistryFiltration membraneSolvent

The invention discloses a method for separating and purifying EGCG (Epigallocatechin Gallate) by medium-pressure high polymer inversed phase chromatography. The method comprises the steps of dissolving a tea polyphenol raw material by taking acidified ethanol water with certain concentration as a mobile phase, filtering the acidified ethanol water by a micro-filtration membrane, then eluting the mobile phase by using a CCTRI-1 monodisperse high polymer inversed phase chromatographic column, collecting eluted cut fractions in a segmenting manner, concentrating the cut fractions to a certain concentration by a nanofiltration membrane, and drying the concentrate in a vacuum freeze drier to obtain a high-purity EGCG product. According to the method, the process is simple, the operation is convenient, the production cycle is short, the separating efficiency is high, the product purity is high, and a solvent used in the separation and purification process is ethanol solution which is non-toxic and can be recycled, so that the low carbon and environmental protection effect is realized, and the safety problem caused by the using of organic solvents can be effectively avoided.

Owner:HANGZHOU TEA RES INST CHINA COOP

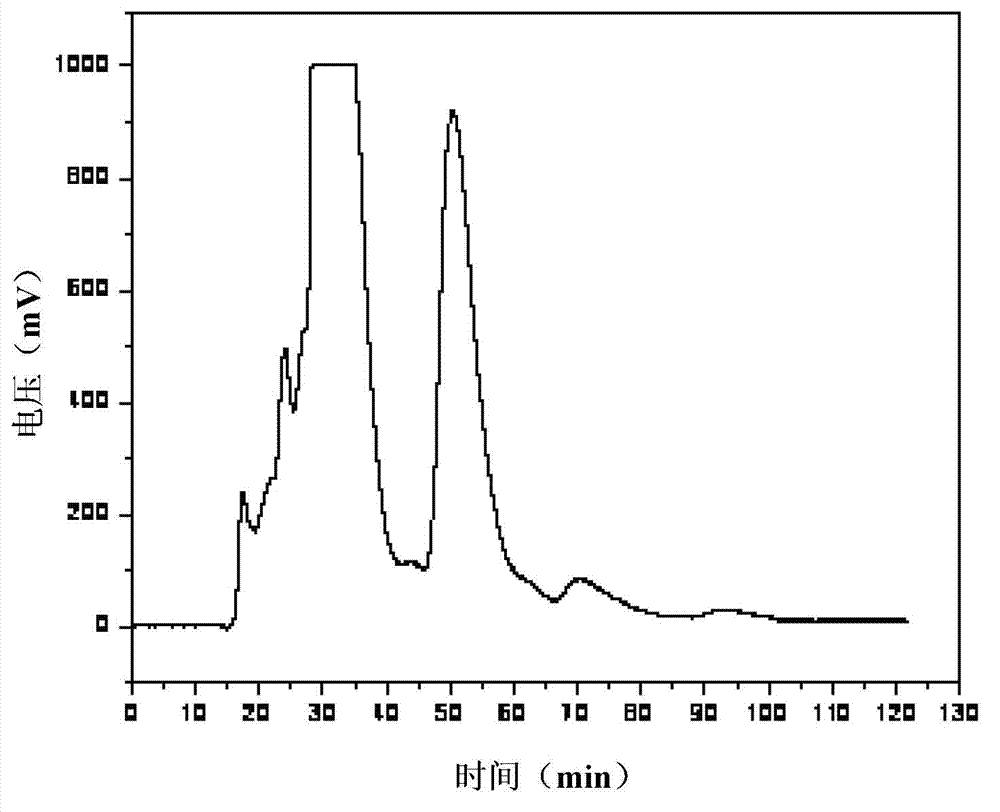

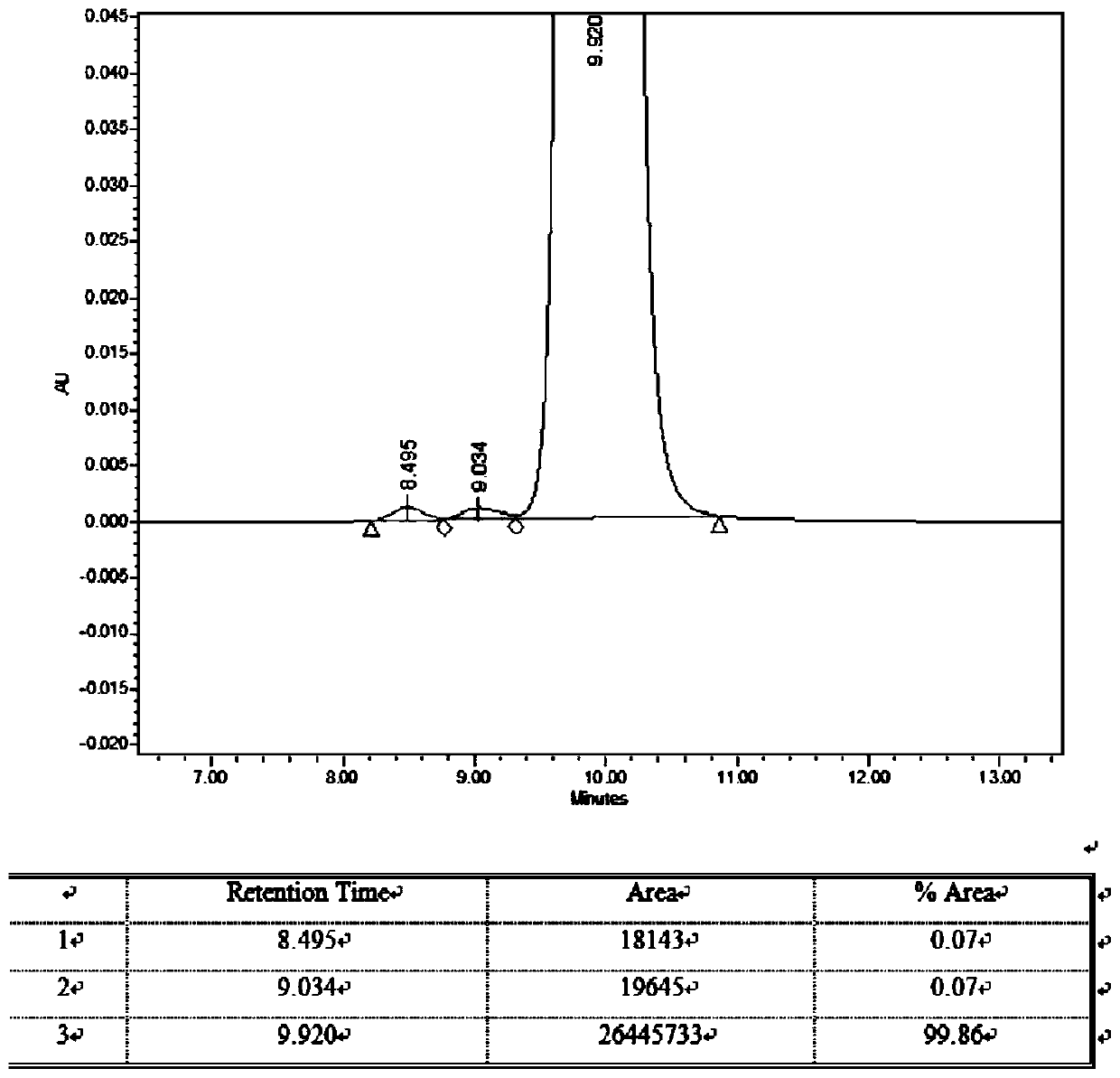

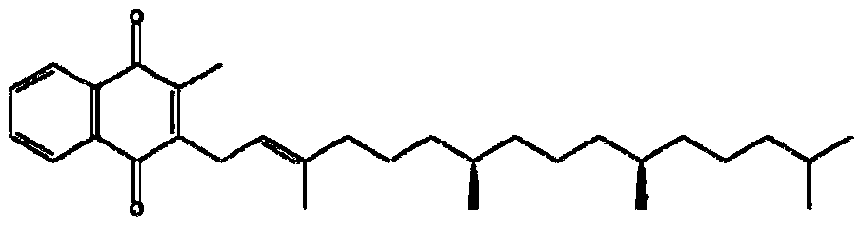

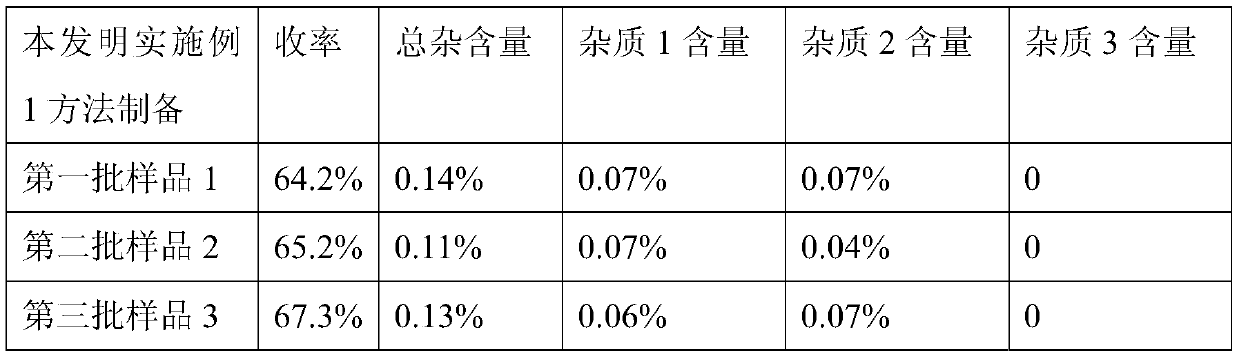

Purification process of vitamin K1

ActiveCN111574348ASave time and costReduce labor costsQuinone separation/purificationEthyl acetateSilica gel

The invention relates to a purification process of vitamin K1, which comprises the following steps: 1, carrying out chromatographic purification on synthesized crude VK1 by using a DAC600 preparativechromatographic column taking a C18 reversed-phase silica gel column as a filler and using a mixed solution of methanol and ethyl acetate as a mobile phase; and 2, further carrying out chromatographicpurification on the VK1 obtained in the step 1 and subjected to chromatographic purification by the reversed-phase silica gel column by taking normal-phase chromatographic silica gel as a filler andtaking normal hexane as a mobile phase.

Owner:ZHEJIANG CHENGYI PAHRMACEUTICAL

Industrial device and process for lithium iron phosphate liquid-phase thermal synthesis

PendingCN114643024AHigh level of integrationThe device takes up little spaceReverse osmosisPhosphorus compoundsFluid phaseElectrode material

The invention provides an industrial device for lithium iron phosphate liquid-phase thermal synthesis, which comprises a liquid-phase reaction kettle used for mixing raw materials for preparing lithium iron phosphate and auxiliaries to form nano-scale or micron-scale lithium iron phosphate particles under proper reaction conditions; the washing and separating integrated kettle is communicated to the mixed liquid outlet of the liquid-phase reaction kettle, at least one group of separating components for dynamically filtering the mixed liquid are arranged in the washing and separating integrated kettle, and each separating component comprises a hollow rotating shaft rotatably arranged on the kettle and a plurality of hollow separating membranes arranged on the hollow rotating shaft at intervals; the separation membrane can enable liquid to penetrate through the surface to enter the inner cavity, the inner cavity of the separation membrane is communicated with the hollow rotating shaft, and a liquid outlet of the hollow rotating shaft is communicated with the reaction liquid recovery unit; the washing and separating integrated kettle is communicated with a washing solvent inlet pipe and a wet material outlet pipe, a liquid outlet of the hollow rotating shaft is further communicated with a washing liquid recycling unit, and the lithium iron phosphate battery positive electrode material with excellent electrochemical performance can be prepared by adopting the device.

Owner:SHANGHAI ANHORN ENVIRONMENTAL TECH CO LTD

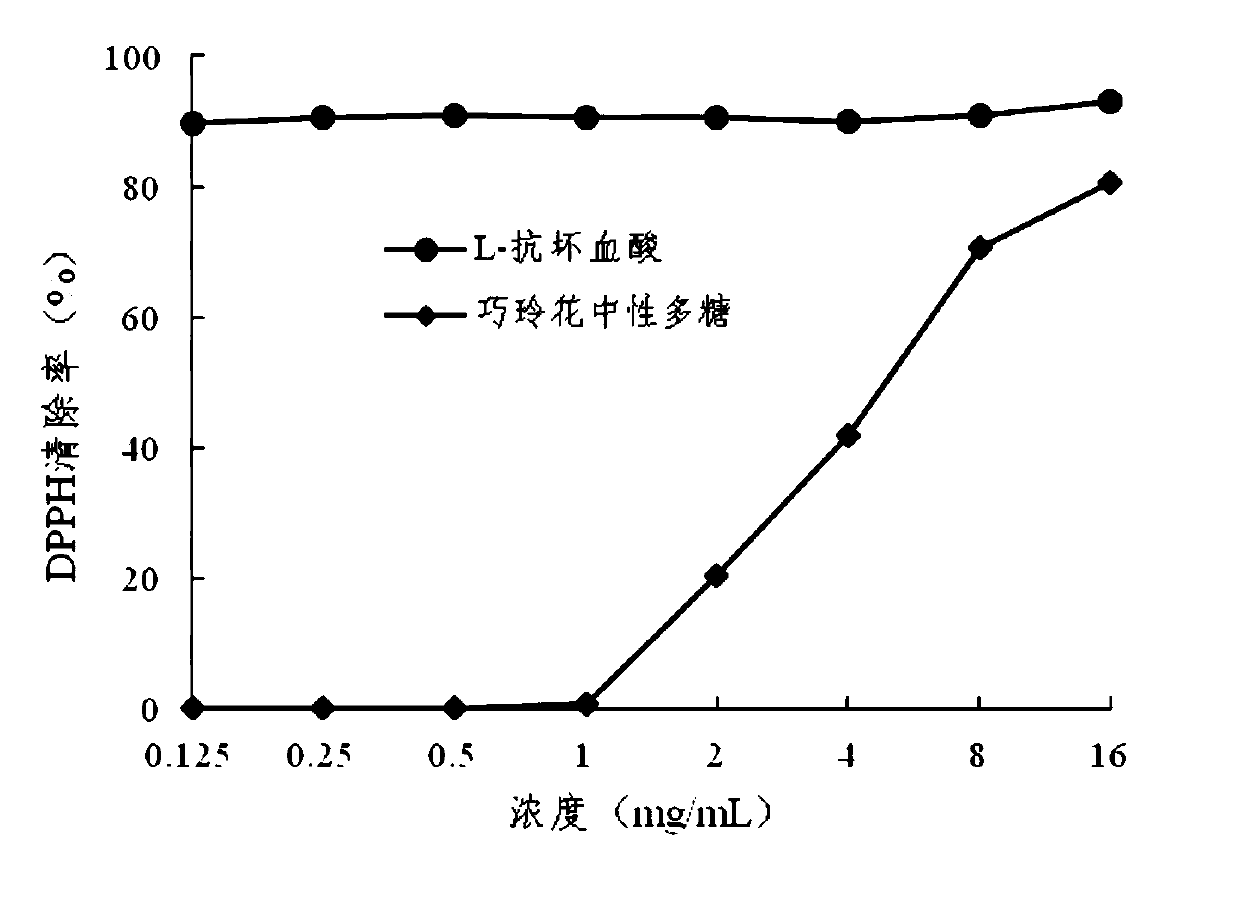

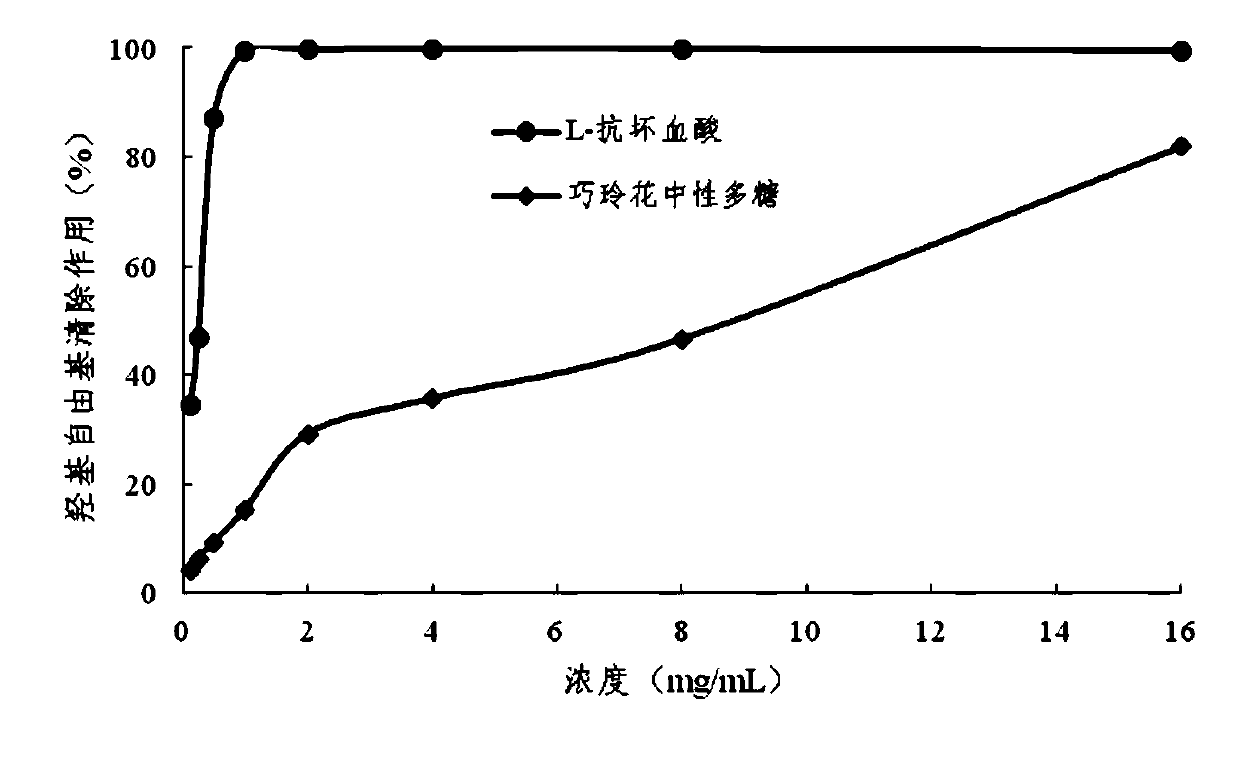

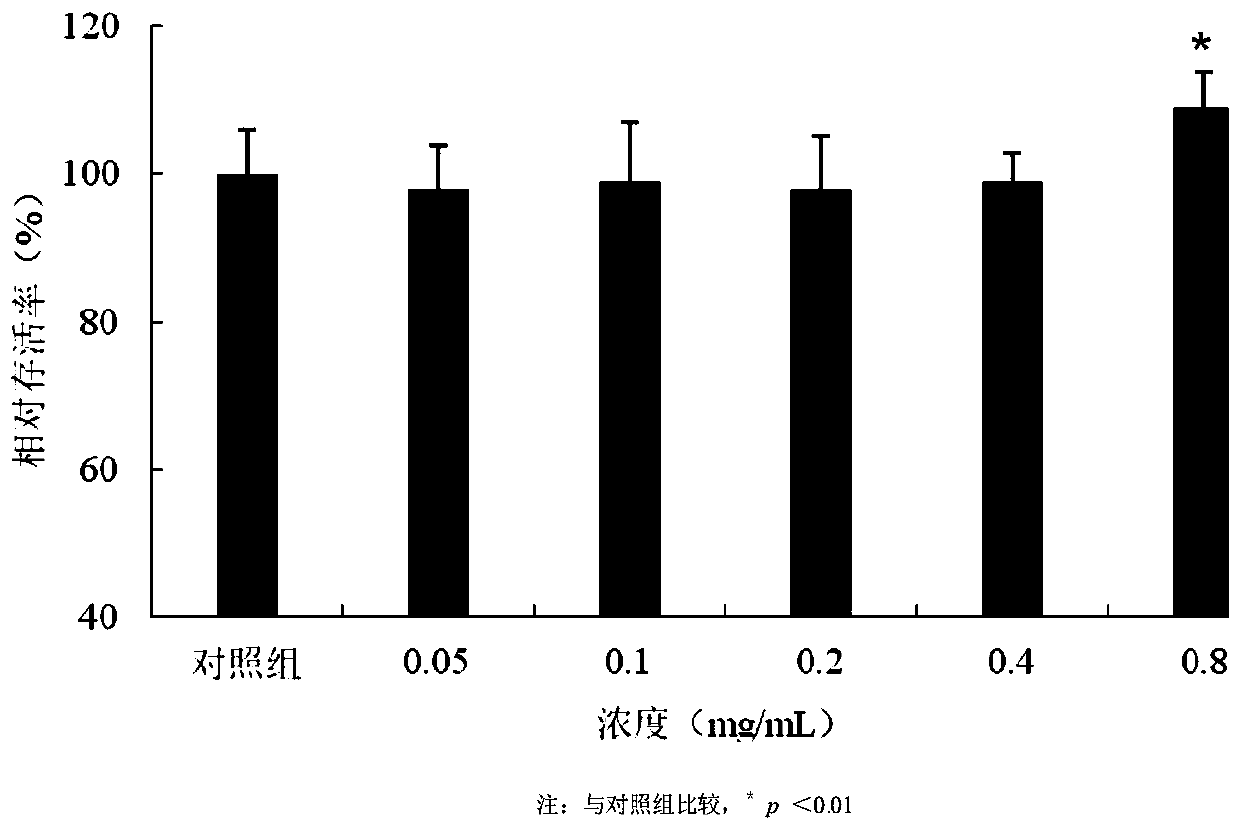

Method for preparing neutral polysaccharide from syringa pubescens turcz

The invention provides a method for preparing neutral polysaccharide from syringa pubescens turcz. An ultrasonic extraction method provided by the invention has the characteristics of high efficiency,simplicity and convenience; a trichloroacetic acid method is short in deproteinization time, small in solvent amount, simple and feasible and high in protection removal rate; a resin method is high in decolorizing efficiency and low in cost and resin can be repeatedly used; DEAE (diethyl-aminoethanol)-cellulose has a large adsorption capacity and good stability so that the DEAE-cellulose is especially suitable for separating the neutral polysaccharide. The method for preparing the neutral polysaccharide from the syringa pubescens turcz, provided by the invention, is scientific, reasonable andfeasible; the neutral polysaccharide prepared by the invention can be further developed into an antioxidant or a food additive and the like and is suitable for being popularized and applied in a large range.

Owner:HENAN UNIV OF SCI & TECH

A method and process device for recycling waste high boiling point heat transfer oil

InactiveCN104178210BSuitable for separationLower operating temperatureTreatment with hydrotreatment processesHeat conductingGas phase

A method for recovering waste high-boiling-point heat-transfer oil comprises the steps: 1, pre-processing waste heat-transfer oil; 2, performing hydrogenation refining on the waste heat-transfer oil pre-processed in the step 1; and 3, performing fractional distillation on the waste heat-transfer oil subjected to hydrogenation refining in the step 2. Concretely, fractional distillation in the step 3 is performed according to the following steps: 1), enabling liquid-phase oil separated out from hydrogenation low-pressure separation composition to enter a reduced-pressure flash-evaporation tower, cooling a gas phase getting out from the top of the reduced-pressure flash-evaporation tower by a condenser, and enabling the cooled gas phase to enter a reflux tank at the tower top, pumping and exhausting the gas phase into atmosphere, pumping out a liquid phase via a reflux pump and taking the liquid phase as naphtha and sending to a storage tank; and 2) pressurizing falling-film distillation tower bottom distillates and conveying to a reduced-pressure distillation tower by a conveying pump, cooling a gas phase getting out from the top of the reduced-pressure distillation tower by a condenser and enabling the cooled gas phase to enter a reflux tank at the tower top for oil-gas separation, enabling the liquid phase to be as reduced-pressure tower-top oil and enter a condenser for cooling, one branch of the reduced-pressure tower-top oil is used for column-plate refluxing, one branch of the reduced-pressure tower-top oil is used as 7# white oil and conveyed to an irrigated-area storage tank for self use and export sale, and one branch of the reduced-pressure tower-top oil is used 15# white oil and conveyed to an irrigated-area storage tank for self use and export sale. The method has the characteristics of low energy consumption, cleaning, environmental protection, high economic benefit economic benefit and high yield.

Owner:山东恒利热载体工程技术有限公司

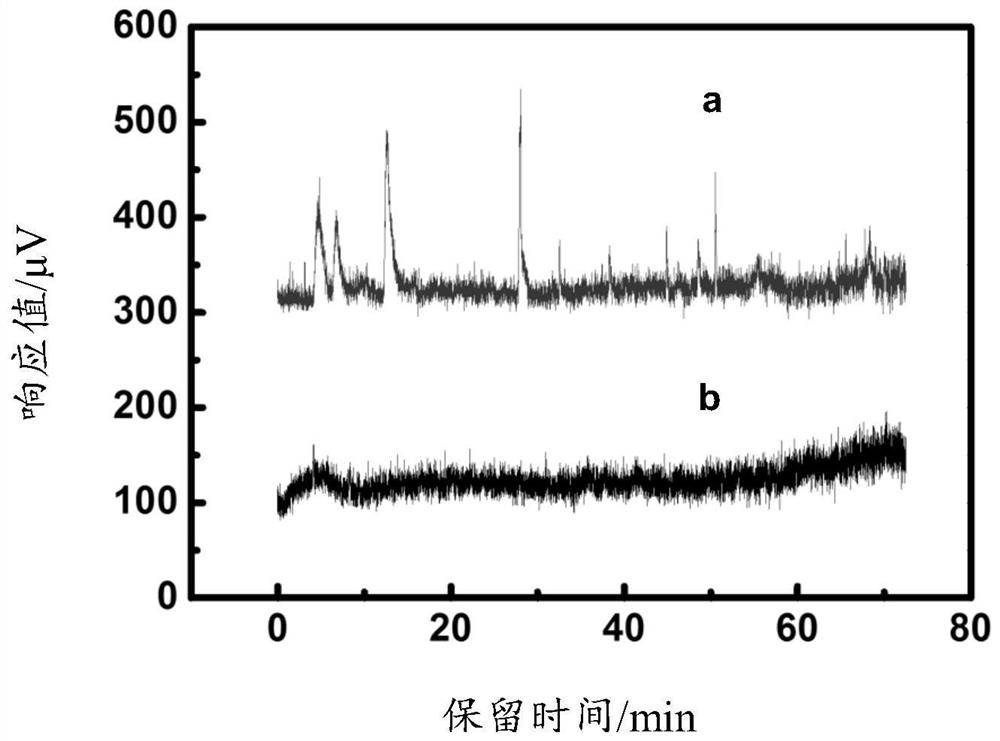

Method for detecting the structure and/or content of polar substances in non-polar matrices

ActiveCN109709219BAccurate analysisEasy to operateComponent separationChemical physicsChemical compound

The present invention proposes a method for detecting the structure and / or content of polar substances in nonpolar substrates. The method for detecting the structure and / or content of polar substances in non-polar substrates of the present invention includes: 1) using a polar solvent to extract the non-polar substrates; 2) extracting the polar extracts obtained through step 1) Carry out the headspace extraction operation to obtain the carrier containing the enrichment; 3) send the carrier containing the enrichment obtained through step 2) into the analytical tester, and determine the structure and / or structure of the polar substance in the non-polar matrix to be tested or content. The method of the invention can overcome the interference of a large number of non-polar substances in complex non-polar matrices, can enrich trace polar compounds in complex non-polar matrices with high selectivity, and is especially suitable for separation, enrichment, and detection of gas Trace amounts of polar substances such as sulfides and nitrides in the complex matrix of diesel oil.

Owner:CHINA PETROLEUM & CHEM CORP +1

Monolithic columns combining deep eutectic solvent monomers and hybrid monomers

ActiveCN110124633BGood water solubilityImprove adsorption capacityMaterial analysis using wave/particle radiationOther chemical processesPolymer scienceFunctional monomer

The present invention relates to a monolithic column combining deep eutectic solvent monomers and hybrid monomers. Using DES monomer (choline chloride-methacrylic acid) and hybrid monomer (3-aminopropyltriethoxysilane-methacrylic acid) as binary functional monomers, ethylene glycol dimethacrylate As the cross-linking agent, methanol and PEG 20000 were used as binary porogens, and a new type of monolithic column was prepared by in-situ thermal polymerization technology. The invention has the advantages of low cost and simple synthesis process, and the novel monolithic column produced has good permeability, strong mechanical strength and biocompatibility, and can successfully separate bovine serum albumin and cytochrome C. Proteins can be better enriched. The proposed method provides a new idea for the separation and purification of proteins.

Owner:TIANJIN MEDICAL UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com