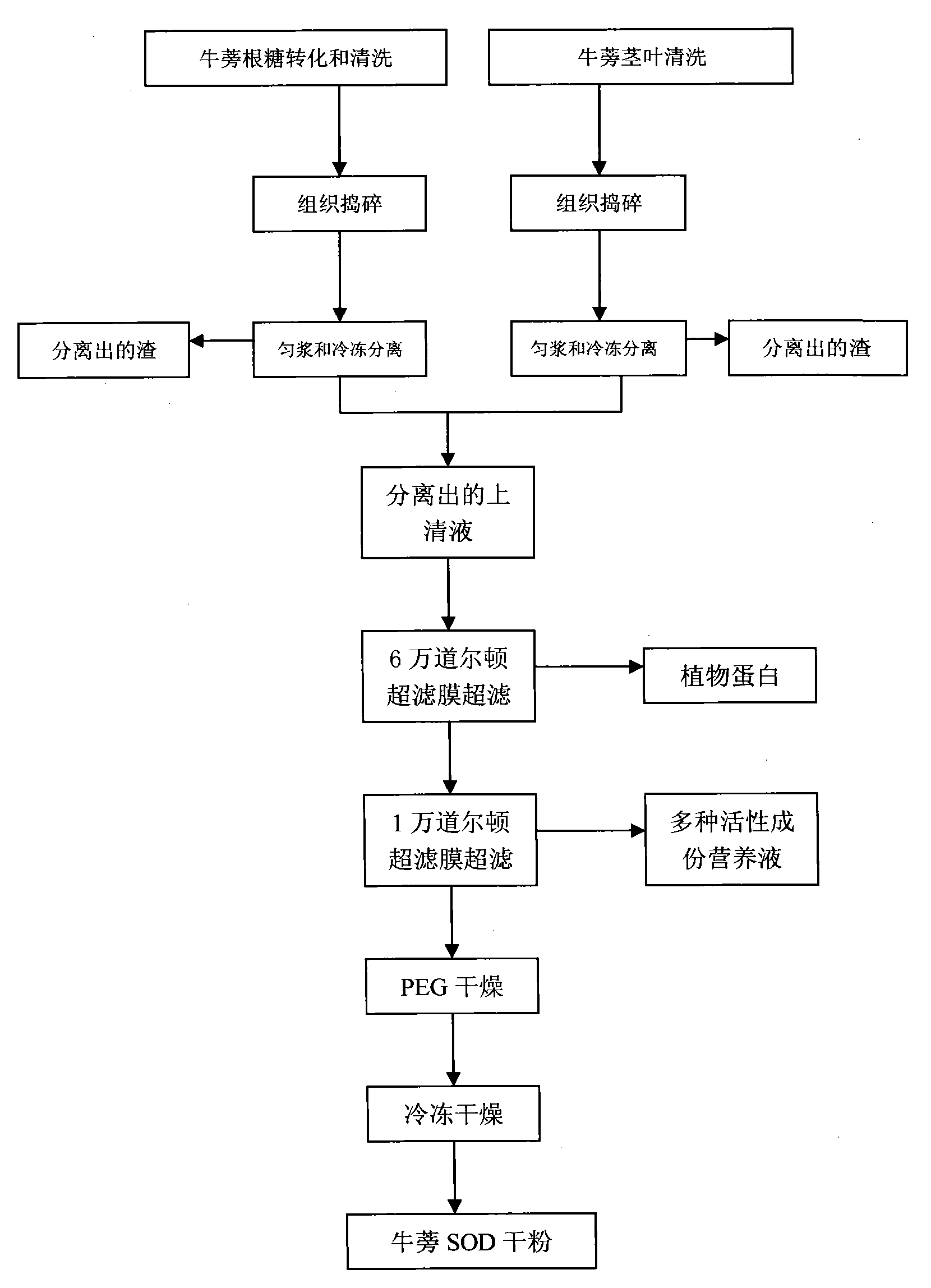

Process method for extracting superoxide dismutase from root, stem and leaf of burdock

A process method, superoxide technology, applied in the direction of oxidoreductase, peptide preparation method, chemical instrument and method, etc., can solve the problems of loss of SOD, abandonment, environmental pollution, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0007] The cleaned burdock stems and leaves are mashed with a tissue masher, and 0.001%-0.1% sodium erythorbate is added in the mashing process to prevent SOD and other active components from being oxidized. Then homogenize with a homogenizer, centrifuge with a refrigerated centrifuge at 5,000rpm-10,000rpm for 5-15 minutes, and pass ultrafiltration twice on the obtained supernatant. For the first time, use an ultrafiltration membrane with a cut-off of more than 60,000 Daltons, usually a hollow fiber ultrafiltration membrane, with a working pressure of 0.15MPa; the second ultrafiltration is to use an ultrafiltration membrane with a cut-off of more than 10,000 Daltons Ultrafiltration, usually with hollow fiber ultrafiltration membrane, the working pressure is 0.15Mpa. The 60,000 to 10,000 Dalton concentrate obtained by two ultrafiltrations is a solution containing SOD substances. The first ultrafiltration membrane material: polysulfone, membrane area: 0.12M 2 : Diameter: 10cm,...

Embodiment 2

[0009] The burdock rhizomes that have been washed and undergone sugar conversion are mashed with a tissue masher, and 0.001%-0.1% sodium erythorbate is added in the mash process to prevent SOD and other active components from being oxidized. Then homogenize with a homogenizer, centrifuge with a refrigerated centrifuge at 5,000rpm-10,000rpm for 5-15 minutes, and pass ultrafiltration twice on the obtained supernatant. The first ultrafiltration is performed with an ultrafiltration membrane with a cut-off of 60,000 Daltons, usually a hollow fiber ultrafiltration membrane, and the working pressure is 0.15MPa; the second ultrafiltration is performed with an ultrafiltration membrane with a cut-off of 10,000 Daltons , usually with hollow fiber ultrafiltration membrane, the working pressure is 0.15Mpa. The 60,000 to 10,000 Dalton concentrate obtained by two ultrafiltrations is a solution containing SOD substances. The first ultrafiltration membrane material: polysulfone, membrane area...

Embodiment 3

[0011] The cleaned burdock stems and leaves are mashed with a tissue masher, and 0.001%-0.1% sodium erythorbate is added in the mashing process to prevent SOD and other active components from being oxidized. Then homogenize with a homogenizer, centrifuge with a refrigerated centrifuge at 5,000rpm-10,000rpm for 5-15 minutes, and pass ultrafiltration twice on the obtained supernatant. For the first time, ultrafiltration with a flat ultrafiltration membrane with a cutoff of more than 60,000 Daltons was used, and the working pressure was 0.17 MPa; the second ultrafiltration was performed with a flat ultrafiltration membrane with a cutoff of more than 10,000 Daltons, and the working pressure was 0.17Mpa. The 60,000 to 10,000 Dalton concentrate obtained by two ultrafiltrations is a solution containing SOD substances. The first ultrafiltration membrane material: polysulfone, membrane area: 0.15M 2 : Length: 30cm; Width: 15cm; Height: 5cm, 0.17MPa, ultrafiltration for 45 minutes. S...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com