Transverse stretching method and device thereof

A technology of transverse stretching and conveying mechanism, which is applied in the field of transverse stretching methods and devices, can solve the problems of reduced heating efficiency, scattering, disorder, etc., and achieve the effect of preventing the reduction of thermal efficiency and improving heating efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

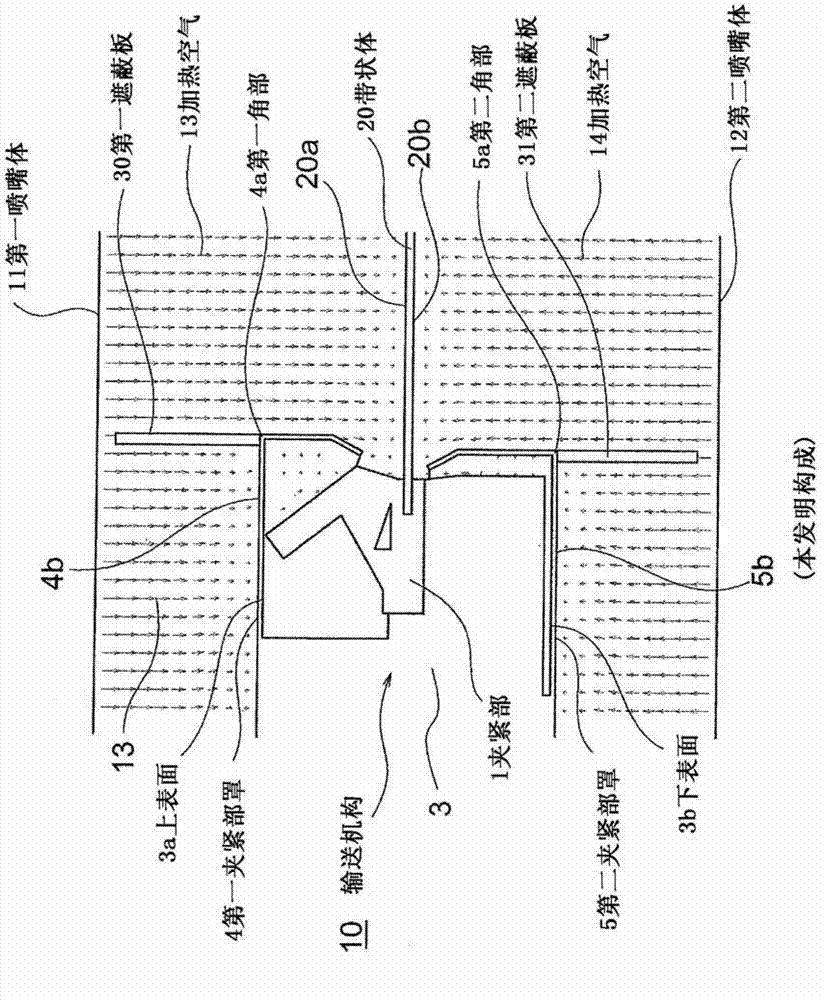

[0058] It is an object of the present invention to provide a lateral stretching method and apparatus for improving heating efficiency by providing a shielding plate to a conveying mechanism for conveying a belt-shaped body to rectify the flow of heating air.

[0059] 【Example】

[0060] Next, preferred embodiments of the transverse stretching method and apparatus of the present invention will be described with reference to the drawings.

[0061] The same reference numerals are used to describe the same or equivalent parts as those in the conventional example.

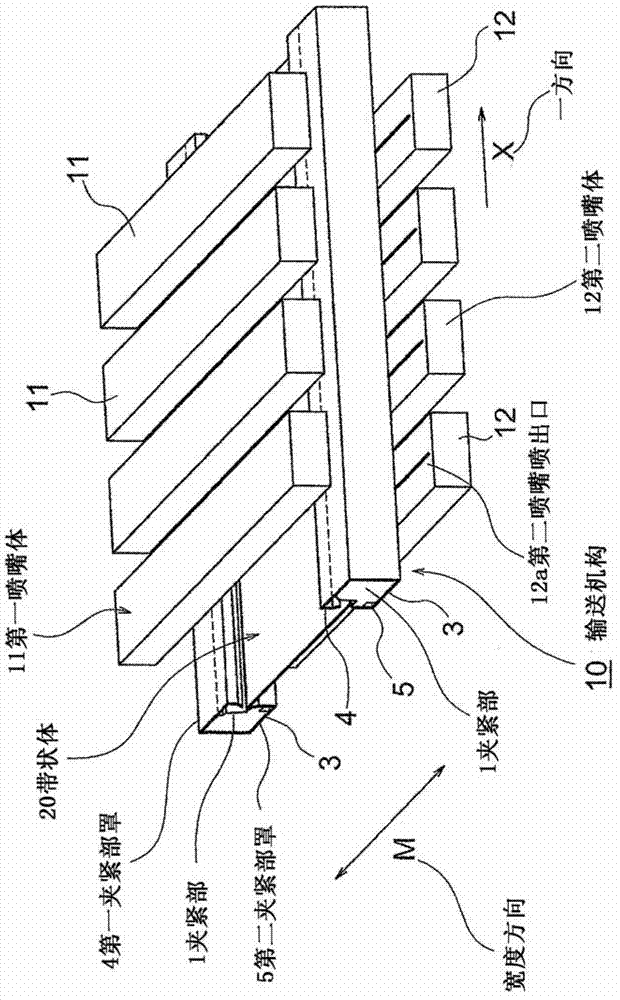

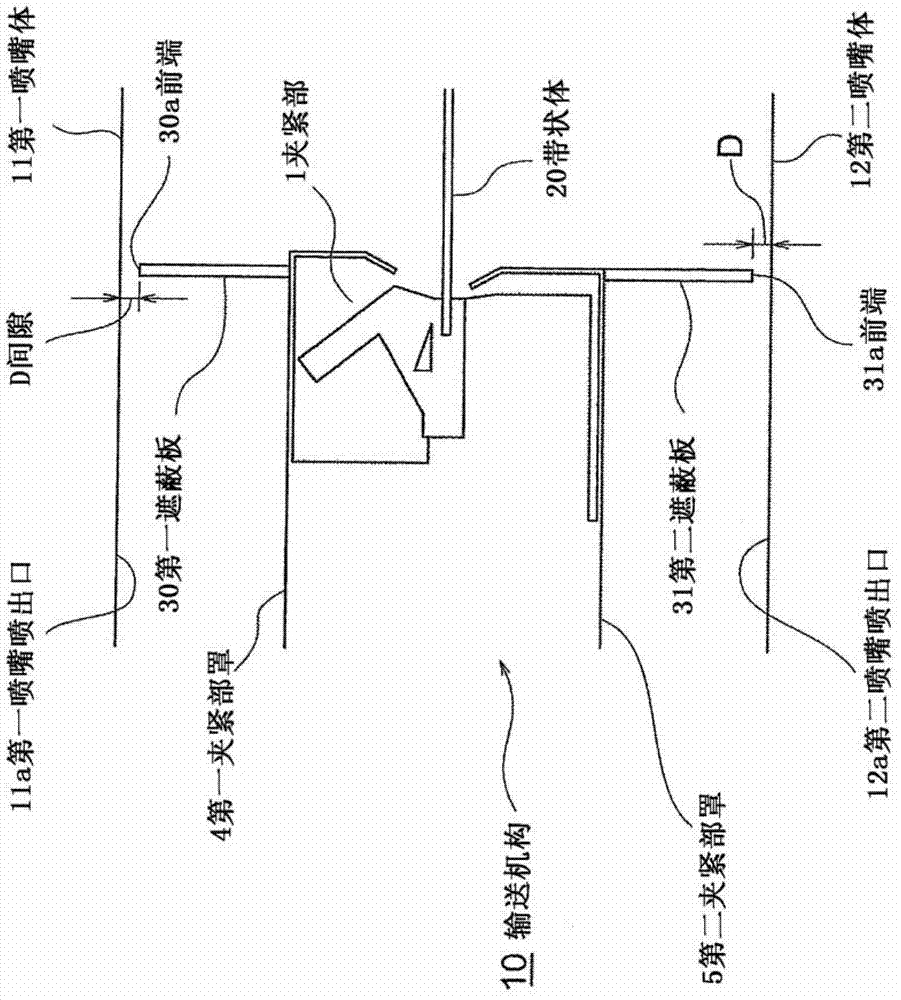

[0062] figure 1 Among them, reference numeral 10 indicates a conveying mechanism, and the conveying mechanism 10 has a pair of clamping parts 1 separated from each other along the width direction M, and each clamping part 1 is formed in a long strip shape.

[0063] The above-mentioned clamping parts 1 are actually held by the elongated holder 3, and, in image 3 The shown upper surface 3 a and the lower surface 3 b o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com