Electromagnetic internal heating type hot cover process for water-wheel generator rotor support

A hydro-generator and rotor support technology, which is applied in the manufacture of motor generators, induction heating, and stator/rotor bodies, etc., can solve the problems of slow heating speed of electric hot plates, large workload of heat preservation shed, and hub clearance, etc. The effect of reducing labor intensity, reducing floor space and uniform heating

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

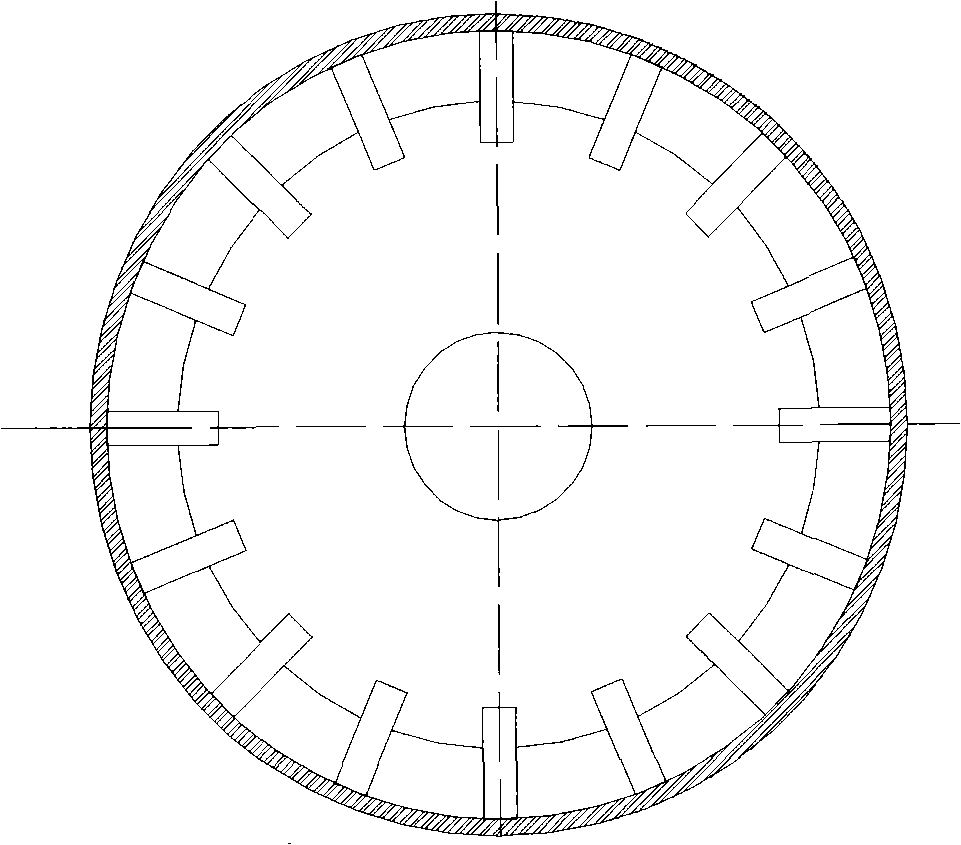

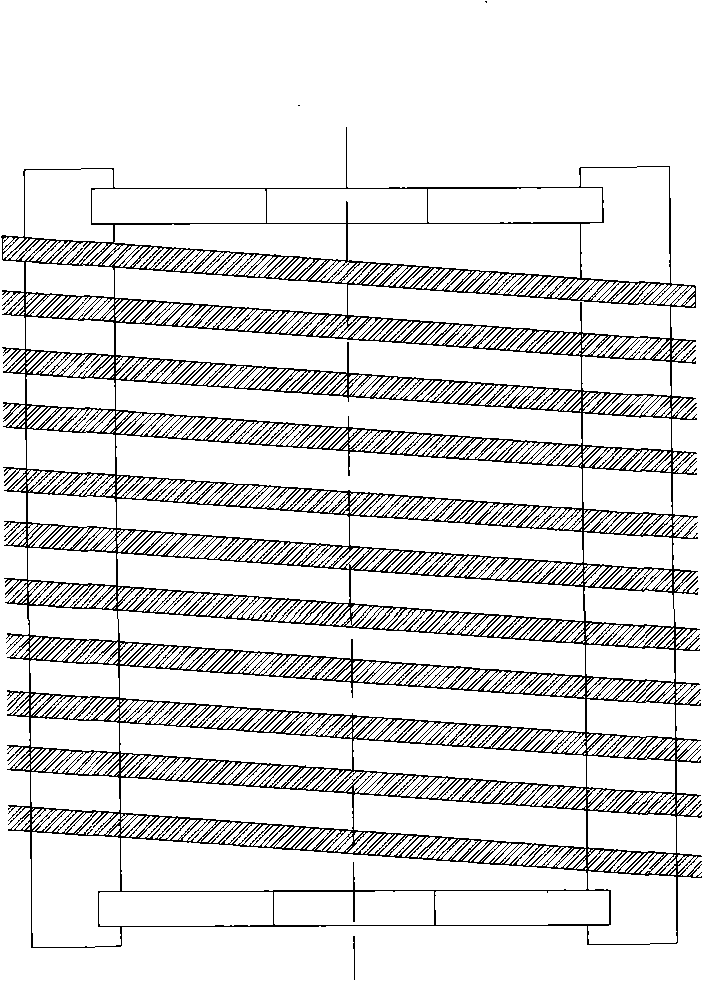

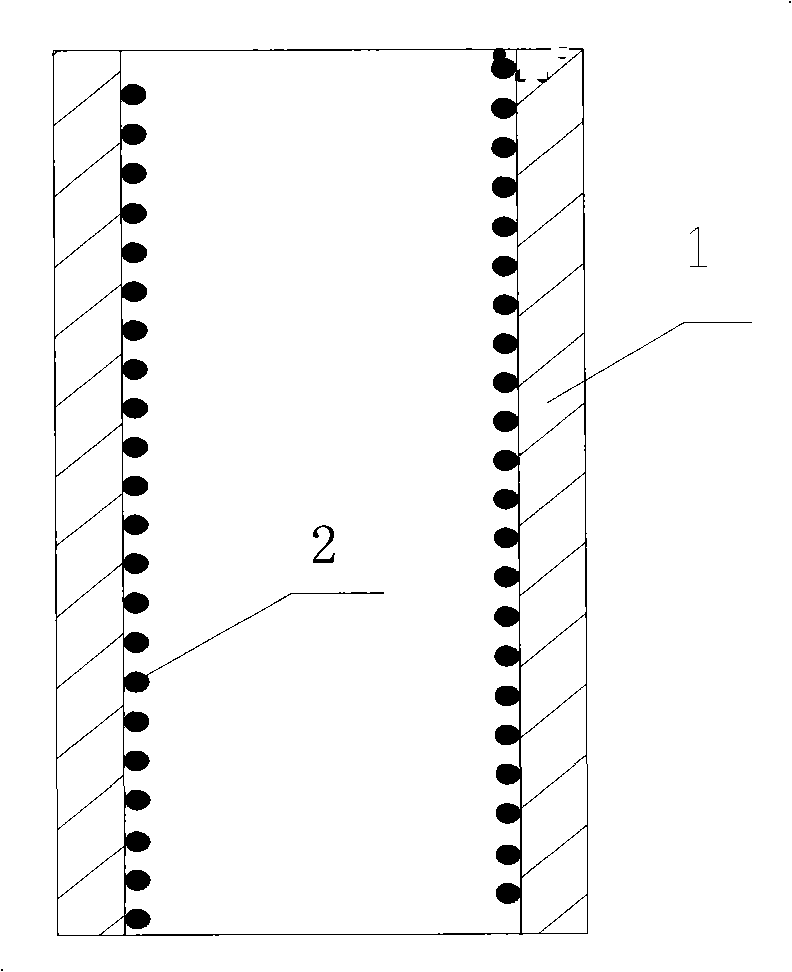

[0033] The present invention is an electromagnetic internal heating heat-shrinking process for a rotor bracket of a hydraulic generator, such as figure 1 The magnet wire shown is wound on the bracket made of laminated epoxy glass cloth, and the bracket wrapped with the magnet wire is inserted into the wheel hub. The magnet wire is covered with insulating cloth for intermediate frequency induction heating. The heating equipment is KGPS100 static intermediate frequency power supply. The heating frequency is 8000Hz:

[0034] (1) Calculate the shrink-fit gap according to the maximum interference: the weight of the rotor bracket is relatively large, so it needs to be hoisted by a crane, and the actual centering time is relatively long. Therefore, the value of the shrink-fit gap δ0 should be considered to avoid stuck shafts. The empirical values are:

[0035] When L>3d, δ 0 = d 900 ~ ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com