Monolithic columns combining deep eutectic solvent monomers and hybrid monomers

A deep eutectic solvent and monolithic column technology, applied in the field of separation and analysis, can solve the problems affecting the life and durability of the monolithic column, and achieve the effects of easy control of reaction conditions, good mechanical strength, and high enrichment effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] Preparation of functional monomers,

[0025] Preparation 1.DES monomers: the choline chloride (60 mmol, 8.4 g) and methacrylic acid (120 mmol, 10.2mL) in a 1: 2 molar ratio threaded vial was added, followed by 90 deg.] C oil bath for 1 H , a uniform transparent solution can be obtained. Placed in a desiccator;

[0026] 2. Preparation of hybrid monomers: Take 1498 μL (6.4 mmol) of 3-aminopropyl triethoxysilane (the APTES) and 688 μL (8.1 mmol) of methacrylic acid (MAA) into the reaction flask mixture ultrasound 10 min dissolution. And then placed at 60 ℃ pot, removed 24 h after the reaction, to give a clear yellow liquid is the hybrid monomer APTES-MAA;

Embodiment 2

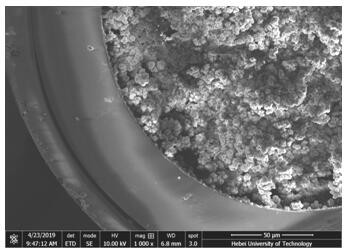

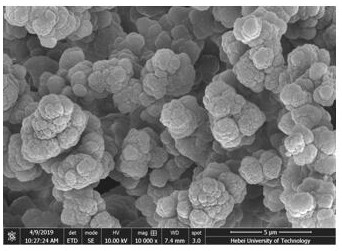

[0028] Preparation of monolithic column

[0029] In 670 μL of methanol and 70 mg PEG 2000 was added two yuan porogen functional monomer APTES-MAA (64 μL) and DES monomer ChCl-MAA (144 μL), a crosslinking agent ethylene glycol dimethacrylate ( 62 μL) and the initiator azobisisobutyronitrile (2.6 mg), after the formation of the ultrasonic mixing was poured into the prepolymerization already processed capillary, capillary ends sealed with rubber plugs, placed in the pot 60 deg.] C water bath, after 2 h the reaction capillary removed, rinsed, and other substances soluble matter monolith unreacted with acetonitrile.

Embodiment 3

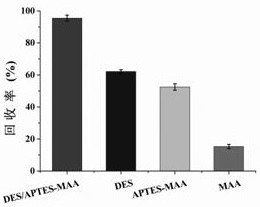

[0031] To determine the effect of the type of functional monomer extraction efficiency of protein synthesis a single monomer (APTES-MAA monolith, DES monolith) and a conventional monomer (MAA monolithic column) is used as a control monolith. Specific steps are as follows:

[0032] DES / APTES-MAA prepared monolithic column prepared in Example 2 is the monolithic columns embodiment;

[0033] Control group was prepared monolithic column

[0034] Preparation APTES-MAA Monolith: DES except that no monomer was added, the same methods, and experimental conditions in Example 2 Synthesis embodiment; DES monolith prepared: except that no monomer was added APTES-MAA, the same as in Example 2, synthetic methods, and experimental conditions; MAA monolith prepared: except that no monomer was added and DES APTES-MAA monomer, the monomer MAA was added 210 L, synthesized by the same method of Example 2 and the experimental conditions. After completion of the polymerization, rinsed with acetonitri...

PUM

| Property | Measurement | Unit |

|---|---|---|

| volume | aaaaa | aaaaa |

| molecular weight | aaaaa | aaaaa |

| molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com