Double-frequency pulse and double-vertical ring high-gradient magnetic separator

A high-gradient magnetic separator and double-pulse technology, applied in the field of magnetic separators, can solve problems such as increased investment and operating costs, unfavorable particle group evacuation, and large metal loss, so as to improve the separation effect, take into account the metal recovery rate, Taking into account the effect of concentrate quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

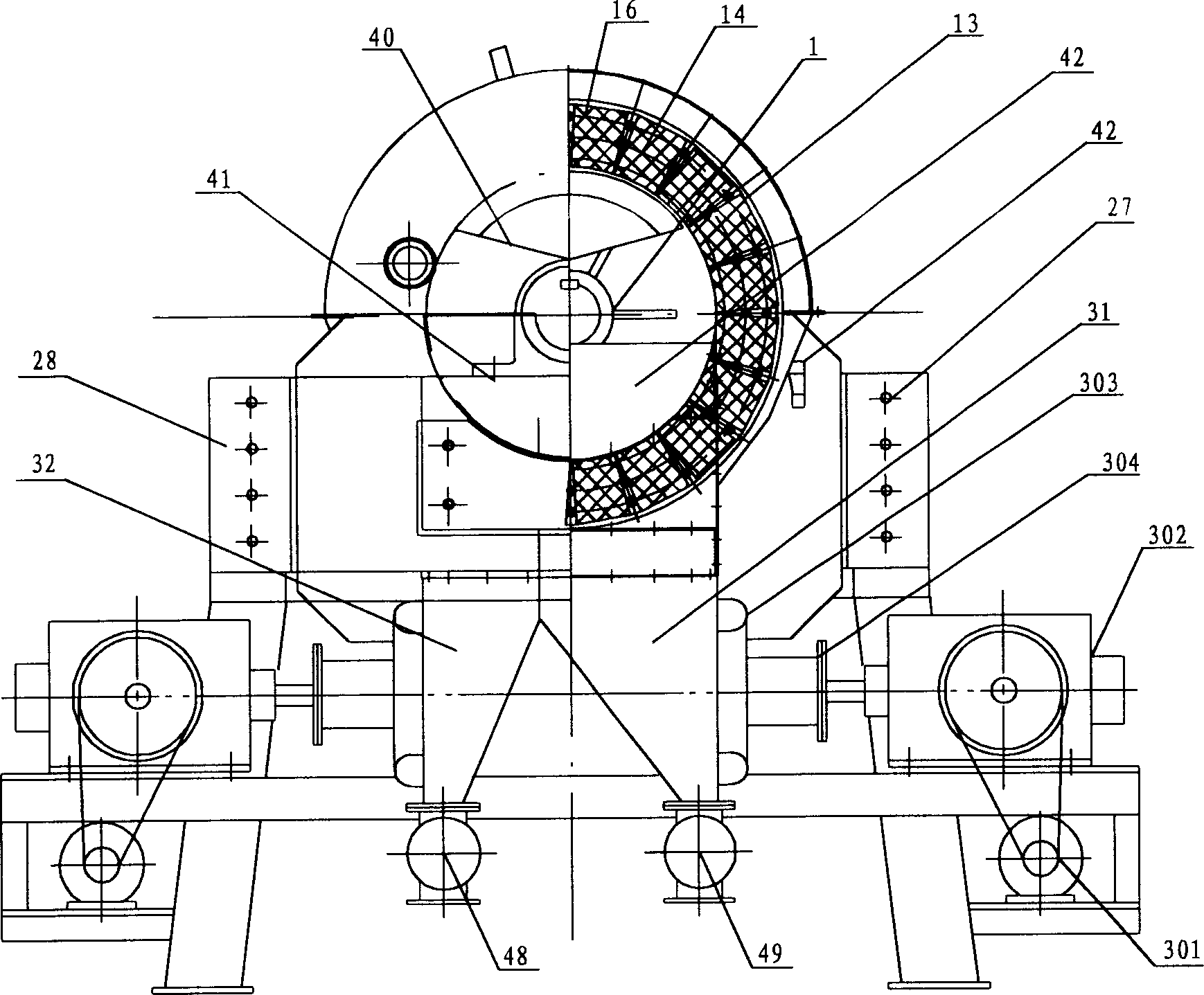

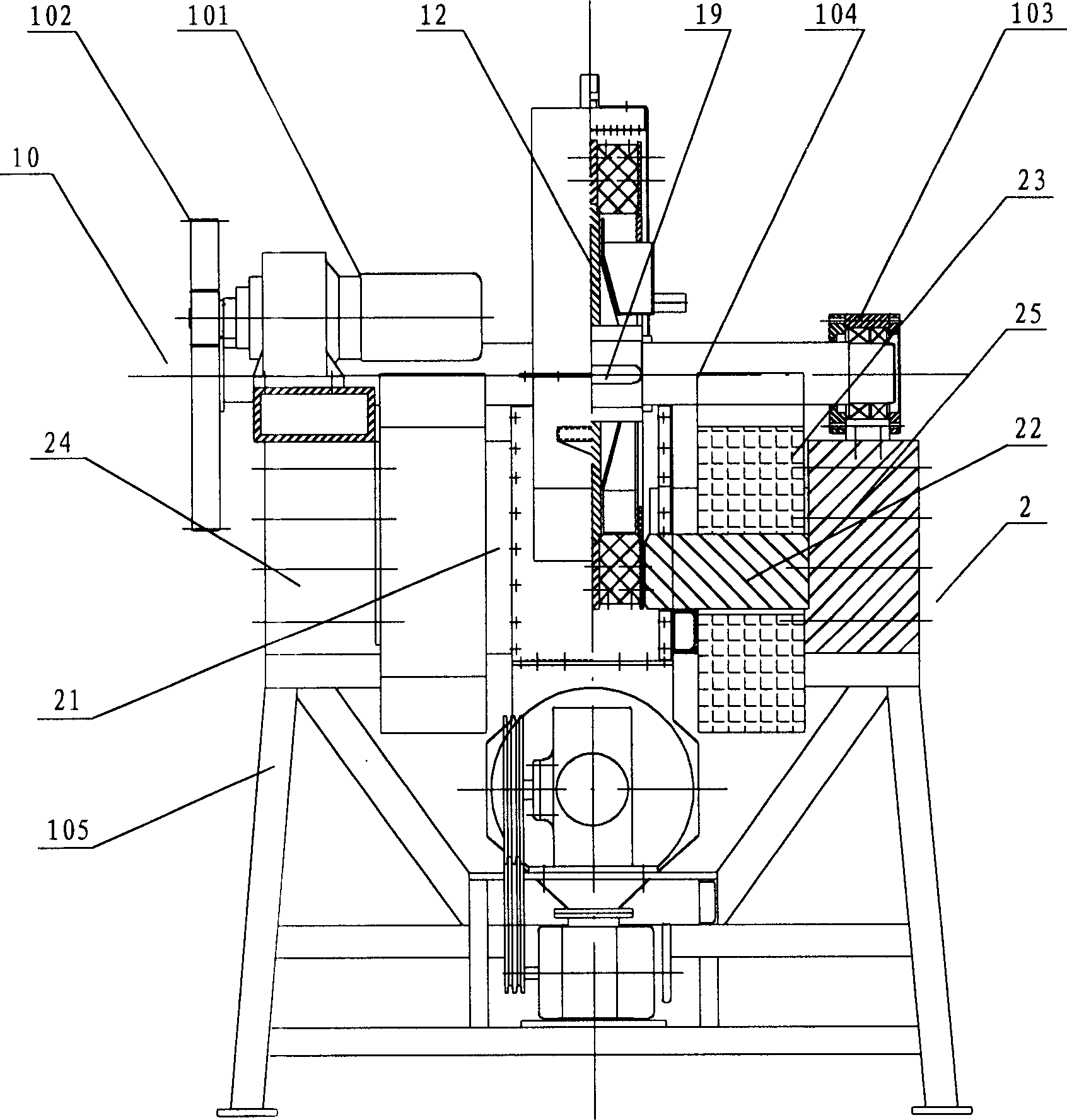

[0019] A double-frequency pulse double vertical ring high-gradient magnetic separator, comprising a sorting ring 1 and a magnetic field device 2, characterized in that the magnetic field device 2 is distributed on both sides of the sorting ring 1, which can generate magnetic lines of force running through the sorting ring 1, Below the separation ring 1 is provided at least one set of pulse devices that can cause the pulp to move in a direction perpendicular to the magnetic lines of force.

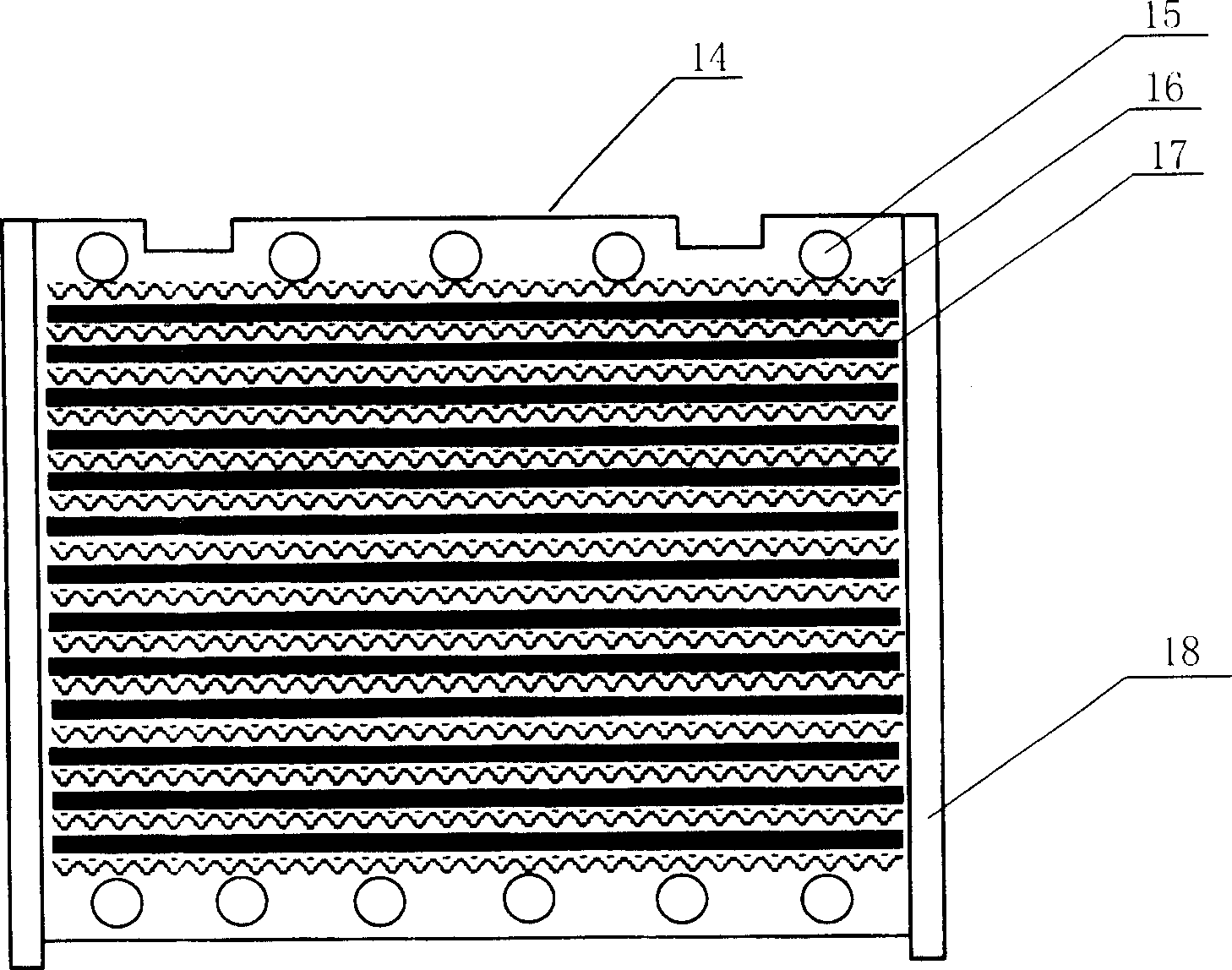

[0020] like figure 1 , figure 2 As shown, the present invention includes a sorting ring 1, a magnetic pole 2, and a double-pulse device 3. The sorting ring 1 is composed of a thick-walled ring, a thin-walled ring, a magnetic medium, and bolts, wherein the ring body 13 is a vertical double-ring structure, and the ring body 13 is a vertical double-ring structure. There is a turntable 12 that connects the double rings as a whole. The outer edge of the turntable is made of magnetically condu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com