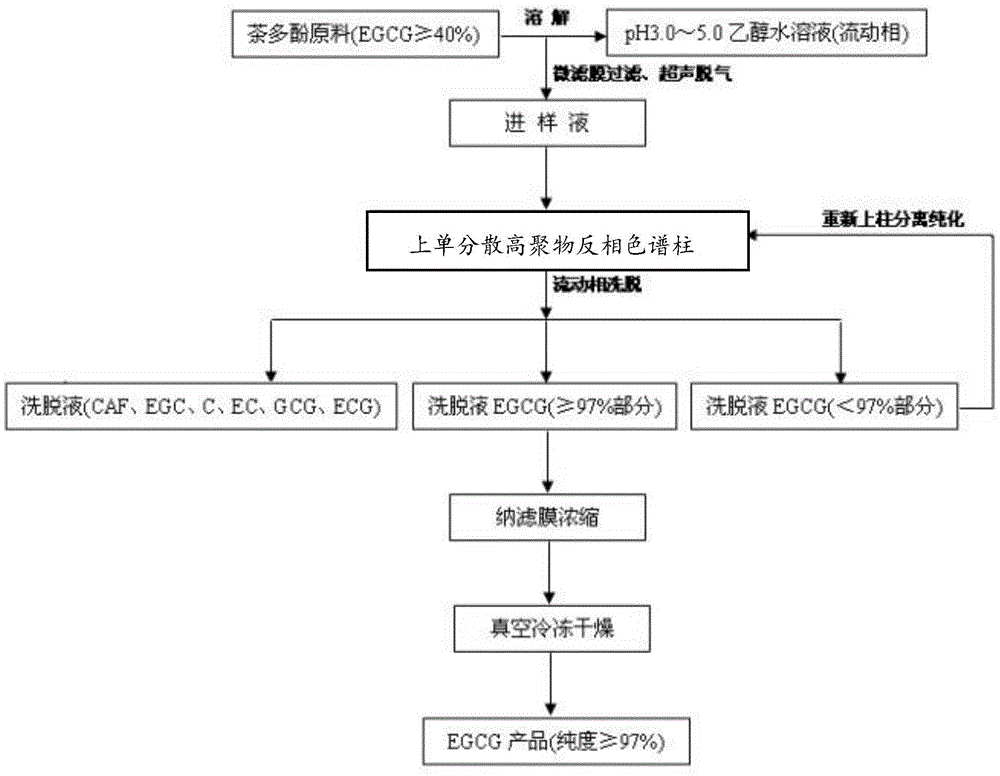

Method for separating and purifying EGCG (Epigallocatechin Gallate) by medium-pressure high polymer inversed phase chromatography

A technology of epigallocatechin and gallate, which is applied in the field of separation and purification of epigallocatechin gallate by medium-pressure high polymer reverse-phase chromatography, and can solve the separation performance of adsorption resin and dextran gel chromatography Poor, C18 bonded silica gel is expensive, dextran gel is expensive, etc., to achieve the effect of not being easy to non-specific adsorption, convenient for industrial continuous production, and non-polar on the surface

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

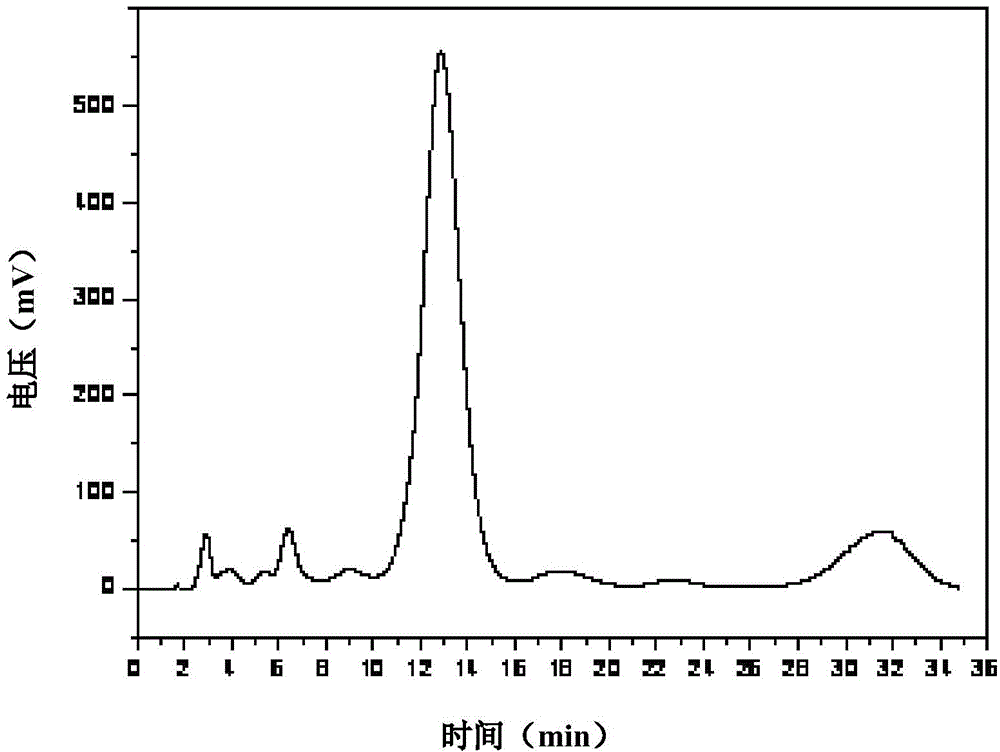

Embodiment 1

[0039]A 65% ethanol aqueous solution (pH=3.0, acidified with citric acid) was used as the mobile phase and a 25% tea polyphenol solution was prepared. Pass the solution through a 0.45 μm microfiltration membrane and collect the filtrate. The filtrate was ultrasonically degassed (ultrasonic frequency 50HZ) for 30 minutes, and then left to stand for 10 minutes. Monodisperse polymer reversed-phase chromatographic column on solution, sample volume 3mL, column length 26cm, column diameter 1.2cm, filler particle size 10μm, column pressure 10Mpa, elution with mobile phase, mobile phase flow rate 5mL / min, the eluted fractions were collected in sections, the fractions with EGCG figure 2 As shown, detected by HPLC method, the obtained EGCG purity is 98.69%.

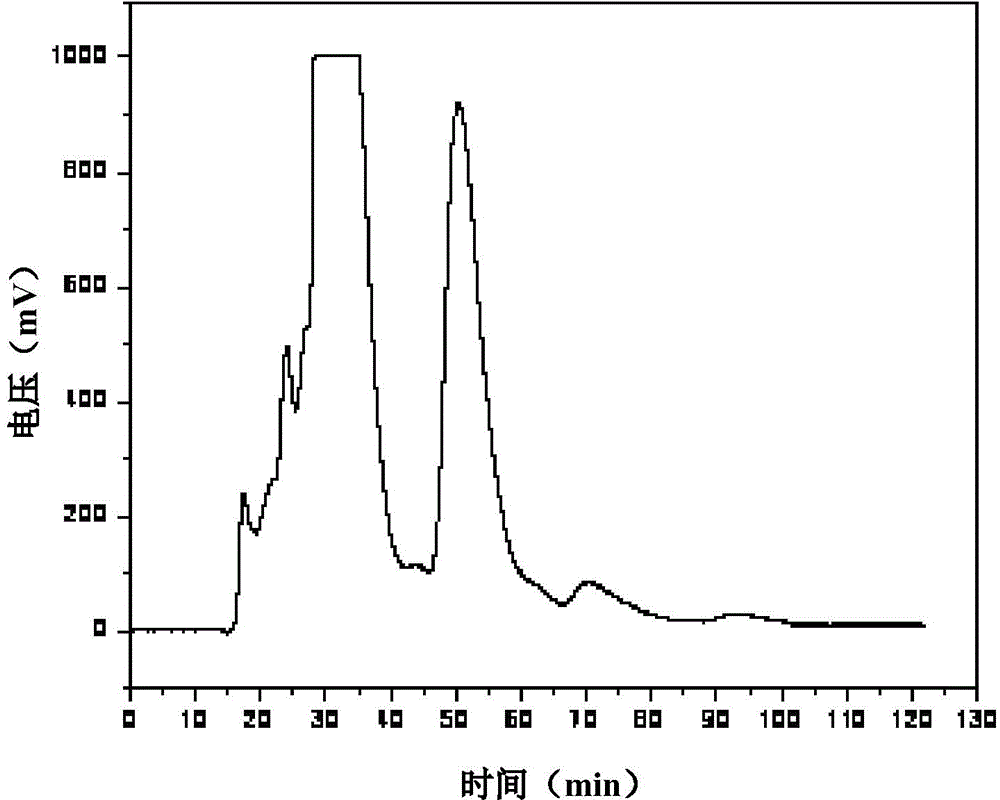

Embodiment 2

[0041] A 15% ethanol aqueous solution (pH=4.0, acidified with citric acid) was used as the mobile phase and a 25% tea polyphenol solution was prepared. Pass the solution through a 0.45 μm microfiltration membrane and collect the filtrate. The filtrate was ultrasonically degassed (ultrasonic frequency 50HZ) for 30 minutes, and then left to stand for 10 minutes. Monodisperse polymer reversed-phase chromatographic column on solution, sample volume 100mL, column length 49cm, column diameter 5cm, filler particle size 40μm, column pressure 5Mpa, elution with mobile phase, mobile phase flow rate 100mL / min , the fraction after elution is collected in sections, the fraction of EGCG image 3 As shown, through HPLC detection, the EGCG purity obtained is 98.1%.

Embodiment 3

[0043] A 40% ethanol aqueous solution (pH=5.0, acidified with citric acid) was used as the mobile phase and a 25% tea polyphenol solution was prepared. Pass the solution through a 0.45 μm microfiltration membrane and collect the filtrate. The filtrate was ultrasonically degassed (ultrasonic frequency 50HZ) for 30 minutes, and then left to stand for 10 minutes. Monodisperse polymer reversed-phase chromatographic column on solution, sample volume 100mL, column length 48cm, column diameter 6.8cm, filler particle size 40μm, column pressure 2Mpa, use mobile phase for elution, flow rate of mobile phase is 900mL / min, the eluted fractions were collected in sections, the fractions with EGCG Figure 4 As shown, through HPLC detection, the EGCG purity obtained is 97.6%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com