Method for separating mixed gas FTrPSA in reaction for preparing propylene by dehydrogenizing propane

A propane dehydrogenation and separation method technology, applied in the direction of hydrocarbons, adsorption purification/separation, chemical instruments and methods, etc., can solve the problems of high investment and operation costs, low equipment investment costs, low comprehensive energy consumption, etc., to achieve Avoid cold and brittle, low equipment investment cost, low overall energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] A kind of propane dehydrogenation produces propylene reaction mixture gas FTrPSA separation method, comprises the steps:

[0041] (1) The reactant mixed gas in the propane dehydrogenation to propylene reaction zone is used as the raw material gas, and its main components are 35 to 40% (volume ratio, the same below) of propylene, 40 to 55% of hydrogen, and the remaining components Including, methane, ethane, propane, isobutene, isobutane, n-butane, propyne, dienes and other C2+ hydrocarbon components, as well as solid particles, green oil, carbon six (C6+) and water components, etc. For other impurity components, the temperature is 120°C, the pressure is 1.0MPa, and the processing capacity is 10,000 standard cubic meters per hour. Pretreatment includes dust removal, chlorine removal, oil removal, and / or heat exchange, blasting and / or compression, pretreatment Treatment and removal include solid particles, green oil, and carbon six (C6+) impurity components, and the raw m...

Embodiment 2

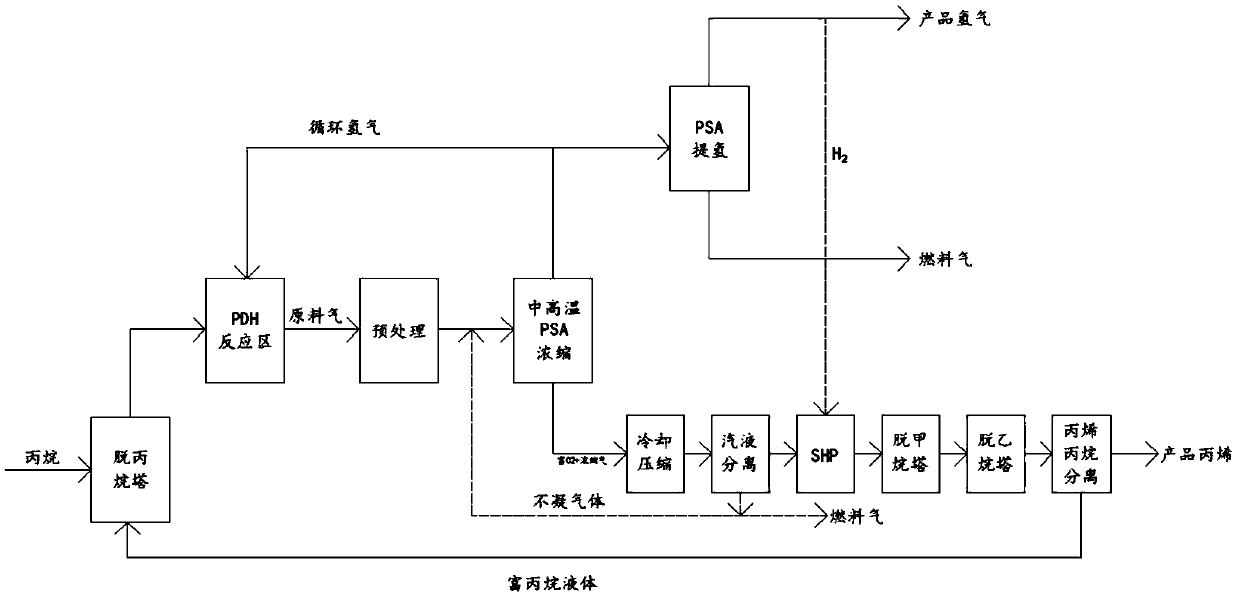

[0048] Based on Example 1, such as figure 1 As shown, the mixed gas of reactants in the reaction zone of propane dehydrogenation to propylene is used as the raw material gas, the temperature is 150°C, the pressure is 0.6MPa, and other conditions remain unchanged. After pretreatment, it directly enters the process of medium and high temperature PSA concentration and PSA hydrogen extraction. Carry out C2+ concentration and hydrogen extraction respectively, wherein, the number of times of pressure equalization in the medium-high temperature PSA concentration and PSA hydrogen extraction process can be 3 times, compared with the yield in Example 1, this embodiment can be higher by 1 to 1.5% .

Embodiment 3

[0050] Based on Example 1, such as figure 1 As shown, the mixed gas of the reactant in the reaction zone of propane dehydrogenation to propylene is used as the raw material gas, the temperature is 90°C, the pressure is 1.5MPa, and the other conditions remain unchanged. After pretreatment, it directly enters the process of medium and high temperature PSA concentration and PSA hydrogen extraction. Carry out C2+ concentration and hydrogen extraction respectively, wherein, the number of times of pressure equalization in the process of medium-high temperature PSA concentration and PSA hydrogen extraction can be 3 times, compared with the yield in Example 1, this embodiment can be higher by 1 to 3% .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com