Tyre separation device of tyre transportation line

A separation device and conveying line technology, applied in the direction of conveyor objects, transportation and packaging, roller table, etc., can solve the problems of unable to complete the separation of tires, easy to be clamped between two arms and so on

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

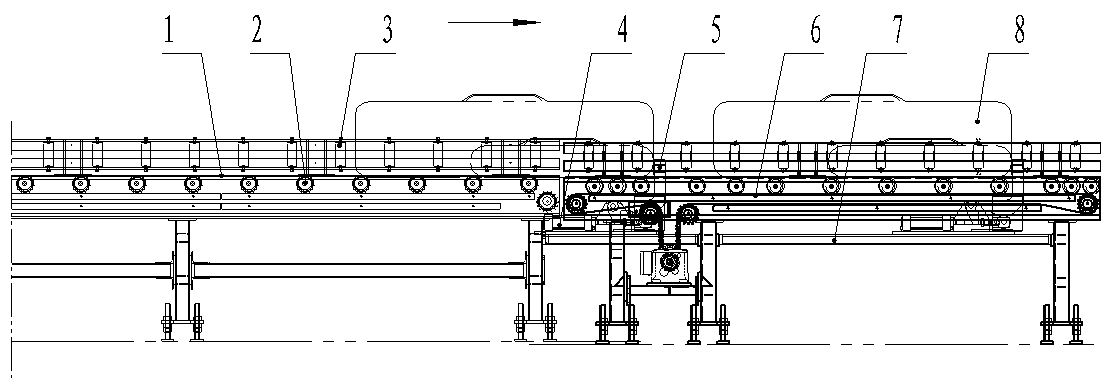

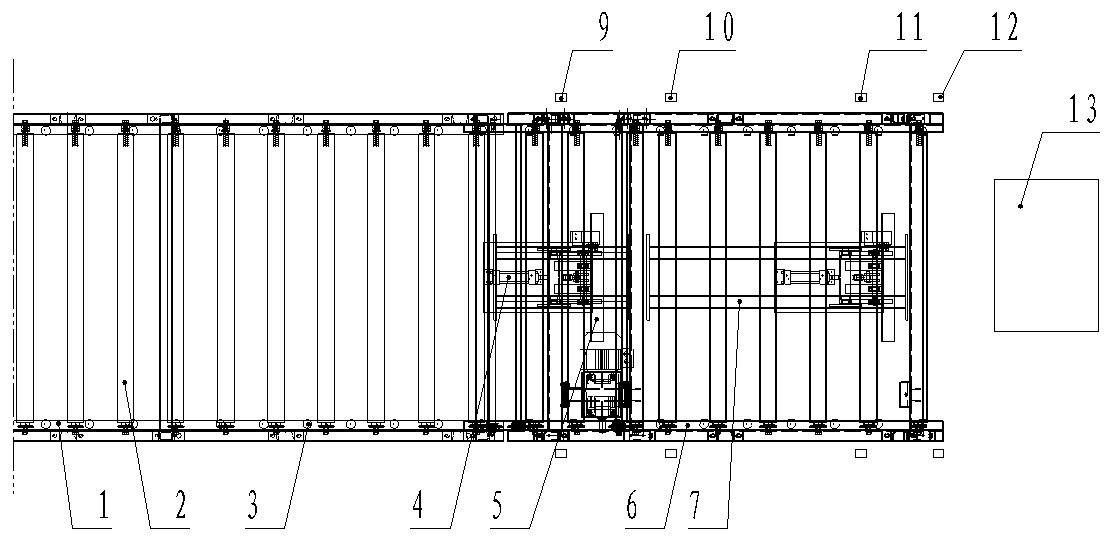

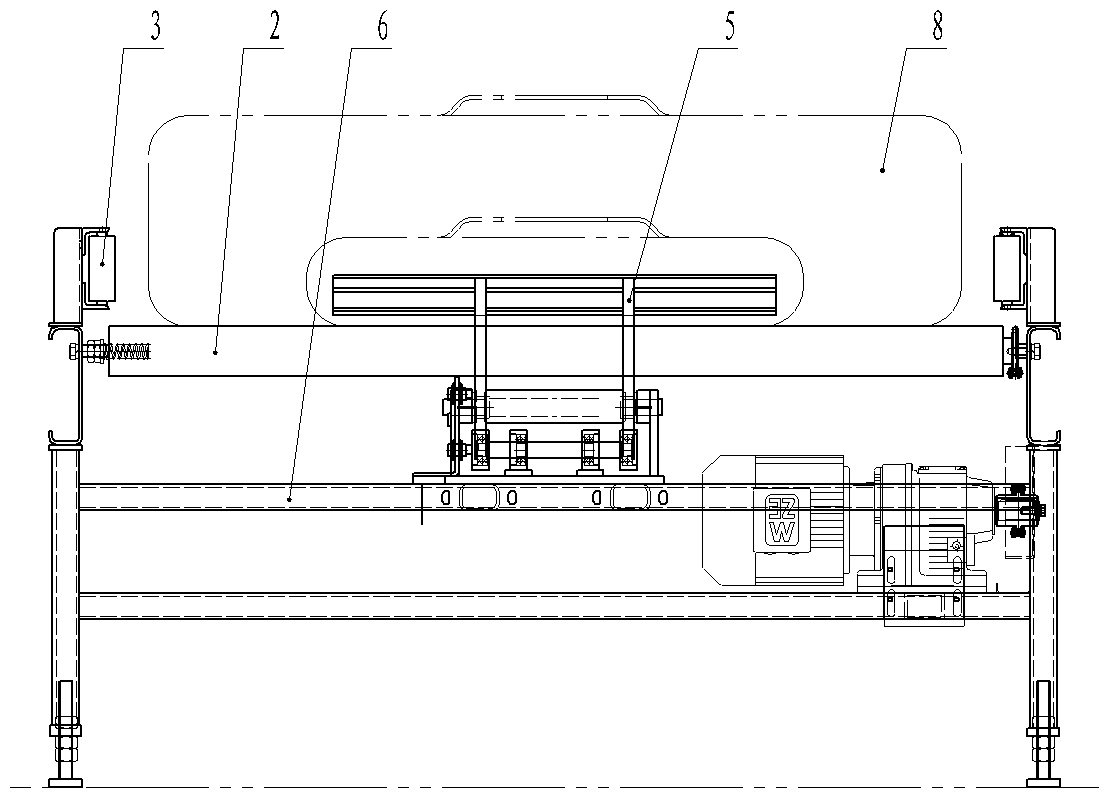

[0032] Such as figure 1 , figure 2 , image 3 The tire separation device of a tire conveying line shown includes a main conveying roller table 1, and the output end of the main conveying roller table 1 is connected with a high-speed roller table 6 for separating individual tires, and the conveying surface of the high-speed roller table 6 is lower than The conveying surface of the main conveying roller table 1 is 8mm. Both sides of the main conveying roller table 1 and the high-speed roller table 6 are equipped with guide guardrails, and the guide guardrails are composed of vertically arranged guide rollers 3 . Hook-type stoppers are respectively installed under the feeding end and the discharging end near the high-speed roller table 6, such as Figure 4 , Figure 5 , Figure 6The shown hook stopper has a retaining arm part 5 that is rotatably connected to the frame 7, and the frame 7 is equipped with a power cylinder 4 that drives the retaining arm part 5 to rotate and s...

Embodiment 2

[0038] The difference between this embodiment and Embodiment 1 is that: the conveying surface of the high-speed roller table 6 is 12 mm lower than the conveying surface of the main conveying roller table 1; other features are the same as in Embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com