Filter paper having function of oil-water separation, and simple preparation method and application of filter paper

A technology of oil-water separation and filter paper, which is applied in the direction of separation method, filter paper, filtration separation, etc., can solve the problems of repeated use of separation materials, environmental pollution, complicated process, cumbersome steps, etc., and is suitable for large-scale production and application, simple process, The effect of simple preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] (1) In terms of weight ratio, mix nano-silica, hexadecyltrimethoxysilane, triethylamine, ethanol and water in a ratio of 3:5:5:90:10, and ultrasonically disperse for 10 minutes.

[0023] (2) Immerse the filter paper in the solution obtained in the above step (1), ultrasonically disperse it for 10 seconds, take it out and let it dry naturally at room temperature.

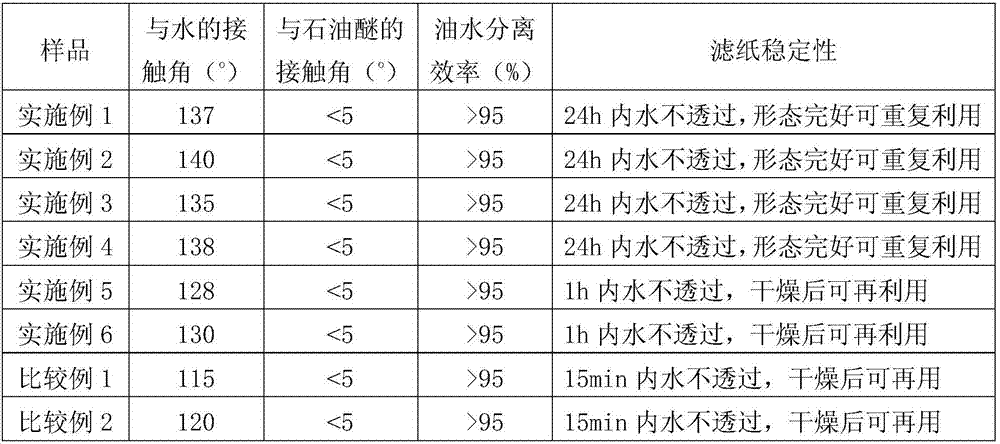

[0024] The contact angle of the filter paper with water and petroleum ether (boiling point 60-90°C) is good for oil-water mixtures (by volume ratio, the ratio of deionized water to petroleum ether is 2:1) and oil-water emulsions (by volume ratio, The ratio of deionized water, petroleum ether and sodium lauryl sulfate is 2:1:0.01), the separation effect and the stability of filter paper are shown in Table 1.

Embodiment 2

[0026] (1) In terms of weight ratio, mix nano-silica, hexadecyltrimethoxysilane, triethylamine, ethanol and water in a ratio of 3:5:5:90:10, and ultrasonically disperse for 20 minutes.

[0027] (2) Immerse the filter paper in the solution obtained in the above step (1), ultrasonically disperse it for 10 seconds, take it out and let it dry naturally at room temperature.

[0028] The contact angle of the filter paper with water and petroleum ether (boiling point 60-90°C) is good for oil-water mixtures (by volume ratio, the ratio of deionized water to petroleum ether is 2:1) and oil-water emulsions (by volume ratio, The ratio of deionized water, petroleum ether and sodium lauryl sulfate is 2:1:0.01), the separation effect and the stability of filter paper are shown in Table 1.

Embodiment 3

[0030] (1) In terms of weight ratio, mix nano-silica, hexadecyltrimethoxysilane, triethylamine, ethanol and water in a ratio of 4:5:5:90:10, and ultrasonically disperse for 10 minutes.

[0031] (2) Immerse the filter paper in the solution obtained in the above step (1), ultrasonically disperse it for 10 seconds, take it out and let it dry naturally at room temperature.

[0032] The contact angle of the filter paper with water and petroleum ether (boiling point 60-90°C) is good for oil-water mixtures (by volume ratio, the ratio of deionized water to petroleum ether is 2:1) and oil-water emulsions (by volume ratio, The ratio of deionized water, petroleum ether and sodium lauryl sulfate is 2:1:0.01), the separation effect and the stability of filter paper are shown in Table 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com