Sulfonated tail gas recycling method and sulfonated tail gas recycling system

A tail gas circulation and sulfonation technology, applied in chemical instruments and methods, chemical methods for reacting liquid and gas media, separation methods, etc., can solve the problem of effective separation of gas-liquid separators and foams that affect the normal operation of alkali cleaning , high cost and other issues, to reduce the pressure of environmental protection treatment, low cost, save investment costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

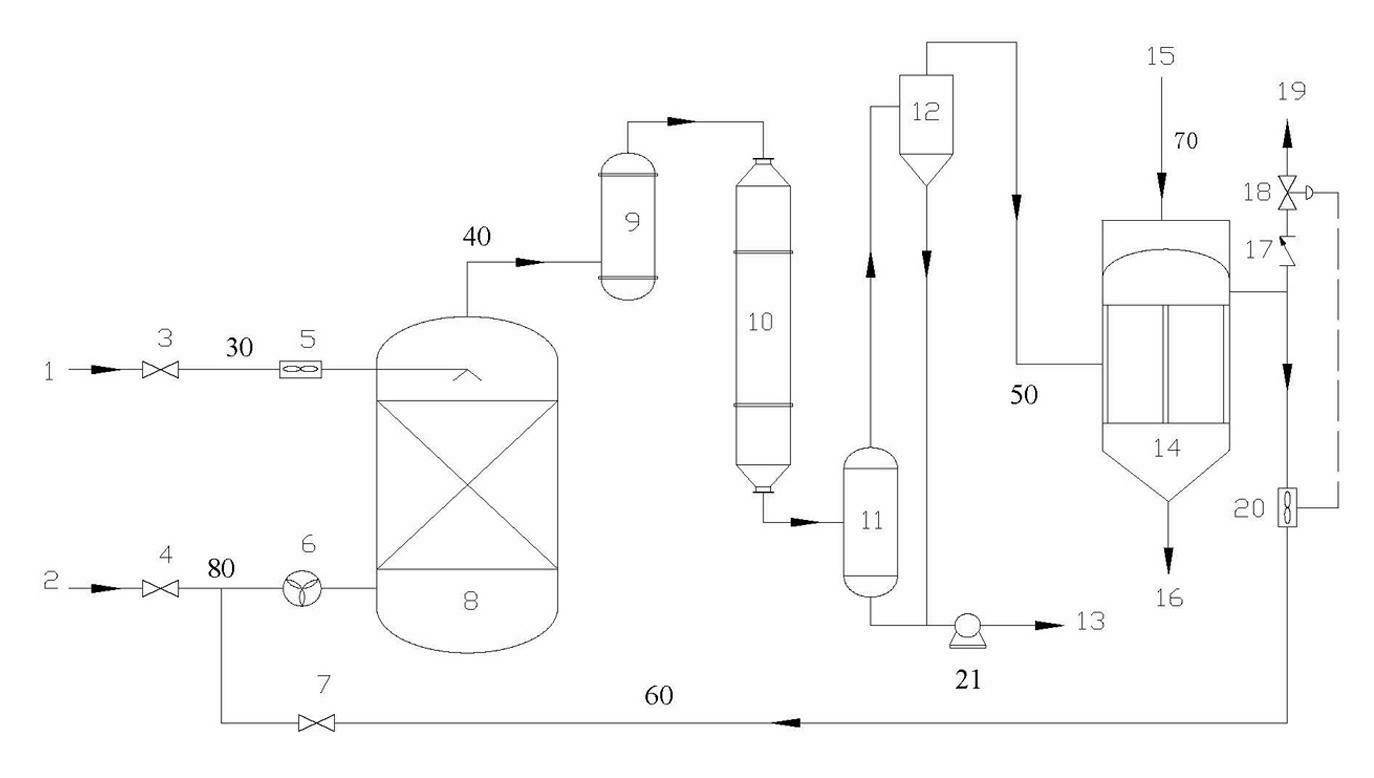

[0036] In the 3.8 tons / hour sulfonation production unit, adjust the flow rate of dry air 2 to 8000m 3 / hr, the pressure is 45 KPa, (simultaneously another part of dry air 15 sweeps the electrostatic demister 14, and the flow rate is 800 m 3 / hr), into the sulfur trioxide evaporator 8, the lower temperature of the mixer is 130°C. Adjust the flow rate of liquid sulfur trioxide 1 to 680kg / h, and enter the upper part of the sulfur trioxide evaporator, and the temperature of the upper part of the mixer is 60°C; after the evaporated sulfur trioxide gas passes through the shell and tube heat exchanger 9, the temperature drops to 55°C , and then enter the sulfonator 10 to carry out sulfonation reaction with organic materials; then pass through the gas-liquid separator 11 and the cyclone separator 12 successively to carry out the gas-liquid separator, and the separated liquid product enters the neutralization system 13 through a metering pump, and separates The sulfonated tail gas that...

Embodiment 2

[0038] In the 1.6 tons / hour sulfonation production unit, adjust the flow rate of dry air 2 to 2000m 3 / hr, the pressure is 45 KPa, (simultaneously another part of dry air 15 sweeps the electrostatic demister 14, and the flow rate is 400 m 3 / hr), into the sulfur trioxide evaporator 8, the temperature of the lower part of the mixer is 100°C. Adjust the flow rate of liquid sulfur trioxide 1 to 225kg / h, and enter the upper part of the sulfur trioxide evaporator, the temperature of the upper part of the mixer is 70°C; the evaporated sulfur trioxide gas passes through the shell and tube heat exchanger 9, and the temperature drops to 35°C , and then enter the sulfonator 10 to carry out sulfonation reaction with the organic material; then carry out the gas-liquid separator through the gas-liquid separator 11 and the cyclone separator 12 successively, and the separated liquid product enters the neutralization system 13 through the metering pump 21, The separated sulfonated tail gas ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| water content | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com