Method for recycling sulfonation tail gas

A technology of sulfonation reaction and tail gas circulation, applied in chemical instruments and methods, formation/introduction of sulfonic acid group/dihydroxysulfonyl group, inorganic chemistry, etc., can solve problems such as inapplicable sulfonation production mode, and achieve energy reduction consumption, broad application prospects, and the effect of reducing pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

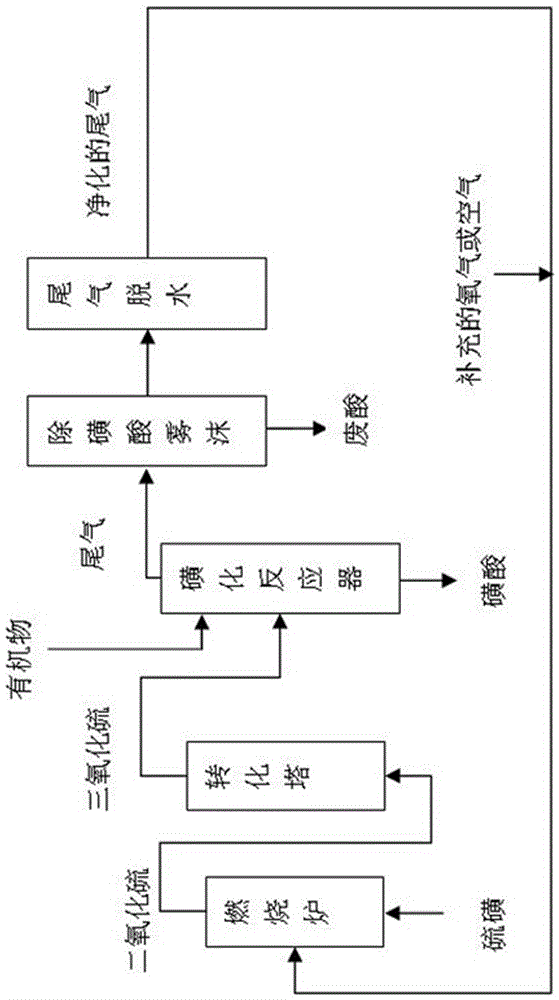

[0023] Embodiment 1, as attached figure 1 As shown, the method for recycling the tail gas of the sulfonation reaction is carried out according to the following steps: first remove the acidic oil mist carried in the tail gas produced by the sulfonation reaction and dehydrate it, and then remove the acidic oil mist and dehydrate the tail gas Enter the sulfur combustion system together with supplementary oxygen or air to obtain a gas mainly composed of sulfur dioxide, then further oxidize the gas mainly composed of sulfur dioxide to obtain a gas mainly composed of sulfur trioxide, and finally convert the gas mainly composed of sulfur trioxide The gas is sent into the sulfonation system to participate in the sulfonation reaction, so that the tail gas can be recycled without being discharged.

Embodiment 2

[0024] Example 2, as an optimization of the above example, remove the acidic oil mist carried in the exhaust gas so that the mist removal rate can reach more than 98%.

Embodiment 3

[0025] Embodiment 3, as an optimization of the above embodiment, the water content in the tail gas after dehydration is less than or equal to 0.01g·H 2 O / kg dry gas.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com