Dehydration and de-heavy hydrocarbon technology for production of liquefied natural gas from methane-rich mixed gas

A technology of liquefied natural gas and mixed gas, which is applied in liquefaction, gas fuel, methane capture, etc., can solve the problems of high system energy consumption and high equipment investment costs, and achieve low system energy consumption, reduced energy consumption, and convenient start-up and parking Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

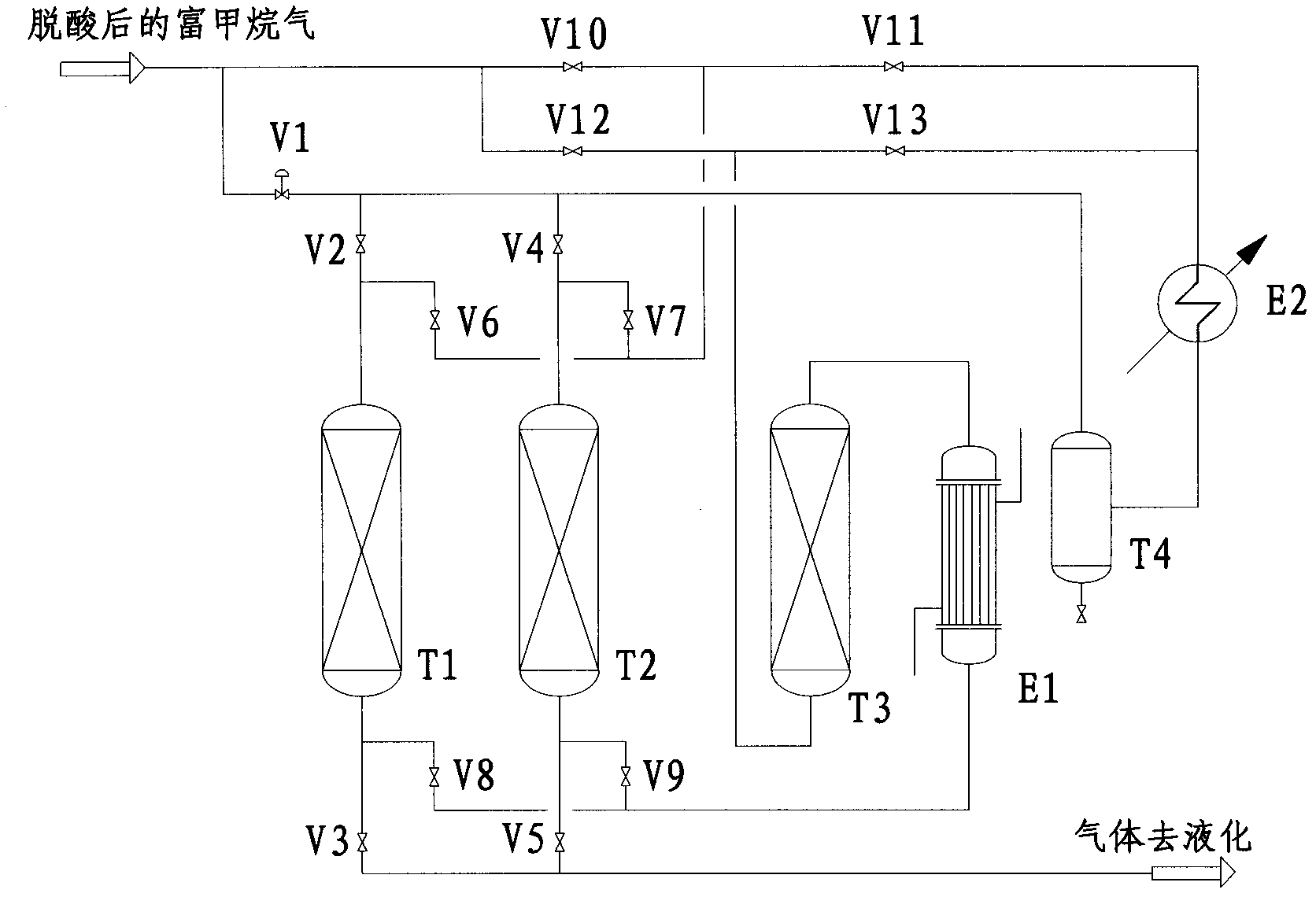

[0029] The dry dehydration and composite heavy hydrocarbon removal process for producing liquefied natural gas from methane-rich mixed gas provided by the present invention uses an adsorbent composite bed to dehydrate and remove heavy hydrocarbons; the methane-rich mixed gas after deacidification treatment is passed through three towers, etc. Pressure drying treatment, using a composite bed to remove moisture and heavy hydrocarbons in the gas at the same time, the moisture is removed to an atmospheric dew point ≤ -76 ° C, and the heavy hydrocarbon components above C6 and C6 are removed to ≤ 217ppm (preferably ≤ 200ppm, More preferably ≤100ppm, further preferably ≤50ppm, most preferably ≤10ppm); part of the methane-enriched gas is used as the regeneration gas, and after the regeneration step is completed, this part of the regeneration gas is returned to the system process gas.

[0030] Refer to attached figure 1 , the dehydration and heavy hydrocarbon removal device for produci...

PUM

| Property | Measurement | Unit |

|---|---|---|

| freezing point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com