Method and device for removing free formaldehyde in urea-formaldehyde resin

A technology for urea-formaldehyde resin and free formaldehyde, which is applied in the field of removing free formaldehyde in urea-formaldehyde resin, can solve the problems of high viscosity and restrict the diffusion of free formaldehyde monomers, and achieve the effects of simple structure, reduced process cost and high removal rate.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

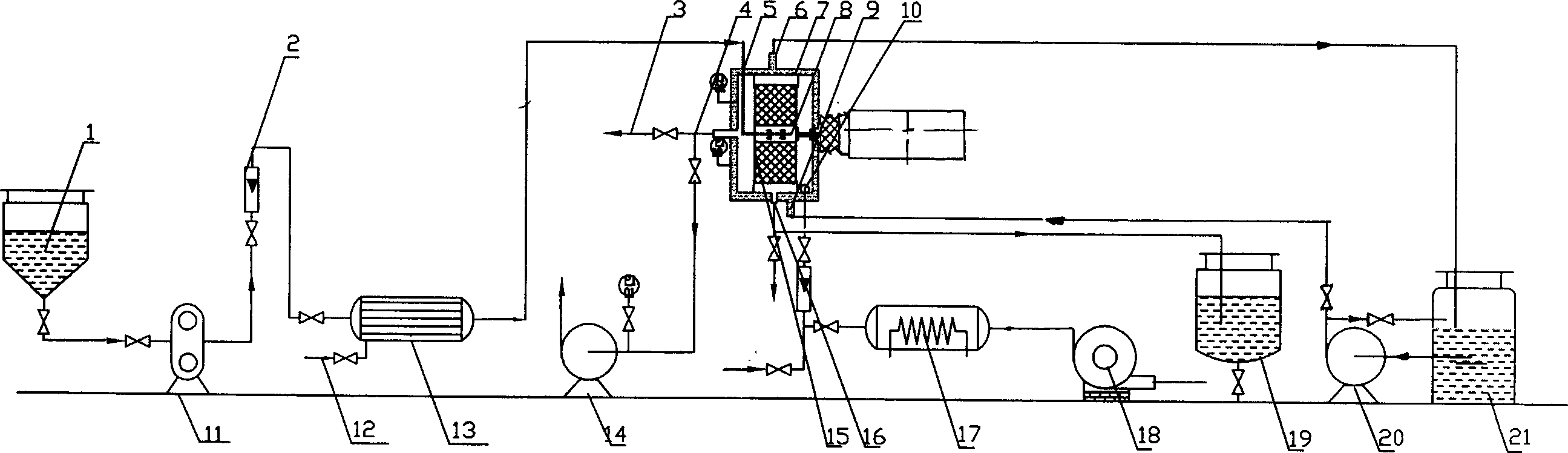

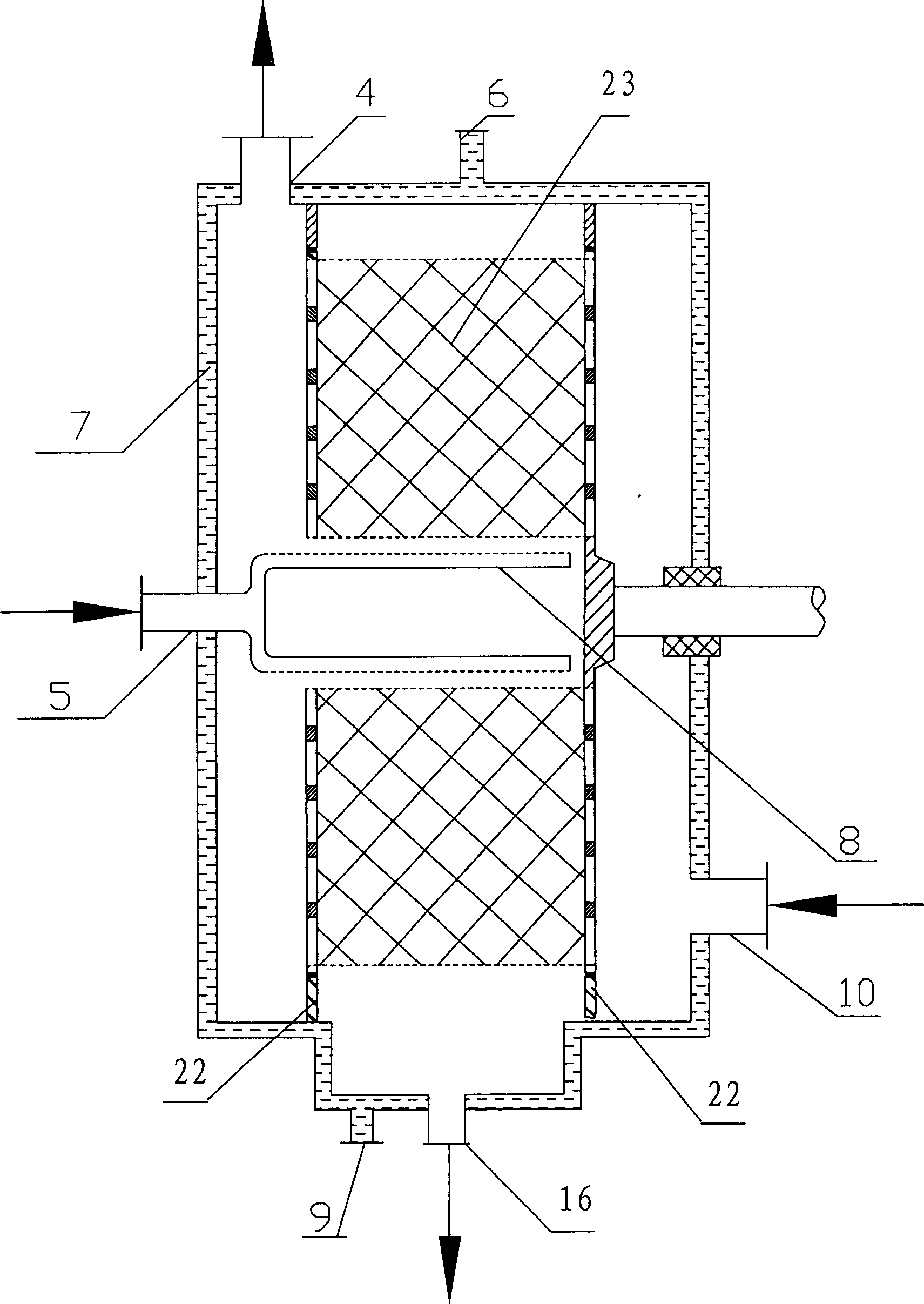

[0038] Removal of free formaldehyde monomers in urea-formaldehyde adhesives: the amount of high-temperature curing urea-formaldehyde adhesives to be treated is 0.5m 3 / h, the free formaldehyde content is 2.52% (mass ratio).

[0039] First, heat the urea-formaldehyde adhesive with a water bath to raise the temperature of the resin to 70°C, turn on the water bath of the rotating packed bed to maintain the body temperature at about 70°C; turn on the rotating packed bed, and adjust the rotating speed of the rotating packed bed rotor to 2800r / min through a frequency converter. After the rotary packed bed is stabilized (about two minutes), the preheated adhesive is passed into the rotary packed bed, and the preheated hot air with a temperature of 100-110°C is passed into the rotary packed bed at the same time, and passed through the regulating valve Gradually increase the volume to 400m 3 / h. The free formaldehyde content of the treated urea-formaldehyde resin is reduced to less t...

Embodiment 2

[0043] Removal of free formaldehyde monomers in urea-formaldehyde resin: the amount of cold-setting urea-formaldehyde adhesive to be treated in the process is 1m 3 / h, the free formaldehyde content is 1.21% (mass ratio).

[0044] First, heat the urea-formaldehyde resin with a water bath to raise the temperature of the resin to 55°C; turn on the water bath of the rotating packed bed to maintain the body temperature at about 55°C; turn on the vacuum pump; turn on the rotating packed bed, and adjust the rotating speed of the rotating packed bed rotor to 2500r through a frequency converter / min, after the rotary packed bed is stabilized (about two minutes), the preheated urea-formaldehyde resin is passed into the rotary packed bed, and 0.07MPa water vapor is passed into the rotary packed bed at the same time, and the gas volume is gradually increased through the regulating valve up to 5m 3 / h. And maintain the internal vacuum at 10-15kPa; the free formaldehyde content of the tre...

Embodiment 3

[0046] Removal of free formaldehyde monomer in urea-formaldehyde resin: the amount of urea-formaldehyde resin to be treated in the process is 1000kg / h, and the content of free formaldehyde is 3.13% (mass ratio).

[0047] In this embodiment, the process of removing free formaldehyde monomers in the urea-formaldehyde resin is combined with the dehydration process of the urea-formaldehyde resin. Start the discharge of the reaction kettle, turn on the vacuum pump; turn on the water bath circulation of the rotary packed bed, and maintain the body temperature at about 70°C-80°C; turn on the rotary packed bed, and adjust the rotor speed of the rotary packed bed to 1200r / min through the frequency converter. After the rotary packed bed is stabilized (about two minutes), the steam heater before the resin in the reactor opens the material valve at about 70°C and enters the rotary packed bed, and the temperature is about 115°C after heating with 0.20-0.30MPa steam. Enter the rotating pack...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com