Flue gas desulfurization and dust removal technology and integrated apparatus applicable to ship

A technology for desulfurization, dust removal, and flue gas, which is applied in the direction of combined devices, gas treatment, chemical instruments and methods, etc. It can solve the problems of difficult operation of equipment, poor dust removal effect, high investment cost, etc., and achieves a wide range of gas treatment volume and simple structure , the effect of high dust removal rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

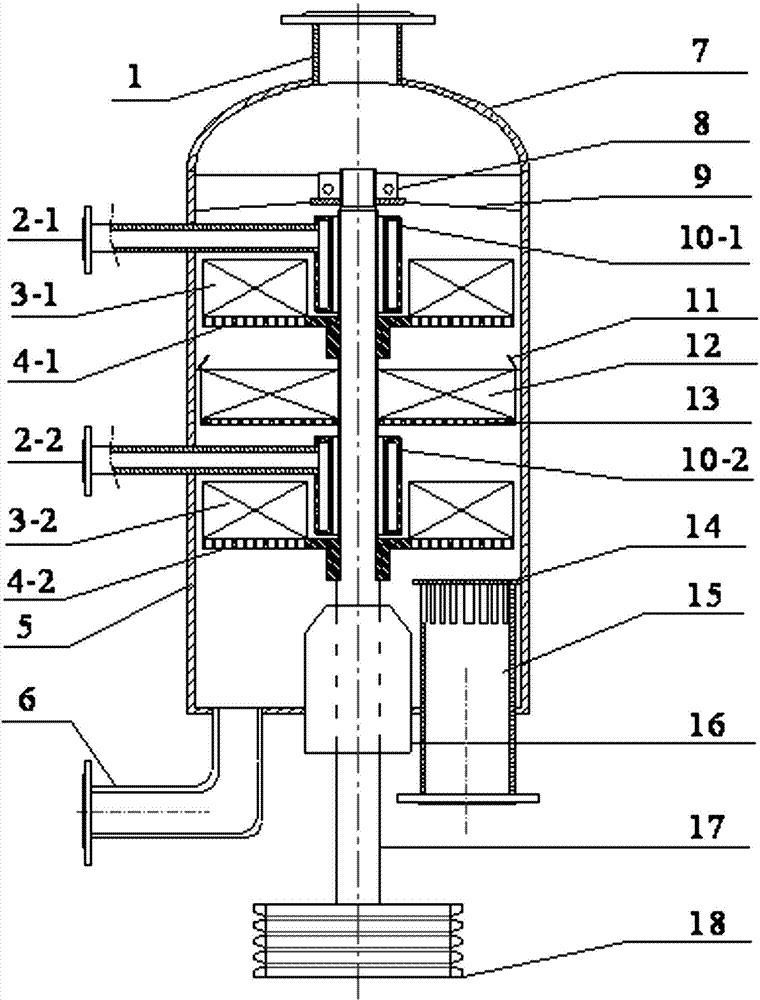

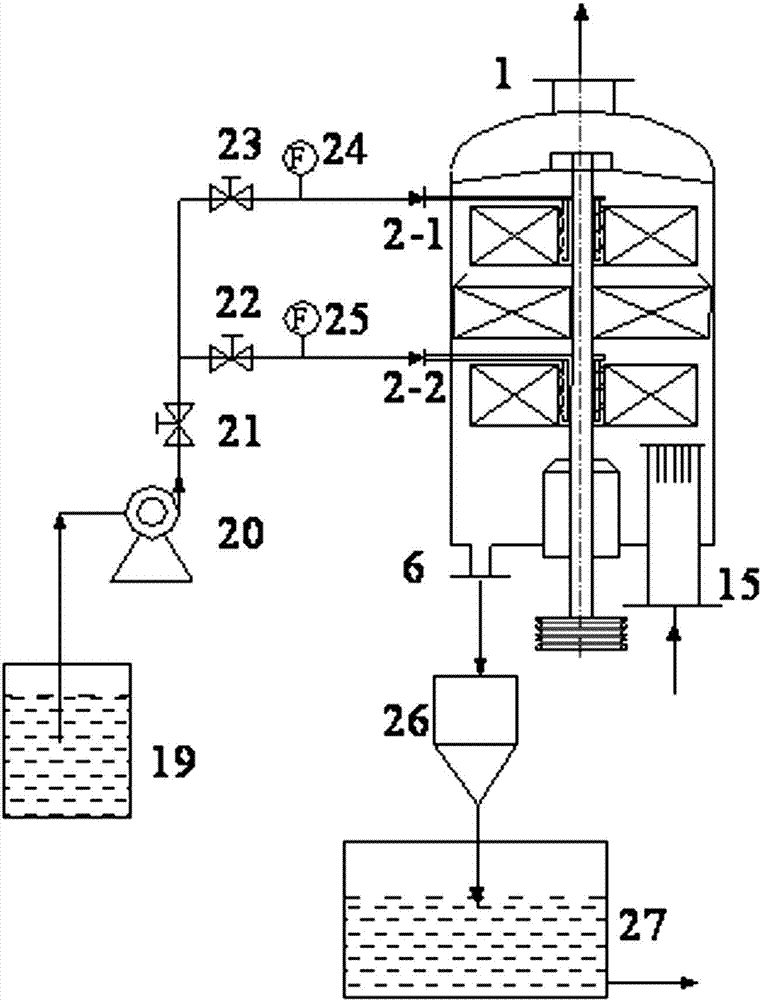

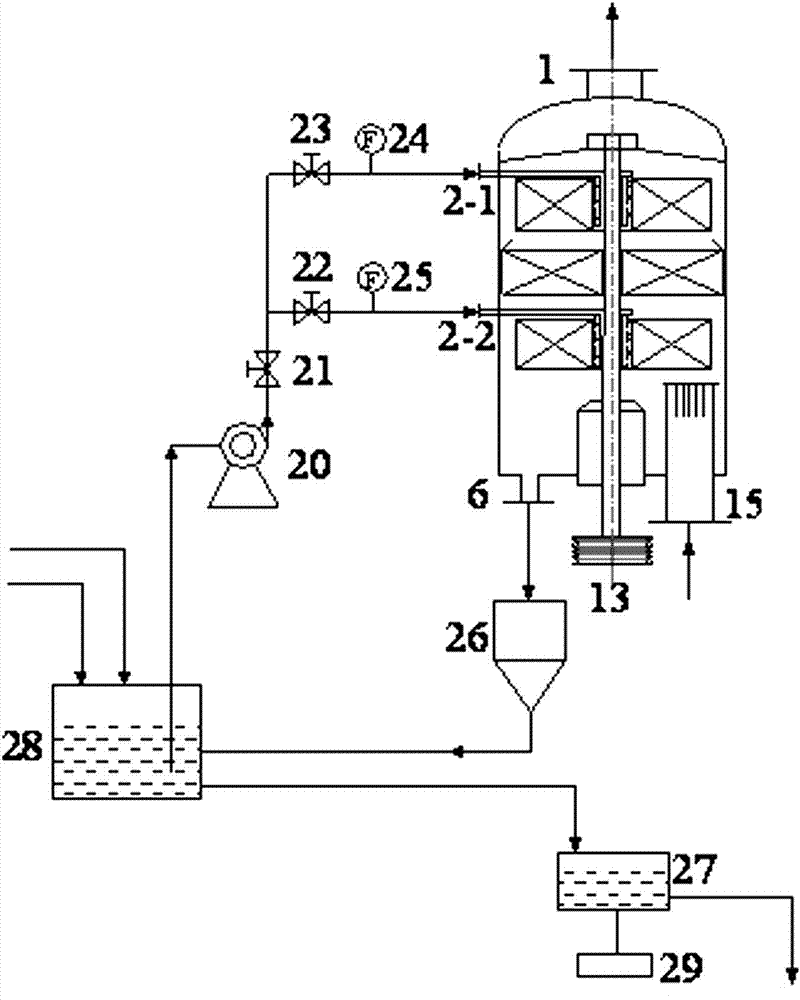

Method used

Image

Examples

Embodiment 1

[0064] SO in flue gas 2 The concentration is 2000 ppm, the inlet flue gas temperature is 140°C; the liquid-gas ratio of the seawater method is 6 L / m 3 , the desulfurization rate is 99.3%, and the dust removal rate is 99.8%. The liquid-gas ratio of the lye method is 2 L / m 3 , the desulfurization rate is 99.5%, and the dust removal rate is 99.6%.

Embodiment 2

[0066] SO in flue gas 2The concentration is 1500 ppm, the inlet flue gas temperature is 80°C; the liquid-gas ratio of the seawater method is 3 L / m 3 , the desulfurization rate is 99.1%, and the dust removal rate is 99.5%. The liquid-gas ratio of the lye method is 1 L / m 3 , the desulfurization rate is 99.2%, and the dust removal rate is 99.4%.

Embodiment 3

[0068] SO in flue gas 2 The concentration is 800 ppm, the inlet flue gas temperature is 50°C; the liquid-gas ratio of the seawater method is 2 L / m 3 , the desulfurization rate is 98.9%, and the dust removal rate is 99.2%. The liquid-gas ratio of lye method is 0.5 L / m 3 , the desulfurization rate is 98.8%, and the dust removal rate is 99.1%.

[0069] Compared with other flue gas scrubbing devices, such as the packed tower, two-stage series spray tower, foam tower and bubble tower adopted by PureSOx, BELCO, Hamworthy and Ecosilencer respectively, the first three devices adopt hybrid system, and the last one adopts open The ring is the seawater desulfurization system. Their desulfurization rates are 99%, >97%, 99%, and 90%. Although good results have been achieved, the size of these tower equipment is about Φ5 m×10 m. The volume occupies a large amount of ship space, and the investment cost and operating cost are relatively high. The application number published in 2006 is 200...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com