Patents

Literature

45results about How to "Eliminate entrainment" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

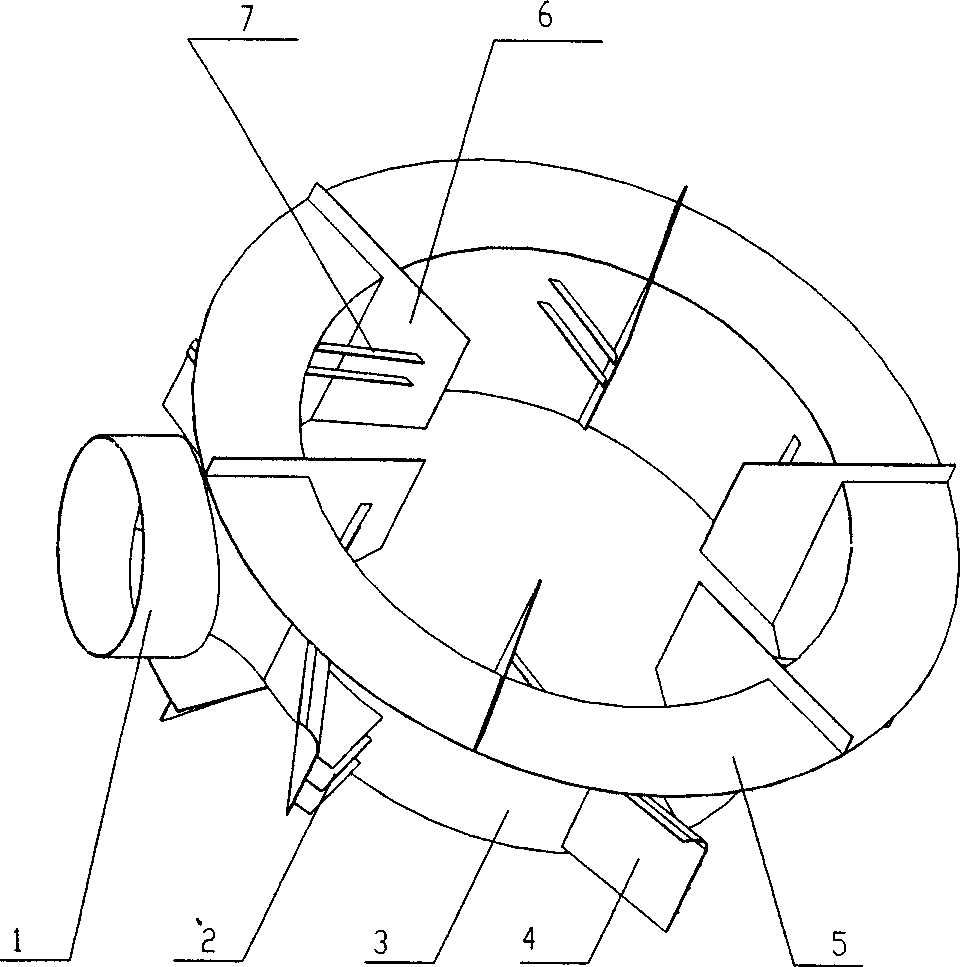

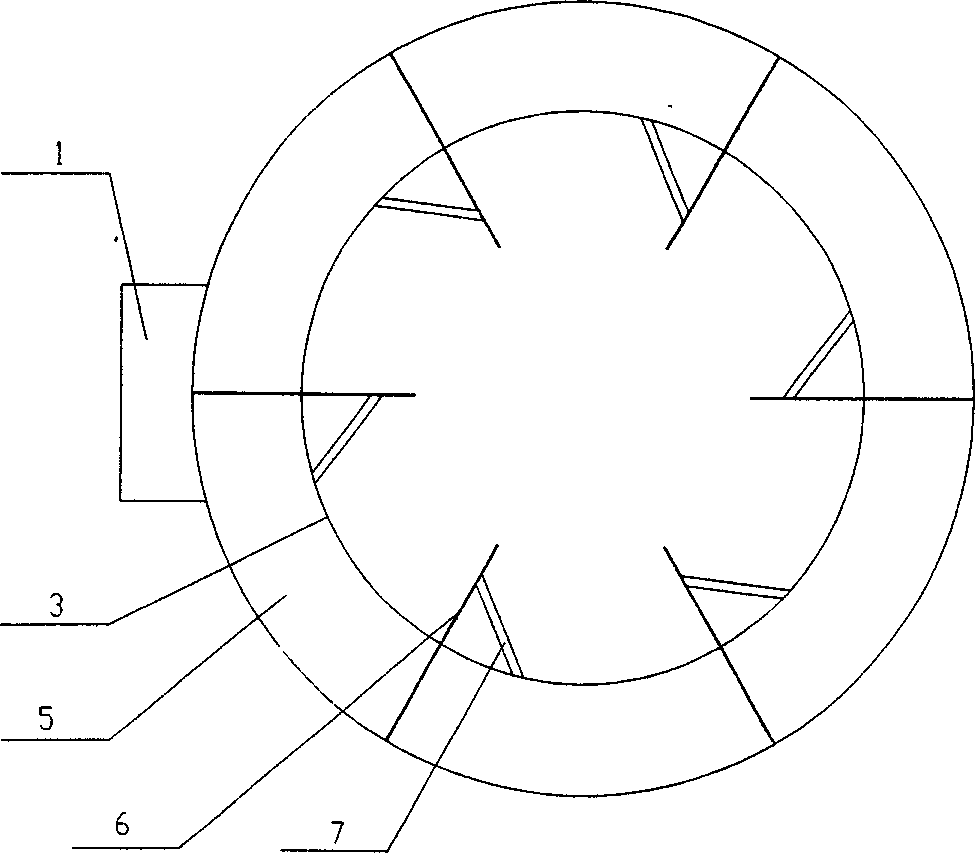

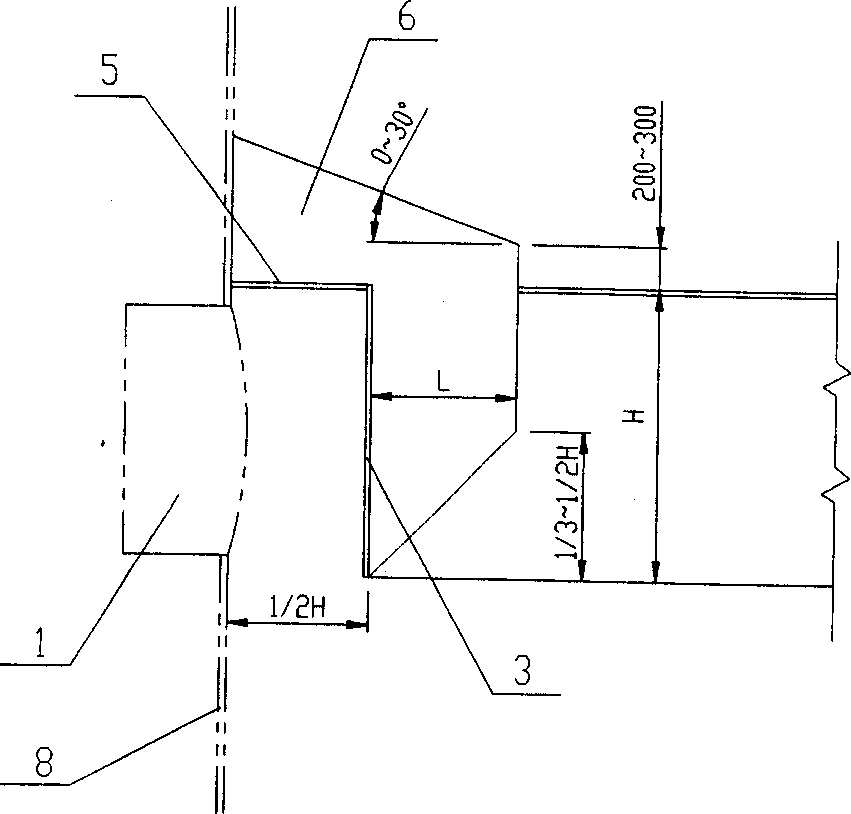

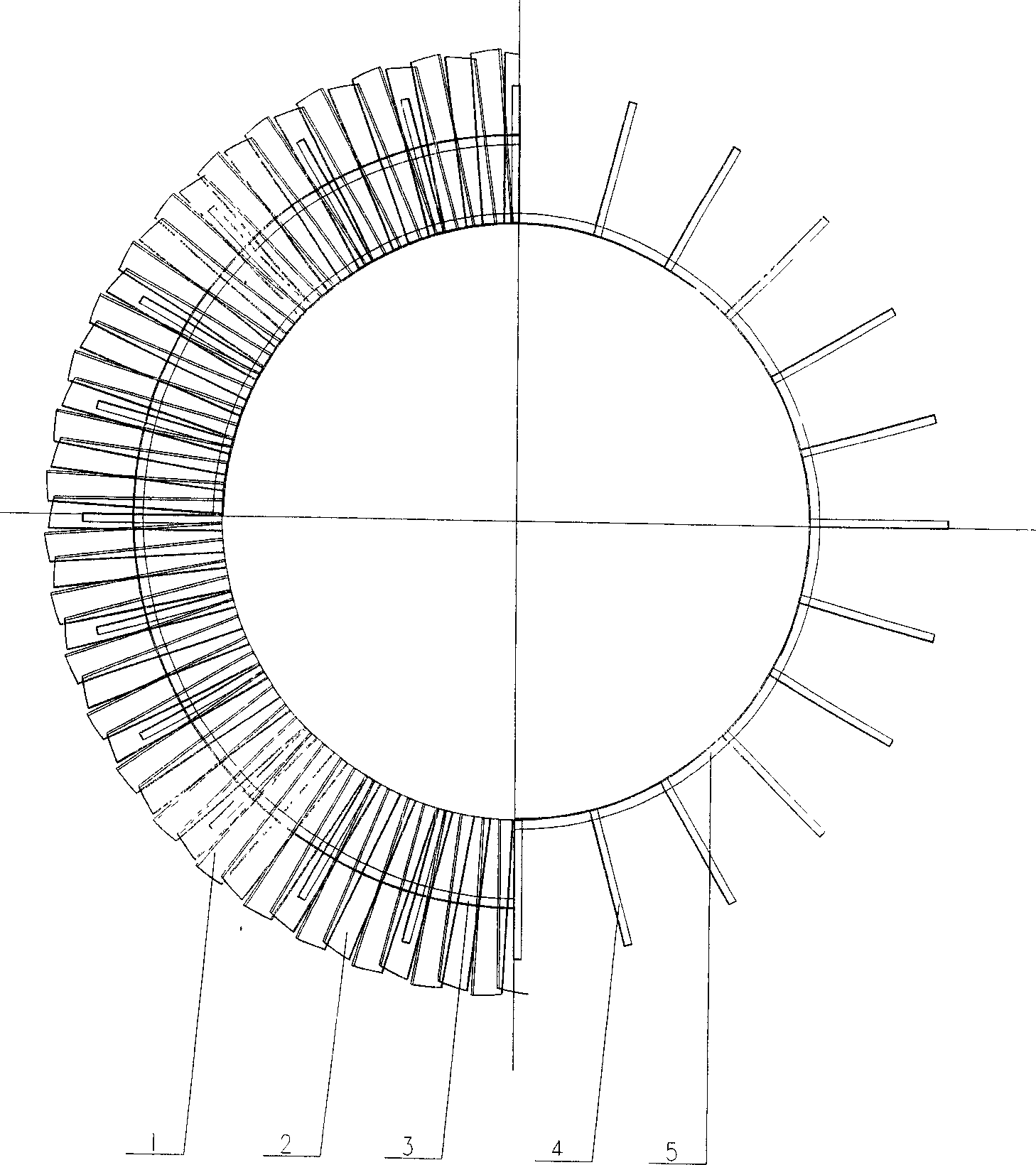

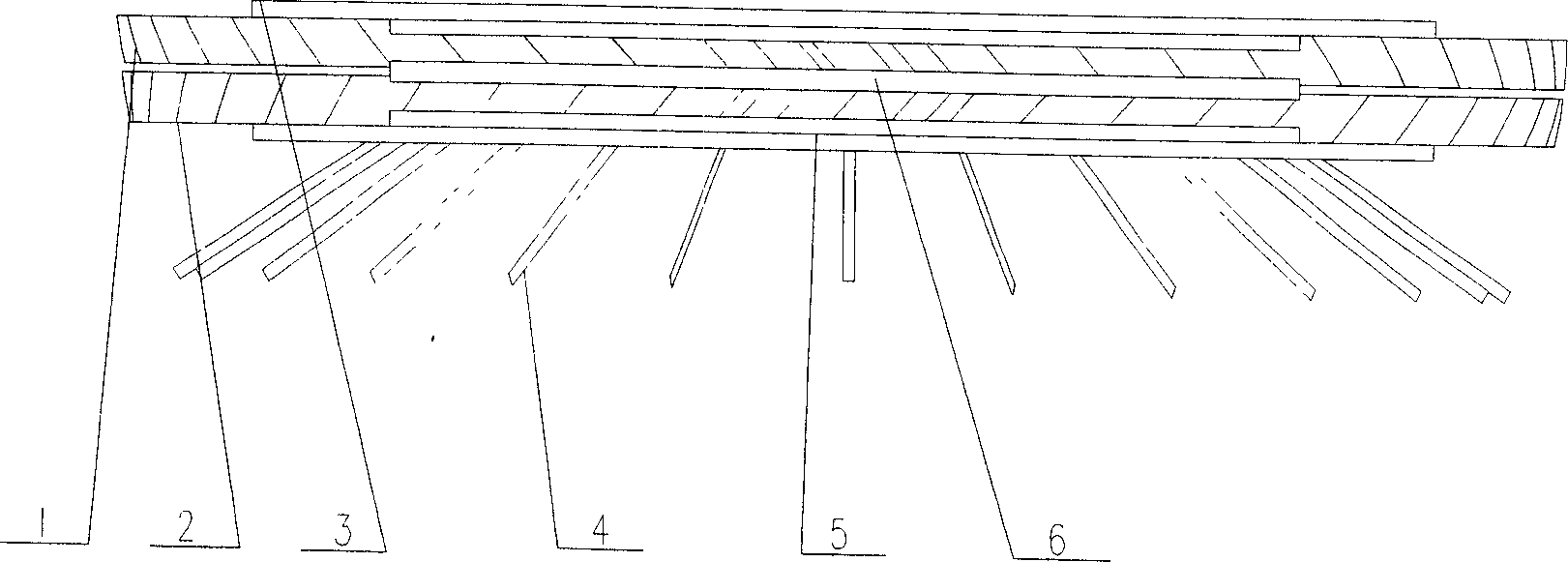

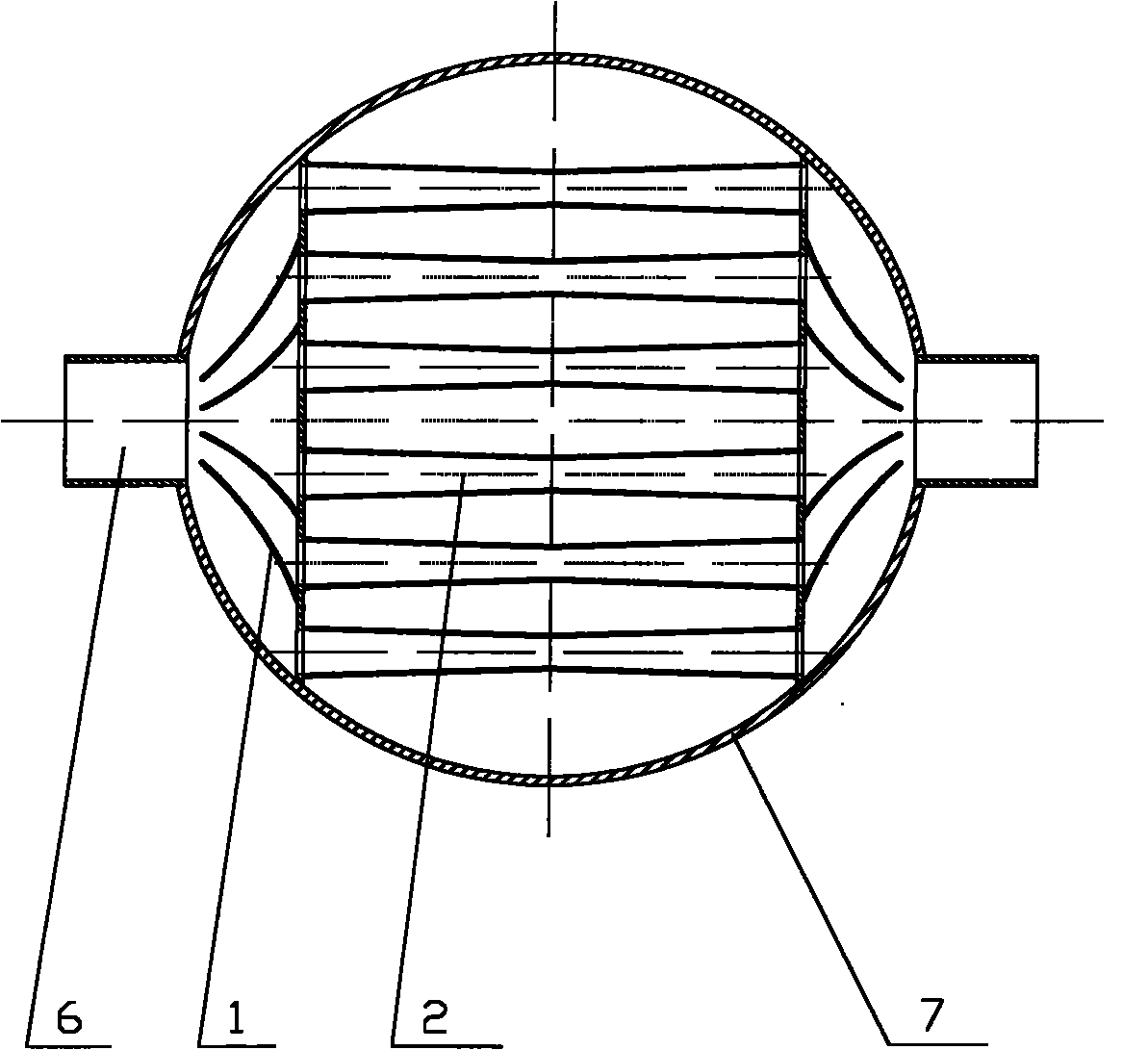

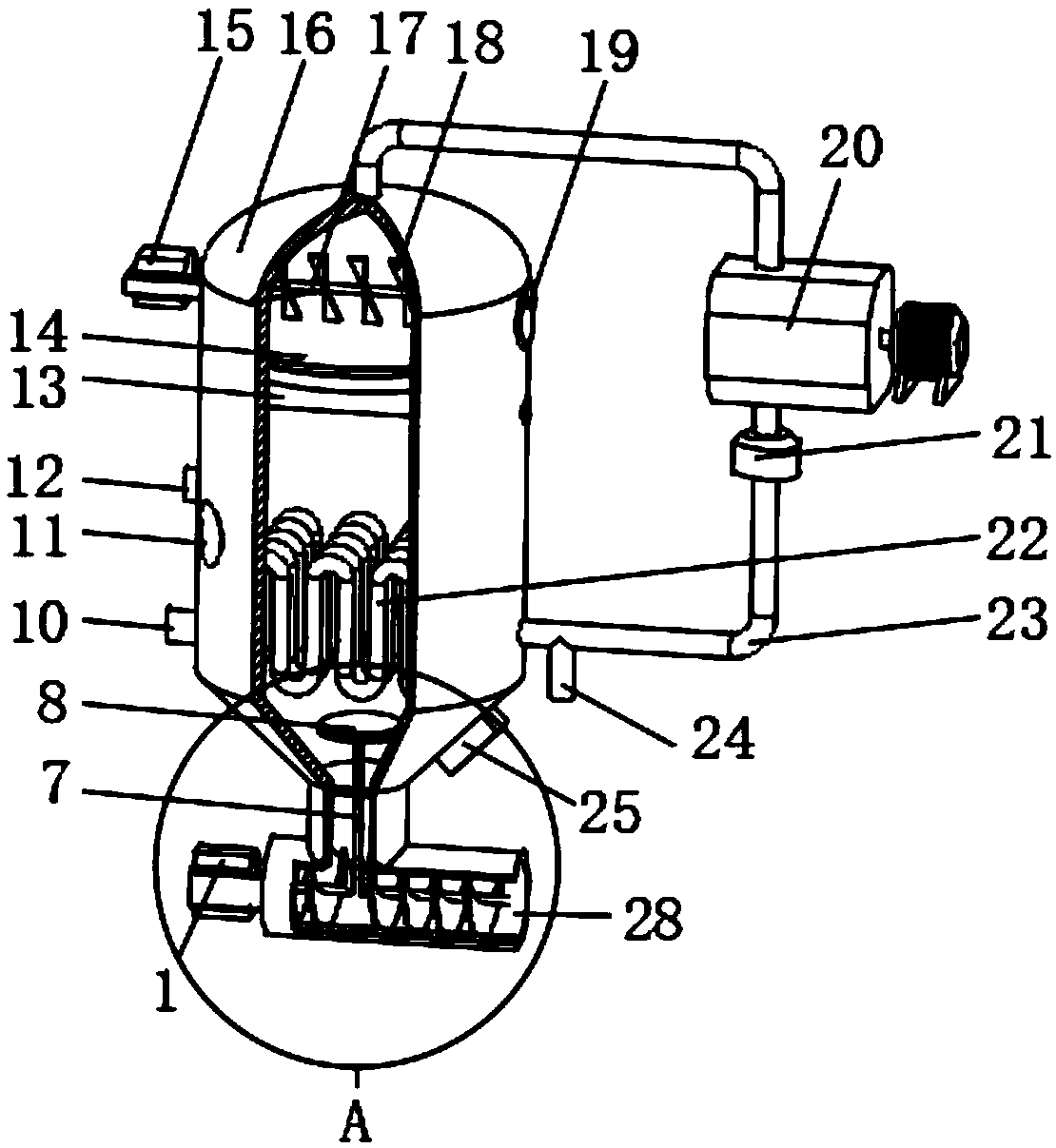

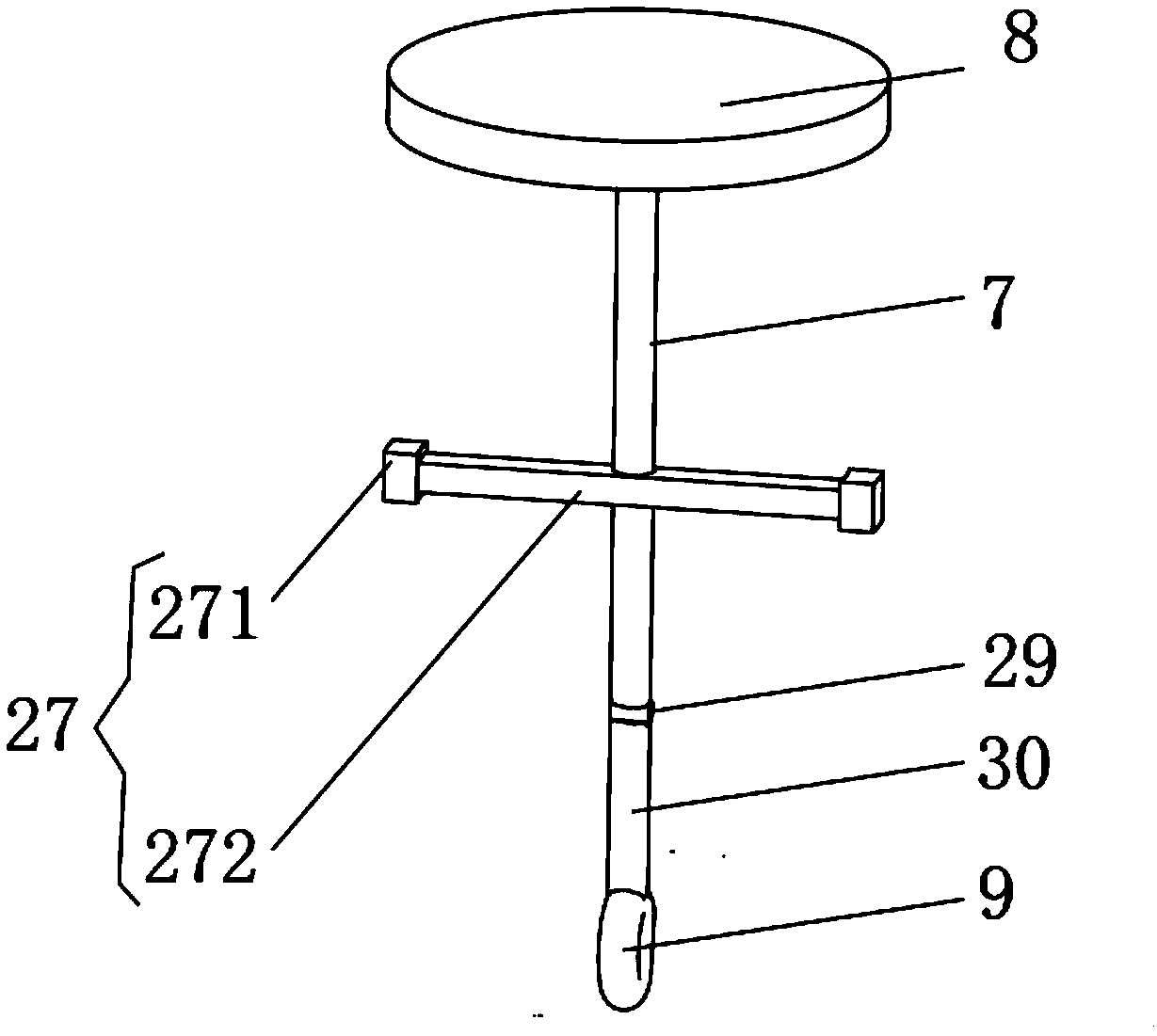

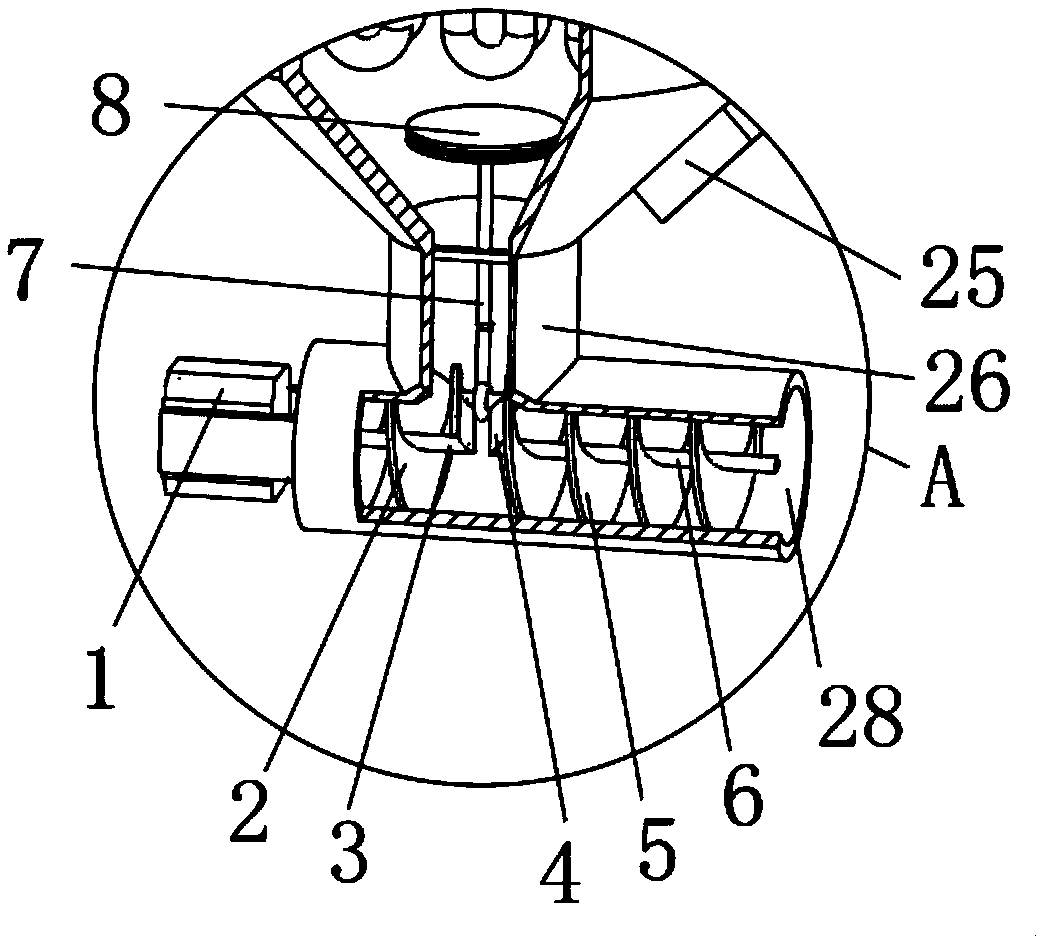

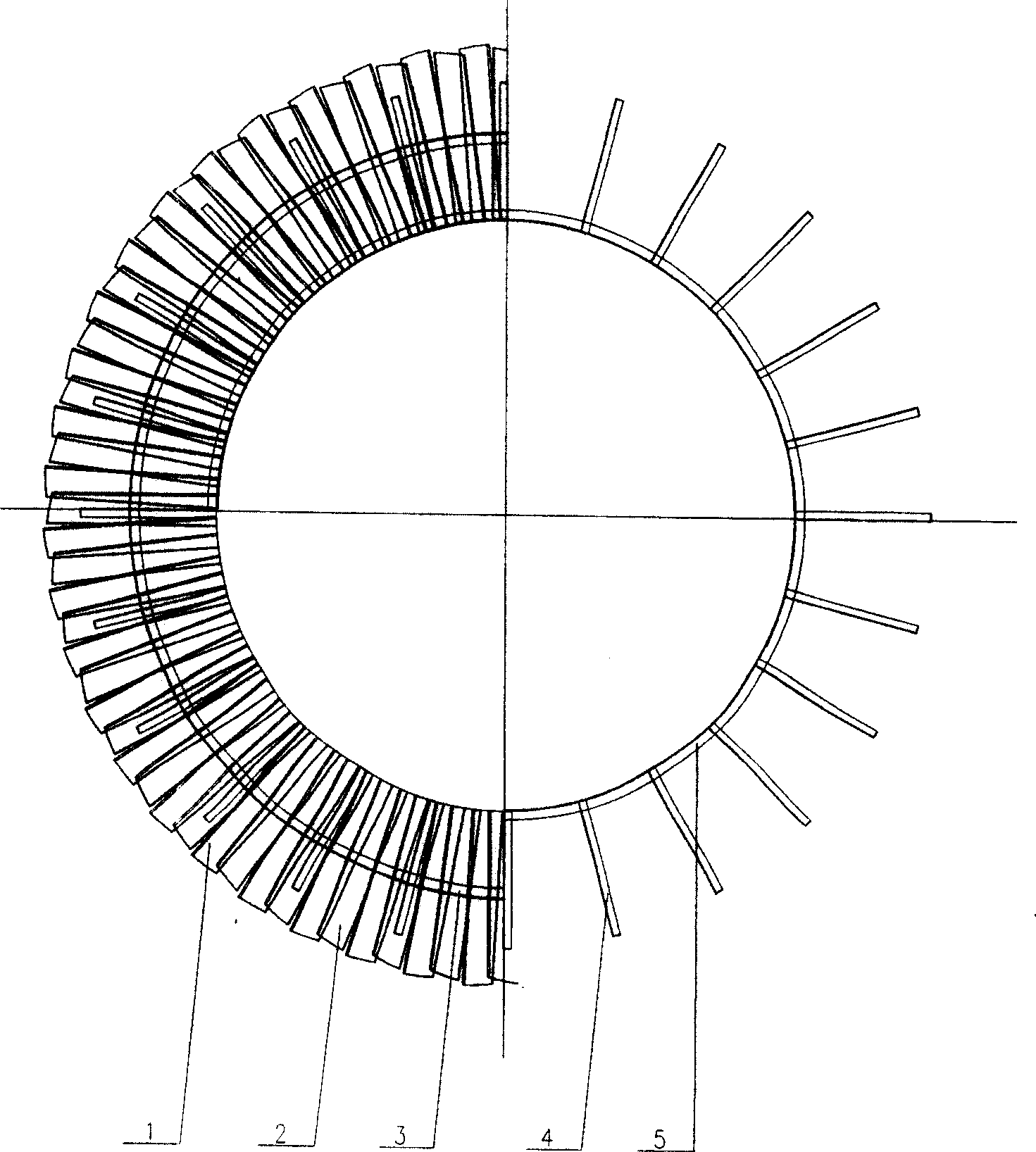

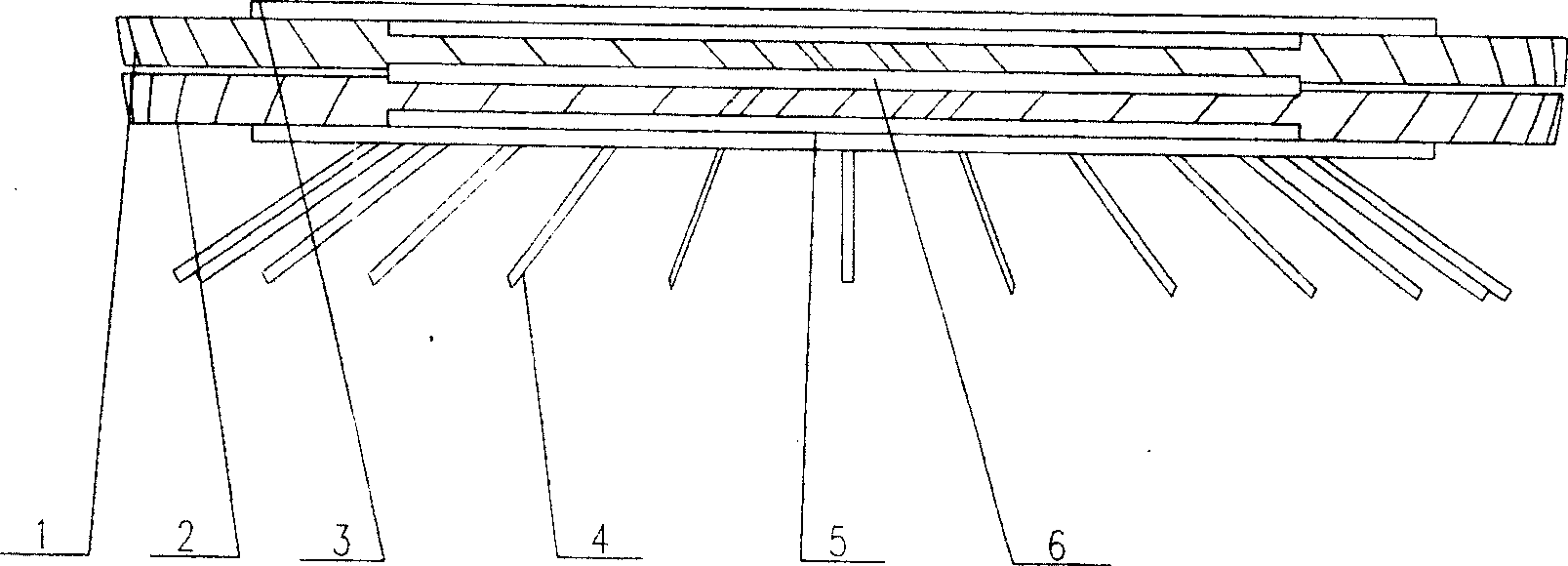

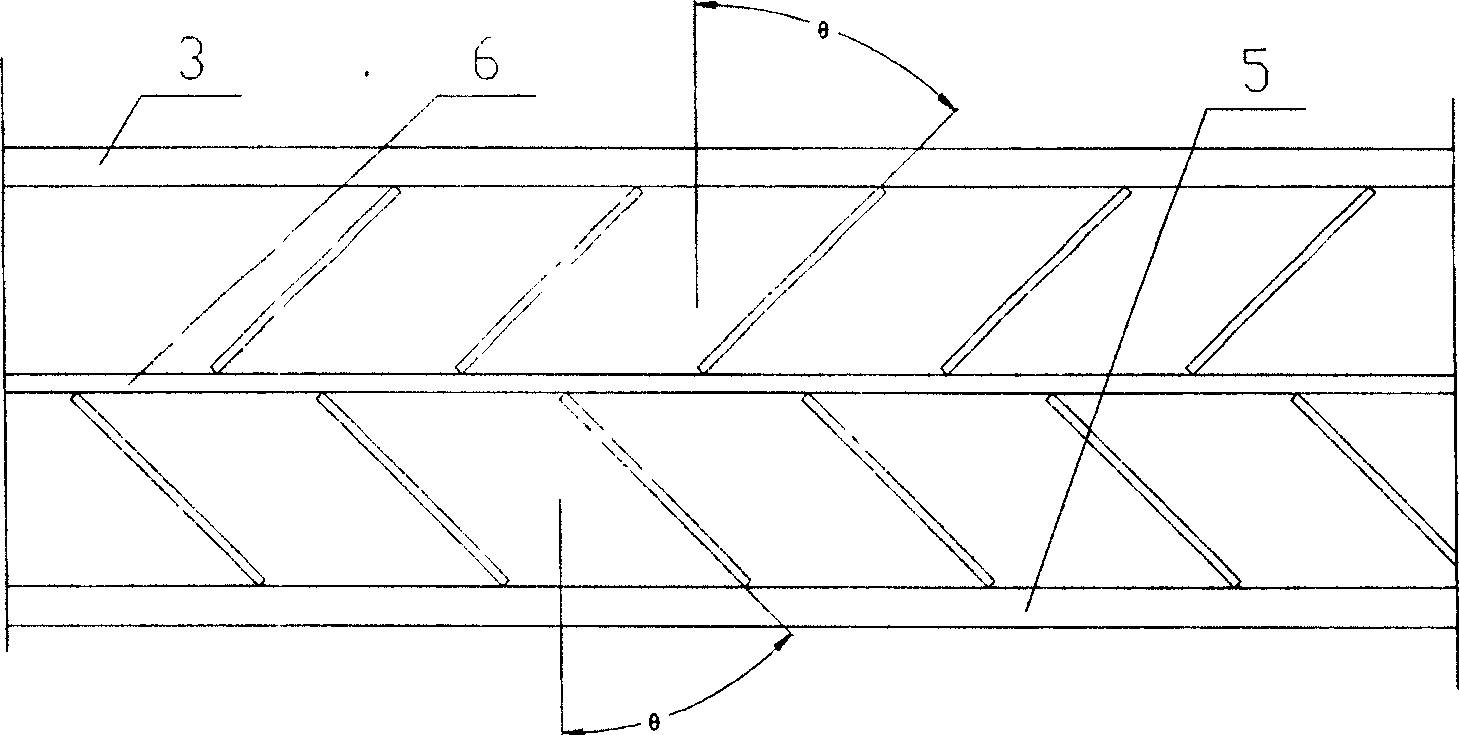

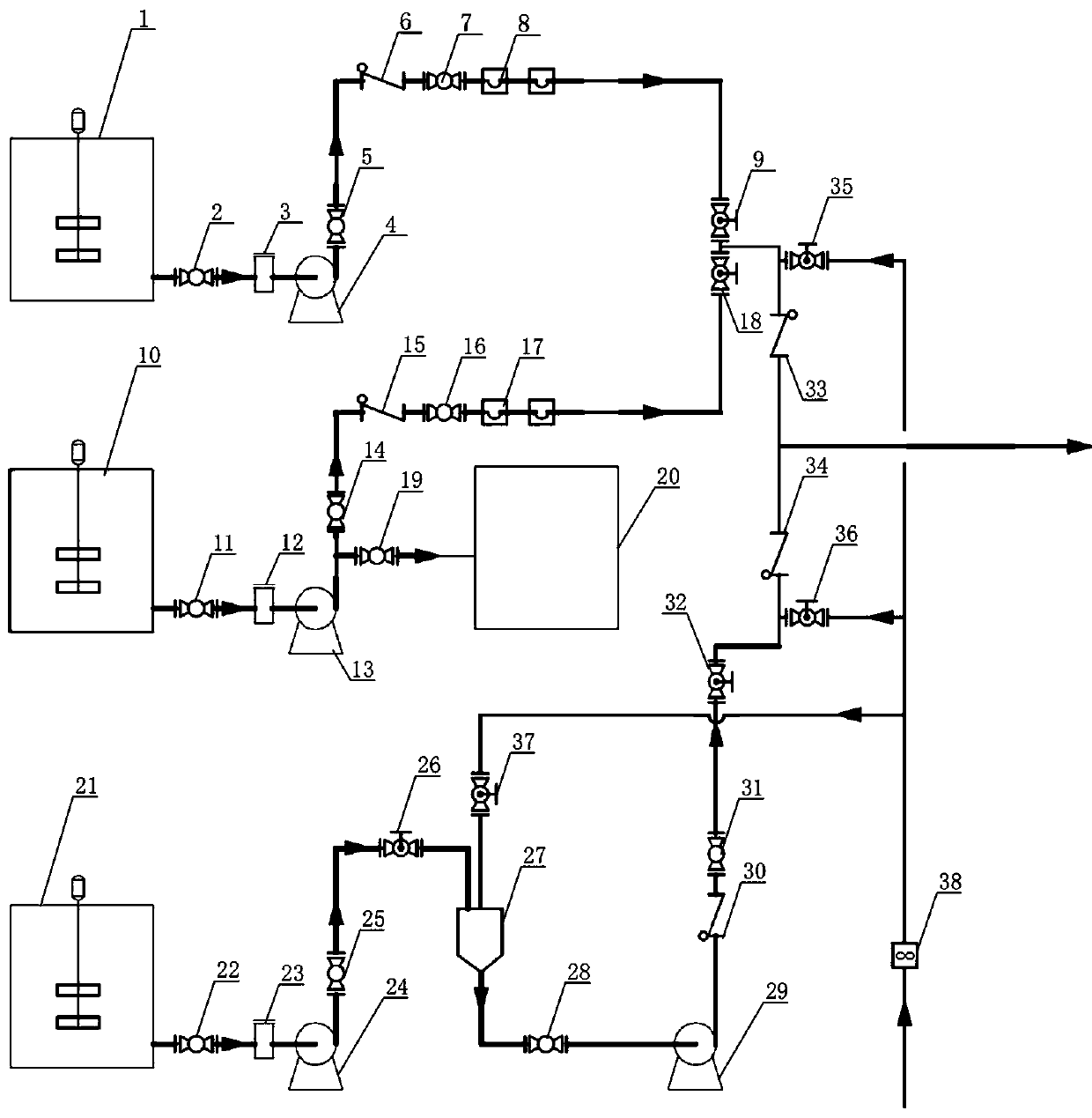

Flue gas desulfurization and dust removal technology and integrated apparatus applicable to ship

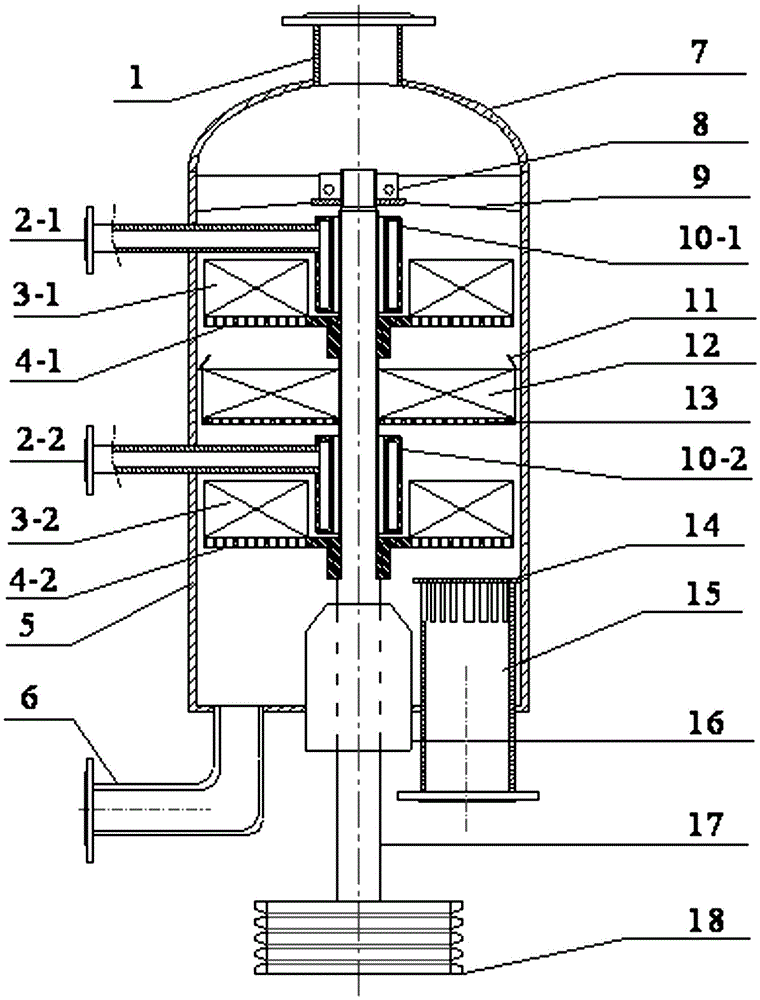

ActiveCN104492210AEnhanced mass transferIncrease capture rateCombination devicesGas treatmentFlue gasDust control

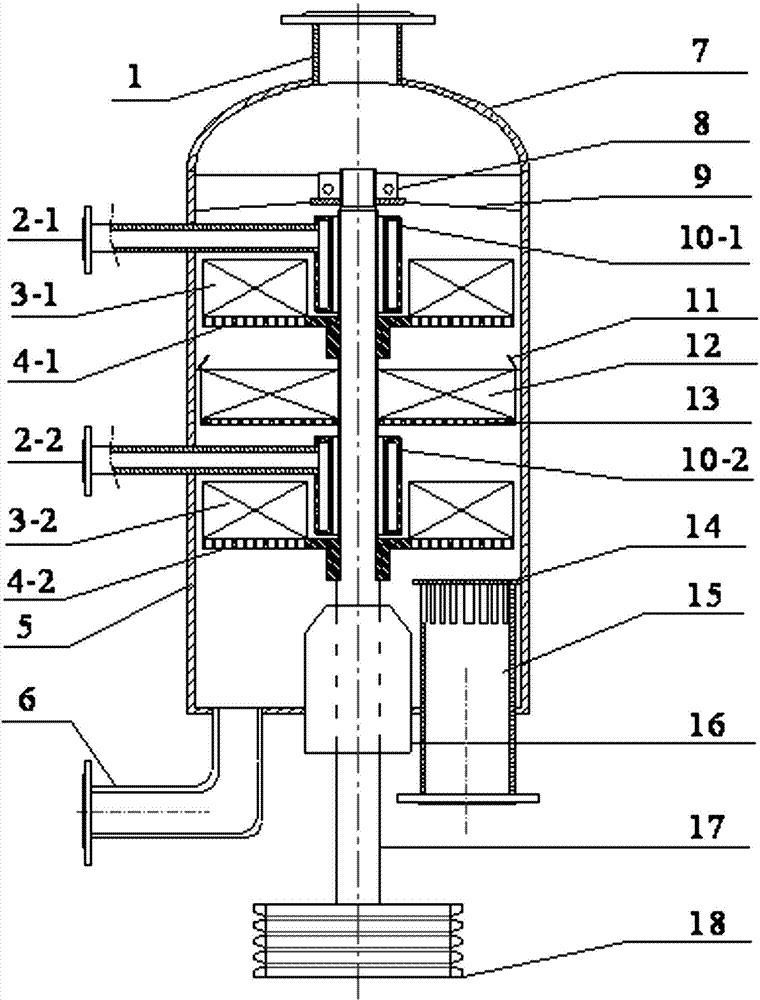

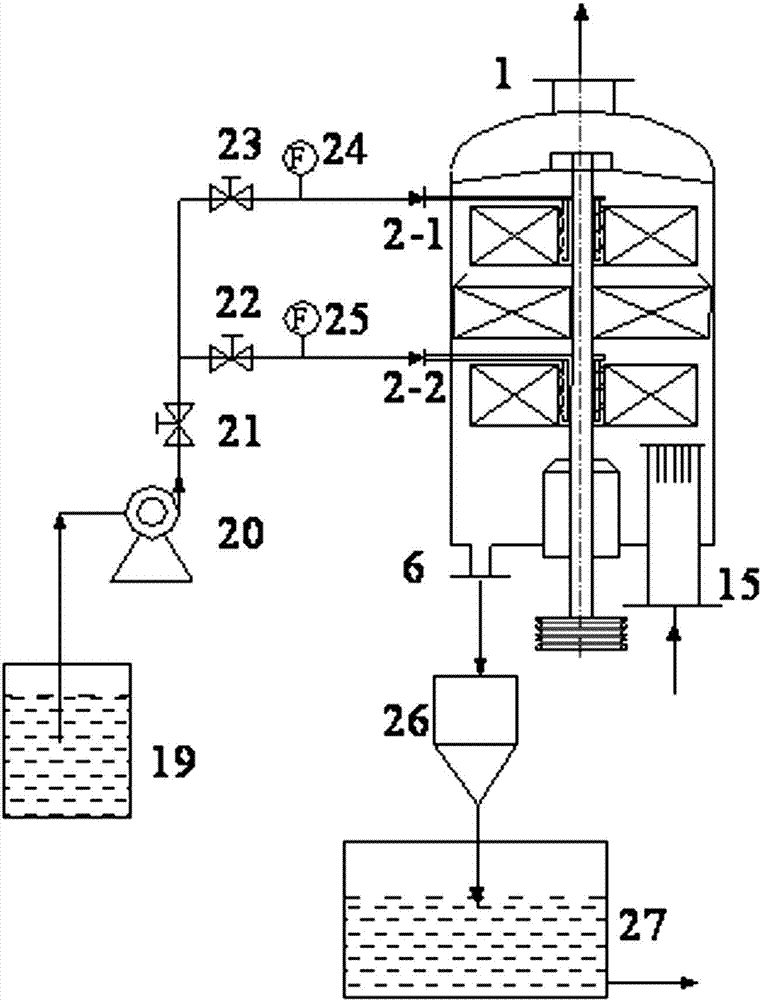

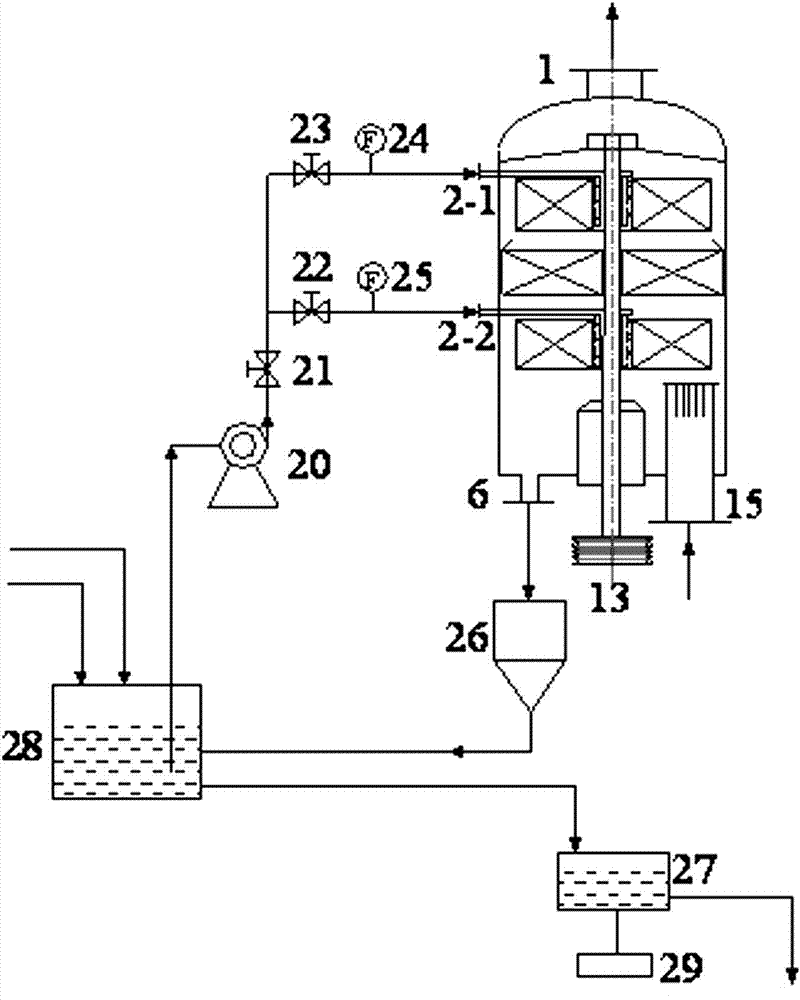

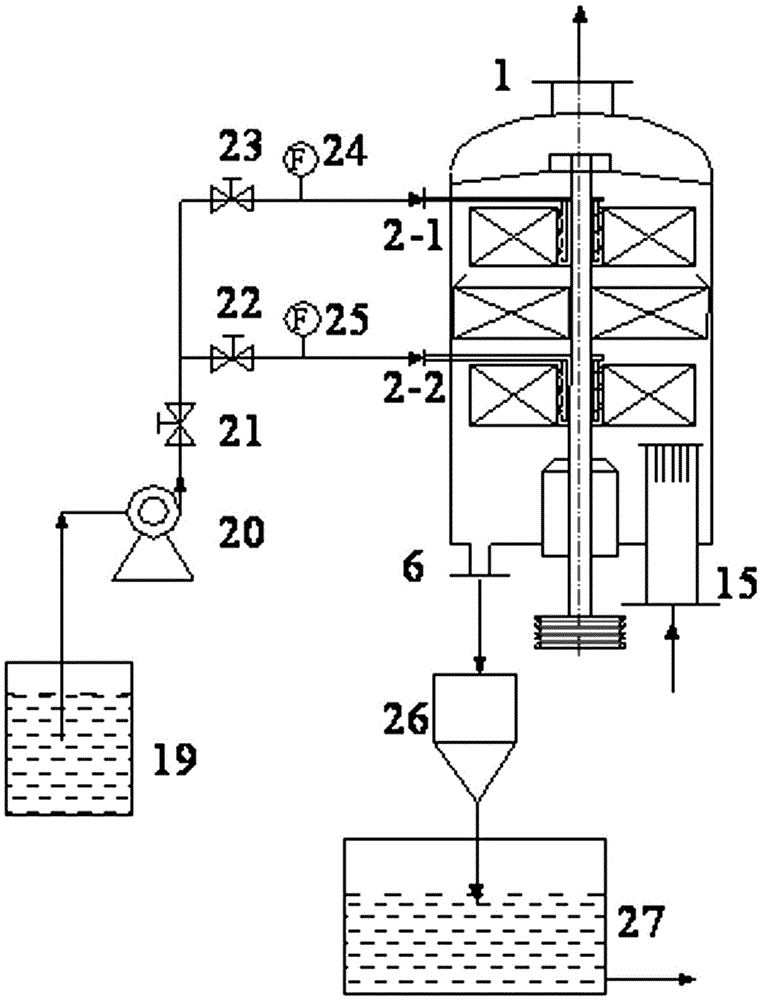

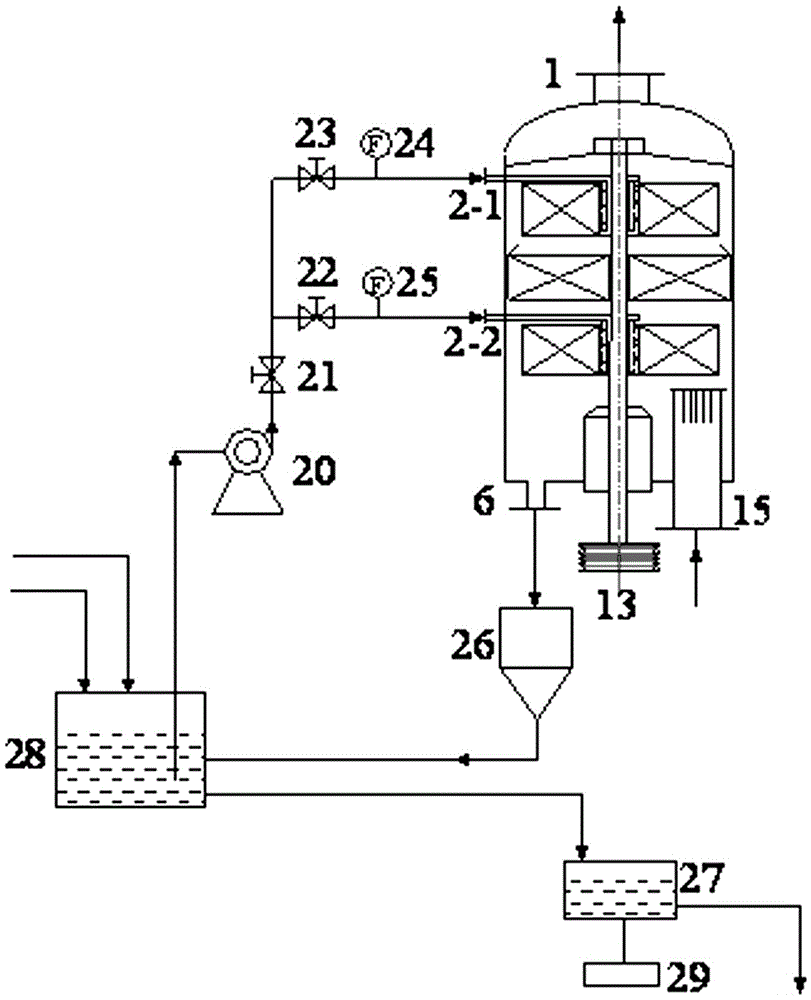

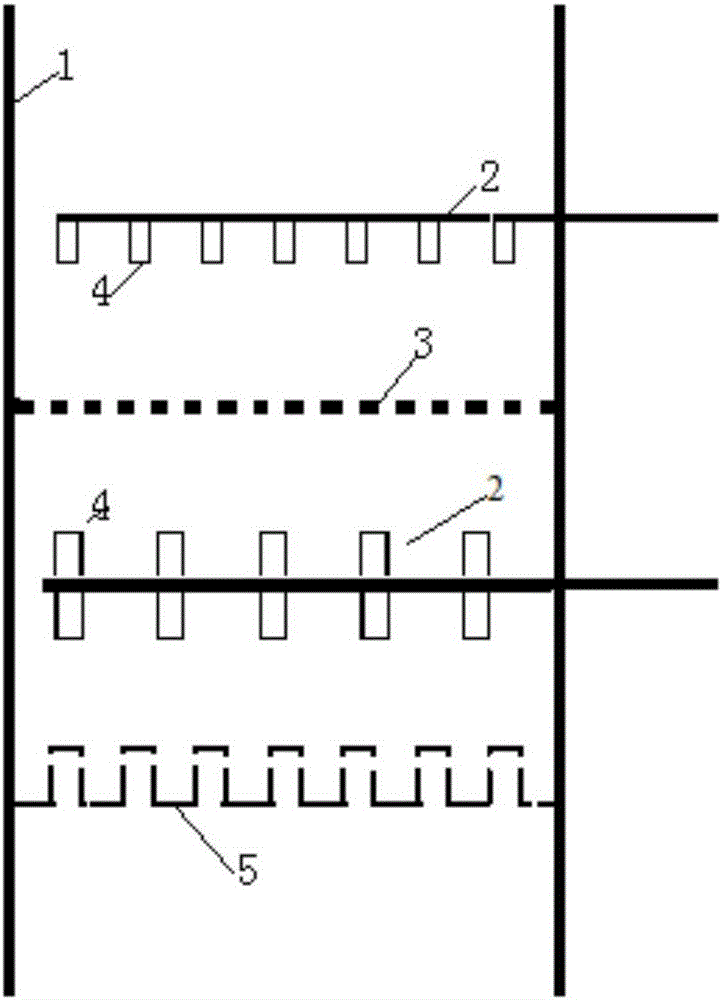

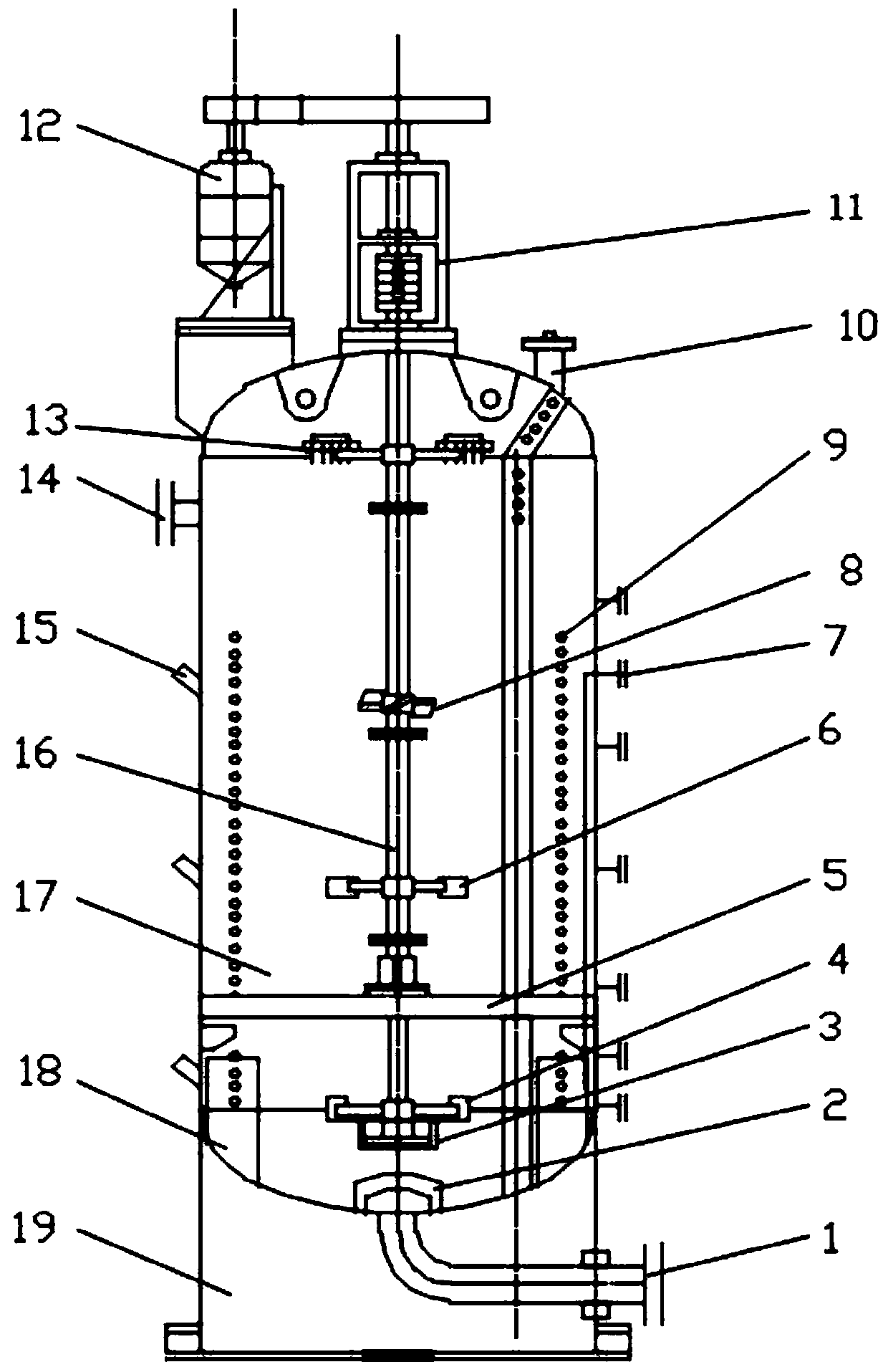

The invention belongs to the technology of flue gas desulfurization and dust removal, and in particular relates to a flue gas desulfurization and dust removal technology and an integrated device applicable to ships, and solves the problems in the flue gas desulphurization technology and equipment for ships of the prior art. The flue gas desulfurization and dust removal apparatus includes a multi-stage cross flow rotating packed bed, a barren liquor tank, a barren liquor circulating pump and an aeration tank. The flue gas desulfurization process includes an open seawater method flue gas desulphurization technology and a enclosed alkali method flue gas desulfurization technology. Two technologies can be combined with the rotating packed bed, and the invention has the advantages of high desulfurization efficiency, low energy consumption, simple process, low investment and operation cost, stable operation, convenient startup and shutdown, and integrated desulphurization and dust removal.

Owner:ZHONGBEI UNIV

Cold-rolled steel strip rolling method

InactiveCN103521519AImprove thickness control accuracyEliminates emulsion entrainmentWork treatment devicesMeasuring devicesEngineeringControl system

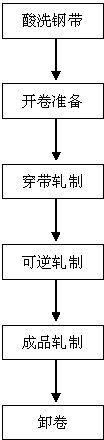

The invention relates to a cold-rolled steel strip rolling method. A straightening strip head of a straightening machine is arranged in the front of an original rolling-mill housing, a CPC alignment device is arranged on an uncoiler and enables strip materials to enter the rolling-mill housing in an aligned mode for rolling, a main rolling mill is a six-roller rolling mill, an upper middle roller and a lower middle roller of the main rolling mill have an axial horizontal moving function, an upper work roller and a lower work roller have positive and negative roller bending functions, the main rolling mill is additionally provided with an AGC hydraulic screw down control system, and the front portion and the rear portion of the main rolling mill are respectively provided with an X-ray thickness gauge, a vacuum oil removing device, an upper row of air knives and a lower row of air knives. Steel strip pickling undergoes uncoiling preparation, threading rolling, reversible rolling, finished product rolling and coil unloading for rolling of steel strips, the technical problems that work rollers need an original convexity degree, the diameters of the work rollers are difficult to reduce, roller rolling and bending can not be effectively achieved, storage amount of spare work rollers and roller consumption is increased are solved, and the thickness control precision and plate face cleanness are improved.

Owner:山东泰山轧钢有限公司

Feeding distributor with anti-eddy flow baffle plate

InactiveCN1843567AEliminate relative rotationEliminate entrainmentDispersed particle separationDistillation separationEngineeringTower

The invention provides a feeding distributor with anti-cyclone baffle plate, which comprises an inner muffle, a cover plate, a guide plate and an anti-cyclone baffle plate. Wherein, the guide plate is arranged between the tower wall and the inner muffle; the surface of guide plate that back to the inlet has a strengthen bar; the anti-cyclone baffle plate is arranged at the inner side of inner muffle whose side surface has a tie-bar; another end of tie-bar is fixed on the inner muffle; the cover plate is annular at the top of inner muffle whose one end is fixed on the tower wall and another end is fixed on the inner muffle; the baffle plate is used to resist the revolution of ascending airflow to reduce the entrainment on the liquid and distribute the ascending airflow. The invention has the advantages that: it can eliminate the airflow revolution caused by cyclone material feeding and eliminate the entrainment on the liquid drops, to avoid the non-uniformity of gas caused by the break of flow area and speed.

Owner:TIANJIN UNIV

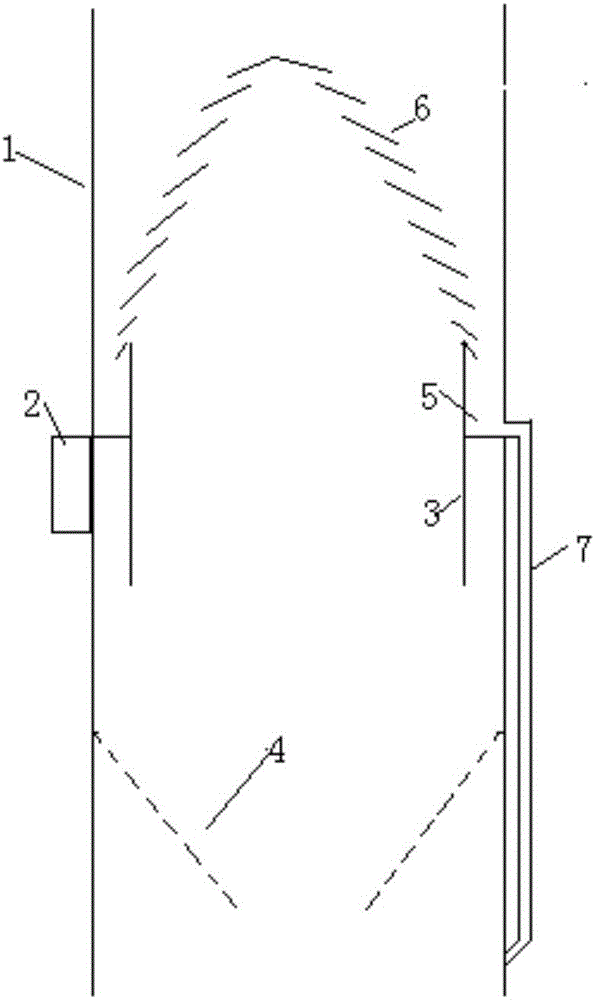

Liquid-collecting energy absorption device

InactiveCN1864787ASlow down the flowImprove operational efficiencyUsing liquid separation agentFractional distillationEnergy absorptionProduct gas

The invention relates to a liquid-catching power absorber. It comprises liquid-catching power absorbing plate and annular mounting plate; said liquid-catching power absorbing plate includes upper layer liquid-catching power absorbing plate 1 and lower layer liquid-catching power absorbing plate 2, between two said plates equipped with a annular plate 6, the upper of upper layer liquid-catching power absa orbing plate is connected with upper layer annular plate 3, while the one at lowe layer iconnected with lower layer annular plate 5; supporting stand 4 is installed on lower layer annular plate 5, the other end of supporting stand is welded on tower wall. The liquid-catching power absorber greatly reduces flowing speed of gas from circulating gas distributor, eliminates impact to liquid surface in tower bottom by gas and entrainment, and the liquid in gas is catched by said two liquid-catching power absorbing plate, which avoids back-mix-flow and increases operating efficiency.

Owner:TIANJIN UNIV

Tower feeding distributor

ActiveCN102049149AEliminate entrainmentAvoid uneven distributionFractional distillationWindow shutterGas phase

The invention relates to a tower feeding distributor, comprising a feeding inlet, a splitter and a shutter flow channel. The splitter is of a fan-shaped structure, comprising an arch-shaped guide plate, upper and lower cover plates and a support end plate. The shutter flow channel is a horizontal channel with a gradually decreasing flow area, and an inlet end of the shutter flow channel is fixed on a support end plate of the splitter. At both sides of the shutter flow channel, 4-12 groups of blades are arranged in order from the inlet end, and directions of the blades on the two sides are staggered to form an outlet between the adjacent blades. The feeding distributor can carry out both uniform distribution on the gas-liquid mixing feed for two times and gas-liquid separation on the gas-liquid mixing feed for two times, and generate airflow collision by utilizing an inertial force of the gas phase, thereby basically eliminating the entrainment of liquid drop by gas. Non-uniform gas distribution caused by a sudden change in feeding amount is avoided. High uniform rising gas distribution is realized. Meanwhile, a tower diameter width is fully used to ensure the feeding distributor to be low and to effectively save the space.

Owner:CHINA PETROLEUM & CHEM CORP +1

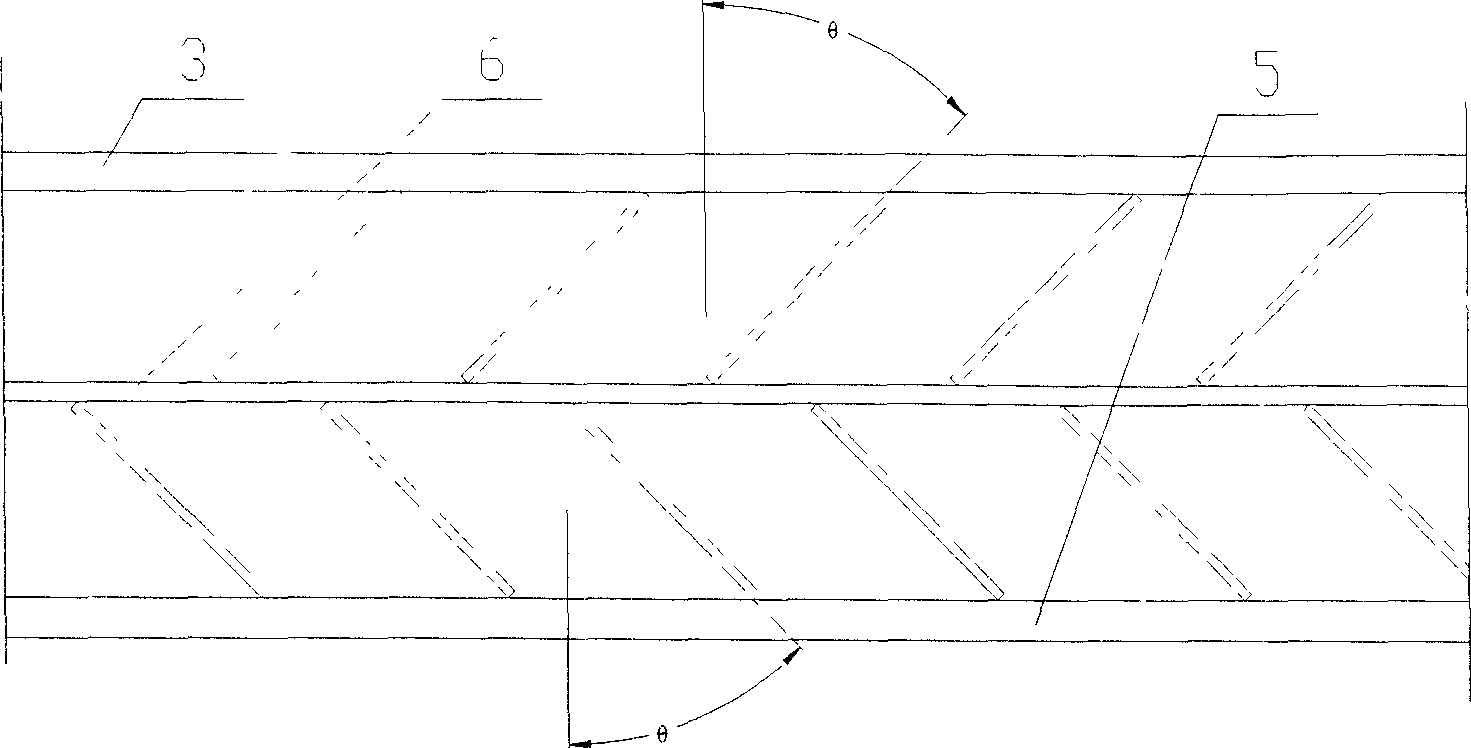

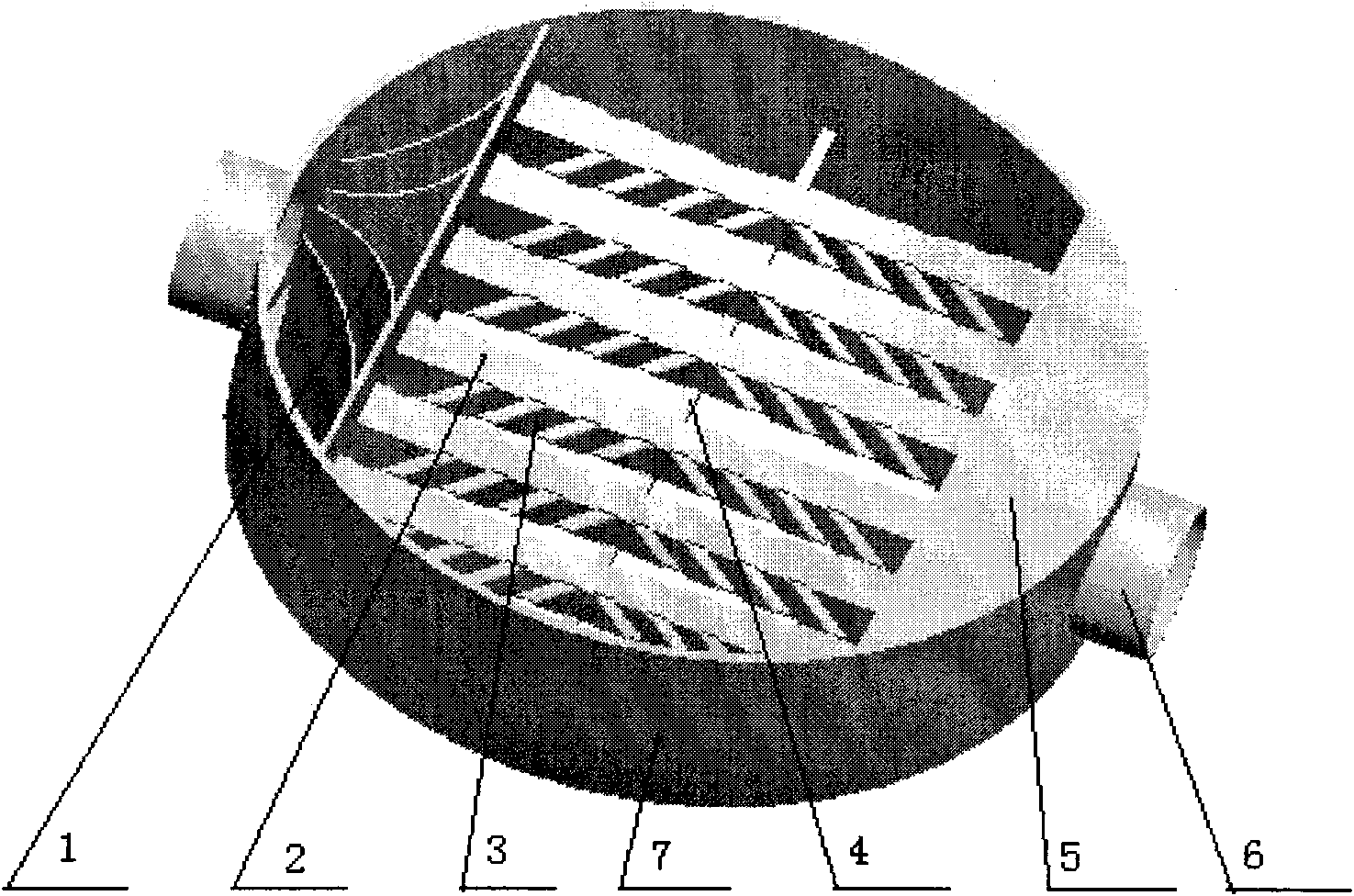

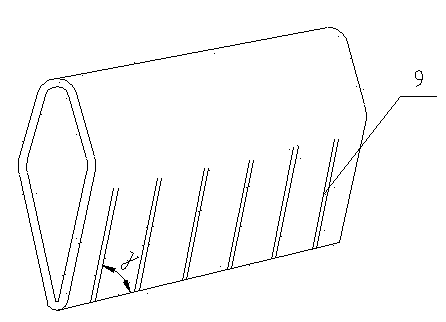

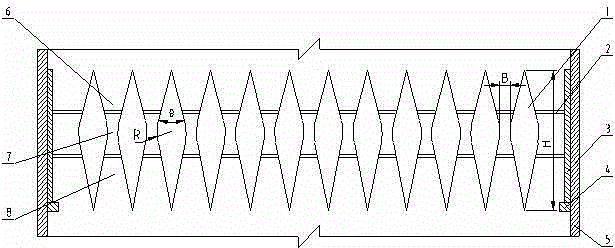

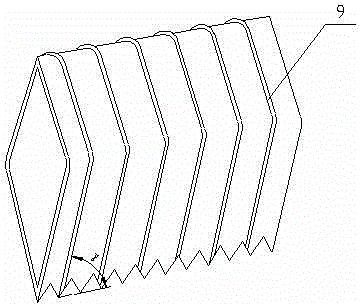

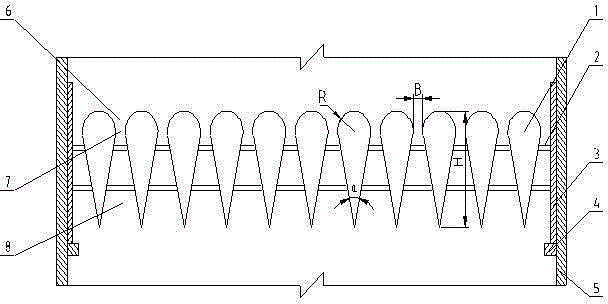

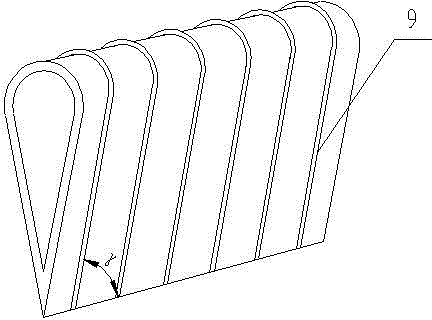

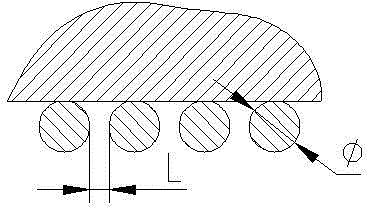

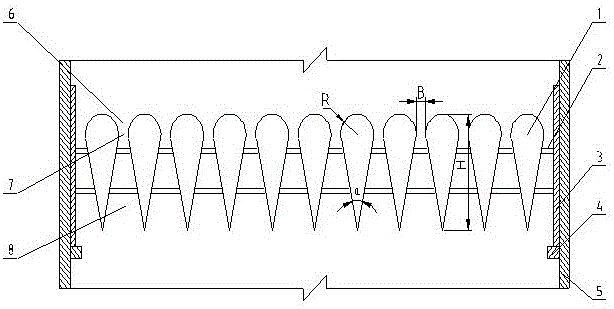

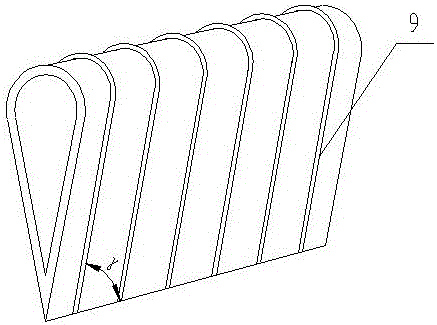

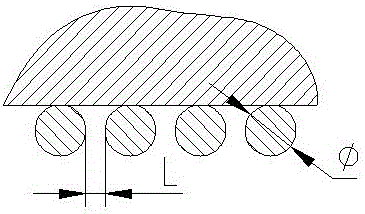

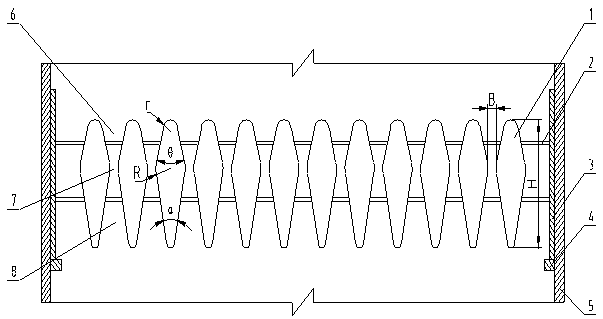

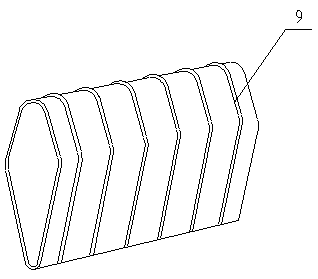

Spindle-shaped structured packing

ActiveCN104607136AIncrease in specific surface area per unitAchieve decentralizationDispersed particle separationChemical/physical/physico-chemical processesFlue gasGas phase

The present invention discloses a spindle-shaped structured packing, which comprises at least a packing layer comprising a plurality of horizontally-placed spindle-shaped special-shaped pipes connected in parallel, wherein the plurality of the horizontally-placed spindle-shaped special-shaped pipes connected in parallel form a plurality of parallel channels with collection sections, laryngeal orifices and dispersion sections, the cross section of the spindle-shaped special-shaped pipe is the spindle shape, the top portion and the lower portion of the spindle-shaped special-shaped pipe are the arc shapes, and the radius of the arc on the top portion is larger than the radius of the arc on the lower portion. Compared with the existing structured packing, the spindle-shaped structured packing of the present invention has advantages of high mass transfer efficiency, simple structure, small size, fouling resistance and low pressure drop, has less gas-phase liquid foam entrainment after the mass transfer reaction, is suitable for the gas-liquid two-phase mass transfer and reaction processes, especially for the dust removal and desulfurization treatment of flue gas and process exhaust gas, and can be widely used in the fields of petrochemical industry, environmental protection and the like.

Owner:CHINA PETROLEUM & CHEM CORP +1

Direct discharging structure of crystallized salt wastewater evaporation device

InactiveCN109621467AHigh degree of intensificationGuaranteed uptimeEvaporation with vapour compressionEvaporator accessoriesMotor driveSpiral blade

The invention discloses a direct discharging structure of a crystallized salt wastewater evaporation device. The structure comprises a tank body, the lower portion of the inner wall of the tank body is fixedly provided with a heat exchange column pipe through a fixing frame, an air outlet of the heat exchange column pipe is communicated with an evaporator condensate port in the lower portion of the outer side face of the tank body, an air outlet in the upper end of the tank body is communicated with an air inlet of a steam compressor through a guide pipe, and an air outlet of the steam compressor is communicated with an air inlet of a check valve; a first servo motor drives a first transmission shaft, a U-shaped rod and a second transmission shaft to rotate, the U-shaped rod drives a connecting rod and vertical rods to move up and down through a sleeving ring, the vertical rods drive a circular plate to move up and down, the circular plate moves in the tank body and a vertical pipe back and forth to make a concentrated raw material move, a vibration motor makes crystallized salt attached to the bottom of the inner wall of the tank body fall off, a first spiral blade and a second spiral blade enable the concentrated raw material to move rightwards, and discharging is smooth.

Owner:江苏易简环保科技有限公司

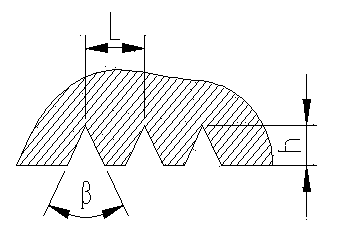

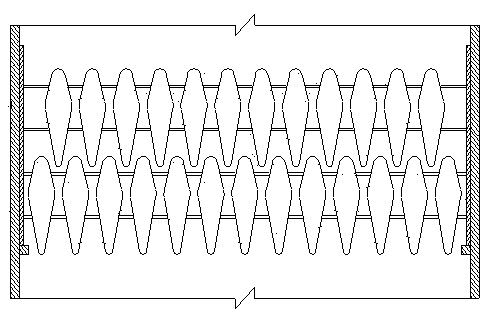

Common jujube seed-shaped grid type structured packing

ActiveCN104607135ALarge specific surface areaMass transfer reactionGas treatmentUsing liquid separation agentFlue gasEngineering

The present invention discloses a common jujube seed-shaped structured packing, which comprises at least a layer of a plurality of horizontally-placed common jujube seed-shaped special-shaped pipes connected in parallel, wherein the plurality of the horizontally-placed common jujube seed-shaped special-shaped pipes connected in parallel form a plurality of parallel channels with collection sections, laryngeal orifices and dispersion sections, the cross section of the common jujube seed-shaped special-shaped pipe is the common jujube seed shape, the top portion and the lower portion of the common jujube seed-shaped special-shaped pipe are the acute angle triangles, and the middle portion is the arc shape. Compared with the existing structured packing, the common jujube seed-shaped structured packing of the present invention has advantages of high mass transfer efficiency, simple structure, small size, fouling resistance, low pressure drop and less liquid foam entrainment. In addition, the common jujube seed-shaped structured packing of the present invention is suitable for the gas-liquid two-phase mass transfer and reaction processes, especially for the dust removal and desulfurization treatment of high dust content flue gas and process exhaust gas, and can be widely used in the fields of petrochemical industry, environmental protection and the like.

Owner:CHINA PETROLEUM & CHEM CORP +1

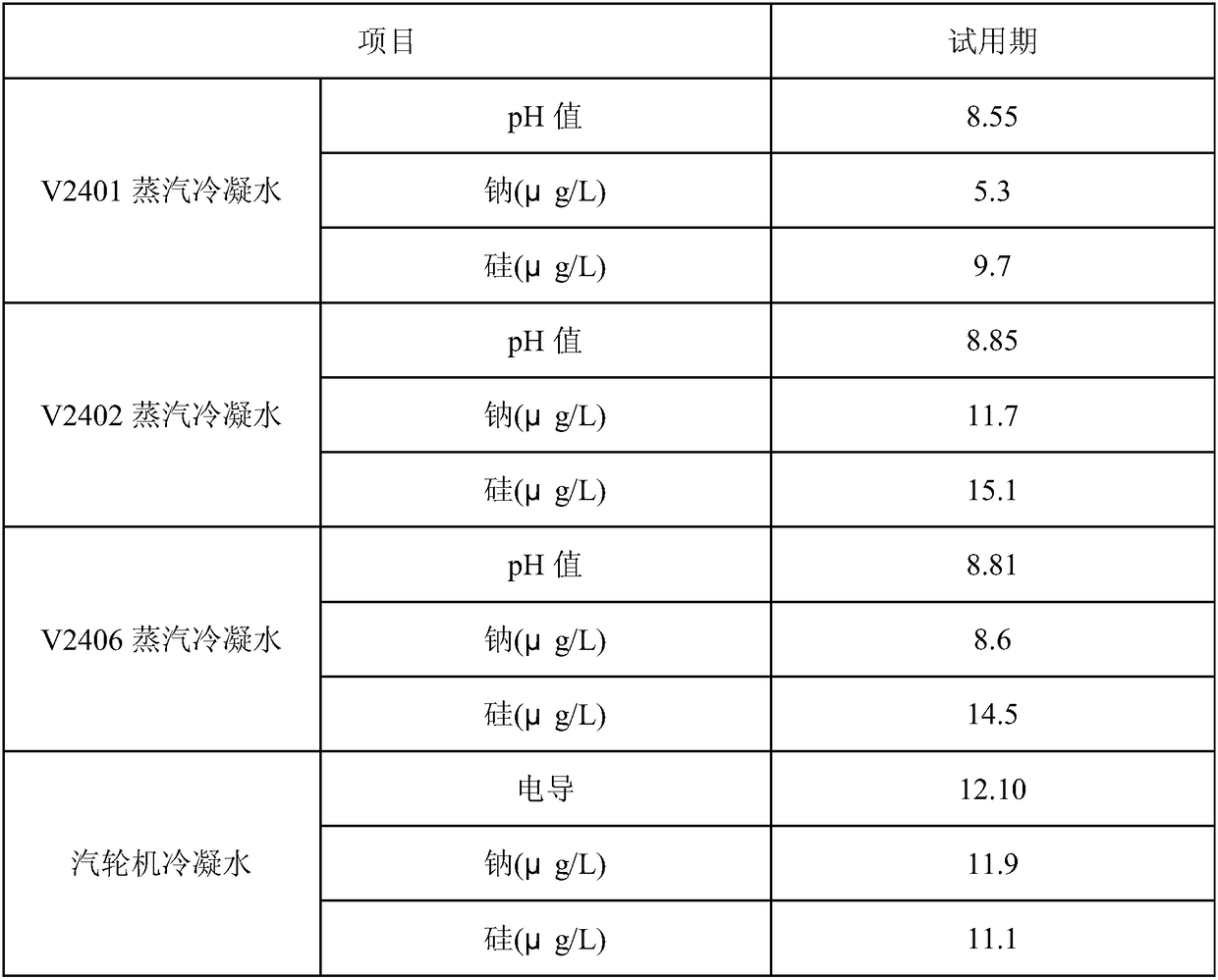

Special anti-scaling agent for petroleum refinery enterprise boiler and steam pocket and application of special anti-scaling agent

InactiveCN108529765AEvenly dispersedGood dispersionSpecific water treatment objectivesScale removal and water softeningTricarboxylic acidCarboxylic acid

The invention discloses a special anti-scaling agent for a petroleum refinery enterprise boiler and a steam pocket and application of the special anti-scaling agent. The special anti-scaling agent consists of organic phosphonic acids, organic carboxylic acid polymers and water, wherein the organic phosphonic acids comprise one or more of 2-phosphonic acid based-1,2,4-tricarboxylic acid butane, ethylene diamine tetra (methylene phosphonic acid) sodium, amino trimethylene phosphonic acid and diethylenetriamine pentamethylene phosphonic acid; the organic carboxylic acid polymers comprise one or more of polyacrylic acid, polymaleic anhydride, polyaspartic acid, polyepoxysuccinic acid, an acrylic acid / hydroxypropyl acrylate copolymer and an acrylic acid-2-acrylamide-2-methyl propanesulfonic acid. By adopting the special anti-scaling agent, inorganic matters can be effectively prevented from scaling within a very large concentration range, formation of free alkalis and water scale sedimentscan be reduced to the maximum extent, the ratio of sodium ions to phosphate can be effectively regulated, and system damage caused by free alkalis can be avoided while scaling is inhibited. The special anti-scaling agent has very good temperature resistance and dispersion properties, and quality of steam can be effectively improved.

Owner:廊坊明泉化工建材有限公司

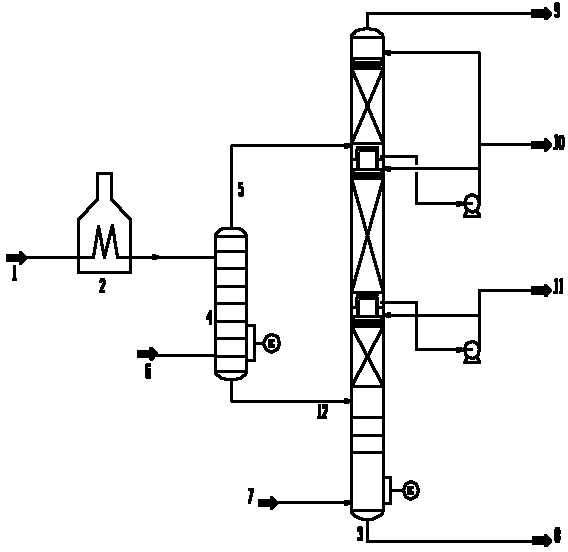

Sectional feeding vacuum distillation method and apparatus for crude oil

InactiveCN102911716AAvoid lateral thermal displacementLess investmentTreatment with plural serial refining stagesProcess engineeringSuperheated steam

The invention discloses a sectional feeding vacuum distillation method and an apparatus for crude oil. The method comprises the steps of omitting relatively long transfer line from the outlet of a vacuum furnace to the vacuum tower; arranging a flashing tower between the vacuum tower and a vacuum distillation tower; passing superheated steam through the bottom of the flashing tower; introducing the raw materials of vacuum distillation to the flashing tower through the vacuum furnace after being heated; educing relative light components (hereinafter referred to flashing top gas) in the flashing tower from the tower top after steam stripping evaporation; entering below a packing layer of some fractioning section of the vacuum distillation tower; and introducing the liquid phase (hereinafter referred to flashing bottom oil) educed from the bottom of the flashing tower to the feeding section of the vacuum distillation tower to perform vacuum distillation. The sectional feeding vacuum distillation method and the apparatus for the crude oil can obviously increase pull-out rate of the vacuum distillation process and improve the quality of the vacuum distillates.

Owner:CHINA PETROLEUM & CHEM CORP +1

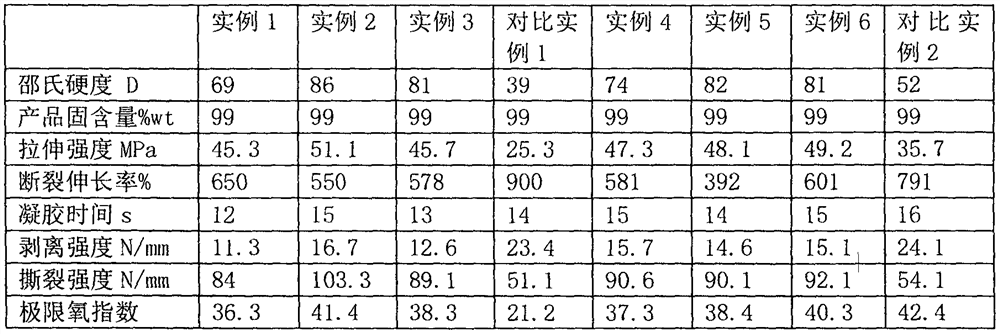

Preparation method of high-performance solvent-free flame-retardant polyurea coating

InactiveCN113480925ANo pollution in the processImprove color vibrancyFireproof paintsPolyurea/polyurethane coatingsPolymer sciencePolyaspartic acid

The invention discloses a preparation method of a high-performance solvent-free flame-retardant polyurea coating. The preparation method is characterized in that the coating is composed of a component A, a component B and a component C and the preparation method comprises the following steps: firstly, dehydrating and prepolymerizing raw materials of the component A to form a prepolymer; secondly, uniformly mixing raw materials in a component B, namely a liquid amine chain extender, polyaspartic acid ester and 2,5-dichloro-p-phenylenediamine, with an anti-settling agent in the component C in a mixing kettle to form a uniform solution, and then adding a pigment, a flame-retardant filler and an auxiliary agent in the component C; under the condition of a certain stirring speed, conducting mixing to form a component-D mixture; and mixing the component-A prepolymer and the component-D mixture according to a main component ratio of 1: 1 mol / mol to obtain the polyurea coating, thereby completing the preparation of the flame-retardant polyurea coating. The coating has excellent mechanical property and performance, and is a novel solventless coating which is simple to operate and wide in application range; and the coating is applicable to flame-retardant protection of interior decoration of house interior walls, traffic vehicles, airplanes and ships, and is suitable for manual construction or / and spraying.

Owner:SICHUAN CHUANWEI ELECTRONICS

Biodiesel oil multiple-grade molecular distillation process and its device

InactiveCN1884442AShort stayLower distillation temperatureHydrocarbon distillationBiodiesel feedstockBiodiesel

The invention discloses biological diesel fuel polymolecular distillation process, comprising the following steps: putting the biological diesel fuel into first grade molecular distillation device, evaporating water and air, putting the distillate into container, then putting the materials without being distilled into second grade distillation device; the putting the materials into container; putting the material without being distilled into gathering tank, or putting them into next grade distillation device; after n grades distilling, putting the valid combination into container, and putting the refuse into gathering tank. The distillation number of steps is between 2 and 6.

Owner:杜小星

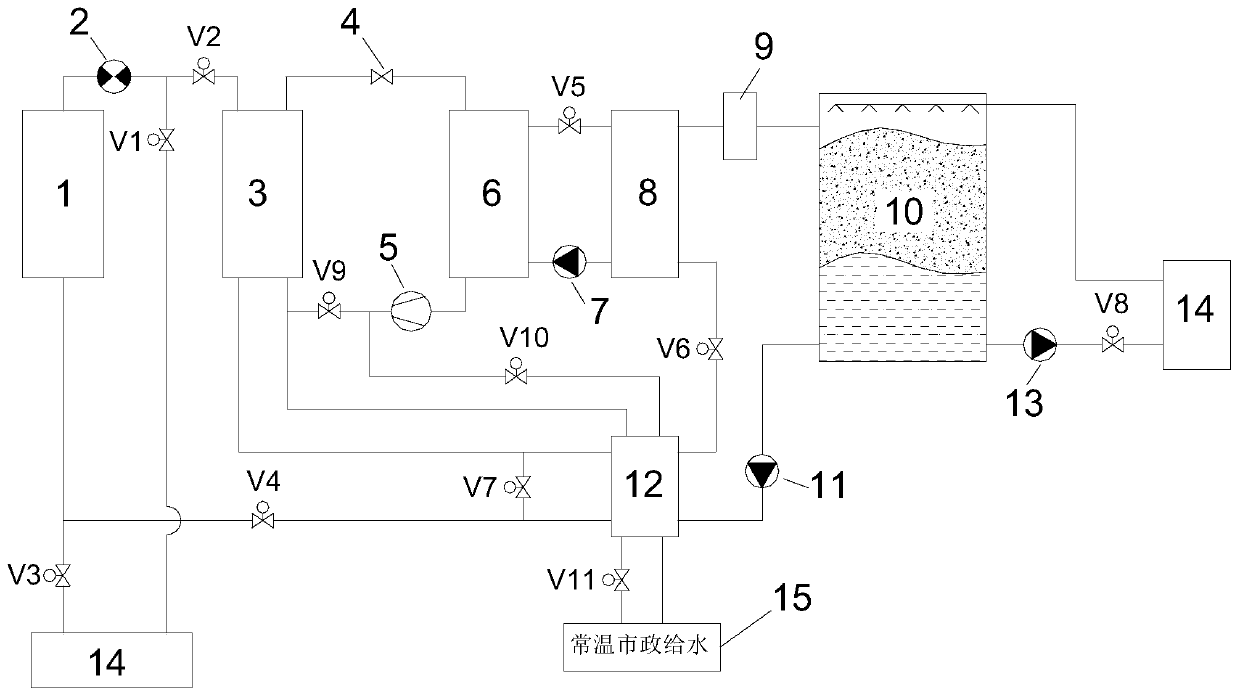

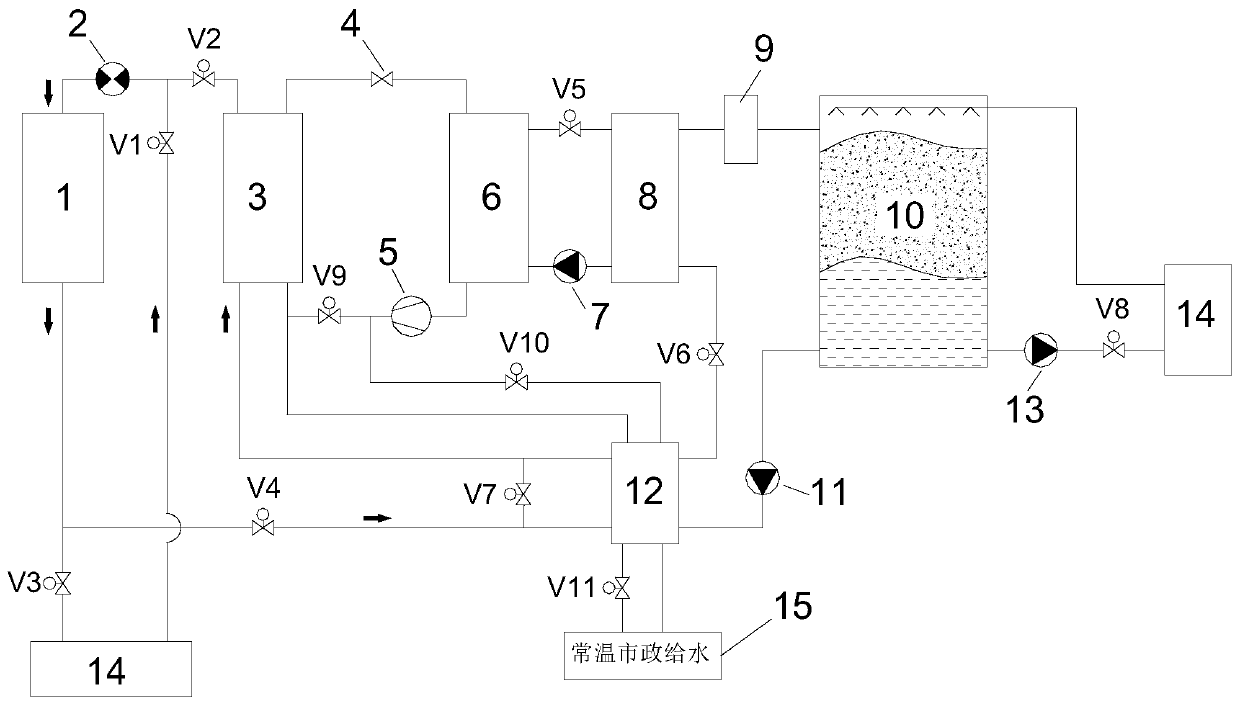

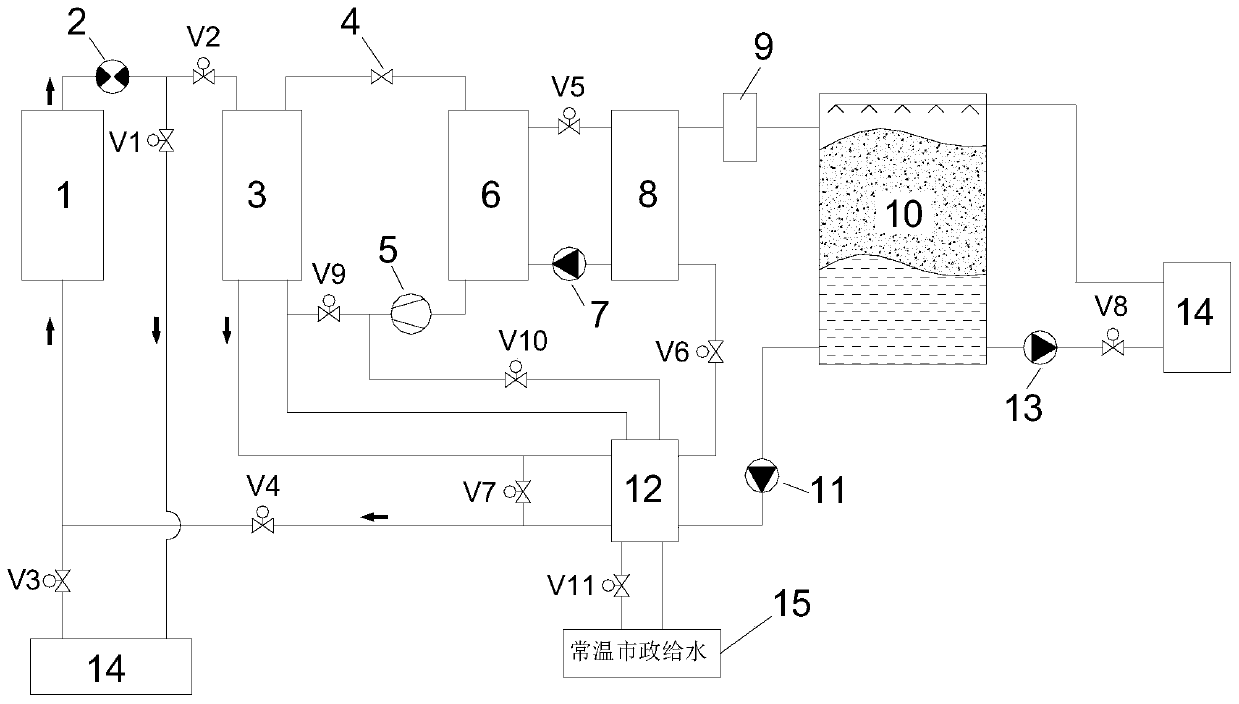

Cascade type supercooling method ice storage system

PendingCN109945371AEliminate entrainmentPrevent ice blockageMechanical apparatusFluid circulation arrangementIce storageEngineering

The invention discloses a cascade type supercooling method ice storage system. The cascade type supercooling method ice storage system comprises a water chilling unit, a double-way pump, a low-temperature condenser, a throttling valve, a compressor, an evaporator, a refrigerating medium pump, a supercooling heat exchanger, a supercooling reliever, an ice storage groove, an ice storage pump, a heatexchanger and end equipment; the water chilling unit, the double-way pump and the end pump form a cold supply loop; the water chilling unit, the double-way pump, the cold side of the low-temperaturecondenser and the first hot side of the hot exchanger form a refrigerating / preheating loop; the hot side of the low-temperature condenser, the throttling valve, the cold side of the evaporator and thecompressor form a refrigerating agent loop; the hot side of the evaporator, the cold side of the supercooling heat exchanger and the refrigerating medium pump form a refrigerating medium loop; and the hot side of the supercooling heat exchanger, the supercooling reliever, the ice storage groove, the ice storage pump and the cold side of the heat exchanger form a supercooling loop. The cascade type supercooling method ice storage system is high in operating reliability, can effectively reduce the energy consumption of an ice making system and can increase the system COP; meanwhile, the prepared dynamic ice slurry is high in cooling speed and high in heat exchange efficiency, and the operation cost and the initial cost are greatly reduced.

Owner:GUANGZHOU INST OF ENERGY CONVERSION - CHINESE ACAD OF SCI

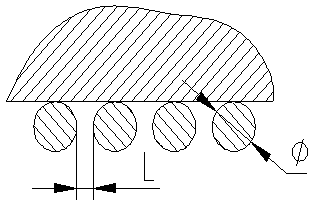

Waterdrop-shaped grid type structured packing

ActiveCN104607137AAchieve dust removalImprove responseChemical/physical/physico-chemical processesFlue gasDust control

The present invention discloses a waterdrop-shaped grid type structured packing, which comprises at least a layer of a packing zone comprising a plurality of horizontally-placed waterdrop-shaped special-shaped pipes connected in parallel, wherein the plurality of the horizontally-placed waterdrop-shaped special-shaped pipes connected in parallel form a plurality of parallel channels with collection sections, laryngeal orifices and dispersion sections, the cross section of the waterdrop-shaped special-shaped pipe is the waterdrop shape, the top portion and the lower portion of the waterdrop-shaped special-shaped pipe are the arc shapes, the radius of the arc on the top portion is larger than the radius of the arc on the lower portion, and the outer periphery of the waterdrop-shaped special-shaped pipe is provided with a plurality of parallel and projecting bosses. Compared with the existing structured packing, the waterdrop-shaped grid type structured packing of the present invention has advantages of high mass transfer efficiency, simple structure, small size, fouling resistance, low pressure drop and less liquid foam entrainment. In addition, the waterdrop-shaped grid type structured packing of the present invention is suitable for the gas-liquid two-phase mass transfer and reaction processes, especially for the dust removal and desulfurization treatment of flue gas and process exhaust gas, and can be widely used in the fields of petrochemical industry, environmental protection and the like.

Owner:CHINA PETROLEUM & CHEM CORP +1

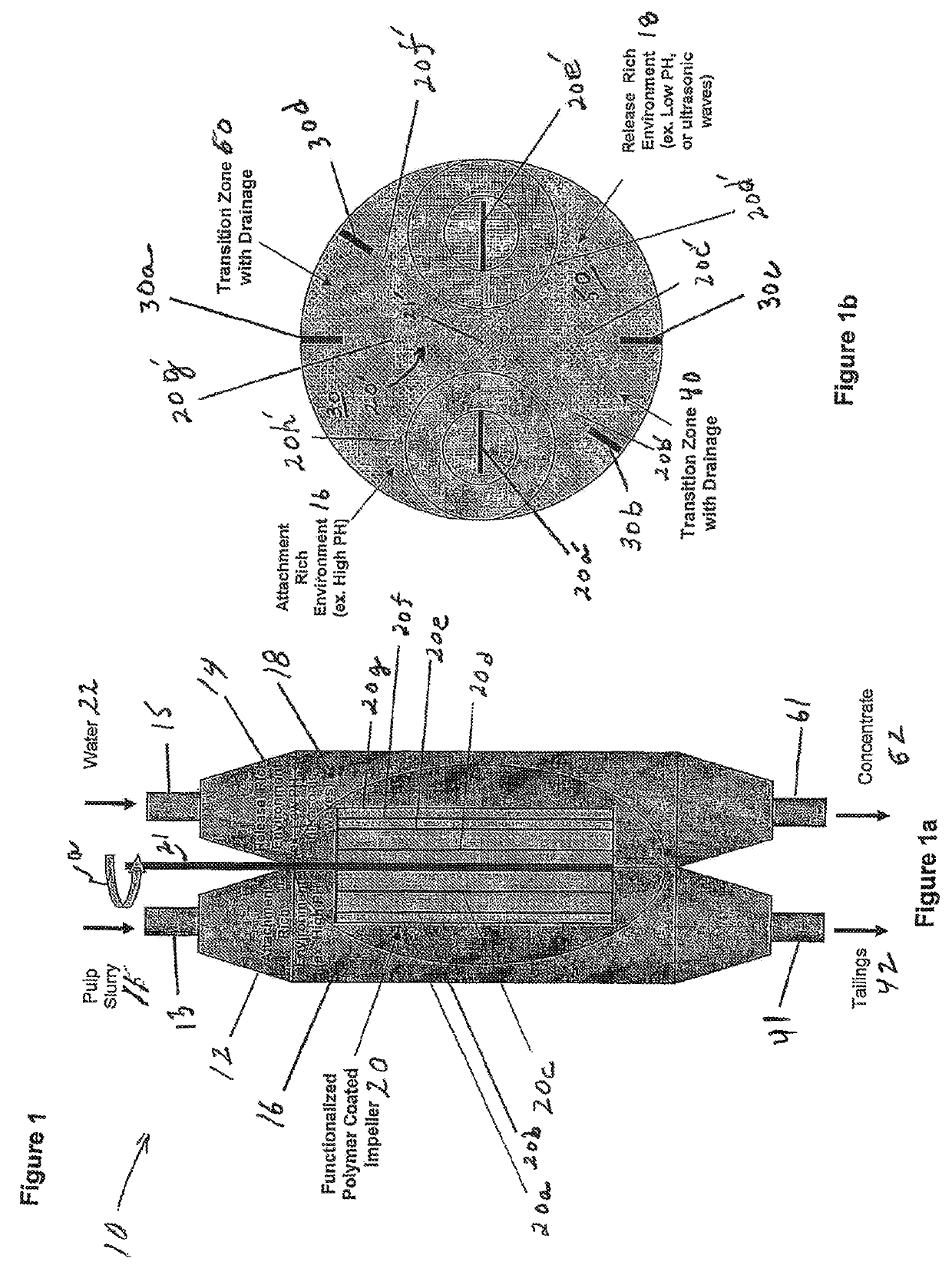

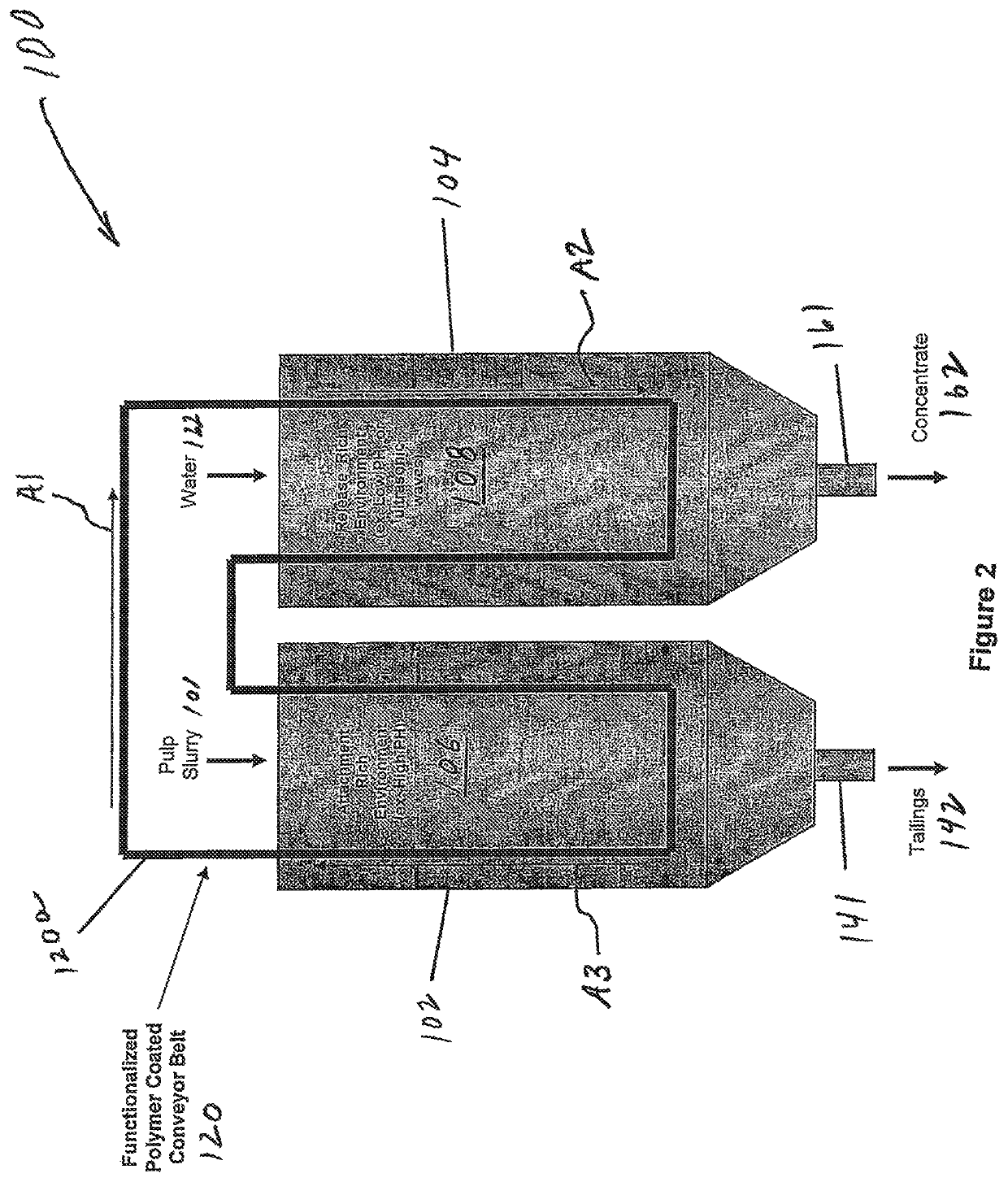

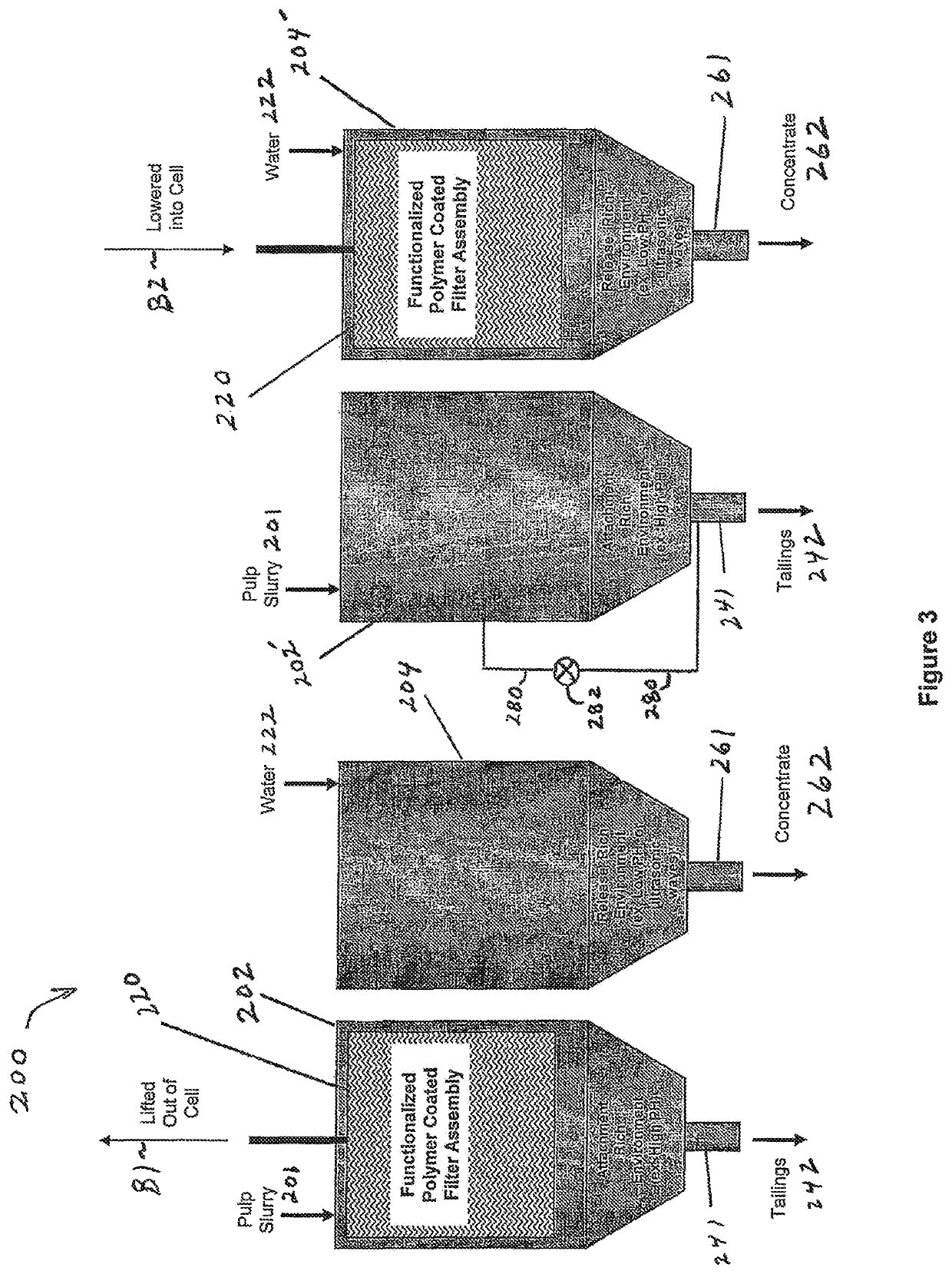

Opportunities for recovery augmentation process as applied to molybdenum production

ActiveUS20180274060A1Eliminate entrainmentSedimentation separationMolybdeum compounds preparationSodium hydrosulfideSlurry

A copper / molybdenum separation processor is provided featuring a slurry / media mixture stage configured to receive a conditioned pulp containing hydrophobic molybdenite and hydrophilic copper, iron and other minerals that is conditioned with sodium hydrosulfide together with an engineered polymeric hydrophobic media, and provide a slurry / media mixture; and a slurry / media separation stage configured to receive the slurry / media mixture, and provide a slurry product having a copper concentrate and a polymerized hydrophobic media product having a molybdenum concentrate that are separately directed for further processing. The slurry / media mixture stage include a molybdenum loading stage configured to contact the conditioned pulp with the engineered polymeric hydrophobic media in an agitated reaction chamber, and load the hydrophobic molybdenite on the engineered polymeric hydrophobic media.

Owner:CIDRA CORP SERVICES

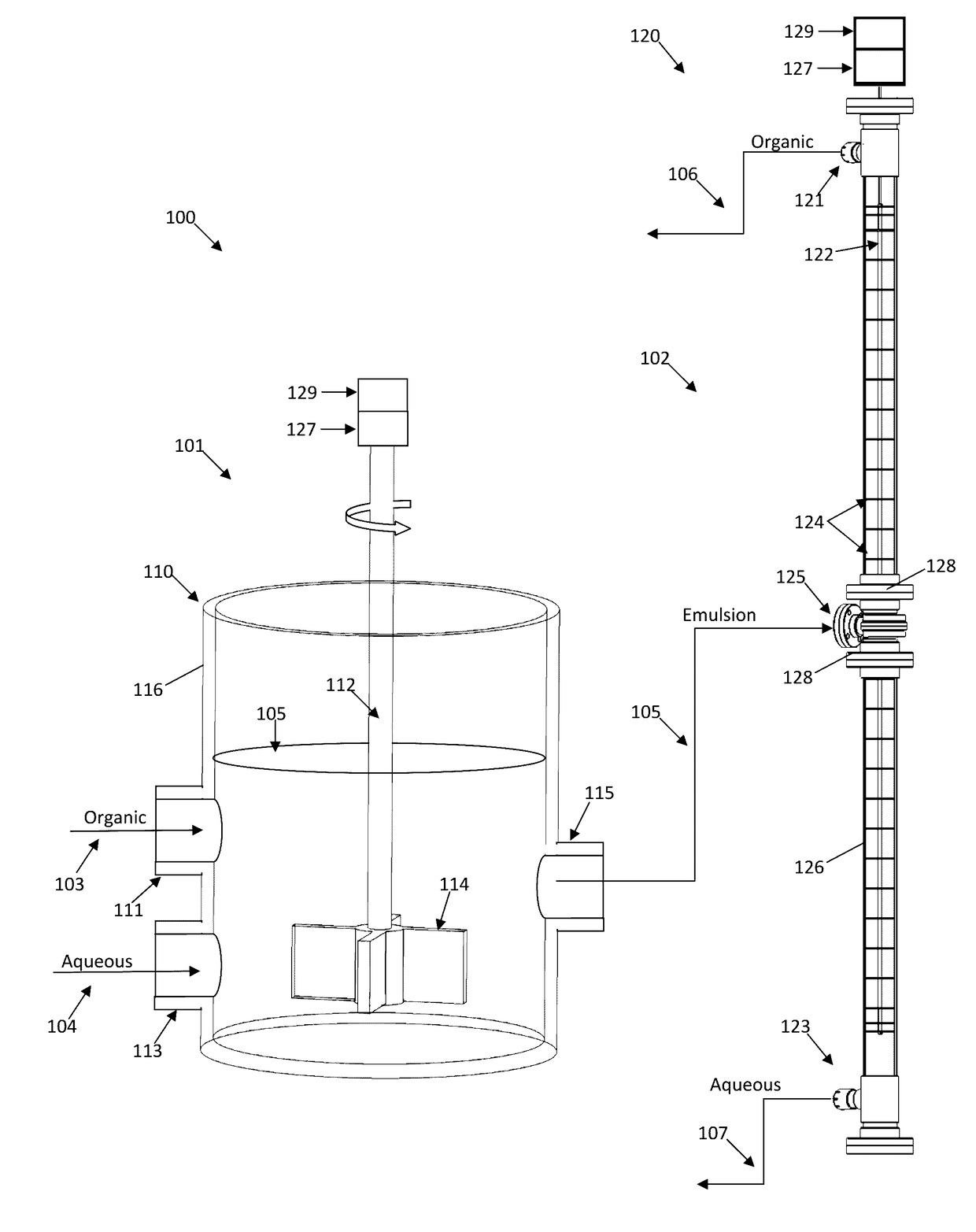

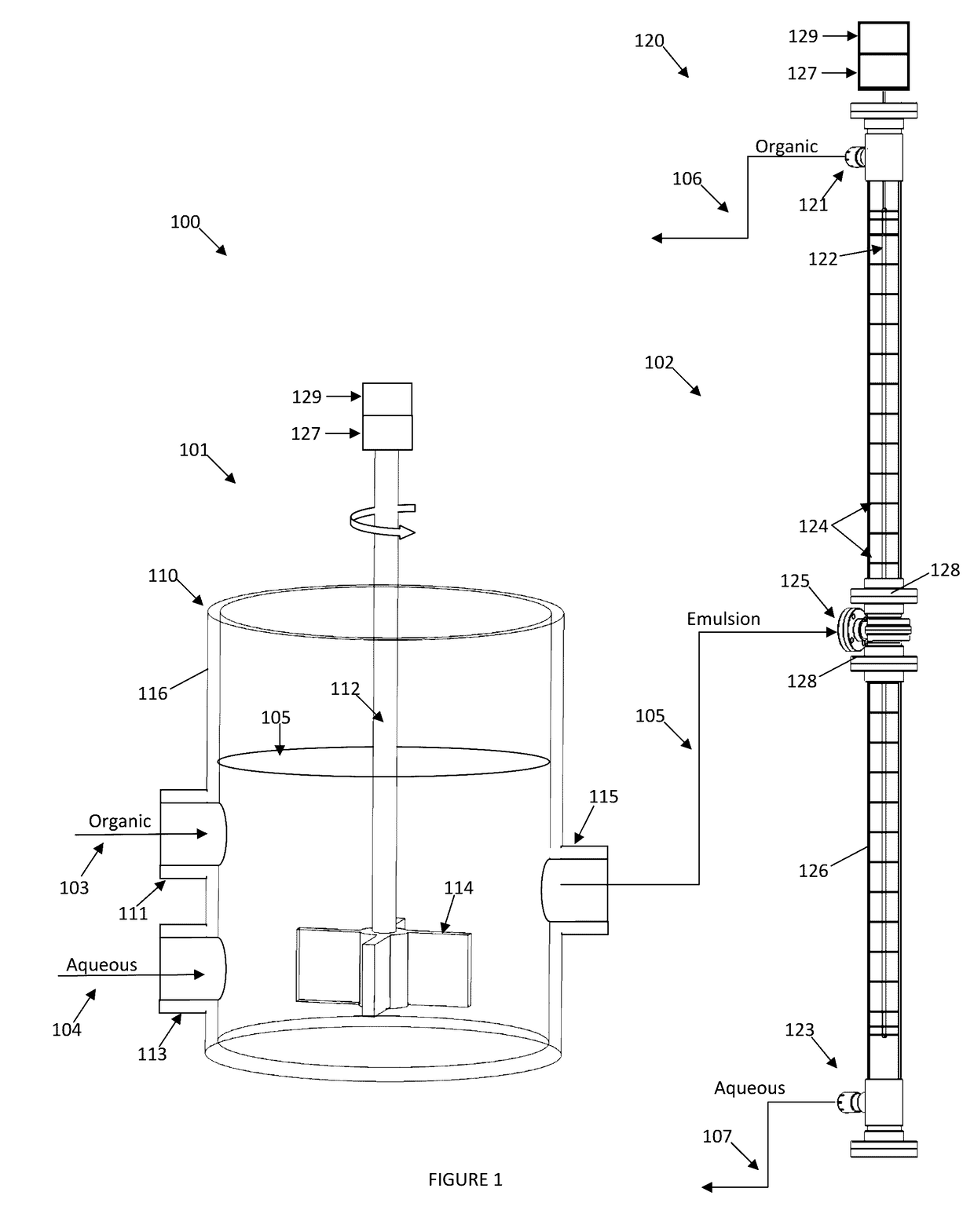

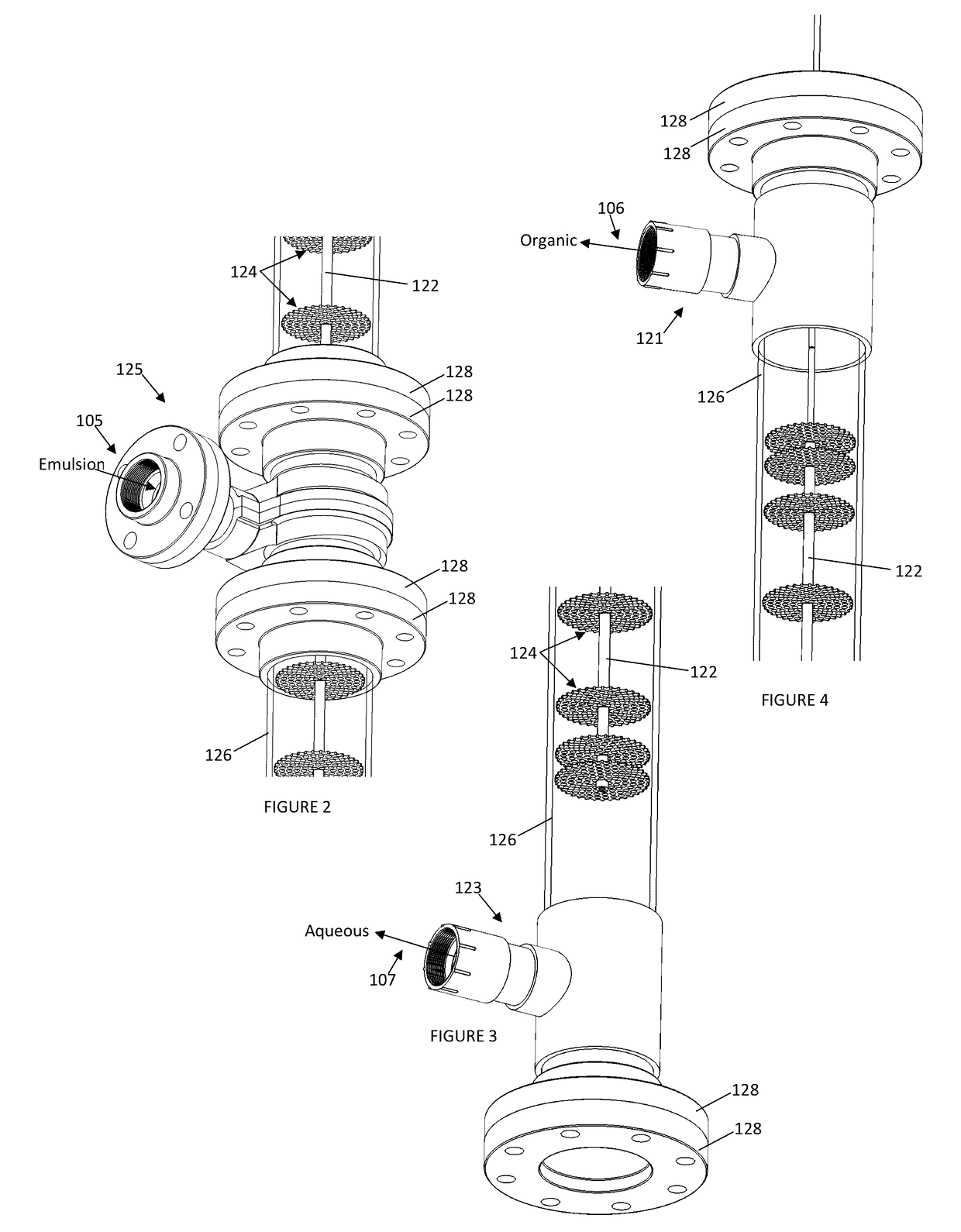

Column settler for high performance liquid/liquid phase separations in hydromellurcial processes and methods thereof

InactiveUS20170080355A1Reduces necessary footprint areaFaster and short residence timeLiquid solutions solvent extractionNon-miscible liquid separationEmulsionMixer-settler

A mixer settler system is disclosed. The system comprises a mixer [110] configured for receiving an organic phase and an aqueous phase, the mixer [110] being further configured to maintain the organic phase and the aqueous phase in a single unstable emulsion phase, wherein mass transfer occurs between said organic phase and said aqueous phase; and, a column settler [120] which is configured to receive a single unstable emulsion phase from the mixer [110] via an emulsion inlet [125] and is also configured to separate the single unstable emulsion phase into a stable organic phase and a stable aqueous phase by virtue of coalescence; the column settler further comprising an organic outlet [121] above the emulsion inlet [125] and an aqueous outlet [123] below the emulsion inlet [125]; the column settler [120] further discouraging mass transfers within the unstable emulsion phase and further promoting coalescence of each of said stable organic phase and stable aqueous phase. A method of settling two immiscible liquids is further disclosed. The method comprises providing a mixer [110] configured for receiving an organic phase and an aqueous phase; maintaining the organic phase and the aqueous phase in a single unstable emulsion phase using the mixer [110], wherein mass transfer occurs between said organic phase and said aqueous phase; providing a column settler [120] which is configured to receive a single unstable emulsion phase from the mixer [110]; sending the single unstable emulsion phase to the column settler [120]; and separating the single unstable emulsion phase into a stable organic phase and a stable aqueous phase within the column settler [120] by virtue of coalescence.

Owner:BACZEK FR +1

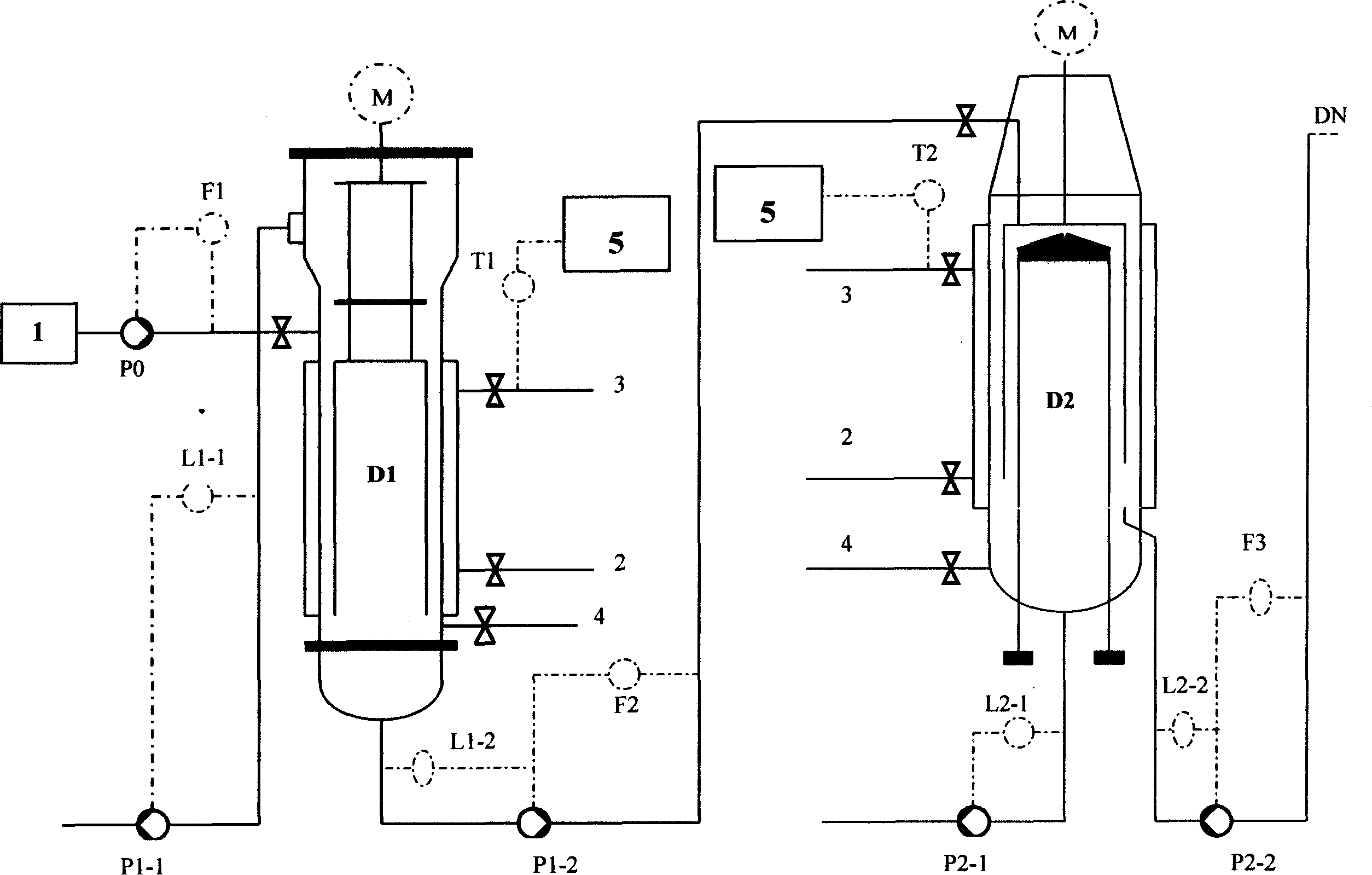

A flue gas desulfurization and dust removal process and integrated device suitable for ships

ActiveCN104492210BEnhanced mass transferIncrease capture rateCombination devicesGas treatmentDust controlProcess engineering

The invention belongs to flue gas desulfurization and dust removal technology, in particular to a flue gas desulfurization and dust removal process and integrated device suitable for ships, which solves the problems existing in the existing ship flue gas desulfurization and dust removal process and equipment. Flue gas desulfurization and dust removal equipment, including multi-stage cross-flow rotary packed bed, lean liquid tank, lean liquid circulating pump, aeration tank, etc. The flue gas desulfurization process includes the open seawater flue gas desulfurization process and the closed alkali liquor flue gas desulfurization process. The two processes can be used in combination, and combined with the rotating packed bed, it has the advantages of high desulfurization rate, low energy consumption, simple process, low investment and operating costs, stable operation, convenient start and stop, and realizes the integration of desulfurization and dust removal.

Owner:ZHONGBEI UNIV

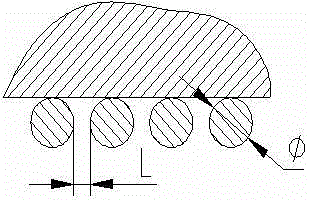

Two-way spray heat-removing vacuum tower inner part provided with dual-flow tray for despumating

ActiveCN106621433AReduce the overall heightReduce the overall diameterDistillation regulation/controlVacuum distillation separationFuel tankEngineering

The invention relates to a two-way spray heat-removing vacuum tower inner part provided with a dual-flow tray for despumating. Two layers of branch-shaped jet type liquid distributors are arranged on each heat removing section, wherein an atomization nozzle of the liquid distributor arranged at the upper layer sprays downwards, and the liquid distributor arranged at the lower layer is provided with two groups of atomization nozzles which respectively spray upwards and downwards; one layer of dual-flow sieve tray is installed between the two layers of branch-shaped jet type liquid distributors; the distances between the liquid distributors and the dual-flow sieve tray is spray distances from atomizer cones of the atomization nozzles at the outmost circles of the liquid distributors to the wall of the tower; an oil collecting tank is installed under the liquid distributor arranged at the lower layer, and the distance between the oil collecting tank and the liquid distributor is greater than 600mm.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

Visualized biological fermentation tank for teaching

PendingCN110317719AReal-time observation of the fermentation processEasy to controlBioreactor/fermenter combinationsBiological substance pretreatmentsAgricultural engineeringProduct gas

The invention relates to a visualized biological fermentation tank for teaching. The top of a tank body is provided with a motor, a speed reducer and an exhaust port, and a stirring shaft is connectedto the output end of the speed reducer, extends into the tank body and is provided with a stirrer; one side of the tank body is provided with a feeding port, the other side of the tank body is provided with sampling ports, the tank body is internally provided with a serpentine tube cooler, the bottom of the tank body is provided with an air feeding / discharging port, the end portion of the air feeding / discharging port is provided with an air distributor, the tank body, the feeding port, the air feeding / discharging port, the sampling ports, the exhaust port, the stirring shaft, the stirrer, theserpentine tube cooler and the air distributor are all made of transparent materials, and the feeding port, the air feeding / discharging port, the sampling ports and the exhaust port are fixed by glue. The visualized biological fermentation tank for teaching is scientific and reasonable in structural design, light, portable and convenient to operate, students can manually carry out fermentation experiment operation at any time and observe the fermentation process in the fermentation tank in real time, the control over the fermentation process and research on the fermentation process are facilitated, and the fermentation tank is suitable for teaching demonstration.

Owner:TIANJIN VOCATIONAL INST

Liquid-collecting energy absorption device

InactiveCN100488590CSlow down the flowImprove operational efficiencyUsing liquid separation agentFractional distillationEnergy absorptionProduct gas

The invention relates to a liquid-catching power absorber. It comprises liquid-catching power absorbing plate and annular mounting plate; said liquid-catching power absorbing plate includes upper layer liquid-catching power absorbing plate 1 and lower layer liquid-catching power absorbing plate 2, between two said plates equipped with a annular plate 6, the upper of upper layer liquid-catching power absa orbing plate is connected with upper layer annular plate 3, while the one at lowe layer iconnected with lower layer annular plate 5; supporting stand 4 is installed on lower layer annular plate 5, the other end of supporting stand is welded on tower wall. The liquid-catching power absorber greatly reduces flowing speed of gas from circulating gas distributor, eliminates impact to liquid surface in tower bottom by gas and entrainment, and the liquid in gas is catched by said two liquid-catching power absorbing plate, which avoids back-mix-flow and increases operating efficiency.

Owner:TIANJIN UNIV

A drop-shaped grid-type structured packing

ActiveCN104607137BLarge specific surface areaMass transfer reactionChemical/physical/physico-chemical processesFlue gasEngineering

The present invention discloses a waterdrop-shaped grid type structured packing, which comprises at least a layer of a packing zone comprising a plurality of horizontally-placed waterdrop-shaped special-shaped pipes connected in parallel, wherein the plurality of the horizontally-placed waterdrop-shaped special-shaped pipes connected in parallel form a plurality of parallel channels with collection sections, laryngeal orifices and dispersion sections, the cross section of the waterdrop-shaped special-shaped pipe is the waterdrop shape, the top portion and the lower portion of the waterdrop-shaped special-shaped pipe are the arc shapes, the radius of the arc on the top portion is larger than the radius of the arc on the lower portion, and the outer periphery of the waterdrop-shaped special-shaped pipe is provided with a plurality of parallel and projecting bosses. Compared with the existing structured packing, the waterdrop-shaped grid type structured packing of the present invention has advantages of high mass transfer efficiency, simple structure, small size, fouling resistance, low pressure drop and less liquid foam entrainment. In addition, the waterdrop-shaped grid type structured packing of the present invention is suitable for the gas-liquid two-phase mass transfer and reaction processes, especially for the dust removal and desulfurization treatment of flue gas and process exhaust gas, and can be widely used in the fields of petrochemical industry, environmental protection and the like.

Owner:CHINA PETROLEUM & CHEM CORP +1

Opportunities for recovery augmentation process as applied to molybdenum production

ActiveUS10774400B2Eliminate entrainmentSedimentation separationMolybdeum compounds preparationSodium hydrosulfideSlurry

A copper / molybdenum separation processor is provided featuring a slurry / media mixture stage configured to receive a conditioned pulp containing hydrophobic molybdenite and hydrophilic copper, iron and other minerals that is conditioned with sodium hydrosulfide together with an engineered polymeric hydrophobic media, and provide a slurry / media mixture; and a slurry / media separation stage configured to receive the slurry / media mixture, and provide a slurry product having a copper concentrate and a polymerized hydrophobic media product having a molybdenum concentrate that are separately directed for further processing. The slurry / media mixture stage include a molybdenum loading stage configured to contact the conditioned pulp with the engineered polymeric hydrophobic media in an agitated reaction chamber, and load the hydrophobic molybdenite on the engineered polymeric hydrophobic media.

Owner:CIDRA CORP SERVICES

Polymerization feeding optimization system and method

InactiveCN110917999AIncrease production capacitySimplify the feeding procedureRotary stirring mixersTransportation and packagingProcess engineeringIndustrial engineering

The invention discloses a polymerization feeding optimization system and an optimization method. The polymerization feeding optimization system comprises dispersing agent kettle inlet pipelines, initiator kettle inlet pipelines and flushing pipelines; the dispersing agent kettle inlet pipelines are in on-to-one correspondence with dispersing agent storage tanks. The optimization method sequentially comprises the steps of water and monomer feeding, initiator preparation, first dispersing agent feeding, first dispersing agent mixing for 1 min and second dispersing agent feeding. According to theinvention, each dispersing agent is provided with an independent kettle inlet pipeline, and the flow of the dispersing agent is metered through a mass flow meter, so that the material preparation occupation time is reduced, the polymerization kettle feeding procedure is effectively simplified, the kettle feeding time is shortened, the single-kettle production capacity is improved, and the yield can be improved by 4.4%; meanwhile, metering, washing and process monitoring are all carried out through electronic equipment, a manual confirmation procedure in a traditional process is replaced, manpower is saved, and meanwhile the metering accuracy and the working efficiency of the whole kettle feeding process are effectively improved.

Owner:昊华宇航化工有限责任公司

Cyclone separating type gas-liquid mixed phase feeding distributor

PendingCN106730969AEliminate entrainmentGood separation works wellLiquid distribution in distillationFractional distillationFuel tankTower

The invention relates to a cyclone separating type gas-liquid mixed phase feeding distributor which is characterized in that a rectangular feeding structure along a tangential direction is arranged at a gas-liquid mixed phase feeding port; the rectangular feeding structure is communicated with an annular sleeve in a tower; the lower end of the annular sleeve is open; a conical funnel with holes on a panel is arranged on a tower wall at the altitude being 0.8-3 times of the altitude of the feeding port at the lower end of the annular sleeve; the conical angle is at 10-90 degrees; the diameter of the conical opening of the funnel is 0.1-1.5 times of the width of the feeding port; the middle part of the annular sleeve is closed and an annual oil collecting box is formed; a parallel flow filling layer for stabilizing flow, removing foam and self-washing is connected with the upper end of the annular sleeve; umbrella-shaped structures are arranged along the connecting lines of inner edges and outer edges of the parallel flow filling layer; and the annular width of the filling layer is 3-500 times of the interval of the filling plates.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

A spindle-shaped grid-type structured packing

ActiveCN104607138BLarge specific surface areaMass transfer reactionChemical/physical/physico-chemical processesFlue gasFusiform shape

The present invention discloses a spindle-shaped grid type structured packing, which comprises at least a layer of a packing zone comprising a plurality of horizontally-placed spindle-shaped special-shaped pipes connected in parallel, wherein the plurality of the horizontally-placed spindle-shaped special-shaped pipes connected in parallel form a plurality of parallel channels with collection sections, laryngeal orifices and dispersion sections, the cross section of the spindle-shaped special-shaped pipe is the spindle shape, the top portion and the lower portion of the spindle-shaped special-shaped pipe are the arc shapes, the radius of the arc on the top portion is larger than the radius of the arc on the lower portion, and the outer periphery of the spindle-shaped special-shaped pipe is provided with a plurality of parallel and projecting bosses. Compared with the existing structured packing, the spindle-shaped grid type structured packing of the present invention has advantages of high mass transfer efficiency, simple structure, small size, fouling resistance, low pressure drop and less liquid foam entrainment. In addition, the spindle-shaped grid type structured packing of the present invention is suitable for the gas-liquid two-phase mass transfer and reaction processes, especially for the dust removal and desulfurization treatment of flue gas and process exhaust gas, and can be widely used in the fields of petrochemical industry, environmental protection and the like.

Owner:CHINA PETROLEUM & CHEM CORP +1

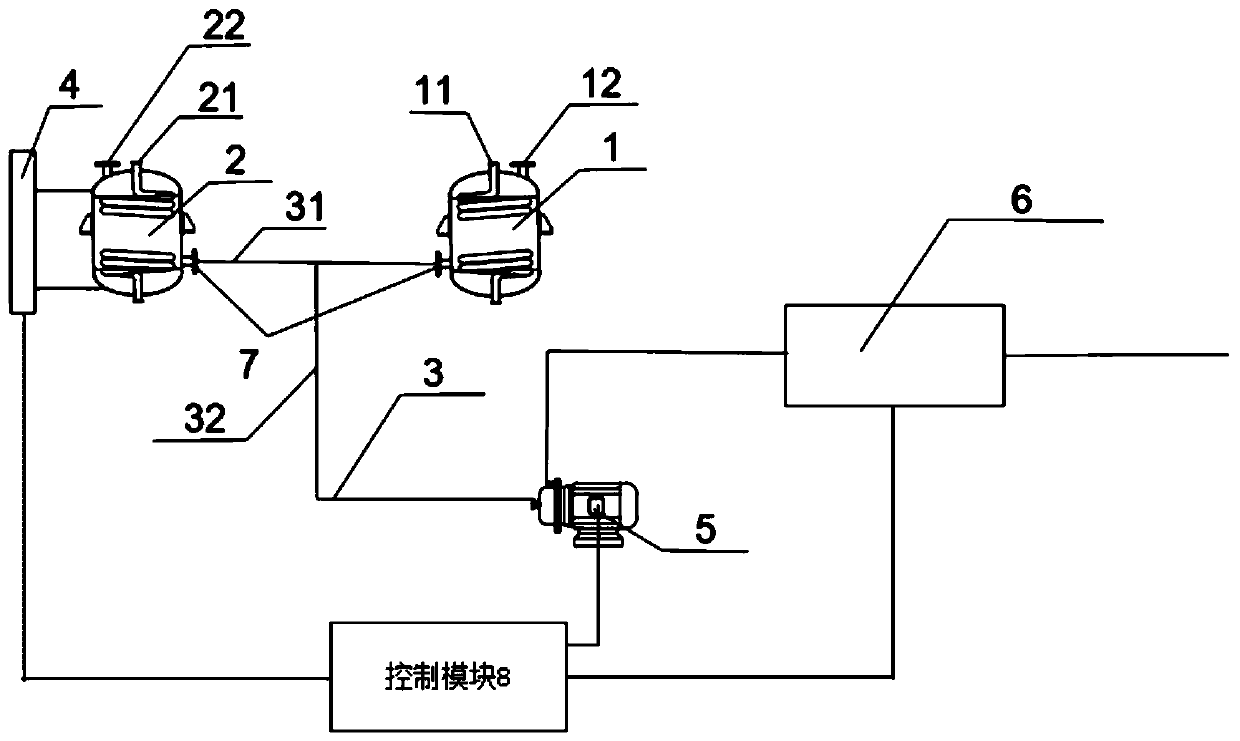

Smart metering device for condensation rate of traditional Chinese medicine concentrating equipment condensate

PendingCN110389151AEliminate entrainmentAvoid errorsMaterial condensationDifferential pressureSmart meter

A smart metering device for the condensation rate of a traditional Chinese medicine concentrating equipment condensate, comprises a control module, a first metering tank, a second metering tank, a condensate collecting pipe, a differential pressure liquid level gauge, a conveying pump and a mass flow meter, wherein the first metering tank is in communication with the second metering tank through the condensate collecting pipe, and is connected to the inlet of the conveying pump through the condensate collecting pipe; the differential pressure liquid level gauge is used for detecting the liquidlevel of the condensate; the outlet of the conveying pump is connected with the mass flow meter; the conveying pump is driven by a variable-frequency motor.

Owner:TIANJIN UNIV OF TRADITIONAL CHINESE MEDICINE

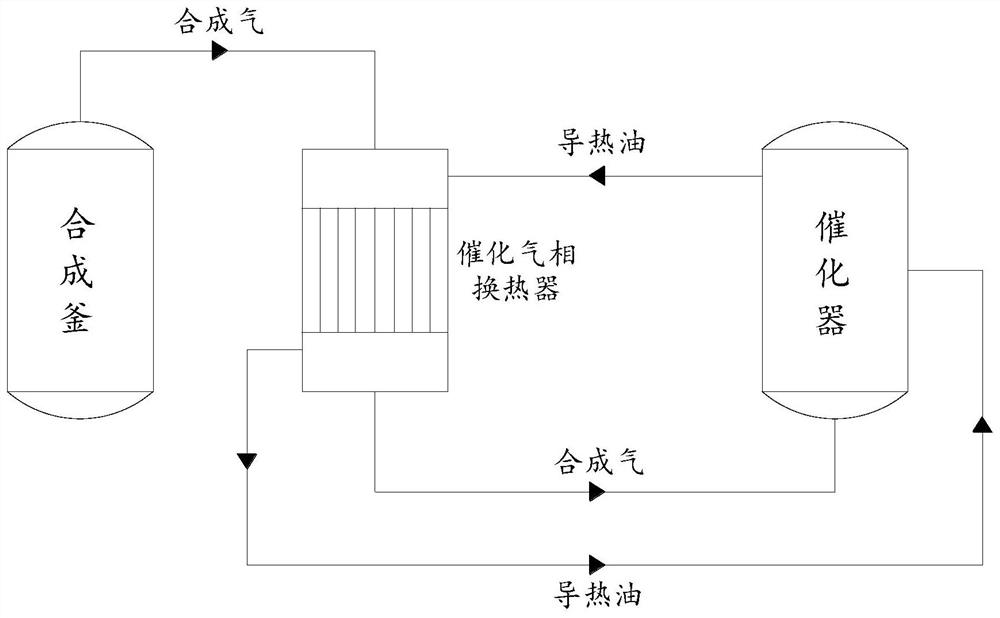

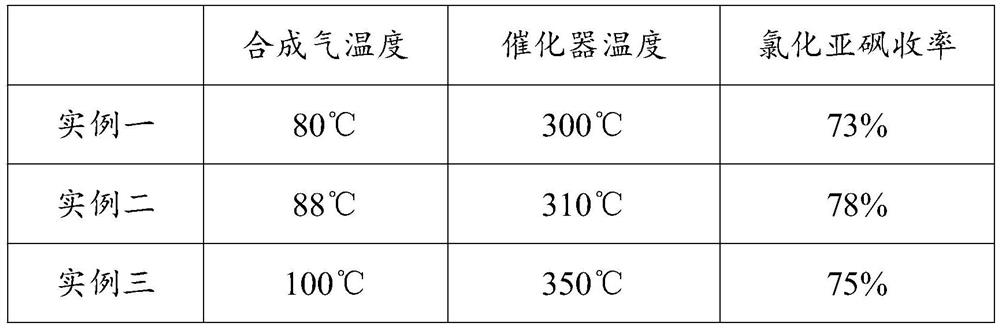

Method for improving synthesis yield by utilizing thionyl chloride synthesis energy

PendingCN114314524AReduce lossesEliminate entrainmentChemical industryIndirect heat exchangersProcess engineeringOrganic chemistry

The invention discloses a method for improving synthesis yield by utilizing synthesis energy of thionyl chloride, which comprises the following steps: S1, introducing low-temperature heat-conducting oil into a jacket of a catalyst, and taking away redundant heat generated by reaction of the catalyst by utilizing the low-temperature heat-conducting oil through the jacket of the catalyst to control redundant heat generated during catalytic synthesis of thionyl chloride; s2, heating the synthesis gas generated by the synthesis kettle in a catalytic gas-phase heat exchanger by the heat-conducting oil after heat exchange, and preventing gas foam generated by the synthesis gas from being entrained into a catalyst for reaction; and S3, introducing the synthesis gas heated in S2 into a catalyst for catalytic synthesis of a thionyl chloride crude product. According to the method, the defects in the prior art are overcome, the yield of catalytic synthesis of thionyl chloride is increased, energy is recycled, the production cost is reduced, the production efficiency is greatly improved, meanwhile, the reaction efficiency and the material utilization rate of the whole production process are optimized, the economic benefits of enterprises are increased, and the method has high social use value and application prospects.

Owner:安徽金轩科技有限公司

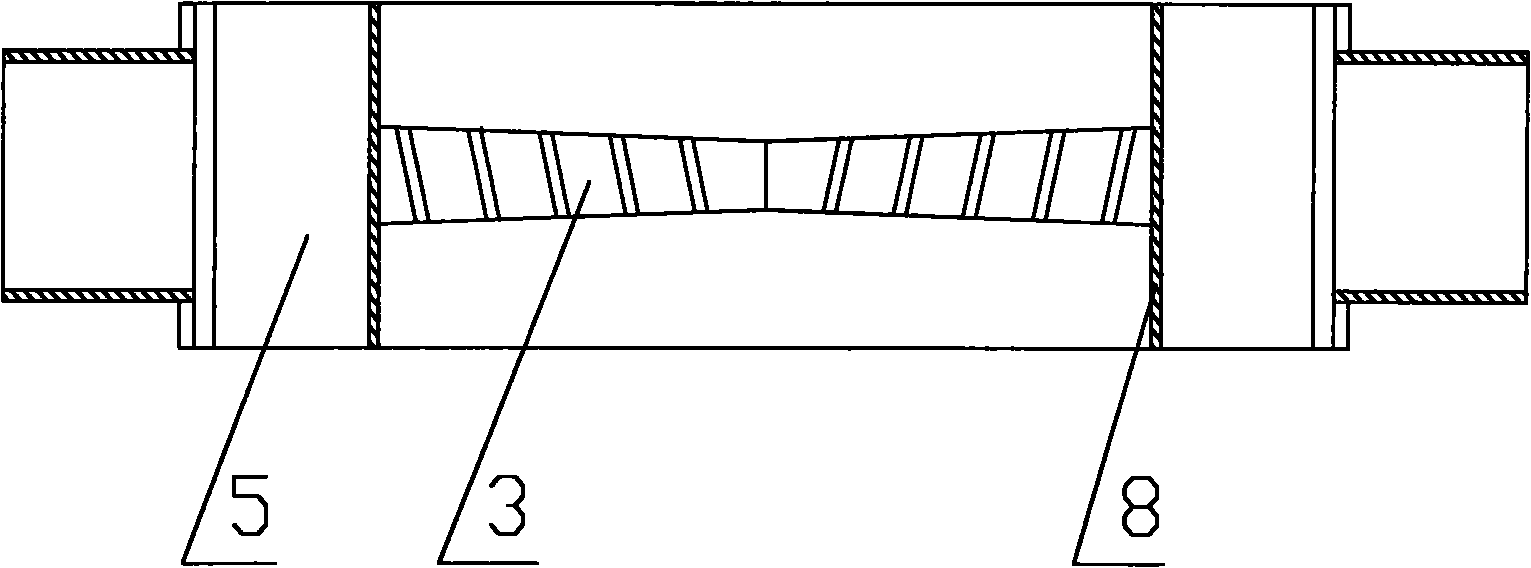

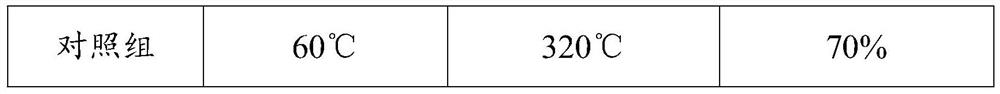

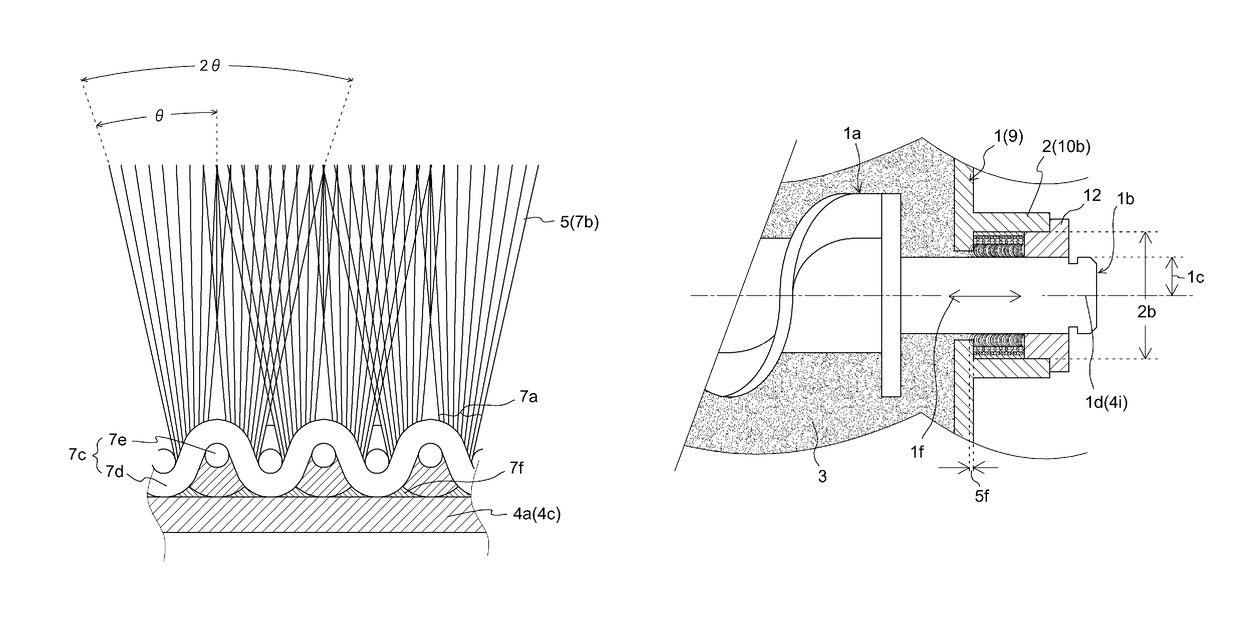

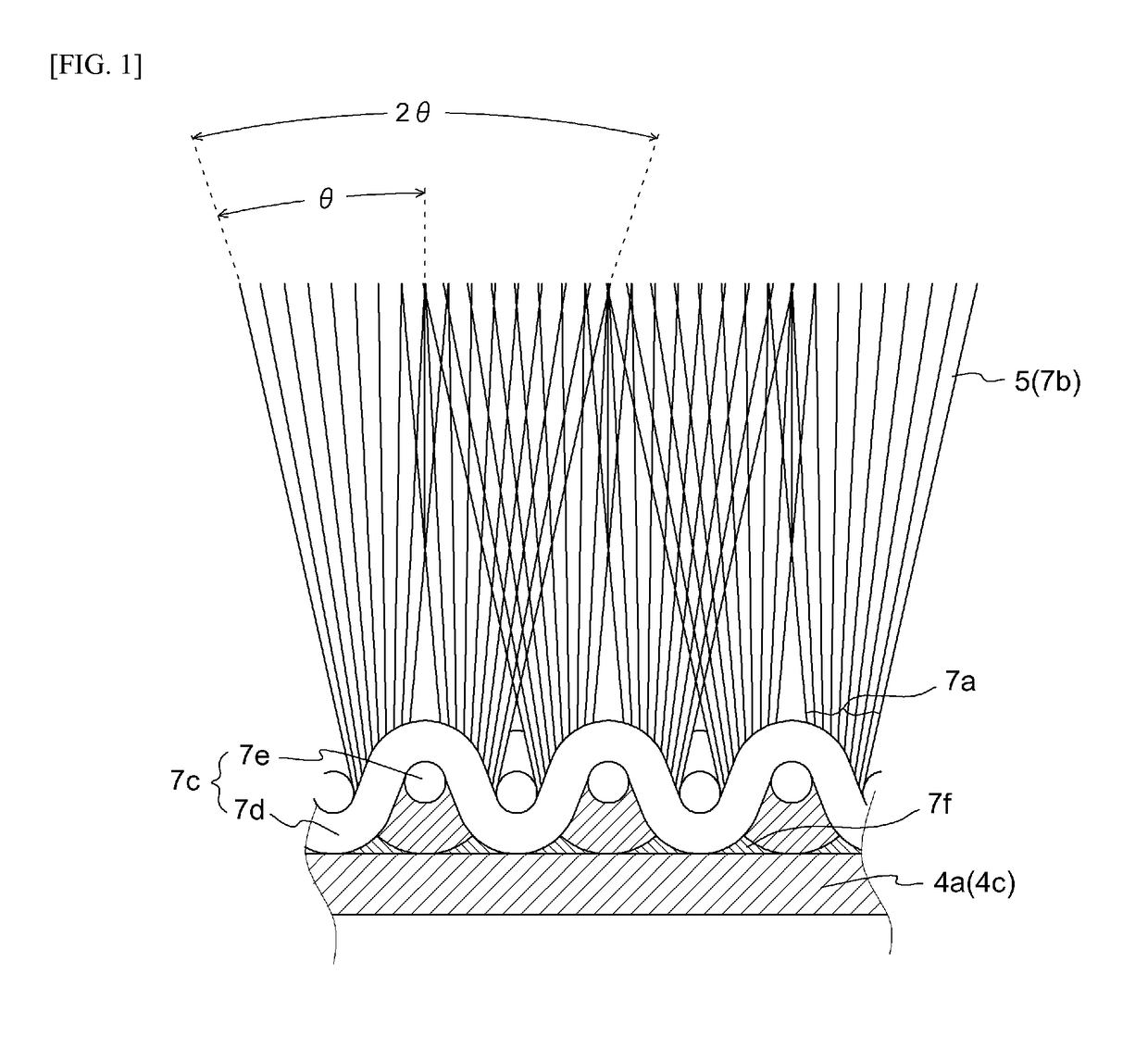

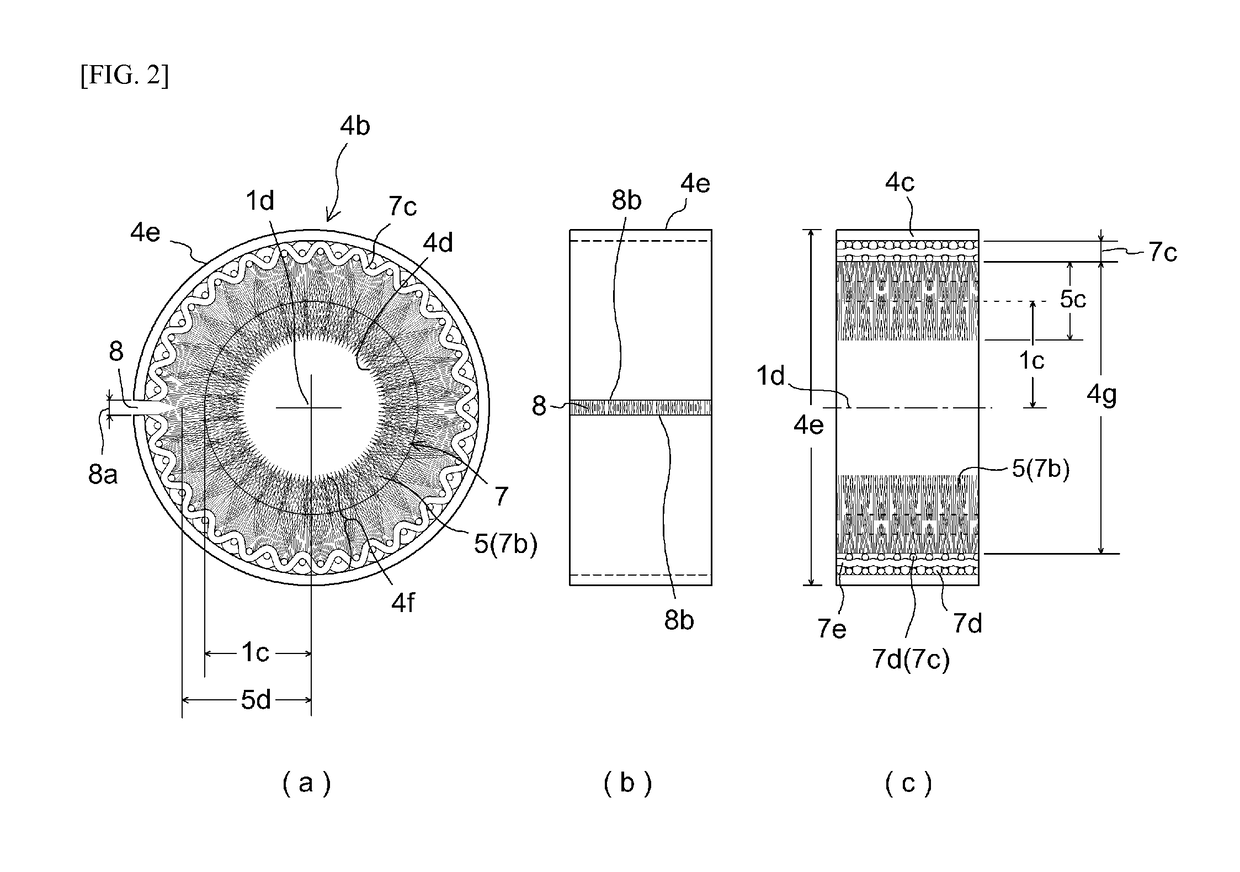

Cylindrical shaft-sealing material obtained from pile weave or knit

ActiveUS9903476B2Eliminate entrainmentReduce wasteEngine sealsLeakage preventionMechanical engineeringExternal pressure

A rotational shaft seal member which does not cause leakage of powder and which has a slit capable of being enlarged as a result of occurrence of springback. Cylindrical shaft seal member 4b at powder container 1 includes pile 5 including woven / knit pile fabric 7 having cut pile 7b at the inside of cylindrical shaft seal member 4b and pile cylindrical support member 4c; the outside diameter 4e being capable of shrinkage as a result of external pressure, and being capable of enlargement as a result of pressure on the inside diameter 4d. When cylindrical shaft seal member 4b is inserted in attachment hole 2a of support frame 2 at the rotating body, attachment is achieved because slit 8 causes shrinkage of outside diameter 4e of cylindrical shaft seal member 4b, enlargement due to springback of slit 8 causing intimate contact with attachment hole 2a.

Owner:SHOJI SUSUMU +1

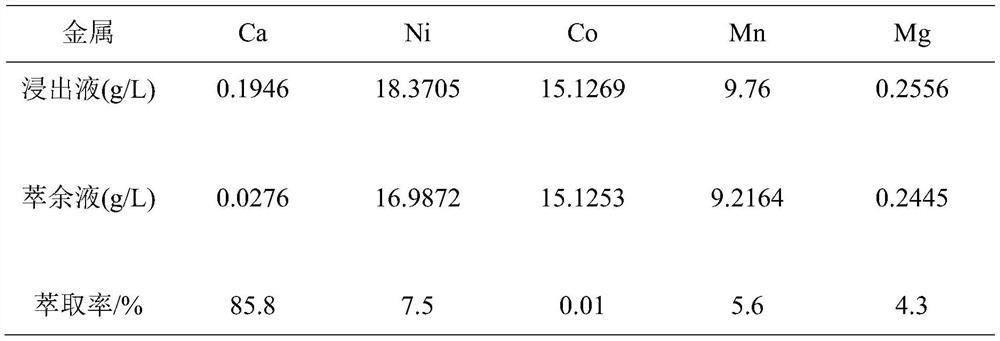

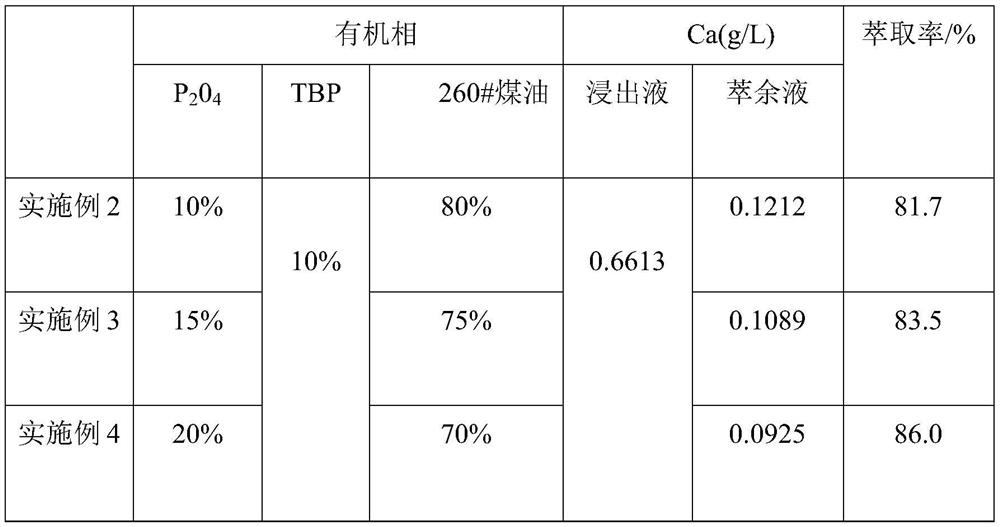

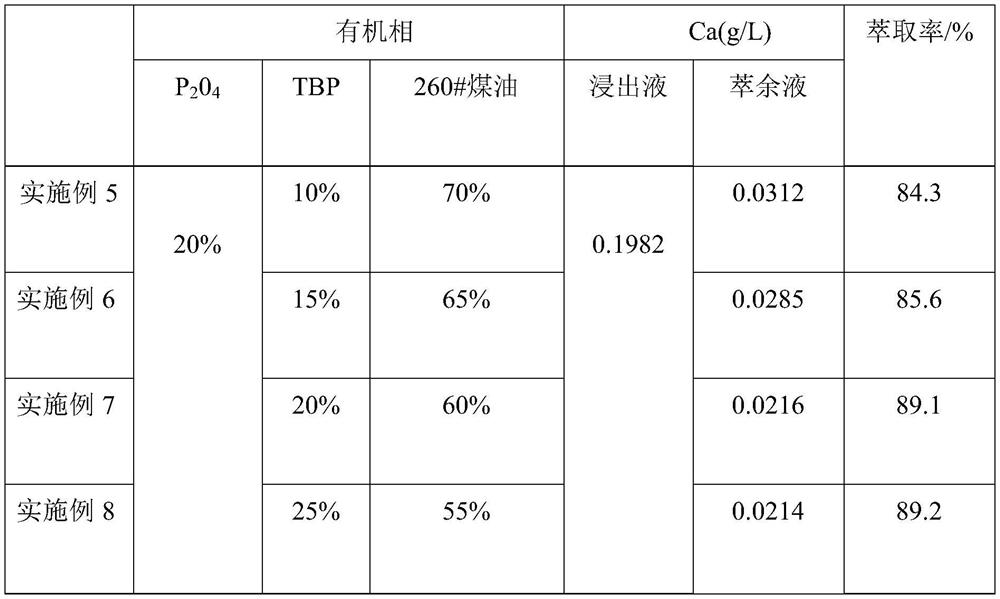

A kind of method for extracting calcium without saponification

Owner:HUNAN BRUNP RECYCLING TECH CO LTD +2

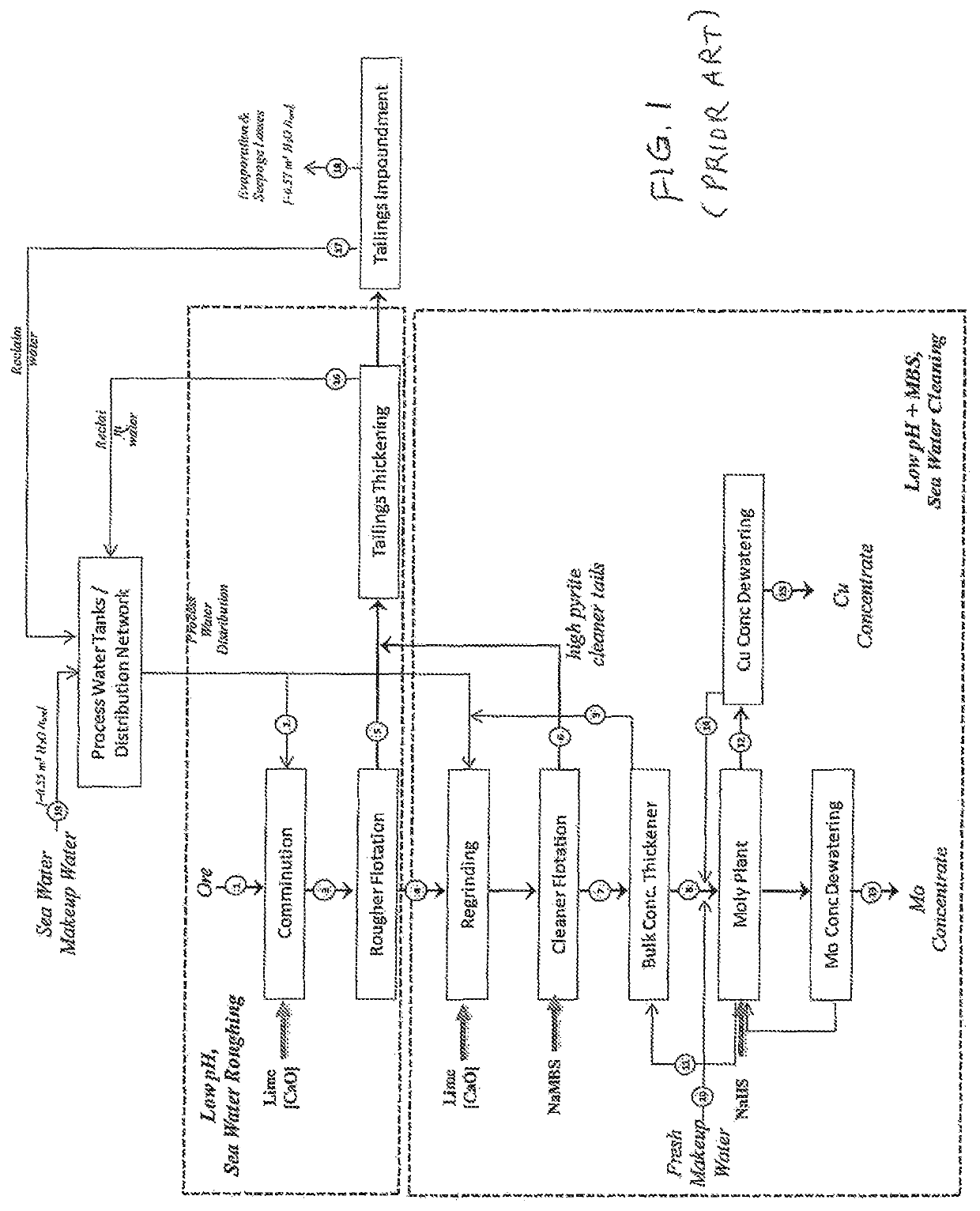

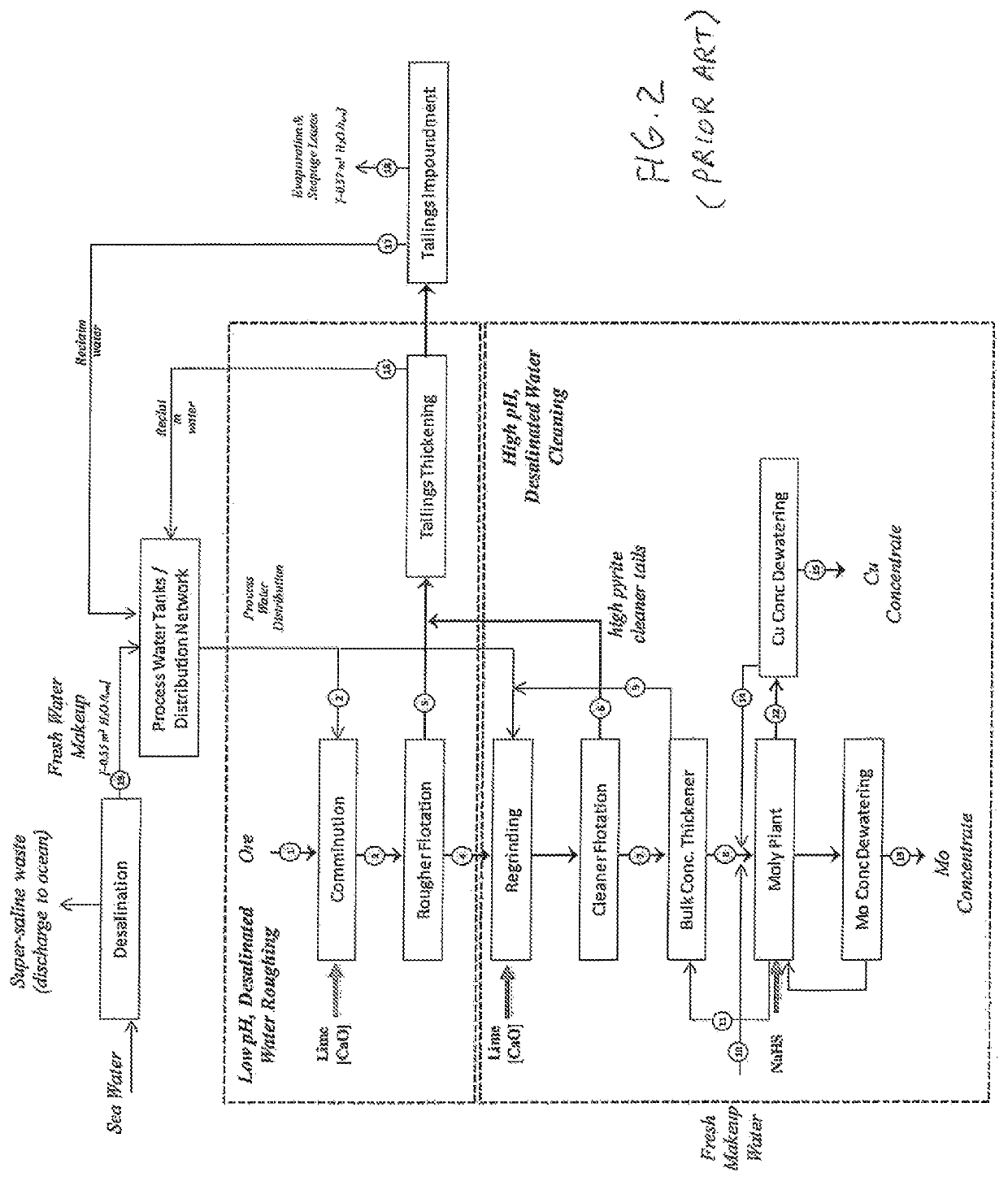

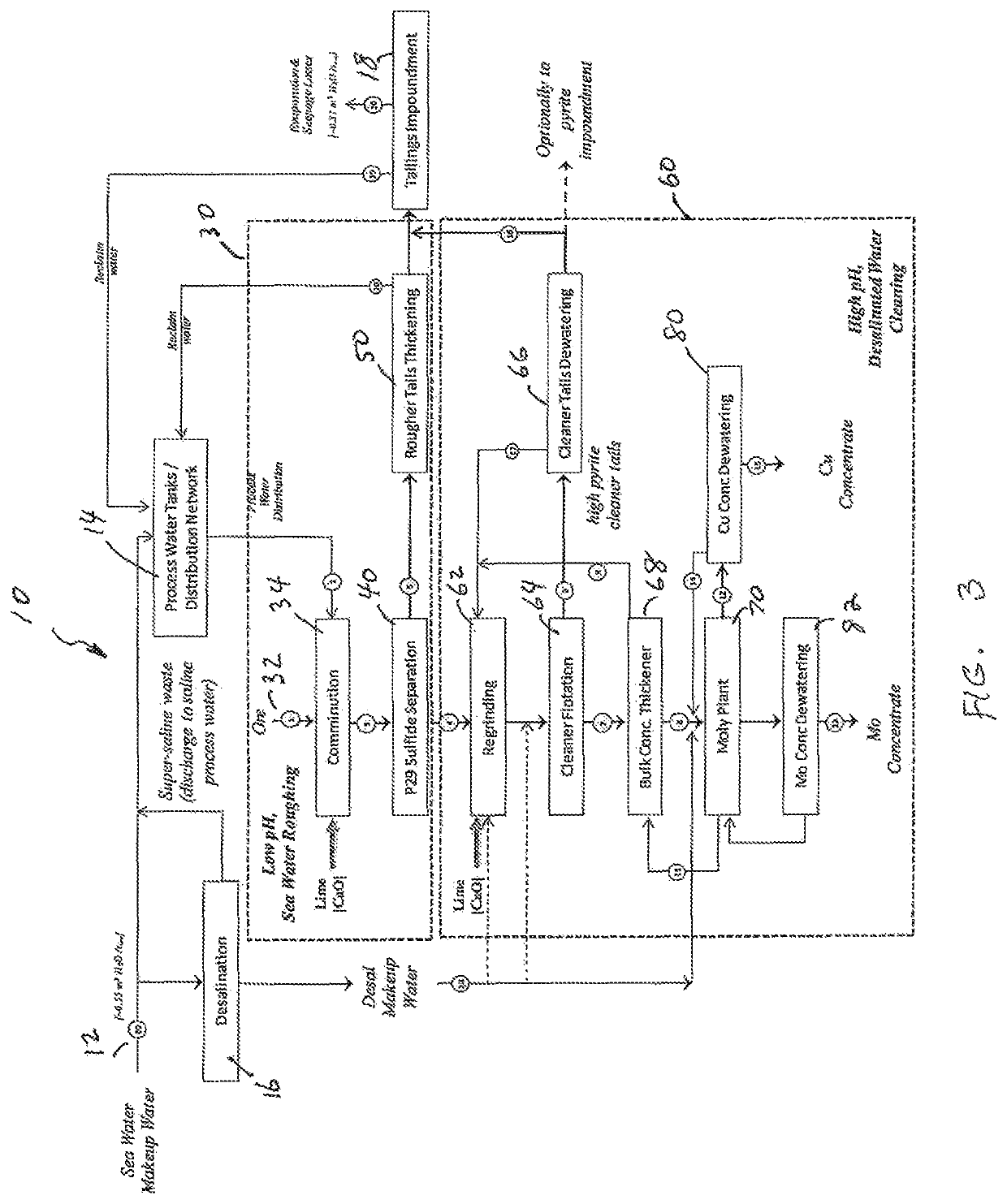

Separation of copper and molybdenum sulfides from pyrite using a sea water/desalinated water hybrid process

ActiveUS11060165B2Reduce quality problemsHigh porositySolvent extractionCopper sulfidesSoil sciencePyrite

A copper / molybdenum separation system uses sea water in the roughing circuit and desalinated water in cleaning circuit. In both roughing circuit and cleaning circuit, hydrophobic engineered media are used to recover the mineral particles of interest. The cleaning circuit includes a molybdenum loading stage configured to contact the conditioned pulp with the engineered media in an agitated reaction chamber, and load the hydrophobic molybdenite on the engineered media.

Owner:CIDRA CORP SERVICES

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com