Method for improving synthesis yield by utilizing thionyl chloride synthesis energy

A thionyl chloride and energy technology, applied in the field of thionyl chloride synthesis, can solve the problems of impact, affect the yield of synthetic thionyl chloride, and form air entrainment, and achieve lower production costs, high social use value and Application prospects, the effect of eliminating air entrainment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

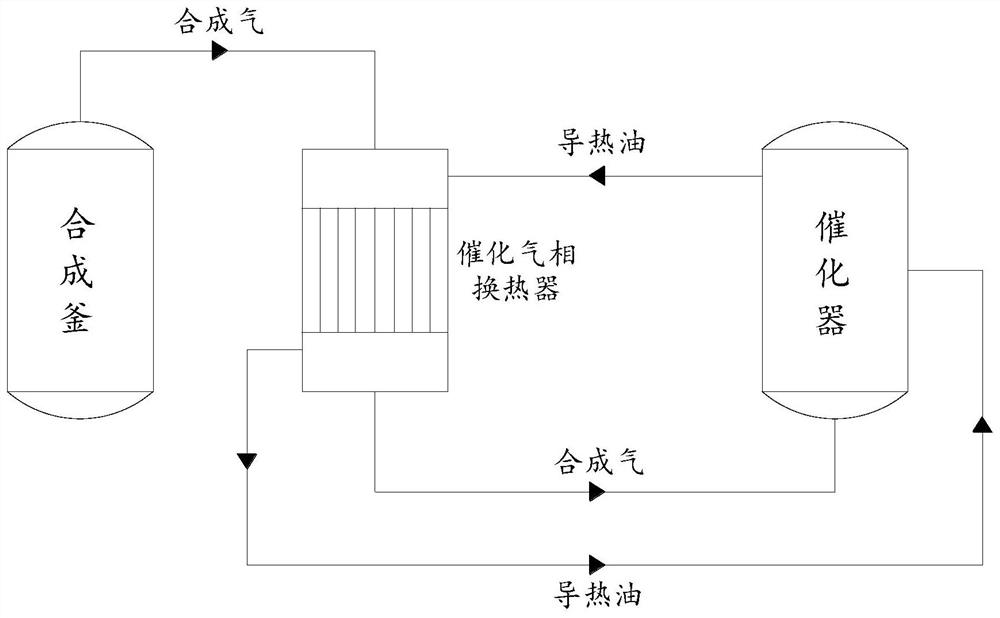

[0026] refer to figure 1 , a kind of synthetic energy utilization of thionyl chloride improves the method for synthetic yield, comprises the following steps:

[0027] S1: Introduce low-temperature heat transfer oil at -20-0°C to the jacket of the catalytic converter, and use the low-temperature heat transfer oil to pass through the jacket of the catalytic converter to take away the excess heat generated by the reaction of the catalytic converter to control the generation of thionyl chloride during catalytic synthesis excess heat;

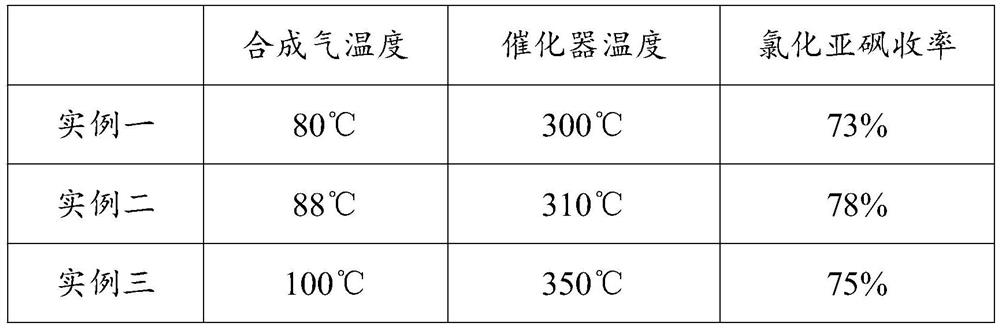

[0028] The temperature of the catalytic converter is controlled at 300°C, and the temperature of the heat transfer oil after heat exchange is 200°C;

[0029] S2: The heat transfer oil after heat exchange heats the 60°C synthesis gas generated in the synthesis tank in the catalytic gas phase heat exchanger to prevent the synthesis gas from being entrained into the catalytic converter for reaction;

[0030] Among them, the composition of the synthes...

Embodiment 2

[0034] refer to figure 1 , a kind of synthetic energy utilization of thionyl chloride improves the method for synthetic yield, comprises the following steps:

[0035] S1: Introduce low-temperature heat transfer oil at -20-0°C to the jacket of the catalytic converter, and use the low-temperature heat transfer oil to pass through the jacket of the catalytic converter to take away the excess heat generated by the reaction of the catalytic converter to control the generation of thionyl chloride during catalytic synthesis excess heat;

[0036] The temperature of the catalytic converter is controlled at 310°C, and the temperature of the heat transfer oil after heat exchange is 210°C;

[0037] S2: The heat transfer oil after heat exchange heats the 60°C synthesis gas generated in the synthesis tank in the catalytic gas phase heat exchanger to prevent the synthesis gas from being entrained into the catalytic converter for reaction;

[0038] Among them, the composition of the synthes...

Embodiment 3

[0042] refer to figure 1 , a kind of synthetic energy utilization of thionyl chloride improves the method for synthetic yield, comprises the following steps:

[0043] S1: Introduce low-temperature heat transfer oil at -20-0°C to the jacket of the catalytic converter, and use the low-temperature heat transfer oil to pass through the jacket of the catalytic converter to take away the excess heat generated by the reaction of the catalytic converter to control the generation of thionyl chloride during catalytic synthesis excess heat;

[0044] The temperature of the catalytic converter is controlled at 350°C, and the temperature of the heat transfer oil after heat exchange is 230°C;

[0045] S2: The heat transfer oil after heat exchange heats the 60°C synthesis gas generated in the synthesis tank in the catalytic gas phase heat exchanger to prevent the synthesis gas from being entrained into the catalytic converter for reaction;

[0046] Among them, the composition of the synthes...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com