Polymerization feeding optimization system and method

A technology of polymerization kettle and inlet, which is applied in the field of optimization of the feeding of the polymerization kettle, can solve the problems that the feeding time of the dispersant cannot be greatly shortened, the operation of the feeding system is cumbersome, and the production capacity of a single kettle is affected, so as to save manpower and simplify feeding. The effect of shortening the feeding procedure and shortening the time of entering the kettle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

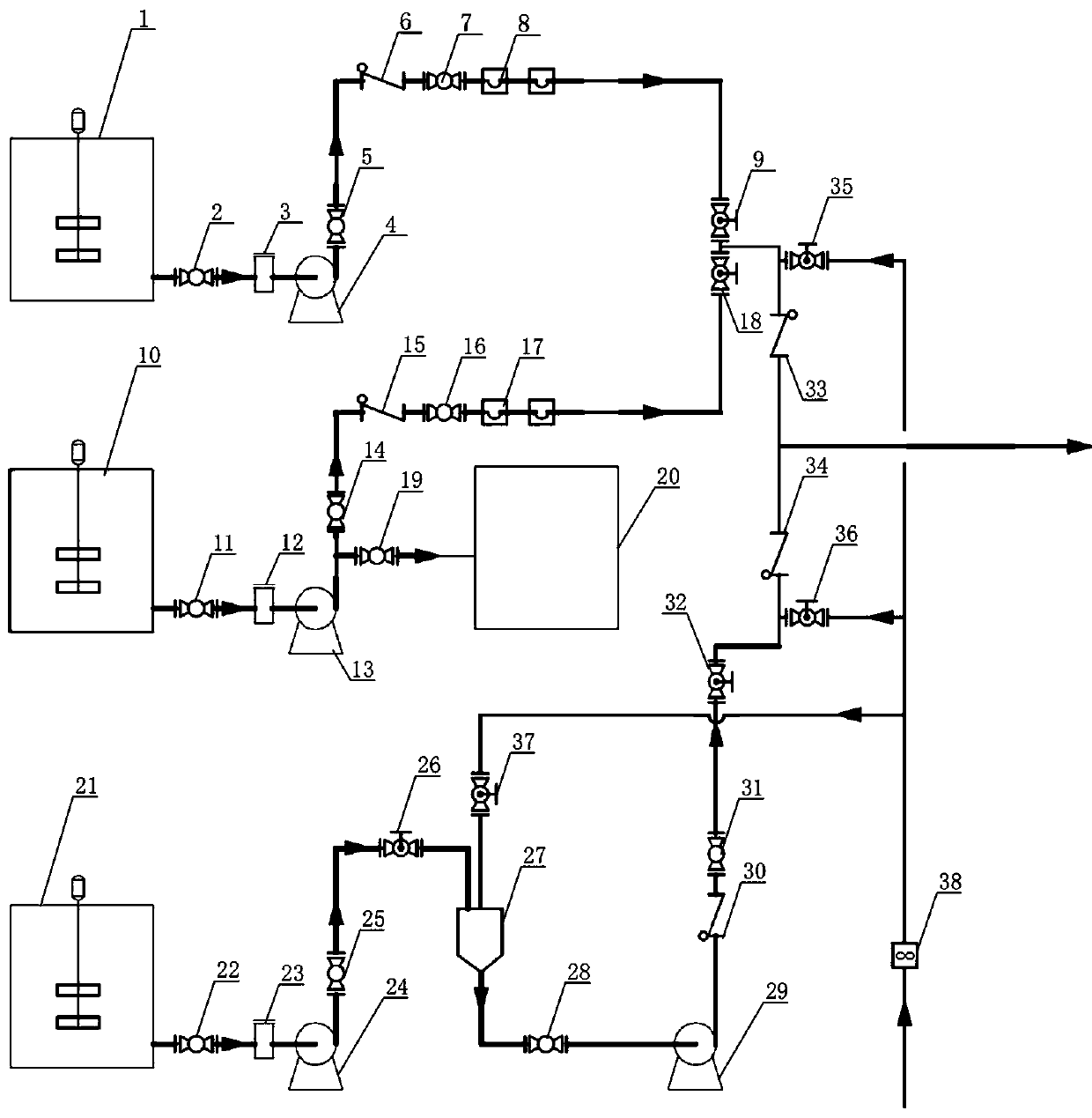

[0040] The invention discloses a polymerization feeding optimization system and method.

[0041] Such as figure 1 As shown, the polymerization feeding optimization system includes a dispersant storage tank, an initiator preparation tank 20, an initiator storage tank 21 and a polymerization kettle, and the initiator preparation tank 20 communicates with the initiator storage tank 21, the dispersant storage tank and the initiator storage tank 21 respectively connected to the polymerization kettle, the number of dispersant storage tanks is at least two, and the dispersant storage tanks are equipped with stirring reducers, which are characterized in that it also includes dispersant inlet pipelines, initiator inlet pipelines and flushing pipes The number of dispersant inlet pipelines is multiple and corresponds to the dispersant storage tank one by one; the inlet of the dispersant inlet pipeline is connected to the corresponding outlet of the dispersant storage tank, and the outlet...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com