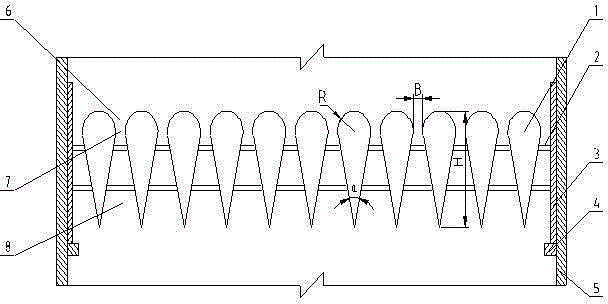

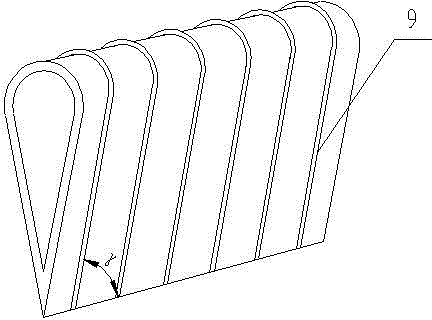

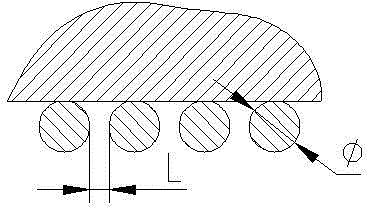

Waterdrop-shaped grid type structured packing

A structured packing and drop-shaped technology, applied in chemical/physical/physicochemical processes, chemical instruments and methods, chemical/physical processes, etc., can solve problems such as poor packing strength, complicated manufacturing process, and ineffective packing efficiency , to achieve the effect of increasing the specific surface area, increasing the surface area, and improving the mass transfer capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] A high-temperature flue gas temperature is 180°C, and the gas volume is 180,000Nm 3 / h,SO 2 The concentration is 800mg / Nm 3 , dust content 300mg / Nm 3 .

[0039] Operating conditions: liquid-gas ratio 3L / Nm 3 , with NaOH solution as absorbent, gas-liquid countercurrent contact.

[0040] After being treated by the invention, the flue gas temperature drops to 60°C, the desulfurization efficiency is 90-95%, and the dust removal efficiency is 90-95%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com