Preparation method of high-performance solvent-free flame-retardant polyurea coating

A manufacturing method and flame-retardant technology, applied in polyurea/polyurethane coatings, fireproof coatings, coatings, etc., can solve the problems of polyurea resin compositions such as long curing time, large particle size, and formulation differences, and achieve excellent Effects of mechanical properties and operability, excellent mechanical properties, and low production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

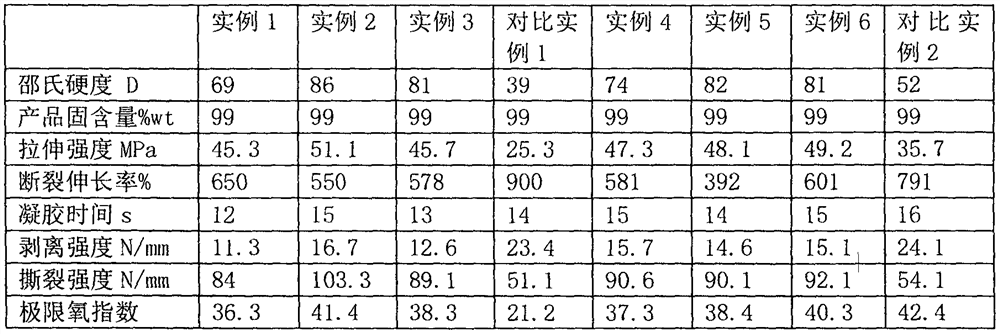

Examples

Embodiment 1

[0043] 1): Add 0.6mol of diethylenetriaminopolyether in the formula of component A into the reactor, and under the condition of passing high-purity dry nitrogen, the temperature of the reactor is raised to 100°C, dehydrated for 4 hours, and the temperature drops to room temperature. Add 0.4mol liquefied MDI to the formula of component A and raise the temperature to 70-110°C, stir and react for 2-5 hours, and cool the obtained mixture to normal temperature under the condition of passing dry nitrogen at normal temperature, and then get the flame-retardant type of component A Polyurea prepolymer;

[0044] 2): Add 0.1mol polyaspartic acid ester and 0.5mol 3,5-dithiotoluenediamine and 3,3'-dichloro4,4'xylylenediamine in the formula of component B; where 3 , the molar ratio of 5-dithiotoluenediamine and 3,3'-dichloro-4,4'-xylenemethanediamine in combination is 1:0.6; and 0.4mol 2,5-dichloro-p-phenylenediamine Put it into a mixing tank, add 0.5wt% polyethylene oxide anti-settling ag...

Embodiment 2

[0048]1): Add 0.4mol of diethylenetriaminopolyether in the formula of component A into the reactor, and under the condition of high-purity dry nitrogen, the temperature of the reactor is raised to 120°C, dehydrated for 2 hours, and the temperature drops to room temperature. Add 0.6mol of trimethyl 1,6-hexamethylene diisocyanate to the formula of component A, raise the temperature to 110°C, stir and react for 2 hours, and cool the obtained mixture to normal temperature under the condition of blowing dry nitrogen at normal temperature, That is, the A-component flame-retardant polyurea prepolymer is obtained;

[0049] 2): Add 0.3mol polyaspartic acid ester and 0.4mol 3,5-diethyltoluenediamine and 3,3'-dichloro4,4'xylylenediamine in the formula of component B; where 3 , the molar ratio of 5-diethyltoluenediamine and 3,3'-dichloro-4,4'-xylenemethanediamine is 1:0.6; and 0.3mol 2,5-dichloro-p-phenylenediamine Put it into the mixing tank, add 2.5wt% polyethylene oxide anti-settling ...

Embodiment 3

[0053] 1): Add 0.5mol xylitol polyether in the formula of component A into the reactor, and under the condition of passing high-purity dry nitrogen, the temperature of the reactor rises to 105°C, dehydrates for 3.5 hours, and the temperature drops to room temperature, then add A 0.5mol trimethyl 1,6-hexamethylene diisocyanate in the component formula, the temperature is raised to 85°C, stirred and reacted for 3.5h, and the obtained mixture is cooled to normal temperature under the condition of blowing dry nitrogen at normal temperature, that is Obtain A-component flame-retardant polyurea prepolymer;

[0054] 2): Add 0.2mol polyaspartic acid ester and 0.45mol 3,3'-dichloro-4,4'-xylylenediamine; and 0.35mol 2,5-dichloro-p-phenylenediamine in the formula of component B Add 1.3wt% carbo resin anti-settling agent to the mixing tank, stir for 11 min at a stirring speed of 1250 rpm, and then add the remaining components in the C component formula. First add 13wt% nano-scale barium s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| elongation | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com