Liquid-collecting energy absorption device

A technology of energy absorber and energy absorbing plate, which is applied in the field of liquid catcher energy absorber, can solve problems such as unfavorable liquid, violent fluctuation of liquid level at the bottom of the tower, and increase of light component content at the bottom of the tower, so as to reduce the flow velocity, The effect of eliminating liquid phase back-mixing and improving operating efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

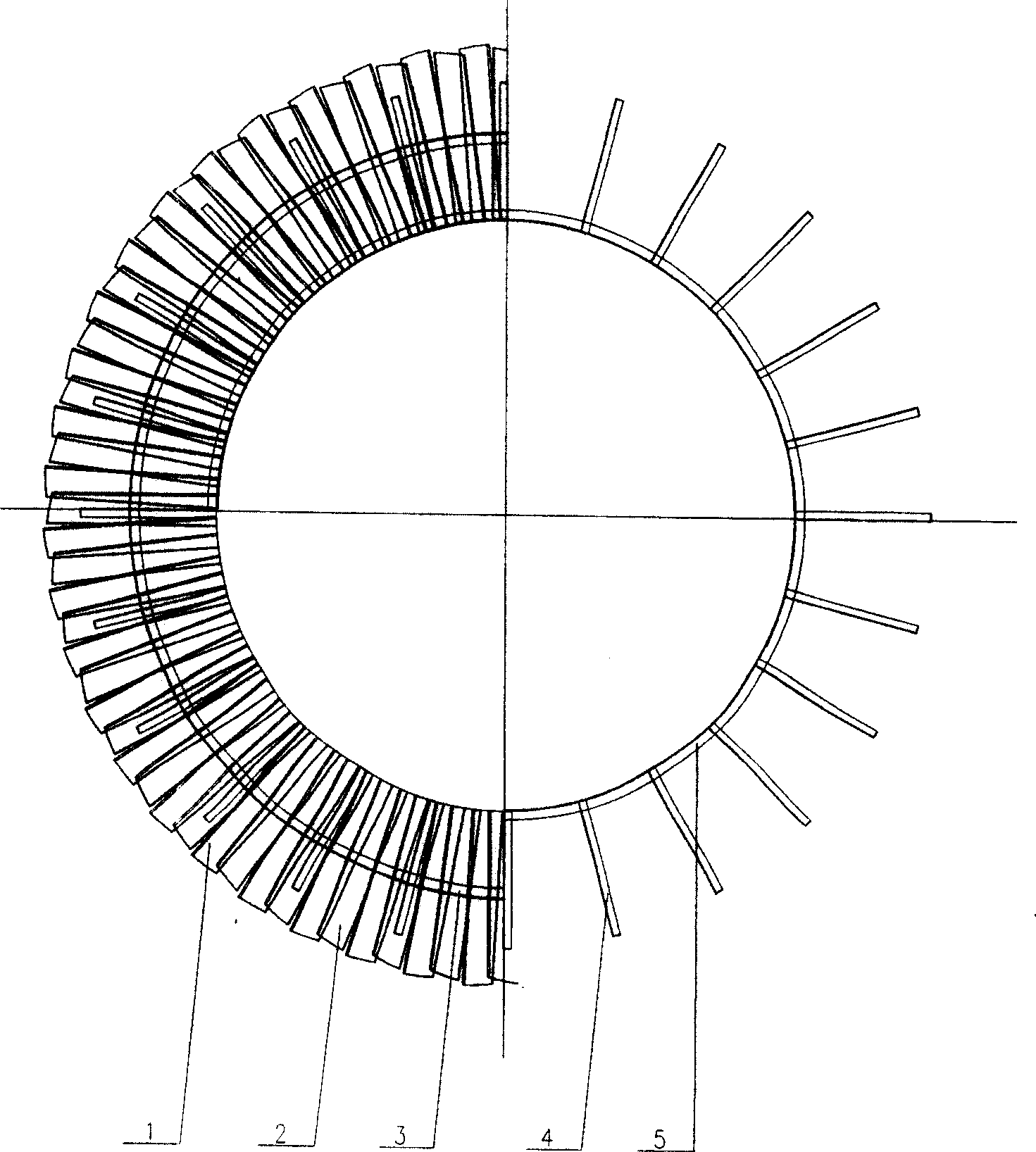

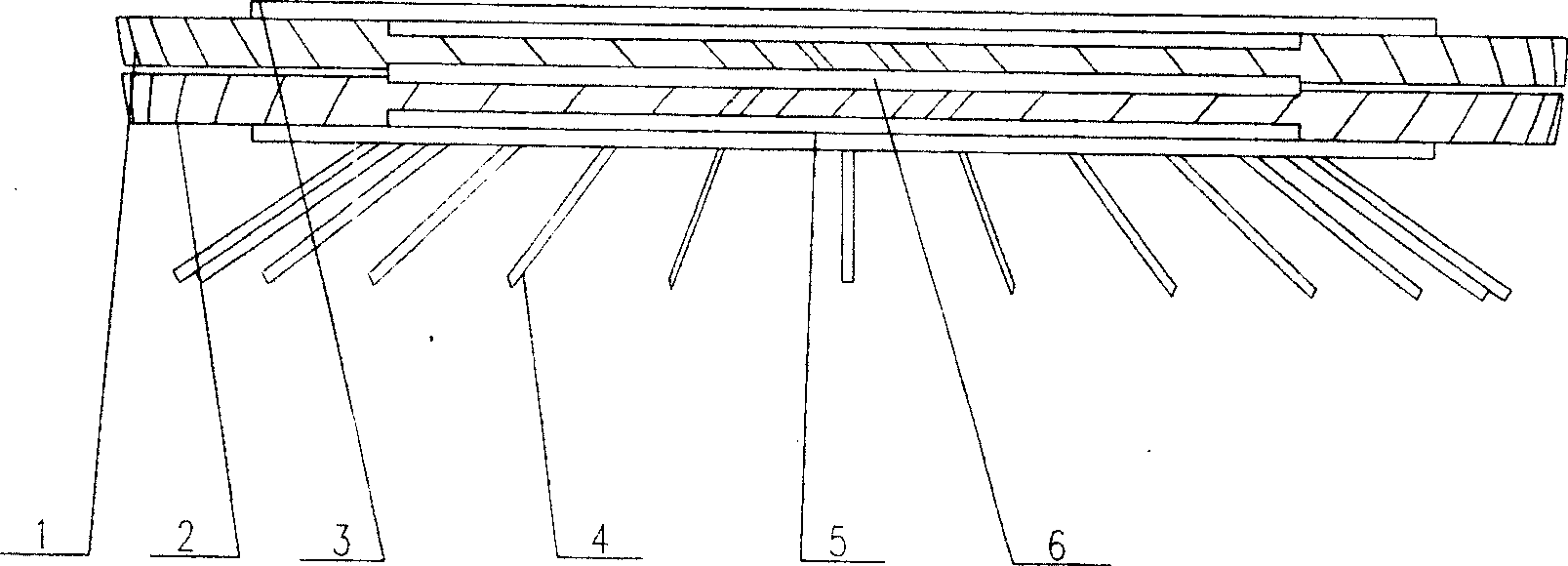

[0023] Such as figure 1 , 2 As shown, the new liquid trapping energy absorber is ring-shaped as a whole, and the upper liquid trapping energy absorbing plate 1 and the lower liquid trapping energy absorbing plate 2 are connected through the upper layer annular angle steel 3, the lower layer annular angle steel 5 and the annular rib plate 6 of the annular angle steel. One end of the supporting angle steel 4 is directly welded on the lower annular angle steel 5, the other end is welded on the tower wall, and the outer edge of the liquid-catching energy-absorbing plate is directly welded on the tower wall.

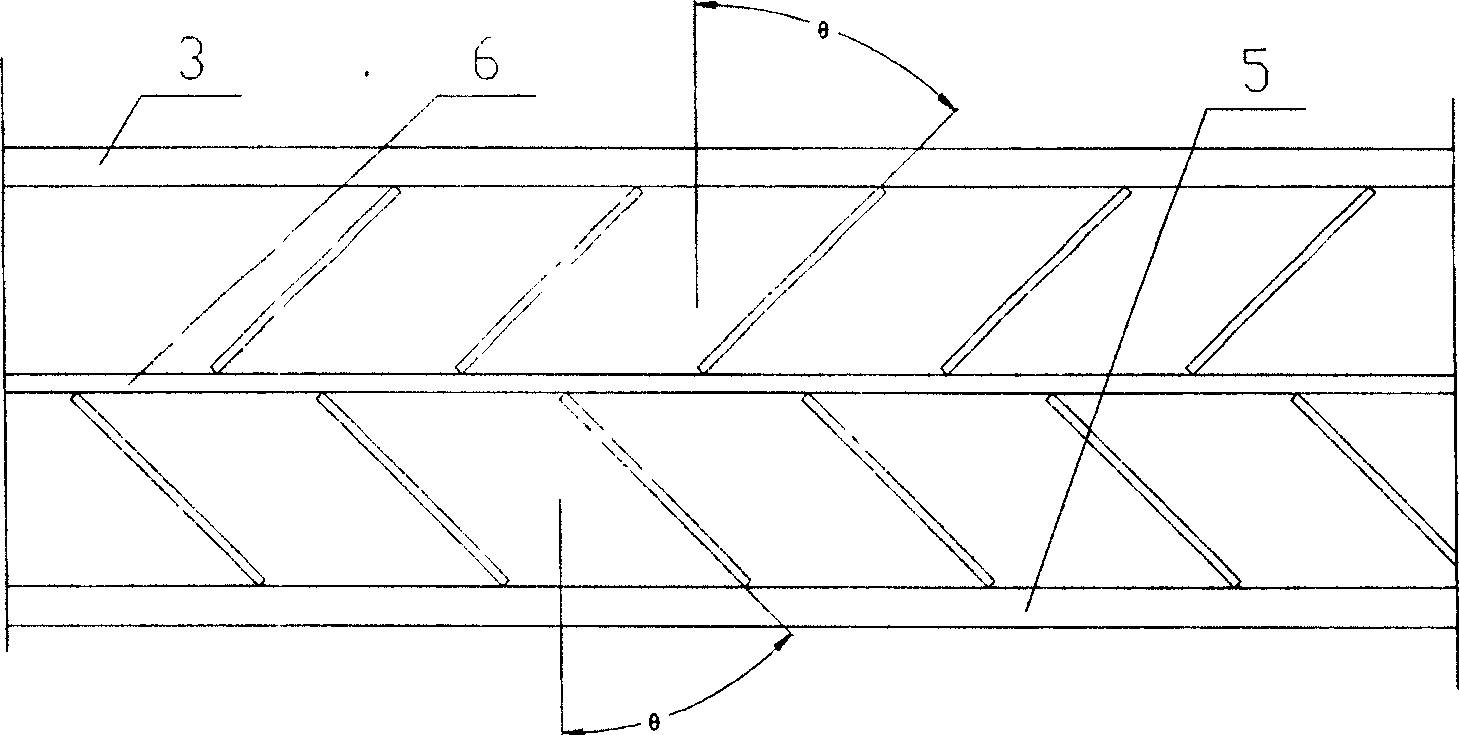

[0024] The upper liquid-catching and energy-absorbing plate 1 can be a rectangular plate or a trapezoidal plate, and is evenly distributed according to the circumference. The upper liquid-catching energy-absorbing plate 1 forms a certain angle relative to the tower body, such as image 3 As shown, the effect of capturing liquid and absorbing energy can be better achieved. ...

Embodiment 2

[0028] The difference from Example 1 is that the bottom of the lower liquid-catching energy-absorbing plate 2 can be provided with a horizontal flap when the gas flow rate is relatively high, so as to slow down the impact of the high-speed gas on the still liquid, such as Figure 4 shown.

Embodiment 3

[0030] The difference from Example 1 is that the upper liquid-catching energy-absorbing plate and the lower liquid-catching energy-absorbing plate are herringbone baffles, and the angles thereof are between 0 degrees and 180 degrees, such as Figure 5 As shown, according to the uniform distribution on the circumference, the number can be converted from the flow area according to the size of the gas flow velocity, and the positions of the upper and lower layers of herringbone baffles are staggered.

[0031] The novel liquid trapping energy absorber described in the present invention is applied to the bottom of a large tower in conjunction with a double tangential circulation gas distributor. It has been practically applied in many towers at present. The results of the application show that:

[0032] The present invention has the following characteristics:

[0033] 1. The new energy absorber for liquid capture can capture the liquid droplets mixed in the intake air at the bottom...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com