Energy-saving gas washing process

A gas washing, energy-saving technology, applied in the separation of dispersed particles, chemical instruments and methods, separation methods, etc., can solve the problems of low recovery rate of low-temperature methanol washing device, increase of methanol circulation, affecting absorption effect, etc. The effect of saving cooling capacity, reducing circulation, and improving CO2 recovery rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

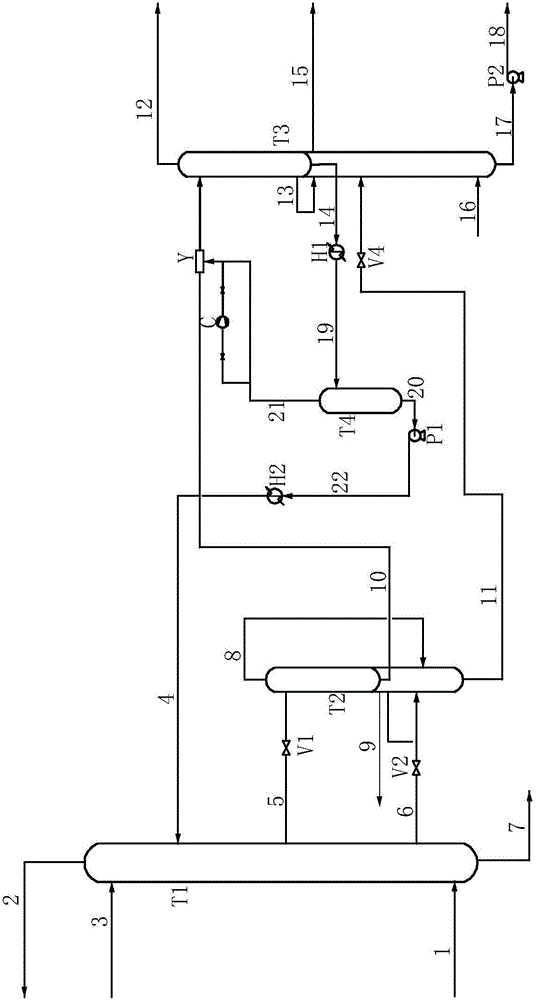

[0041] Such as figure 1 As shown, the energy-saving gas scrubbing process is described as follows:

[0042] The raw material gas enters the absorption tower T1 through the raw material gas pipeline 1, and flows in the absorption tower T1 from bottom to top; the fine cleaning methanol is introduced from the upper part of the absorption tower T1 through the fine cleaning methanol pipeline 3, and the main washing methanol is introduced from the main washing methanol pipeline 4 Imported from the upper part of the absorption tower T1, the fine-washed methanol and the main-washed methanol flow together as absorbents in the absorption tower T1 from top to bottom, and countercurrently contact with the raw material gas to wash out the acid gas in the raw material gas; the purified gas obtained is passed through Pipeline 2 is sent to the outside of the device;

[0043] The molar flow ratio of raw material gas to fine methanol is 1.5:1 to 2:1; the molar flow ratio of fine methanol to ma...

Embodiment 2

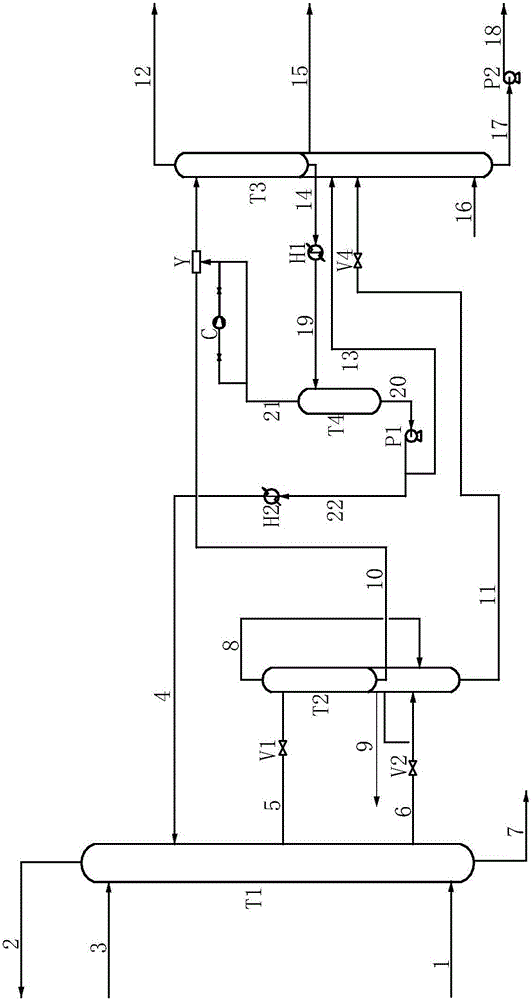

[0056] Such as figure 2 As shown, the energy-saving gas scrubbing process is described as follows:

[0057] The raw material gas enters the absorption tower T1 through the raw material gas pipeline 1, and flows in the absorption tower T1 from bottom to top; the fine cleaning methanol is introduced from the upper part of the absorption tower T1 through the fine cleaning methanol pipeline 3, and the main washing methanol is introduced from the main washing methanol pipeline 4 Imported from the upper part of the absorption tower T1, the fine-washed methanol and the main-washed methanol flow together as absorbents in the absorption tower T1 from top to bottom, and countercurrently contact with the raw material gas to wash out the acid gas in the raw material gas; the purified gas obtained is passed through Pipeline 2 is sent to the outside of the device;

[0058] The molar flow ratio of raw material gas to fine methanol is 1.5:1 to 2:1; the molar flow ratio of fine methanol to m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com