A plant essential oil gradient extraction device

An extraction device and a technology for plant essential oils, which are applied in the directions of essential oils/spices, fat production, etc., can solve the problems of increasing product costs, need to recover solvents, and consume solvents, and achieve the effects of reducing operating costs, rational use of energy, and high energy efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

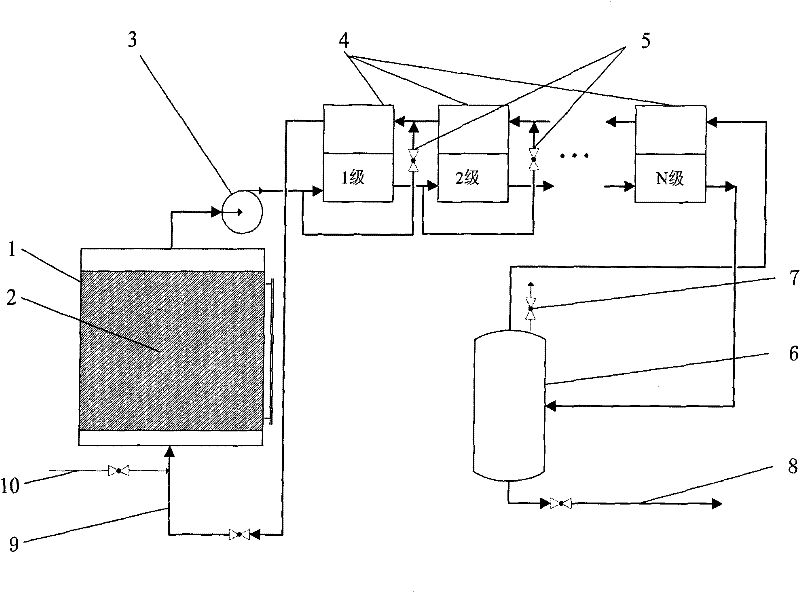

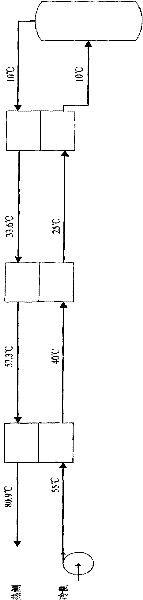

[0039] Embodiment 1: extract peppermint essential oil and hydrosol with device of the present invention, device such as figure 1 , image 3 , Figure 4 As shown, it includes a closeable evaporator 1 with a raw material bed 2 inside. The top of the evaporator is connected to the inlet of a two-stage air pump 3, and the outlet of the air pump is connected to the cold side of the semiconductor refrigeration device. The semiconductor refrigeration device consists of three stages of semiconductor refrigeration. The refrigerators 4 (each refrigerator is a first-stage refrigeration unit) are connected in series, and the flow direction of the cold-side flow is sequentially from the first stage to the third stage. At the cold-side flow inlet of the first-stage to second-stage semiconductor refrigerators, there is a return flow jumper 5 with a valve, which is connected to the hot-side flow inlet of the current-stage semiconductor refrigerator. The outlet of the cold side of the final ...

Embodiment 2

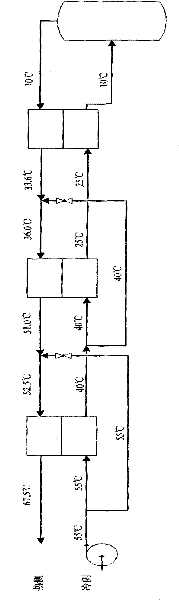

[0041] Embodiment 2: extract peppermint essential oil and pure dew device as embodiment 1, there are 3 stages of semiconductor refrigeration units, at the 1st stage and the 2nd stage semiconductor refrigeration unit hot side outlets, respectively establish inter-stage condensate tank 15 ( See Image 6 ). There are return pipelines with valves from the bottom of the product collection tank to the second-stage condensate tank, and from the bottom of the second-stage condensate tank to the first-stage condensate tank. And the heights of the product collection tank, the second-stage condensate tank, and the first-stage condensate tank are 1.8 meters, 1.0 meters, and 0.2 meters in order, so that the condensate in the three tanks can have sufficient potential difference to flow back step by step , improve the clarity of product cutting, in addition in one or more condensate tanks, add fractionation tower section 15 (see Figure 7 ), the reflux flows in from the top of the tower se...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com