Marine two-stage dehumidification and air-conditioning system with rotary wheels and its operation method

A technology of dehumidification and air-conditioning system with a rotary wheel, which is applied in the direction of air-conditioning systems, applications, heating methods, etc. It can solve the problems of unsuitable waste heat recovery and utilization of ships, and unfavorable air with high temperature and humidity, so as to save energy for regeneration and cooling, The effect of reducing carbon emissions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

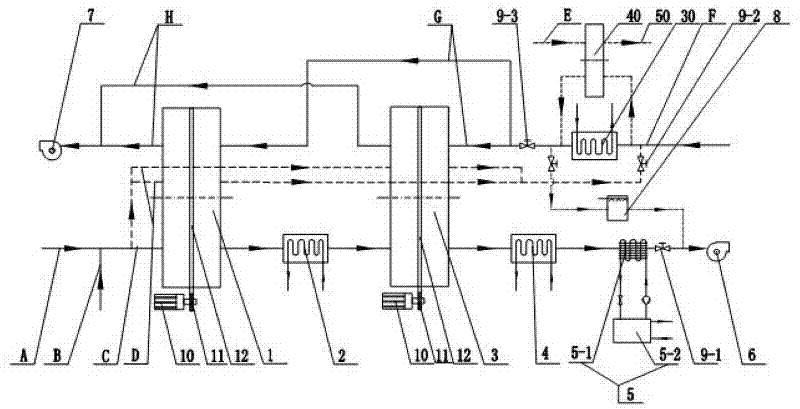

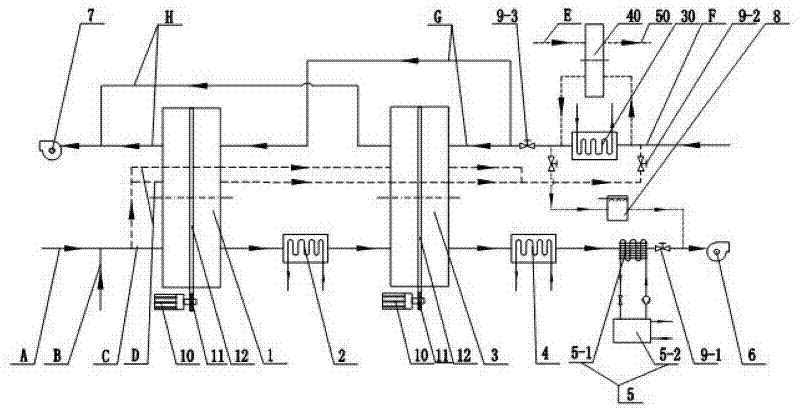

[0022] like figure 1 As shown, the present invention is a two-stage dehumidification and air-conditioning system for ships, which includes a first-stage dehumidification runner 1, a first-stage intercooler 2, a second-stage dehumidification runner 3, and a second-stage intercooler 4 , Compression air conditioner unit 5, processing fan 6, regeneration fan 7, humidifier 8, motor 10, gear 11, chain 12, waste heat heater 30, waste gas heat exchange wheel 40.

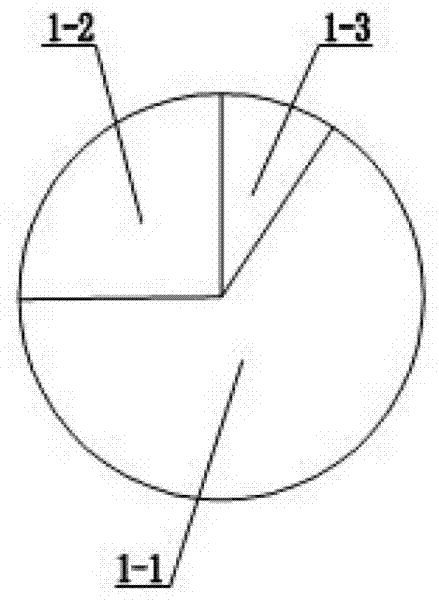

[0023] refer to figure 2 As shown, the first-stage dehumidification wheel 1 includes a dehumidification zone 1-1, a regeneration zone 1-2 and a pretreatment zone 1-3. The pretreatment zone 1-3 is located between the first-stage dehumidification rotor 1 turning from the regeneration zone 1-2 to the dehumidification zone 1-1, and is used to remove the residual high-temperature and high-humidity air during the regeneration process. The regeneration area 1-2 of the first-stage dehumidification rotor 1 accounts for 1 / 4 of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com